Gesipa FireRex C-WT Guide

Other Gesipa Rivet Tools manuals

Gesipa

Gesipa AccuBird Guide

Gesipa

Gesipa Bird Series Operating instructions

Gesipa

Gesipa FireBird Gold Edition User manual

Gesipa

Gesipa taurus 1 Guide

Gesipa

Gesipa 8000 User manual

Gesipa

Gesipa PH 2000 Guide

Gesipa

Gesipa taurus 1 User manual

Gesipa

Gesipa FireFox 2 User manual

Gesipa

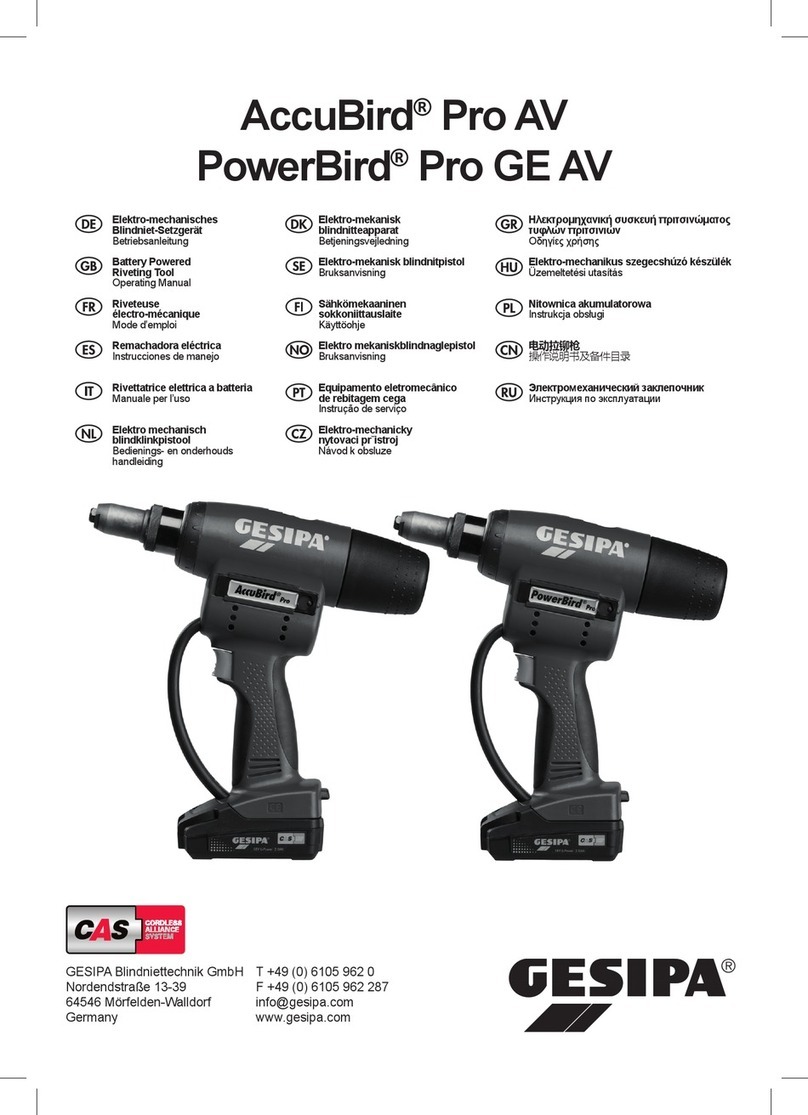

Gesipa AccuBird Pro User manual

Gesipa

Gesipa TAURUS 3 C User manual

Gesipa

Gesipa FireBird Pro User manual

Gesipa

Gesipa FireBird Pro User manual

Gesipa

Gesipa PowerBird Pro Gold Edition Guide

Gesipa

Gesipa PowerBird Pro Guide

Gesipa

Gesipa GBM 95 User manual

Gesipa

Gesipa AccuBird Guide

Gesipa

Gesipa taurus 3 Setup guide

Gesipa

Gesipa TAUREX 1 Axial User manual

Gesipa

Gesipa taurus 1 Guide

Gesipa

Gesipa PH 1 Guide

Popular Rivet Tools manuals by other brands

Würth

Würth ANG 14 Translation of the original operating instructions

Ingersoll-Rand

Ingersoll-Rand 127 Product information

Arconic

Arconic MARSON MP-4V manual

Sealey

Sealey CP316 instructions

Silver Eagle

Silver Eagle SE314 operating instructions

Würth

Würth HES 510 N Translation of the original operating instructions

Stanley

Stanley EZM1000 Instruction and service manual

Stanley

Stanley PROSET PB3400 Accessories manual

HS-Technik

HS-Technik NutBee NBLS-21 operating instructions

Sumake

Sumake ST-6615 manual

GOEBEL

GOEBEL Air power Series Operation manual

Schneider Airsystems

Schneider Airsystems NZ - SYS D322311 Original operating manual