APPLICATIONS & ENVIRONMENTS

The TV-1400 is designed to extract and lter wet paint overspray from enclosures or tents during painting operations where the

removal of overspray particulate, especially chromates, must adhere to the NESHAP Test Method 319 for Aerospace painting and

de-painting operations.

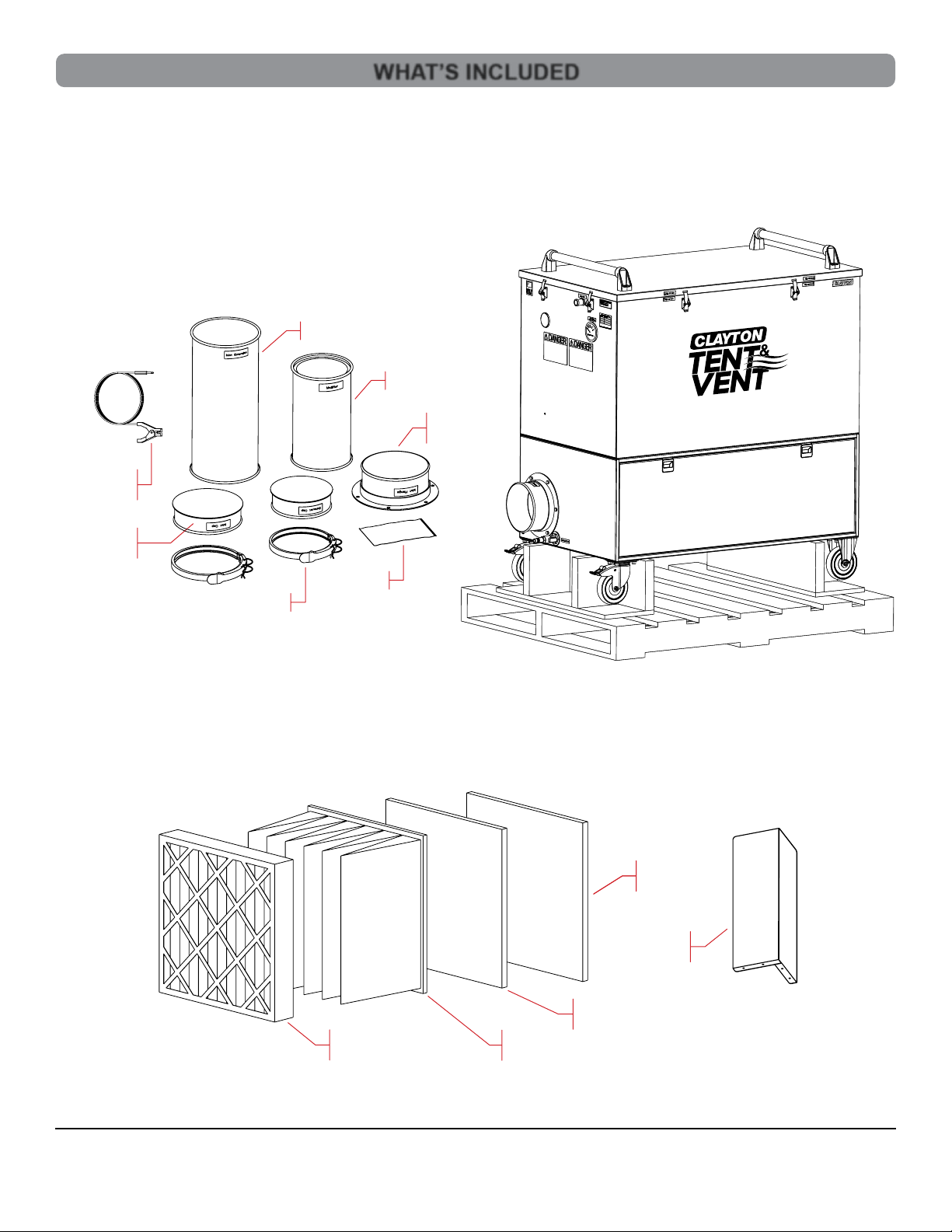

The TV-1400 employs a specic set of Clayton lters that when used together provide ltration that passes the NESHAP Test

Method 319 for both liquid and solid phase particulate.

ONLY APPROVED CLAYTON FILTERS SHOULD BE USED.

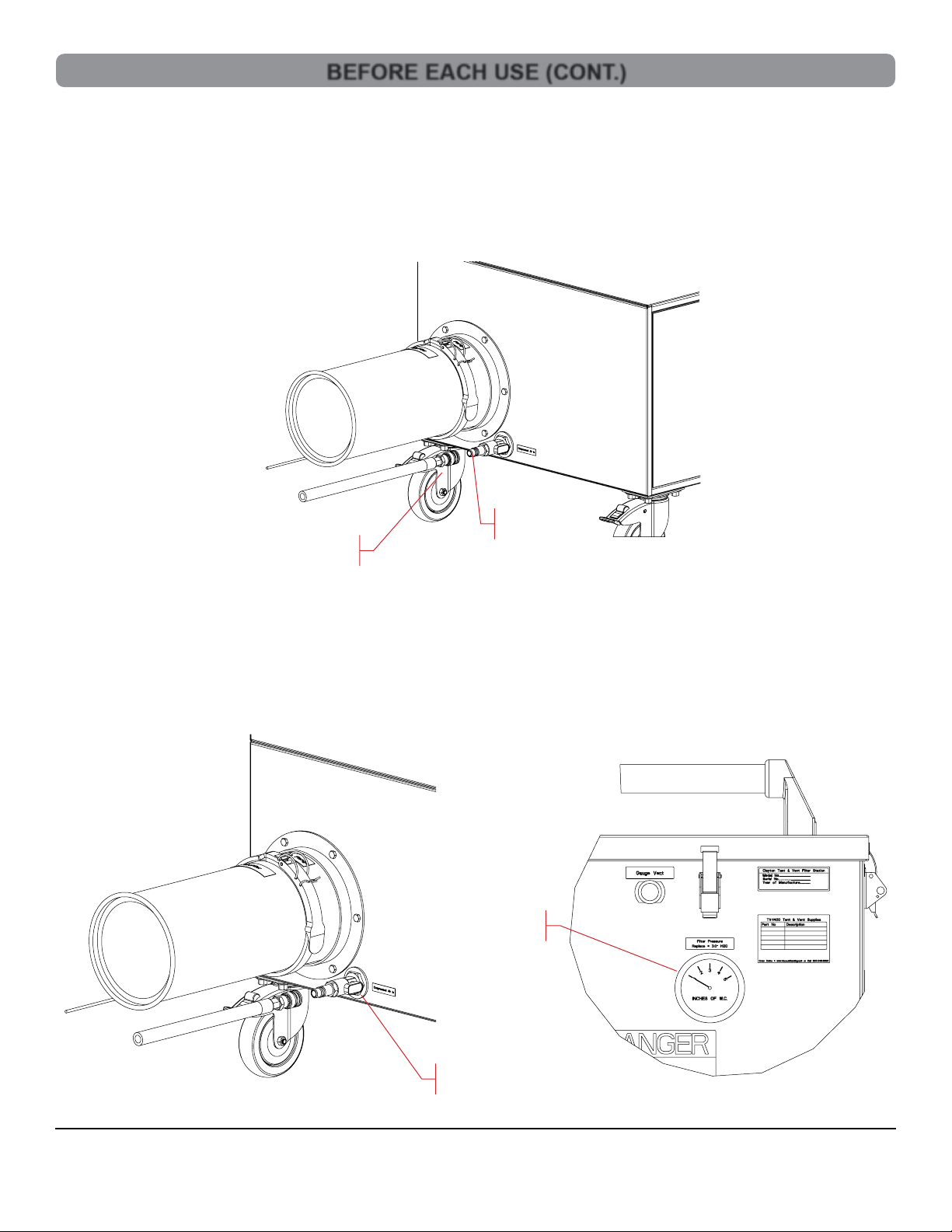

Grounding Instructions

The TV-1400 should be connected to an earth ground source with a Grounding/Bonding Cable. If the TV-1400 should come in contact

with an external electrical source, grounding provides a path of least resistance for electrical current to reduce the risk of electrical shock.

Bonding Instructions

The work piece should be bonded to the same earth ground as the TV-1400. This ensures that the TV-1400 and the work piece are at the

same electrical potential to eliminate static discharge between them.

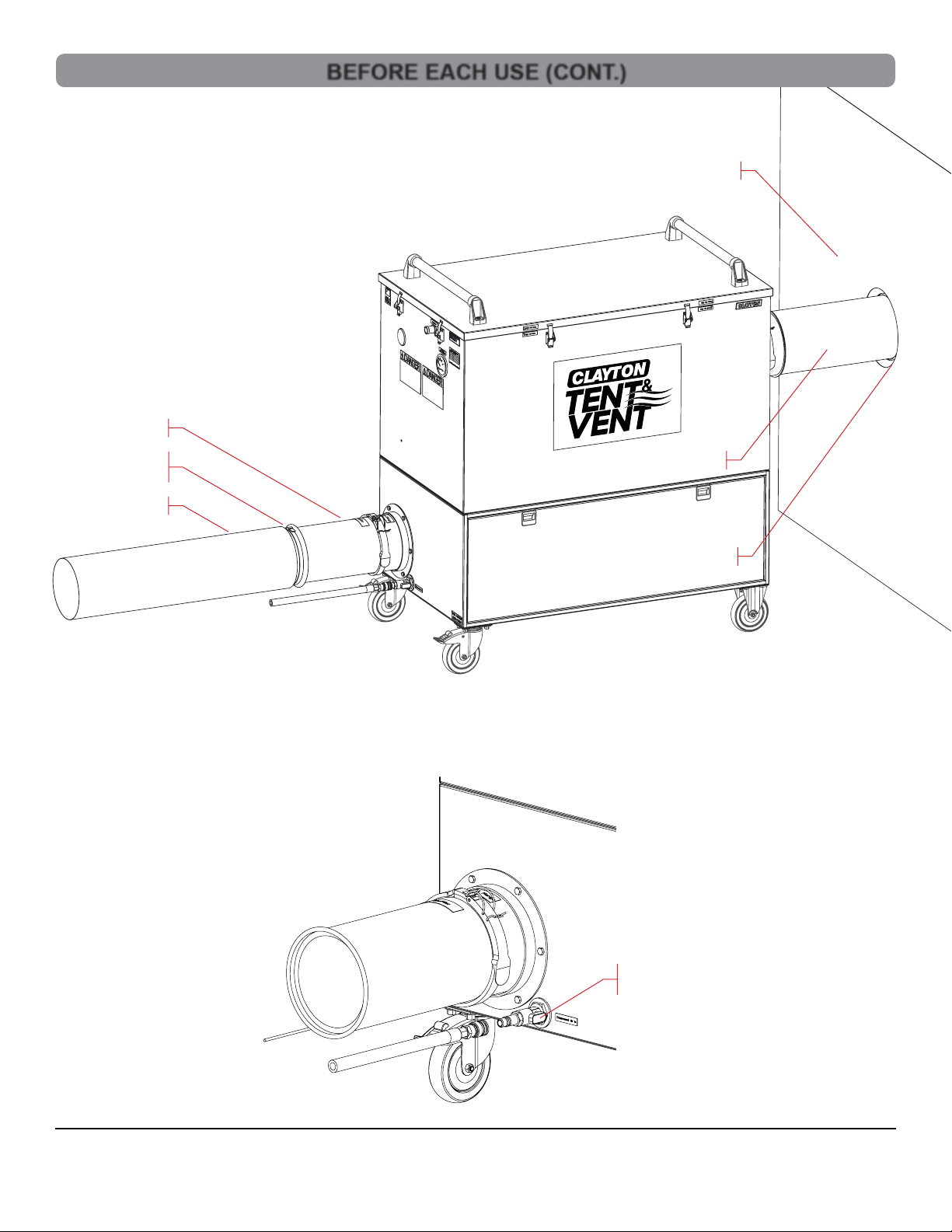

Tools And Attachments

The TV-1400 is only NESHAP compliant when used with the proper lters and accessories provided by Clayton. Proper order and

orientation of the lters is required. Any alteration to this equipment by a third party will nullify its warranty.

Compressed Air Requirements

• Compressed air must be clean, dry and oil free to prevent blockage of the pneumatic system

• Compressed airline and ttings must have a minimum diameter of 1/2in

• Compressed air supply must provide at least 90 psi

• Compressed air supply must provide a minimum of 50 cfm

WARNING

Repair or Warranty Contact Clayton Associates, Inc. •1650 Oak Street •Lakewood, New Jersey 08701 •P.+1-732-363-2100 F.+1-732-364-6084

www.DustlessMadeSimple.com

Page 3