Sherex SSG-912 User manual

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

SHEREX FASTENING SOLUTIONS

PNEUMATIC SPIN-SPIN RIGHT ANGLE INLINE STYLE

RIVET NUT INSTALLATION TOOL

SSG-912

MANUAL

SSG-912

Specifications

R.P.M. - 1100

*Air Pressure - 60-90 psi (oiled)

Weight - 2.3 lbs. (1.0 kg)

Air Inlet - 1/4”

Air Consumption - 5 CFM

Hose Diameter - 3/8”

Thread Size - Unified: 10-24, 10-32, 1/4-20, & 1/4-28

Metric: M5 & M6

* Must be adjusted to suit thread size/application

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

2

(6) (4) (3)

(2) (1)

(1.) Assemble the bearing set & mandrel (parts 2,3,4,5) shown in the figure above.

(3.) Install the pre-assembled bearing set with part 1.

(4.) Insert part 6 into Gun Body’s hexagon slot.

(5.) Push Gun Body’s quick releasing ring backward and

push part 6 into the Gun Body. Completely release the

quick releasing ring to complete the tool assembly.

(2.) Insert part 1 into the Gun Body. Rotate part 1 until

the slot connects with the Gun Body, shown in the figure

to the left.

(5)

(2.)

(3.)

(4.)

(5.)

HEAD SET ASSEMBLY DIRECTIONS

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

3

Instructions for Use:

1. Insert head set into tool as described on page 2.

2. Turn the rivet nut onto the cap screw — 1 complete turn.

3. Insert the rivet nut into the work piece.

4. To install the rivet nut, depress the Position 1 Button. While the button is depressed,

squeeze the Position 2 Lever. When the rivet nut is completely installed the tool will stall.

5. Once the tool stalls, release the Position 1 Button, but continue to hold the Position 2 Lev-

er. The tool will reverse out of the work piece leaving the rivet nut completely installed.

The SSG 910 Series provides a quick and easy way of installing rivet nuts. This tool uses torque

to install rivet nuts so it does not need any adjustment, it is already set for the rivet nut.

If necessary, minor adjustments can be made by increasing or decreasing air pressure.

This tool is recommended for use with Sherex CAL, CAK, CAH, CAO, CPB, CFT/CAT, and

CFW/CAW rivet nuts. Feel free to contact Sherex about special applications, or use with other

rivet nut styles not listed above.

SSG-912 Dimensions

Keep

Threads

Lubricated!

Position 2

Lever

Position 1 Button

2.60

4.0

7.50

19.10

Dimensions shown in bold are in inches.

The other dimensions are in centimeters.

1.37

3.50

Sherex Spin/Spin Inline Right Angle Rivet Nut Tool

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

4

BEARING ASSEMBLY – It is important that the thrust bearing be lubricated with SSG-LUBE available thru Sherex.

The bearing assembly and mandrel (socket head cap screws) are located in the nose piece of the tool. Lubricate as needed,

bearing should not run dry. Remove the nose piece & proceed as follows:

1) Remove the bearing & socket head cap screw.

2) Separate the bearing from the races & lubricate. Work grease into bearing. Replace socket head cap screw if

worn or damaged. Use only high quality grade 8/Class 12.9 socket head cap screws, part number are listed on

page 27 of the Sherex catalog.

3) Reassemble.

PREVENTATIVE MAINTENANCE –

1) LUBRICATE MANDREL. In some applications it may be advisable to dip the first one or two threads of the

mandrel into a light oil after several installations to minimize wear.

2) HANDLE WITH ORDINARY CARE. A large number of tool repairs can be traced to improper

handling. In spite of their durable appearance, air tools should not be used as hammers or pry bars, nor should they

be deliberately dropped or dragged along the floor.

3) IF LINE OILER is not used, apply a small amount of Spindle Oil in the air inlet of the tool and run free for one

minute to insure proper lubrication; repeat after 8 hours of operation.

CAUTION: An excessive amount of lubricant in a tool will affect the speed and power. Each set of planetary gearing

should contain approximately ½ ounce of grease.

FAILURE TO FOLLOW ROUTINE MAINTNANCE DESCRIBED COULD VOID WARRANTY

AIR PRESSURE TROUBLE-SHOOTING: CHECKING SUPPLY AND FITTINGS

If recommended pressures cannot be obtained, the supply system should be checked. Some things to look for are:

1) Inadequate compressor capacity.

2) Improper pipe sizes (I.D. too restrictive).

3) Restrictions caused by fittings with I.D.’s too small. See note above.

4) Be sure hose and quick disconnect fittings have 5/16” I.D.

5) Shut-off valves. It is best to use stop cock type, which lessens restrictions.

6) Improper coupler and quick disconnect. Use only those with good flow characteristics and assure that they mate correctly.

7) Filter-regulator-lubricator should be compatible, properly sized and maintained.

8) Clogged filter.

SSG TOOL MAINTENANCE

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

5

Below are some guidelines for solutions to common setting and tooling problems. By following these steps you should

be able to get back into production as quickly as possible if a problem arises:

1) SCREWS BREAK FREQUENTLY –

a) Too much air line pressure. Check the air pressure specs for the thread size you are placing. Adjust downward

accordingly.

b) Make sure operator is holding the tool at a 90 degree angle to the work piece, and not tilting it over to one side.

2) TOOL STALLS BEFORE FULLY PLACING THE INSERT –

a) Be sure there is a bearing assembly in the tool. Check to be sure it is not worn out, and that it is assembled correctly.

Clean in solvent, blow dry and lubricate with recommended grease.

b) Check for quick disconnect fittings with holes of ¼” or 3/16”. These may be too small to allow the necessary volume

into the tool. This is especially critical with the 5/16, 3/8 and ½” thread sizes.

c) Be sure hose I.D. is 5/16”.

d) Not enough air line pressure. Check the air pressure specs for the thread size you are installing. Adjust upward

accordingly. To prevent against unfavorable drops in air pressure, regulated pressure readings should be measured at

or near (within 30 feet) of the tool. This air pressure should be within the recommended range of the tool.

e) Check the condition of the mandrel. Replace, if worn using high quality socket head cap screws.

f) Check to see if other air tools are being used that are starving the insert installation tool.

3) TOOL WILL NOT START/RUN –

a) With air system connected, quickly change from forward to reverse several times.

b) Check your air line and air pressure to assure there is an adequate supply of air to the tool.

c) Remove the complete tool nosepiece. Manually rotate the square drive shaft. Connect air to tool and depress trigger.

d) Evaluate airline set-up portion.

e) If there is an air motor failure, call Sherex Customer Service.

4) AIR MOTOR RUNS, MANDREL DOESN’T TURN -

a) Make sure hex drive is engaged into the mandrel. Check to see if screw is broken or if the head is rounded out. Check

also, if the hex drive itself has been rounded off. Replace defective parts as may be required to assure proper

installation.

CALL SHEREX CUSTOMER SERVICE IF THESE PROCEEDURES FAIL TO PROPERLY SET THE RIVET NUT.

SSG TOOL TROUBLESHOOTING

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

6

SSG-912 PARTS BREAKDOWN

KEEP BEARING

SET WELL

GREASED!

USE SHEREX

SSG-LUBE OR

LUBRIPLATE

L0161-001

*Use only high Quality Socket

Head Cap Screws such as

Unbrako®, or Holokrome®

PART NO. DESCRIPTION NO.

REQ. PART NO. DESCRIPTION NO.

REQ.

SSG-913-1 MOTOR HOUSING 1SSG-912-32 PLANET GEAR (18T) 6

SSG-913-2 AIT INLET 1SSG-912-33 GEAR CAGE 2

SSG-913-3 RETAINER RING 1SSG-913-34 SUN GEAR (12T) 1

SSG-913-4 DEFLECTOR 1SSG-912-35 INTERNAL GEAR 1

SSG-913-5A SILENCER 2SSG-913-36 RETAINING RING 1

SSG-913-7 LEVER PIN 1SSG-913-37 GEAR SPINDLE 1

SSG-913-8 LEVER 1SSG-913-38 BALL BEARING (6000) 1

SSG-913-9A EXHAUST COVER 1SSG-913-39 BALL BEARING (6001) 1

SSG-913-10 VALVE SCREW 1SSG-913-40 PINION 1

SSG-913-11 O-RING 1SSG-912-41 LOCK RING 1

SSG-913-12 REVERSE RETAINER 1SSG-913-42 BALL CAP 1

SSG-913-13 VALVE SPRING 1SSG-913-43 ANGLE HOUSING 1

SSG-913-14 THROTTLE VALVE 1SSG-913-44 SET CAP 1

SSG-913-15 O-RING 1SSG-913-45 RETAINER RING 1

SSG-913-16 VALVE BUSHING 1SSG-913-46 BALL BEARING (698ZZ) 1

SSG-913-17R REVERSE VALVE (W TYPE) 1SSG-913-47 GEAR 1

SSG-913-17F REVERSE VALVE (S TYPE) 1SSG-913-48 BALL BEARING (6000ZZ) 1

SSG-913-18 REVERSE VALVE BUSHING 1SSG-913-49 KEY 1

SSG-913-19 REVERSE VALVE SPRING 1SSG-913-50 SPINDLE 1

SSG-913-21 GASKET 1SSG-913-51 NOSE HOUSING 1

SSG-913-22 BALL BEARING (696ZZ) 1SSG-913-52 LOCKING BALL 2

SSG-913-23 REAR END PLATE 1SSG-913-53 CHANGE VALUE SPRING 1

SSG-913-24 ROTOR BLADE 5SSG-913-54 QUICK CHANGE SLEEVE 1

SSG-913-25 ROTOR (6T) 1SSG-913-55 CIRCLIP 1

SSG-913-26 PLANET GEAR (12T) 1SSG-913-56 HEX DRIVER 1

SSG-913-27 ROLL PIN (Ø2.5 * Ø10) 2SSG-913-57 MANDREL (Socket Head Cap Screw)*1

SSG-913-28 CYLINDER 1(58, 59, & 60)

Sold as a set

BS-4 to BS-37

BS-M3 to BS-M10

REAR THRUST PLATE,

ROLLER BEARINGS, &

WASHER

1 ea.

SSG-913-29 FRONT END PLATE (Ø34 * Ø6) 1

SSG-913-30 BALL BEARING (626ZZ) 1

SSG-913-31 WASHER 1(61) NOSE PIECE SOLD W/ HEAD SETS 1

58, 59, & 60 SOLD

AS COMPLETE

SET BS-XX

Sherex Fastening Solutions, LLC ~ 400 Riverwalk Pkwy, Suite 600 Tonawanda, NY, 14150

866-4SHEREX ~ www.sherex.com

7

Authorized Sherex Fastening Solutions, LLC Tool

Repair Facility:

Alcorn Industrial, Inc.

5412 Rock Hampton Court ~ Indianapolis, IN 46268

sales@alcornindustrial.com

1-800-317-4775

For All Your Rivet Nut Tool Repairs!

Other Sherex Rivet Tools manuals

Popular Rivet Tools manuals by other brands

FAR

FAR KJ 60 Original instructions for use

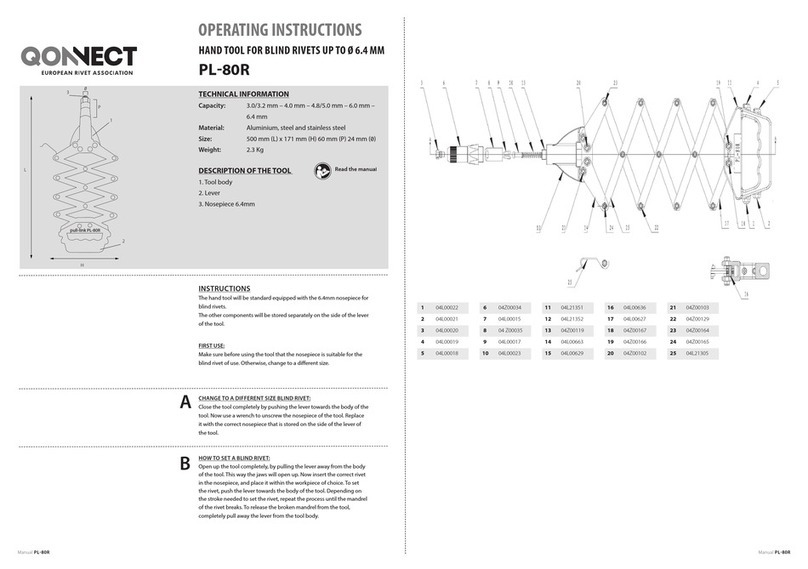

Qonnect

Qonnect PL-80R operating instructions

Matco

Matco Silver Eagle SE214 operating instructions

Gesipa

Gesipa FireRex C-WT Operating manual with spare parts list

Ingersoll-Rand

Ingersoll-Rand 127 Product information

FAR

FAR RAC 181 Translation of the original instructions

Industrial Rivet & Fastener Co.

Industrial Rivet & Fastener Co. RK-9000M Operator's manual

Sealey

Sealey CP316 instructions

Berner

Berner BPT-BR 4-8 Instruction manual/safety instruction

LOBSTER

LOBSTER AR 2000SV instruction manual

Makita

Makita DRV150 instruction manual

Stanley

Stanley AV 25 Instruction and service manual