Sherex FLEX?5S Instruction manual

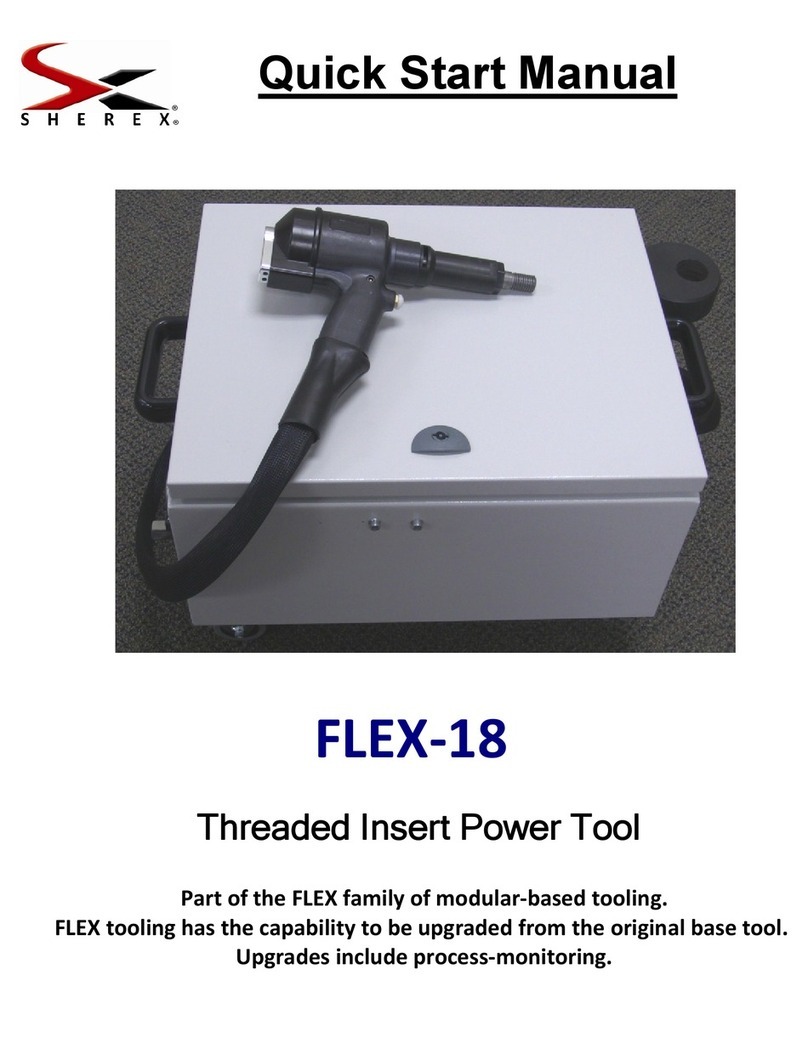

Quick Start Manual

FLEX‐5S

Threaded Insert Power Tool

Pull to Stroke Set Up

PartoftheFLEXfamilyofmodular‐basedtooling.

FLEXtoolinghasthecapabilitytobeupgradedfromtheoriginalbasetool.

Upgradesincludeprocess‐monitoring,conversiontoin‐linetool,

conversiontoasplittoolwitharemotebooster,

andconversiontoapulltopressuretool.

cONTENTS

SAFETY........................................................................................................................................................................2

TOOL OVERVIEW........................................................................................................................................................3

TOOL SPECIFICATIONS.............................................................................................................................................4

AIR SERVICE................................................................................................................................................................5

NOSE KIT ASSEMBLY................................................................................................................................................ 5

NOSE ASSEMBLY COMPONENTS............................................................................................................................6

PULL FORCE REGULATION......................................................................................................................................7

OPERATION.................................................................................................................................................................7

MAINTENANCE...........................................................................................................................................................8

TROUBLESHOOTING.................................................................................................................................................9

SHEREX SHOWCASE.................................................................................................................................................10

Sherex Warranty

Sherex Fastening Solutions FLEX-5S carries a 6 month warranty against defects that are

caused by faulty materials or workmanship. Sherex warranty period commences from the

date of delivery which is confirmed either by the invoice or delivery note. The warranty

becomes invalidated if the installation tool is misused or not serviced, maintained, and

operated according to the instructions in the Quick Start and Repair Manuals.

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

1

SAFETY

DO NOT USE THIS TOOL FOR ANY PURPOSE OTHER THAN THOSE SPECIFIED.

DO NOT USE ANY EQUIPMENT ALONG WITH THE TOOL THAT HAS NOT BEEN

RECOMMENDED OR PROVIDED BY SHEREX FASTENING SOLUTIONS.

▪Failure to do so could result in voided warranty and/or personal injury

THIS TOOL MUST BE KEPT IN EXCELLENT CONDITION AND SHOULD BE CHECKED

BY SPECIALIZED PERSONNEL ON A REGULAR BASIS TO DETECT DAMAGES AND

EVALUATE ITS OPERATING CONDITION.

ALWAYS DISCONNECT THE AIR SUPPLY BEFORE SET UP, ADJUSTMENT, OR

REMOVAL OF THE NOSE ASSEMBLY.

AIR INLET SHALL NOT EXCEED 7 BAR (102 PSI).

DO NOT USE THE TOOL WITHOUT OIL PLUG IN PLACE.

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

2

TOOL OVERVIEW

The FLEX-5S tool is designed for installing Sherex threaded insert/rivet nuts. The tool utilizes a pull to

stroke installation method. The advantage with this method is that the pulling distance of the tool can

be set to a specified distance ensuring the rivet nut insert is pulled to the same position (distance)

with each actuation of the tool (contact Sherex for the conversion instructions for changing this tool to

a pull to pressure installation method).

The tool is designed to install rivet nuts from M3 to M10, # 6-32 to 3/8-24. The recommended

operating air pressure is between 5 - 7 bar (72.5 - 101.5 PSI).

Sherex

Rivet Nut Series

Thread

Sizes

CAL

CAK

CAH

CAO

CPB

CPN

CA

CFH

CFT

CFW

TU

CLM

CKM

#6 & M3 X

#8 & M4 X

#10 & M5 X

1/4 & M6 X

5/16 & M8 X X

3/8 & M10 X X X

FLEX Tool Recommended

X FLEX Tool Not Recommended

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

3

SPECIFICATIONS

FLEX-5S Tool Specifications

AIR PRESSURE Minimum - Maximum 5 – 7 bar 72-101 psi

STROKE Maximum 7 mm .280 in

MOTOR SPEED SPIN ON 1500 rpm

SPIN OFF 2000 rpm

PULL FORCE @ 6.2 bar 22.25 kN 5,000 lbf

CYCLE TIME Approximately 2.5 sec

NOISE LEVEL Less than 70 dB(A)

WEIGHT Without kit 1.9 kg 4.2 lbs

VIBRATION Less than 2.5 m/s2

PLACING FEATURES Inserts M3 – M10 # 6-32 – 3/8-24

Contact Sherex should you require a pull to

stroke setup for this tool (FLEX 5P)

FLEX TOOL DIMENSIONS

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

4

10.24

260.1

10.45

265.43

2.0

50.3

Dimensions shown in bold are in inches. The other

dimenions are in millimeters.

4.32

109.73

SERVICE

AIR SUPPLY

We suggest you use a pressure regulator and automatic oiling / filtering system on the main air

supply, to ensure its maximum life cycle with reliable trouble free use.

NOSE KIT ASSEMBLY

ASSEMBLY INSTRUCTIONS

IMPORTANT

DISCONNECT THE AIR SUPPLY WHEN SETTING UP

OR REMOVING A NOSE ASSEMBLY.

•Choose the proper nose assembly.

•Remove the nose case, if still mounted.

•Unscrew the adaptor nut while moving away the stop pins.

•Insert hex driver 4into spindle, place socket head cap screw (mandrel) 3on to hex driver 4

and reducing sleeve 5on 3.

•Hold the adaptor nut, ensure the stop pins are seated in the last possible notch on the adapter

nut (may require you to turn forward 1 notch).

•Screw on the nose casing and the nose tip 1with the lock nut 2on it.

•To remove the equipment, do the reverse operation.

Nose Casing

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

5

PLACING RIVET NUT ONTO MANDREL- LENGTH CHECK

•Keeping the tool disconnected from air supply, place an insert on mandrel 3 adjust item 1in

order to match the insert and mandrel end. It is ideal to have 1-2 threads of the mandrel

protruding from the back of the rivet nut. This will ensure full thread engagement during the

installation process, lock position by threading 2 against nose casing.

Nose assemblies should be serviced weekly. Any damaged or worn out parts should be replaced.

Check for mandrel wear and replace when necessary. Sherex recommends using high quality socket

head cap screws such as Unbrako® and Holo-Krome®.

NOSE ASSEMBLY COMPONENTS

Nose pieces vary in shape according to the insert thread size. Each nose assembly represents a

unique group of components that can be ordered individually and are unique to the size of the

fastener. We suggest you keep the components listed below in stock to be used as replacements.

(Numbers refer to sketch on previous page).

THREAD SIZE COMPLETE NOSE

ASSEMBLY 1+2

NOSEANDLOCK NUT 3

MANDREL 4

HEXDRIVER 5

REDUCINGSLEEVE

STANDARD RIVET NUTS

M3 FL5-HS-M3 FL5-HS-00903

M-M3-45 FL5-HS-01003 FL5-HS-09103

M4 FL5-HS-M4 FL5-HS-00904

M-M4-45 FL5-HS-01004 FL5-HS-09104

M5 FL5-HS-M5 FL5-HS-00905

M-M5-65 FL5-HS-01005 FL5-HS-09105

M6 FL5-HS-M6 FL5-HS-00906

M-M6-65 FL5-HS-01006 FL5-HS-09106

M8 FL5-HS-M8 FL5-HS-00908

M-M8-65 FL5-HS-01008 FL5-HS-09108

M10 FL5-HS-M10 FL5-HS-00910

M-M10-65 FL5-HS-01010 XXXX

# 4-40 UNC FL5-HS-0440 FL5-HS-00854 M-0440-175 FL5-HS-00754 FL5-HS-09154

# 6-32 UNC FL5-HS-0632 FL5-HS-00856

M-0632-175 FL5-HS-00756 FL5-HS-09156

# 8-32 UNC FL5-HS-0832 FL5-HS-00858

M-0832-175 FL5-HS-00758 FL5-HS-09158

# 10-24 UNC FL5-HS-1024 FL5-HS-00850

M-1024-250 FL5-HS-00750 FL5-HS-09150

# 10-32 UNF FL5-HS-1032 FL5-HS-00850

M-1032-250 FL5-HS-00750 FL5-HS-09150

1/4-20 UNC FL5-HS-2520 FL5-HS-00848

M-2520-250 FL5-HS-00748 FL5-HS-09148

1/4-28 UNF FL5-HS-2528 FL5-HS-00848

M-2528-250 FL5-HS-00748 FL5-HS-09148

5/16-18 UNC FL5-HS-3118 FL5-HS-00840

M-3118-250 FL5-HS-00740 FL5-HS-09140

5/16-24 UNF FL5-HS-3124 FL5-HS-00840

M-3124-250 FL5-HS-00740 FL5-HS-09140

3/8-16 UNC FL5-HS-3716 FL5-HS-00842

M-3716-250 FL5-HS-00742 XXXX

3/8-24 UNF FL5-HS-3724 FL5-HS-00842

M-3724-250 FL5-HS-00742 XXXX

RIV-FLOAT® Riv-float is covered under U.S. Patent No. 7,713,011

M3 FL5-HS-2528R FL5-HS-00848 M-2528-225 FL5-HS-00748 FL5-HS-09148

M4 FL5-HS-2528R FL5-HS-00848 M-2528-225 FL5-HS-00748 FL5-HS-09148

M5 FL5-HS-M5R FL5-HS-R0995 M-M5-65 FL5-HS-01005 FL5-HS-09105

M6 FL5-HS-M6R FL5-HS-R0996 M-M6-65 FL5-HS-01006 FL5-HS-09106

# 4-40 UNC FL5-HS-2528R FL5-HS-00848 M-2528-225 FL5-HS-00748 FL5-HS-09148

# 6-32 UNC FL5-HS-2528R FL5-HS-00848 M-2528-225 FL5-HS-00748 FL5-HS-09148

# 8-32 UNC FL5-HS-2528R FL5-HS-00848 M-2528-225 FL5-HS-00748 FL5-HS-09148

# 10-24 UNC FL5-HS-1024R FL5-HS-R0950 M-1024-250 FL5-HS-00750 FL5-HS-09150

# 10-32 UNF FL5-HS-1032R FL5-HS-R0950 M-1032-250 FL5-HS-00750 FL5-HS-09150

1/4-20 UNC FL5-HS-2520R FL5-HS-R0948 M-2520-250 FL5-HS-00748 FL5-HS-09148

1/4-28 UNF FL5-HS-2528R1 FL5-HS-R0948 M-2528-250 FL5-HS-00748 FL5-HS-09148

RIVET NUT STUDS

M5 Stud FL5-HS-M5S FL5-HS-S0905 FL5-HS-0S005 FL5-HS-01010 XXXX

M6 Stud FL5-HS-M6S FL5-HS-S0906 FL5-HS-0S006 FL5-HS-01010 XXXX

M8 Stud FL5-HS-M8S FL5-HS-S0908 FL5-HS-0S008 FL5-HS-01010 XXXX

# 10-24 UNC Stud FL5-HS-1024S FL5-HS-S0850 FL5-HS-S1024 FL5-HS-01010 XXXX

# 10-32 UNF Stud FL5-HS-1032S FL5-HS-S0850 FL5-HS-S1032 FL5-HS-01010 XXXX

¼-20 UNC Stud FL5-HS-2520S FL5-HS-S0848 FL5-HS-S2520 FL5-HS-01010 XXXX

¼-28 UNF Stud FL5-HS-2528S FL5-HS-S0848 FL5-HS-S2528 FL5-HS-01010 XXXX

5/16-18 UNC Stud FL5-HS-3118S FL5-HS-S0840 FL5-HS-S3118 FL5-HS-01010 XXXX

5/16-24 UNF Stud FL5-HS-3124S FL5-HS-S0840 FL5-HS-S3124 FL5-HS-01010 XXXX

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

6

STROKE ADJUSTMENT PROCEDURE

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

7

Socket Head Cap

Screw Mandrel (2)

Determine the proper stroke distance of the tool based on the size

and style of rivet nut insert you are using for your application material

thickness. Contact Sherex should you require assistance determining

the appropriate stroke. Warning** A stroke setting that is too large

for the application may cause an over installed installation condition

which may damage the mandrel, the base material, and/or the rivet

nut insert.

Stroke Adjustment (3)

Install the proper nose assembly for the rivet nut thread size that you

will be using. Attach an air supply to the Air Inlet (1) per the

recommendations in this manual.

To adjust the stroke distance of the tool, use the key provided with

the tool and place it in the stroke adjustment ring (3) located in the cut

out of the back cover. The ring, when threaded fully in, will pull to 1

mm (0.040”) of stroke. Turning the key counter-clockwise from one side of the window to the other

will increase the stroke approximately .12 mm (.005). Continue to adjust the ring out until you have

approximated the stroke distance required. Test by installing a rivet nut and measuring the collapsed

distance of the part. Adjust the ring as required to achieve the desired installation distance.

Note**Threading the adjustment ring beyond the 6 mm stroke may cause the auto-reverse to not

function. If this occurs, turn the adjustment ring in the opposite direction reducing the stroke distance

to 6 mm.

Manual Reverse

Button (4)

Air Inlet (1)

Thread an insert/rivet nut on to the tool 1 or 2 turns. Apply pressure to the insert and the auto-spin on

feature will engage thereby spinning the rivet nut up the mandrel until it comes in contact with the

nose piece.

If during the set up process the tool does not automatically reverse out of the rivet nut press the

manual reverse button (4).

operation

Operating procedure

•Nose kit assembled, tool connected to air supply, force adjustment complete.

•Screw the rivet nut onto the mandrel a couple turns, then a light pressure on it will start the

spinning of the mandrel (push to spin) and automatically stop when the rivet nut comes in

contact with the nose piece.

•Insert fastener into the application.

•Depress the trigger fully. This will place the insert and automatically reverse the tool out of the

installed rivet nut. (Depress the trigger and hold until auto-reverse engages). If auto-reverse

does not engage and insert has not collapsed, apply a manual pushing force to engage the

auto spin-on, and then depress the trigger. (Ensure the air pressure is within the specified

range).

•If, at any time, manual-reverse (4) needs to be engaged, depress the button at the base of the

handle, to the right of the air inlet.

IMPORTANT

Do not push the mandrel without a rivet nut as this will cause the

mandrel to s

p

in automaticall

y

. Ensure

p

ressure settin

g

s are correct.

MAINTENANCE

Servicing should be performed on a regular basis and a complete inspection will be needed once a

year or every 500,000 cycles, whichever comes first.

IMPORTANT

The employer is the sole responsible party for ensuring the training of staff on proper

tool use and maintenance. The operator should not perform any servicing or repairs,

unless properly trained.

DAILY SERVICING

•Every day, before use, pour a few drops of light lubricating oil on tool air inlet,

if the air supply is not equipped with lubricator.

•Check for air leaks. If damaged, hoses and coupling should be replaced.

•Make sure you are using the proper nose assembly.

•Make sure the pull force is correct for the selected rivet nut.

•Check the mandrel for wear or damage and replace if needed.

WEEKLY SERVICING

•Check for oil and air leaks.

MAINTENANCE

Every 500,000 cycles the tool should be completely checked and parts that are worn or damaged

should be replaced. O rings should be replaced and lubricated with Molykote®55M grease before

assembly.

Only a trained technician should service the Flex 5S tool. Should the Flex 5S tool require repair, the

tool can be sent to the Sherex authorized repair center:

Alcorn Industrial, Inc

5412 Rock Hampton Court

Indianapolis, IN 46268

sales@alcornindustrial.com

1800-317-4775

P R I M I NG P R O C E D U R E

•Place the tool on its side with the oil plug facing up.

•With a 5mm Allen key, unscrew the oil plug

•Fill tool with DEA Astron HLP 32 hydraulic fluid, or equivalent

•Gently rock tool back and forth to express any trapped air

•Return oil plug and tighten

•Connect air supply and cycle the tool multiple times

•Disconnect air supply and unscrew oil plug a few turns

•Re-tighten oil plug

•If, at any time, oil is leaking from the reservoir, replace the oil seal washer

located at the top of the threaded section.

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

8

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE SOLUTION

⇒ Motor air leaks ⇒

Check for worn out seals. Replace

⇒ Low air pressure ⇒

Increase it

Pneumatic motor

runs slowly

⇒ Air vanes jammed ⇒

Lubricate tool through air inlet

⇒ Pull stroke not set properly ⇒

Adjust

⇒ Air pressure outside limits ⇒

Adjust

⇒ Low oil level ⇒

Add oil and prime

Insert does not

deform properly

⇒ Insert out of the grip ⇒

Check the insert grip range

⇒ Mandrel worn/damaged ⇒

Replace Mandrel

⇒ Hex Driver worn/damaged ⇒

Replace Hex Driver

Mandrel does not

spin

⇒ Loose locking ring ⇒

Tighten Locking Ring

⇒ Incorrect insert thread ⇒

Replace with proper insert

⇒ Incorrect mandrel ⇒

Replace with proper mandrel

Insert does not

spin on the

mandrel ⇒ Mandrel out or damaged ⇒

Replace

⇒ Excessive pull stroke

⇒

⇒

⇒

Defective insert

Defective or worn out or

damaged mandrel

⇒

⇒

Tool is locked in

installed insert

Depress manual spin off

If this does not work, disconnect

air, insert a pin through nose

casing slots and unscrew.

Contact Sherex

Replace Mandrel

⇒ Excessive pull stroke ⇒

Re-set pull strokeMandrel breaks

prematurely ⇒ Side load on mandrel ⇒

Keep the tool square to the application

when placing insert

⇒

⇒

No air supply

Insufficient distance between

locknut and spindle

⇒

⇒

Connect

Set distance between 1.5 and 2 mm

Tool does not spin

on insert

⇒ Air motor jammed ⇒

Lubricate through air inlet or if required

contact Sherex authorized repair center

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

9

Sherex Showcase

The FLEX line of tooling is just one of many Product lines that

Sherex offers to help meet your application requirements

BLIND RIVET NUT

S

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

10

Blind rivet nuts are suitable for providing load-bearing threads in thin

materials & blind applications. Sherex Fastening Solutions offers the

most comprehensive line of blind rivet nuts from thin wall parts to heavy

duty. Available in American & European style rivet nuts. Special designs

are available to meet customer specific needs.

BRASS INSERT

S

Brass inserts from Sherex Fastening Solutions are designed to provide a

threaded hole in plastics that are not strong enough to support a thread.

Brass inserts are available in many options such as ultrasonic, press-in,

flanged and molded-in. These inserts have a self aligning lead for accurate

installation and can be easily mounted. Suitable industy applications

include automotive, communication and computer equipment, or almost

anywhere strong durable threads are required in plastics.

RIV-FLOA

T

®

RIV-FLOAT® is the next generation of fastening technology that has

internally floating threads that allow for component attachment in off center

applications. was designed for installation post finish in applications where

cage nuts, clinch nuts, floating nut plates or weld nuts are typically used. By

aligning to the drive angle of the screw, RIV-FLOAT® accounts for tolerance

stack up, saving rework of components and downtime associated with

stripped or cross threaded fasteners.

Internally Floating

Thr

eads

CLINCH NUT

S

Sherex offers three different kinds of clinch nuts to meet the specific

requirements of the customer’s application. Sherex clinch nuts can be

used in various high strength steels such as dual phase alloy, HSLA, and

TRIPS to meet class 10 nut strength requirements. Sherex clinch nuts can

be used in any material that offers access from both sides of the base

material.

Sherex combines world class fastener manufacturing and design

capability with industry leading automation equipment to offer the best

solution for your application. This “One Source” service ensures that

you are receiving the best support before and after the start of

production. Whether you are using 10,000 pieces or 10 million pieces,

Sherex offers different levels of automation capability to meet your

budget requirements and also the proper fastener to meet your

performance requirements.

FASTENER

AUTOMATION

www.sherex.com 866-4SHEREX 400 Riverwalk Pkwy, Suite 600 ~ Tonawanda, NY, 14150

11

SHEREX FASTENING SOLUTIONS

400 Riverwalk Pkwy., Suite 600

Tonawanda, NY 14150

Phone: 866-474-3739

Fax: 716-875-0358

www.sherex.com

SHEREX TAIWAN

No. 201, Sandong Road, Chungli City

Tao-Tuan Hsien, Taiwan, R.O.C.

Phone: 011-886 3 4988689

Fax: 011-886 3 4989395

www.sherex.com.tw

SHEREX MEXICO S. de R. L. de C.V.

Av. Constituyentes 47, Desp 104

Col. El Pocito

Corregidora, Queretaro

C.P. 76910

Mexico

Phone: 52 (442) 196-8075

www.sherex.com

Other manuals for FLEX?5S

1

Table of contents

Other Sherex Power Tools manuals