S H E L C O F I LT E R S - M O D E L C S F

INSTALLATION, OPERATION, MAINTENANCE MAN.UAL

MAINTENANCE

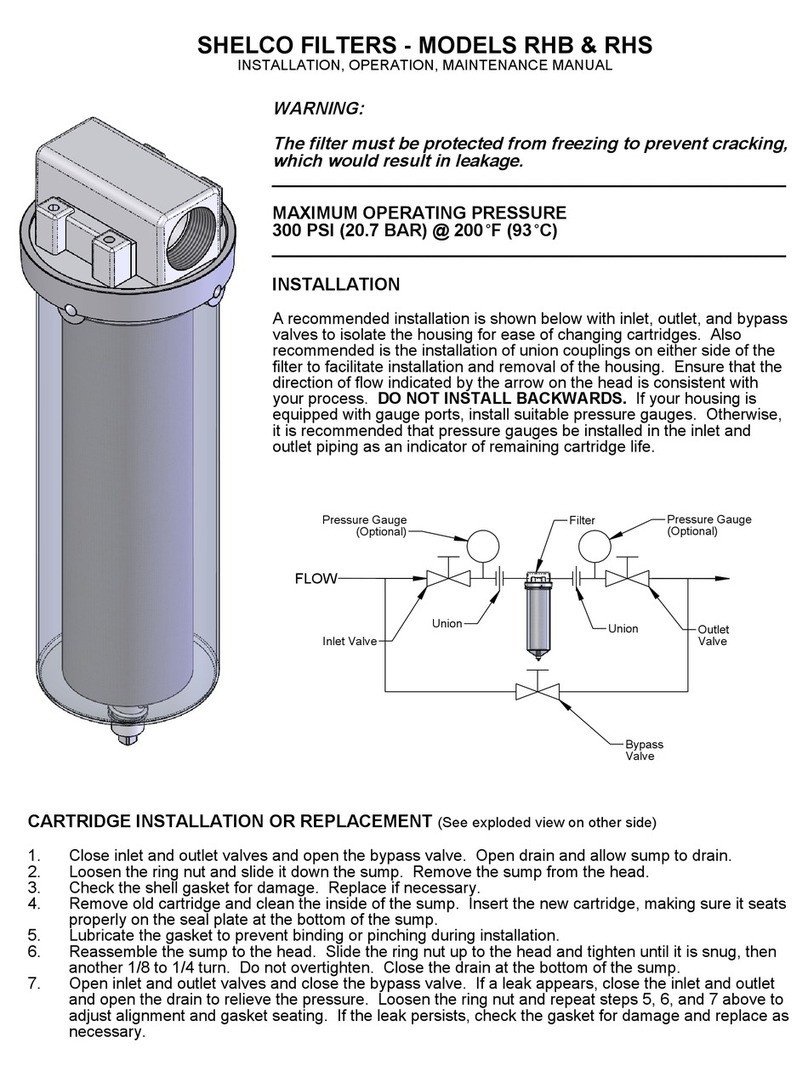

Sheico filters generally require very little maintenance. The filter element should be

replaced when the pressure drop across the filter reaches a maximum of 20 PSI.

Your experience might dictate more frequent cartridge replacement. The gasket

should be inspected and replaced if necessary at the time the cartridge is replaced.

CSF HOUSING RECCMVEN[)t"DSPARE PARTS

ITUyi 1 2 34 5 6 78

MDDEL RINGNITT HEAD GASKET BRACKETKIT CARTRIDGE*' 222 SPRING SUtVP DRAIN PLUG

CSf^786-222 3(B3-P 3CW2-6-222 3001-'* 2501-K 222/RNORRAT CSF-78-316 21CB-S-316

CSF-788-222 3CB3-P 3W2-3-222 3001-* 2501-K 22Z/FINORRAT CSF-78-316 2108-S-316

CSF-78G-226 3C83-P 3032-6-226 SCOl-" 2501-K 226/nNORFLAT N/A CSF-78-316 21C3-S-316

CSF-788-226

aF-8C16-222

3C^P 3032-8-226 3001-* 2501-K 226/FINORFLAT N/A CSF-78-316 21Ce-S-316

3(B3-P 3032-6-222 3001-' 2S01-K 222/FINORFLAT CSF-80-316 21C3-S-316

CSF-8C6-222 3(B3-P 3032-8-222 3001-* 2501-K 222/FINORFLAT CSF-80-316 2103-8-315

CSF-806-226 3C83-P 3032-6-226 3001-* 2501-K 225/RNORFLAT N/A CSF-80-316 21CB-S-316

CSF-8Ce-226 3C83-P 3042-8-226 3001-'* 2501-K 226/FINORFlAr N/A CSF-80-316 21(B-S-316

CSF-906-222 3CB3-P 3032-6-222 BCOl-* 2501-K 222/FINORFLAT CSF-SO-316 2103-S-316

CSF-906-226 3CQ3-P 3032-8-222 3C01-* 2501-K 222/FINORFLAT CSr-90-316 2103-8-316

CSF-9C8-222 3(B3-P 3032-6-226 scm--* 2501-K 225/FINORrLAT N/A CSF-90-316 2103-8-316

CSF-908-726 3(B3-P 3032-8-226 3001-'' 2501-K 226/RNORRAT N/A CSF-90-316 21CS-S-316

1 1

1

* CONSULTYOURSHELCORbTRESEhn'ATlVETODerERMNElHF.a'TlfVlJMMMERIALfORYCXJRAPPUCATION

" CONSULT YOUR SHELCO RtPRESENTATI VE 70 DETERfVl NE THE OPTIMJMCARTRIDGE CONFIGURATION FOR YOUR

APPU CATION

Limited Warranty

Seller warrants each of the products described herein, under normal use and service, and subject to the

user's compliance with these and any other operating instructions and directions given by the seller to

be free from defects in materials or workmanship for a period of one year from dale of shipment from

seller's plant. Seller's liability under this warranty shall be limited to repairing or replacing any such

defective products, at the seller's option, FOB seller's plant in Middletown, CT and reimbursing

purchaser's shipping costs subject to the following: (1) timely receipt of purchaser's written notice that

such products are defective; (2) seller's written authorization to purchaser for the return of such

products to seller with shipping charges prepaid, and {3)seller's inspection of and confirmation that such

products are defective in materials or workmanship.

If seller's inspection shows that the products returned are defective due to dirt, rust, or any foreign ^—

material not attributable to seller, improper usage, over-tightening of threads, abuse or incorrect ( 7

reassembly in the feld or other cause not due to seller's improper manufacture, seller will, subject to V.

purchaser's written authorization, repair or replace such products a! cost Seller's factory inspection and

testing will be made available to purchaser upon request.

T H E W A R R A N T Y I S I N L I E U O F A N Y O T H E R W A R R A N T Y, E X P R E S S E D O R I M P L I E D . I N C L U D I N G

A N Y I M P L I E D WA R R A N T Y O F F I T N E S S O R M E R C H A N TA B I L I T Y. S E L L E R S H A L L N O T B E L I A B L E

FOR ANY SPECIAL. INCIDENTAL OR CONSEQUENTIAL DAMAGES. NO REPRESENTATIVE OR

S E L L E R H A S A U T H O R I T Y T O M A K E A N Y R E P R E S E N TAT I O N S O R W A R R A N T I E S E X C E P T A S

STATED HEREIN.

Under no circumstances shall Seller be liable to Buyer or any third parly for any loss of profits or other

direct or indirect costs, expenses, losses or consequential damages arising out of or as a result of any

defects in or failure of its products or any part or parts thereof or arising out of or as a result of parts or

components incorporated in Seller's equipment but not supplied Seller.

The warranty excludes the following; A) Filter housings used for filtering brackish water, sea water, or

where analysis shows TDS or Chlorides are in excess of 1,000 ppm; B)Gaskets and O-rings, once

used; C) Altered products; D) Products without Seller's identification label.

It is the purchaser's responsibility to make certain the filter is compatible with all materials procured.

Stainless Steel is not 100% non-corrosive. It is the purchaser's responsibility to complete a

comprehensive water analysis (including Chlorides, TDS, and pH) to determine suitability of material.

It is the purchaser's responsibility to inform seller of any application where TDS levels are in excess of

1.000 ppm, and/or where chlorides are in excess of 1000 ppm.

SHELCO

FILTERS

100 Bradley St. Middletown, CT 06457

Ph: 860.854.6121 or 800.543.5843 Fax; 860.854.6120

www.sh0lco.com