3

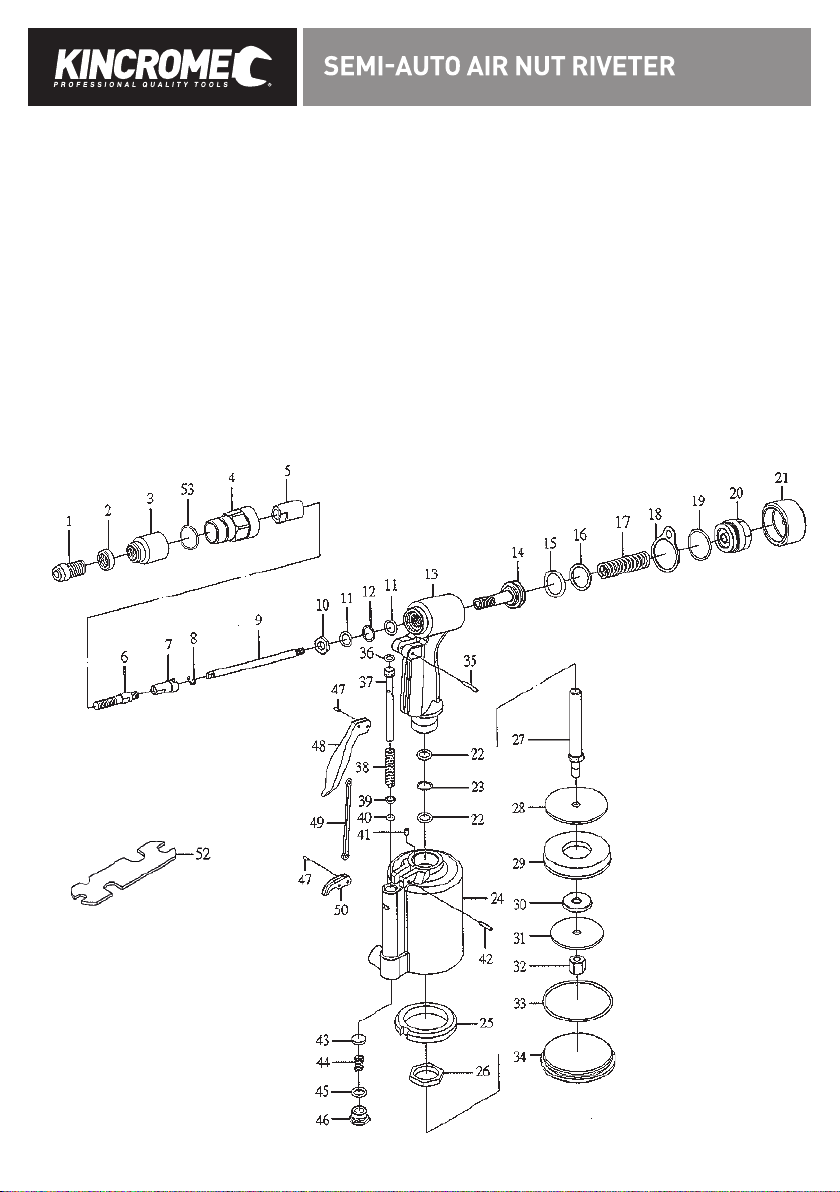

4) Service

a. Tool service must be performed only by qualified repair personnel.

b. When servicinga tool, use only identical replacement parts. Use only authorized parts.

c. Use only the lubricants specified by the manufacturer.

5) Additional Safety Warnings

a. The warnings and precautions discussed in this manual cannot cover all possible conditions and situations that may

occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

b. Only use with accessories rated to handle the forces exerted by this tool during operation. Other accessories not

designed for the forces generated may break and forcefully launch pieces.

c. Attach all accessories properly to the tool before connecting the air supply. A loose accessory may detach or

break during operation.

d. Use the right tool for the job. Do not attempt to force a small tool or attachment to do the work of a larger industrial

tool. There are certain applications for which this tool was designed. Do not modify this tool, and do not use this tool for a

purpose for which it was not intended. Normal use of this product is likely to expose the user to dust and /or microscopic

particles containing chemicals known to (the State of California) cause cancer, birth defects or other reproductive harm.

Always wear appropriate safety equipment and clothing when using this product. Study, understand and follow all

instructions provided with this product.

e. Anyone using vibrating tools regularly, or for an extended period should first be examined by a doctor and then have

regular medical check-ups to ensure medical problems are not being caused or worsened from use. Pregnant women

or people who have impaired blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or

Raynaud’s Disease should not use this tool. If you feel any symptoms related to vibration (such as tingling, numbness, and

white or blue fingers), immediately discontinue use and seek medical advice as soon as possible.

f. Do not smoke during use. Nicotine reduces the blood supply to the hands and fingers, increasing the riskof vibration-related injury.

g. Wear suitable gloves to reduce the vibration effects on the user.

WARNING! Some dust created by power sanding, sawing, grinding, drilling, and other construction activities,

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement or other masonry products

• Arsenic and chromium from chemically treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure

to these chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust

masks that are specially designed to filter out microscopic particles.

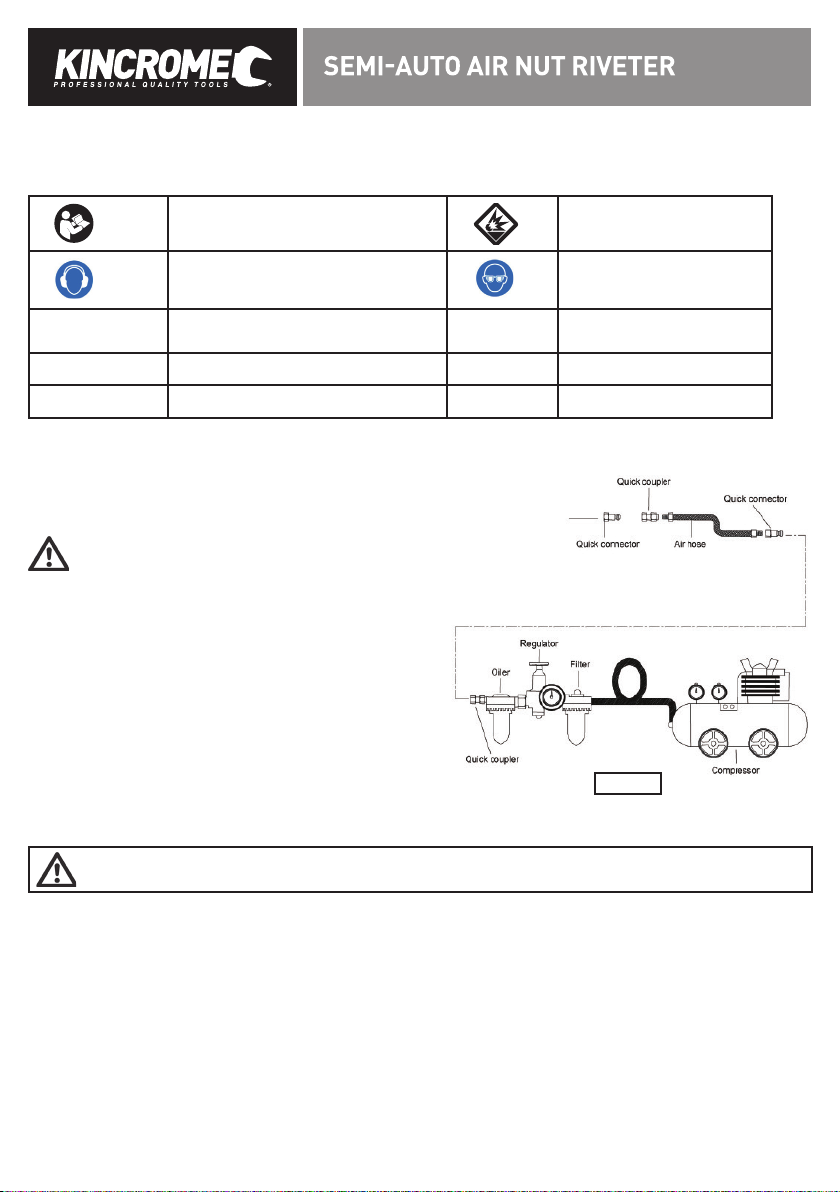

6) Additional Safety Instructions for Air Nut Riveters

a) Stay within air pressure capacity. Do notoperate the Air Nut Riveter above 90 psi.

b) Do not use the tool outside of the designed intent.

c) Fire the Riv-Nuts into an appropriate work surface only. This Air Nut Riveter is designed for use on metal objects only, and is

not suitable for soft surfaces.

d) Do not fire the Riv-Nuts too close to the edge of a workpiece. They may split the workpiece and cause it to fly free, causing

personalinjury.

e) Transport the Riveter safely. Disconnect the air supply when moving the tool in the workplace. Carry the tool by the handle

andavoid contact with the Trigger.