Sherline Products 8700 Guide

SHERLINE CNC Rotary Table

P/N 8700

Dimensions

Table diameter: 4.0" (102mm)

Table height: 2.0" (51mm)

CLICK HERE to view a dimensioned drawing of the rotary table with stepper motor mounted, or see the General Description

page on the CNC rotary table for performance specifications.

INSTALLING AND USING

THE SHERLINE CNC ROTARY TABLE AND CONTROLLER

By Bryan Mumford and Joe Martin

INTRODUCTION

Bryan Mumford and I are very proud of this product. It has taken Sherline twice the investment in both time and money

compared to what we originally planned for this project. This project would have been a lot easier if we built the $4000 product

that we are competing with. We have taken a very expensive product that has only been available to very successful professional

businesses and produced a self-contained unit that not only has the features of the expensive units, it is also simpler to use and

very affordable. In fact, it is so inexpensive, home hobbyists can now afford to own and use this equipment. It should also be

noted that we didn't copy anyone to accomplish this feat. My only disappointment was that I was unable to find a way to adapt

our existing rotary tables to a CNC unit. It just couldn't be done in a cost-effective manner because of the mechanical parts that

couldn't be interchanged due to the way the rotary table is manufactured.

Even though the computer is small, it is a very complex device that both computes and drives the stepper motor in microsteps.

Like all electronic devices, the easier it is to operate, the harder it is to design and program. We believe the instructions are easy

to read and shouldn't give you any problems, but if they do, please notify us at Sherline, and we will attempt to improve them. We

want our instructions to be the best in the business. The most important rule is to always work safely and accurately.

POWER OF THE MOTOR

The stepper motor is rated at over 100 oz-in of torque, with the highest power being achieved at low RPM. The maximum speed

of 50°/sec provides high speed but very little power. To use that setting for positioning, the system must be completely free from

drag. We recommend using a maximum speed of 40°/sec as a positioning speed to avoid stalling the stepper motor. When

cutting, slow speed should be used to take advantage of the motor's power.

POSITIONING ACCURACY

The first thing to understand about the rotary table is the accuracy that can be obtained in real terms. The stepper motor takes

400 steps to make exactly one revolution. This motor drives the worm, which needs to make 72 revolutions to make the rotary

table turn exactly one revolution. This means that it takes 28,800 steps (400 x 72) to drive the rotary table one complete

revolution. Take this number and divide by the number of degrees in a circle (360°) and we end up with 80 steps for each degree

or 0.0125° (or 0.75 minutes) for each step. The built-in computer will calculate to the closest position. This means the final

position will be within ± 1/2 step. This turns out to be a very small amount, because the sine of this angle is only 0.0001091. This

will amount to 0.109" (2.77mm) rise in 1000" (83'- 4" or 25.4 m) when compared to a flat plane. This is just .00022" (.0055mm)

at the edge of the table.

MECHANICAL ACCURACY

The gear that turns electronic signals into a real movement has been hobbed directly into the table, which means the teeth have

been generated on a machine that cuts the teeth with a cutter similar to a worm as the part is turning. This eliminates any error

associated with cutting each tooth individually. As anyone associated with the machine trades realizes, "nothing is perfect". This is

also the case for this product; however, I seriously doubt if anyone buying it could measure the mechanical indexing error of the

worm and gear. The electronic system has no error in its calculations, but it does round off as previously explained.

THE IMPORTANCE OF READING THE INSTRUCTIONS

It is impossible to make a product this complex "idiot proof". The best rule I've ever come up with when dealing with any type of

CNC equipment is this: "You have to know what the unit will do after you push the button BEFORE you push the button." This

can only be accomplished by reading the instructions and "playing with the rotary table" at the same time until you thoroughly

understand how the features of this unit work. It isn't necessary to understand the interfacing options to safely operate the CNC

rotary table. Don't mount this unit on a mill that has a cutter in the spindle until you truly understand how to control it.

PRECAUTIONS WHEN TURNING ON THE UNIT

• As with any piece of electronic equipment, make sure the power is off before plugging the stepper motor connecting cord into

the control unit.

• If a part has been aligned on the table and the power is switched off; the part should be realigned after turning the unit back on

before continuing. Electrical "spikes" can cause the motor to move a few steps when turning it on. The power can be left on

continuously without damage; however, the controller should be left in "Jog" mode to prevent the motor from being energized. If

you don't do this, the motor may be left energized because the motor is electrically locked in position after a controlled move.

Always record your handwheel settings at a "home" for future use.

OPERATING INSTRUCTIONS

The Sherline Rotary Table Controller is a self-contained microprocessor-based controller that will automate the motion of the

Sherline rotary table. Though you can still crank the table by hand when in the jog mode or when the controller is turned off, the

controller is designed to crank it for you in precise, measured steps.

PRECAUTIONS REGARDING MANUAL MODE

When hand cranking the handwheel in the manual mode, the stepper motor acts as a generator. If you crank the handwheel

rapidly, there is a chance that the control box electronics could be damaged by the current generated. If the unit is to be used

extensively in the manual mode, it is recommended that you disconnect the cable from the motor to the controller.

START-UP COMMANDS

Note: You can skip over the START-UP and SETTINGS COMMANDS if you are reading this for the first time. The

factory default settings will work and these settings are only needed for advanced operations.

There are several utility commands that can be issued by holding down certain keys when the controller is first turned on. For

example, to enter the SLAVE MODE (to run the controller with STEP and DIRECTION signals from another CNC controller)

hold down the [ 1 ] key when you first turn the controller on.

The four start-up commands are:

[ 1 ] - Enter "Slave" mode.

[ 7 ] - Show the revision date of the firmware.

[ 9 ] - Erase all program memory locations.

[MODE] - Erase all program memory locations and initialize all settings to factory defaults.

These commands are described in detail in the appropriate section if needed.

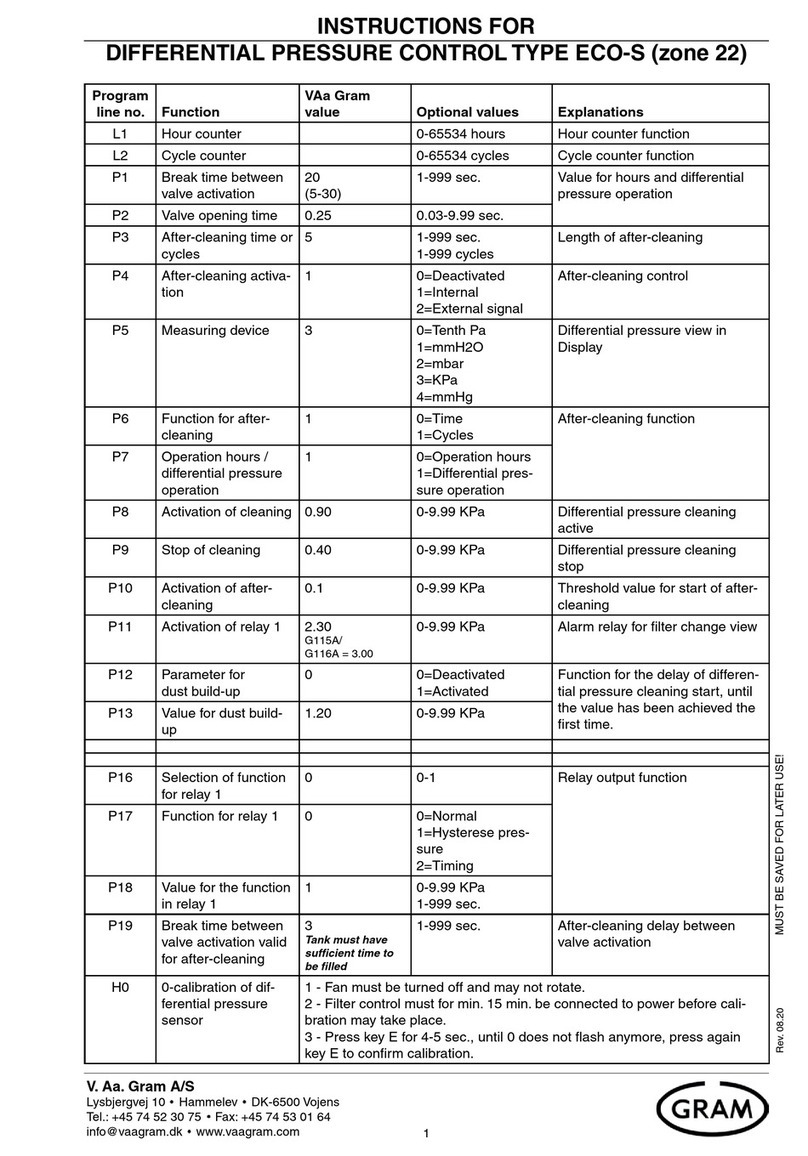

FIGURE 1-The keypad layout

THE "SETTINGS" MODE

The next mode after the Program Mode is the Settings Mode. This allows you to enter some parameters of operation for the

table. These settings are remembered even when you turn the controller off.

SLOW SETTING

When the screen displays:

Settings Mode

Press Enter

Press the [ENTER] key. The screen will then display something similar to:

Slow: 15

Enter a number*

The number after the word SLOW is the minimum feed rate of the rotary table. This is the speed with which the table starts each

movement. The units are degrees per second. Whenever the table moves, it starts at the SLOW feed rate and ramps up to the

FAST feed rate. It also ramps down to the SLOW rate before stopping.

When the screen shows the value you wish to use for SLOW, press the [ENTER] key. The value will be stored and

remembered for all future operations and used with the JOG, DEGREES and DIVISION modes.

*NOTE: When entering more than 72 divisions or less than 5°, use a speed setting of 10 or 15. Faster settings can cause

the motor to overshoot the intended stopping point. (Settings less than 1° require a setting of 10.)

FAST SETTING

The screen will then display something similar to:

Fast: 40

Enter a number

The number after the word FAST is the maximum feed rate of the table. This is the maximum speed the table reaches in each

movement. The units are degrees per second. Whenever the table moves, it starts at the SLOW feed rate and ramps up to the

FAST setting. If you set the FAST rate the same as the SLOW rate, the rate of motion will be constant during the move. The

table does not have much power at the fastest settings, so very fast settings should only be used for positioning, not for cutting

operations. Experience will teach you what speeds are appropriate for your own work. (The maximum speed that can be entered

is 50 degrees/sec.)

When the screen shows the value you wish to use for FAST, press the [ENTER] key. The value will be stored and remembered

for all future operations and used with the JOG, DEGREES and DIVISION modes.

DIRECTION SETTING

The screen will then display something similar to:

Direction: 3

Press 1 or 3

This parameter allows you to enter the default direction of travel. Whenever these instructions display "clockwise" or

"counterclockwise", they assume the default direction is set to be clockwise. If you need the table's motion to be

counterclockwise, this can be arranged. If you type [ 3 ] the default direction will be set to clockwise. If you type the number [ 1 ]

key (marked with a left arrow) the default direction will now be set as counterclockwise.

SETTING THE ELECTRONIC BACKLASH COMPENSATION

The physical backlash in the worm gear can be minimized with proper adjustment (See "Maintenance" section later in these

instructions); however, it cannot be totally eliminated. The controller supports electronic backlash correction to compensate for

whatever actual backlash remains in the worm gear. It works in this way: Every time the table makes a motion in the "reverse"

direction, it will overshoot the amount of travel by the backlash amount, and then move "forward" by the same amount. This takes

up any backlash in the worm gear. You can set the backlash correction to any amount you like. If you set it to zero, it will not be

used. If you set it to a small amount, it can just exactly take up the backlash in your rotary table. If you set it to a relatively large

value, you can see the table overshoot and then return to correct position.

The LCD screen will display something similar to:

Backlash: 010

Enter a number

The number represents the number of motor steps to overshoot by.* When you have typed the backlash setting you want, press

the [ENTER] key to store it. The controller will then go back to the Division Mode.

*NOTE: 8 steps = 1 division line on the handwheel = 0.1° .

You can determine the amount of backlash compensation to use by trial and error and your own preference. To evaluate the

current backlash setting, go to the DIVISION mode. Enter something like 50 divisions. Hit the [PRV] key. The table will move in

the reverse direction and overshoot the distance specified by the backlash amount, then change direction and move forward by

the backlash amount. If the backlash setting is small, you won't notice it. If it is large, it will be easy to see.

THE "JOG" MODE

The Jog Mode allows you to quickly move the table in clockwise and counterclockwise directions with the keypad. To enter the

Jog Mode, press the [STOP] (Jog) key.

In Jog Mode the motor is not powered. This means you can turn the crank by hand for fine positioning. You can also hold down

the [ 1 ] or [ 3 ] keys for rapid, motorized motion. The feed "rapid" feed rate is controlled by the "fast setting" entered in the

Settings mode. "1" will move the table counterclockwise, "3" will move it clockwise. The [ 7 ] and [ 9 ] keys will move the table in

a similar manner only in this case the feed rate will be controlled by the "slow setting." For setting up you can also take very fine,

slow movements. [NXT] will move the table clockwise, [PRV] will move it counterclockwise.

When you are finished with the Jog Mode, press the [MODE] key to go back to the Division Mode.

NOTE: In addition to using it in the Jog Mode, you can also press the [STOP] (Jog) key at any time the table is moving, and it

will serve as a PANIC STOP, immediately stopping the table in place. In any mode other than the Jog Mode, if the table is in

motion and you want to stop it immediately, simply press the [STOP] (Jog) key. Doing so leaves the table in the JOG mode, and

it will need to be reset to your previous mode before continuing.

MOVING THE TABLE

There are four primary ways to move the table electronically:

1. DIVISION MODE - you can enter a number of equal divisions in which to divide one rotation of the table. For example,

if you enter "4", the table will move in 90 degree increments (360 / 4 = 90). A typical application of this mode would be

gear cutting and hole patterns.

2. DEGREES MODE - you can specify the exact number of degrees to move the table. For example, if you enter

"132.130", the table will move 132.130 degrees.

3. JOG MODE - you can move the table clockwise or counterclockwise with the keypad on the controller.

4. PROGRAMMED - you can program of movements. For example, you can have the table move 90°, then 132°, then

reverse rotation 20°, etc. You can enter up to 40 blocks in each of two separate programs. A block of information

contains the speed of rotation (feed rate) for each block, and whether the table is to pause and wait after a block is taken

or move continuously.

GENERAL SPECIFICATIONS

• The resolution of positioning is ± .006 degrees.

• The speed of rotation can be set from one degree per second to 50° per second. Note that the higher speeds do not have much

power and should only be used for positioning the table quickly, not for cutting operations.

• The controller uses "ramping" to accelerate and decelerate during each movement. You can enter the minimum and maximum

speeds used to suit your work. (The amount of ramping becomes more noticeable when the slow feed is set below 5 in the

Settings mode.)

• The controller allows a programmable amount of backlash compensation.

USING THE CONTROLLER

The controller must be plugged into its AC adapter power supply. The power jack is located on the end of the unit. It is turned on

with the toggle switch located next to the power jack. We wish that the power supply connector had a better locking system, but

we had to use what was commercially available. With the power turned off, the motor cable must be plugged into the 5-pin DIN

connector next to the power switch.

The basic operation of the controller is to press the [MODE] key to advance from one mode of operation to the next. This will

cycle through the various modes of operation. When the mode you wish to use is displayed, press the [ENTER] key to start that

mode and enter the parameters of operation. The four modes are:

• Division

• Degrees

• Program

• Settings

THE "DIVISION" MODE

The Division Mode allows you to specify a fixed number of divisions per rotation of the rotary table. For example, you might

specify "four" divisions. Then, each time you tell the table to advance, it will rotate one fourth of 360 degrees, or 90 degrees.

When you first turn on the controller, it will display "Sherline Rotary Table". Press the [MODE] key once to advance to the

first mode. The LCD (liquid crystal display) screen will display:

Division Mode

Press Enter

To use the Division Mode, press the [ENTER] key. The LCD screen will then display:

Divisions: 000

Enter a number

You should now enter the number of divisions in which you wish to divide the rotation. When you press a number key, that

number will appear on the LCD screen where the cursor is blinking. To move the cursor left, press the [PRV] (Previous) key. To

move the cursor right, press the [NXT] (Next) key or type any digit. You can enter any value between zero and 999 divisions.

(Zero is a special case. It will cause the table to run continuously until you stop it. See the section on page 8 regarding continuous

motion for an explanation of this action.)

When the number of divisions you want is displayed, press [ENTER]. For example, suppose you typed "030" for the number of

divisions. After you hit the [ENTER] key, the LCD screen will display:

Division # 1

Press Nxt or Prv

This means that the table is at position one (of 30), and it is waiting for you to press the [NXT] or [PRV] keys. If you press

[NXT], the table will advance 12 degrees clockwise, and the LCD screen will display:

Division # 2

Press Nxt or Prv

If you had pressed the [PRV] key, the table would move 12 degrees counterclockwise, and the LCD screen would display:

Division # 30

Press Nxt or Prv

It displays "Division # 30" because it turned counterclockwise one position, from one to 30.

There is a special function available in the Division Mode. After you have set the controller up to move with the [NXT] and

[PRV] keys, you can press the [MINUS] key. This will cause the table to move one division with a one-second delay between

movements. It will continue making the programmed movement with one-second delay between movements until you stop it with

the [STOP] (JOG) key. (If the [STOP] key is hit between movements while the table is not moving, it must be held down longer

than one second to stop the movement.)

PANIC STOP-Any time the table is moving you can stop it immediately by hitting the [STOP] (Jog) key. This will stop all

motion and put you into the JOG mode. You to lose your place in the program you were running and will have to start over. Hold

the key down until you're sure the program has shut. A momentary "blip" will not shut the program down unless the table is

moving.

To exit the Division Mode, press the [MODE] key.

THE "DEGREES" MODE

The Degrees Mode allows you to specify the exact number of degrees the table will rotate every time you tell it to advance. Keep

in mind that the resolution of the table is .0125 degrees. This means, for example, that it cannot move to a position like "0.010"

degrees which is not an even multiple of "0.0125". However, the table keeps track of exactly where it's supposed to be and

where it is actually able to go, and always gets as close to the correct location as is possible (within .006 degrees).

When the LCD screen displays "Division Mode" you can press the [MODE] key once to advance to the Degrees Mode. The

LCD screen will display:

Degrees Mode

Press Enter

To use the Degrees Mode, press the [ENTER] key. The LCD screen will then display:

Degrees: 000.000

Enter a number

You can now enter the number of degrees you wish to travel at each movement. When you press a number key, that number will

appear on the LCD screen where the cursor is blinking. To move the cursor left, press the [PRV] (Previous) key. To move the

cursor right, press the [NXT] (Next) key or type any digit.

You can also specify whether the table is to move clockwise or counterclockwise when you enter the number of degrees to

move. To enter a counterclockwise value, press the [MINUS] key. This will add a minus sign before the degree amount,

indicating reverse travel. If the degree size is negative, the [NXT] key will move the table counterclockwise and [PRV] will move

clockwise. To make a negative value positive again, press the [MINUS] key again.

(Note that it is also possible to change the default direction of travel from clockwise to counterclockwise. See the Settings mode

for details.)

You can also tell the controller to move zero degrees. This is a special case. It will cause the table to run continuously until you

stop it with the [STOP] key. See the section below labeled "Continuous Motion" for an explanation of this action.

When the number you want is displayed, press [ENTER]. For example, suppose you typed "020.000" for the number of

degrees. After you hit [ENTER], the LCD screen will display:

020.000 000.000

Press Nxt or Prv

The first number is the movement size you selected (20.000 degrees). The second number is the current position (000.000

degrees). The controller is waiting for you to press the [NXT] or [PRV] keys. If you press [NXT], the table will advance 20

degrees clockwise, and the LCD screen will display:

020.000 020.000

Press Nxt or Prv

The current position is now shown to be 20 degrees. If you press [NXT] again, the screen will show:

020.000 040.000

Press Nxt or Prv

The current position is now shown to be 040.000 degrees.

If you had pressed the [PRV] key the first time, the table would move 20 degrees counterclockwise, and the LCD screen would

display:

020.000 340.000

Press Nxt or Prv

The current movement is shown to be 20.000 degrees and the current position is 340 degrees (360 degrees minus 20 degrees).

PANIC STOP-Any time the table is moving you can stop it immediately by hitting the [STOP] (Jog) key. This will stop all

motion and put you into the JOG mode. You to lose your place in the program you were running and will have to start over.

To exit from the Degrees Mode, press the [MODE] key.

THE "PROGRAM" MODE

The Program Mode allows you to prepare a list of many movements to take one after another. For each block you will enter four

parameters:

1) The number of degrees to move,

2) The direction of travel (clockwise or counterclockwise),

3) The feed rate for that move, and

4) Whether or not the table should wait for you to hit the [NXT] key after each block of information is completed.

The program you enter will be remembered indefinitely (unless you change it), even if you turn the controller off. There is room for

two separate programs of 40 blocks each.

Before you enter your program blocks, you'll want to plan them carefully to be sure they're correct before typing them all in.

Write them down on paper and check for errors. (A form that you can copy is provided as the last page of these instructions.)

The Program Mode comes after the Degrees Mode. Press the [MODE] key until the screen displays:

Program Mode

Press Enter

Then press the [ENTER] key. The screen will display:

Which program?

Press 1 or 2...

You can now select which program you will use. Type the digit "one" or "two" and the screen will display something similar to:

Program 1

Run=NXT Edit=PRV

This indicates which program you've selected, and that you should press the [NXT] key to run the program that was stored

previously, or press the [PRV] key to enter a new program.

ENTERING A NEW PROGRAM

If you press the [PRV] key, the LCD screen will show you the degree setting for the first program block and allow you to change

it. For example, the screen might show something similar to this:

Block 1:1

Degrees: 090.000

The "1:1" means you're working on program one, block number one. The first movement in this example will move the table 90

degrees clockwise. To change this amount, type the number keys. You can press [NXT] to move the cursor to the right or

[PRV] to move the cursor to the left.

You can indicate whether you want the table to move clockwise or counterclockwise. To enter a counter- clockwise direction,

press the [MINUS] key. This will place a minus sign before the degree amount, indicating reverse travel. If you press the

[MINUS] key again, the minus sign will be removed and the direction will be clockwise.

(Note that it is also possible to change the default direction of travel from clockwise to counterclockwise. See the Settings mode

for details.)

When the screen shows the movement you wish, press the [ENTER] key to enter (and store) your selection.

The screen will then display something similar to this:

Block 1:1

Feed rate: 15

This means that the feed rate for this programmed block is 15 degrees per second. The number you enter will be the fastest rate

the table will reach during a move. The SLOW rate (the rate it starts at each time) depends on what you entered for SLOW in the

Settings Mode. You can change the feed rate to anything between 1 and 50 degrees per second.

When the screen shows the feed rate you wish to use, press [ENTER] again. The LCD screen will then display something similar

to:

Block 1:1

Pause

You can tell the controller to pause after each block or continue to the next block. If you tell it to pause, you must hit the [NXT]

key during program execution before it will advance. To set the current program block to pause, press the [ 7 ] key (marked

"slow"). To set the current program block to NOT pause, press the [ 9 ] key (marked "fast").

After setting the PAUSE parameter how you want it, hit the [ENTER] key. The LCD screen will then display something similar

to:

Block 1:2

Degrees: 000.000

This indicates that you're ready to program the movement for block number 2 in the first program. You can now define the block

size, feed rate, and pause status just like you did for the first block.

When you've entered all of the program blocks you wish, terminate the program by entering a movement of "000.000" and a

pause or no pause. This tells the controller to stop asking for new input and prepares to run the program you've just entered.

INSERT AND DELETE

When entering a program you may make a mistake, or you may wish to modify a program after it has been entered. You can

INSERT and DELETE program blocks to correct or modify an existing program. To access the INSERT and DELETE

functions, press the [MODE] key while the controller is waiting for you to enter the number of degrees for any program

movement. (You can't use INSERT or DELETE after entering the degree size.) The LCD screen will then display something

similar to:

Block 1:5

Insert?

You can now insert a new movement at this point in the program by hitting the [ENTER] key. The LCD screen will display

something similar to:

Block 1:5

Wait...

After a few seconds the word "Wait..." will go away and you will be able to enter a movement for the new, inserted position.

If you do not INSERT a program block but rather press the [MODE] key a second time, the controller will display:

Block 1:5

Delete?

You can now delete the current program block by hitting the [ENTER] key. The LCD screen will display something similar to:

Block 1:5

Wait...

After a few seconds the word "Wait..." will go away and the previous settings for that program block will have been removed

and replaced by the settings for the next program block.

If you do not INSERT or DELETE a program block, but rather press the [MODE] key a third time the controller will display:

Block 1:5

Exit?

You can now terminate the programming session entirely by pressing the [ENTER] key. Or, if you press the [MODE] key a

fourth time, the controller will return to the editing mode.

THE LOOP COMMAND

If you press the [MODE] key at the very start of a new block the display will read

Block 1:1

Begin Loop?

This means that the instructions entered from this point to the point that an "End Loop" is entered, in the same manner, will be

repeated for as many times as entered after entering the command "End Loop." The "End Loop" can only be entered after a

"Begin Loop" has been entered. It is acceptable to have a "Pause" command entered in the loop program. This would require you

to press [NXT] for each stage of the loop; however, keep track of the loops made. (The lower right corner of the display

displays how many times the loop has left to cycle.) You could inadvertently start into another set of loops by pressing the [NXT]

key one time too many. Remember that the only time you will be offered the loop command choice is when the mode key is

pressed before entering a movement number.

The LOOP COMMAND allows you to easily program a series of identical movements.

RUNNING A STORED PROGRAM

Enter the Program Mode using the [MODE] key and press the [ENTER] key. You now have a choice of program 1 or 2. Enter

your choice using the [ 1 ] or [ 2 ] key. Then press the [NXT] key to run the program. The program will start. While the table is

in motion, the display will read:

Moving...

CONTROLLING THE PROGRAM WHILE ITS RUNNING WITH THE STOP, MODE and PAUSE

COMMANDS

The [ 8 ] "Pause" key can be entered at anytime a program is running, with or without loops and put the program in a 'Pause"

mode. The program will stop running after the computer completes the block it was running when the command was entered;

however the key must be held down until the program ends its present movement. The program can be restarted with the [NXT]

key and will resume running the program from its last completed command.

You can terminate execution at any time by pressing the [MODE] key, which will allow you to go back and enter a new program

or start running the same one over again. Again, the key must be held down until the move for that block was completed.

You can press the [STOP] key at any time to abort table motion and it will enter you into the Jog Mode. Remember that you will

lose your place and have to manually move to your home position before running your program.

RESTARTING THE PROGRAM

After all of the steps in the program are completed, the program will stop and wait for you to hit the [NXT] key if you stored a

"Pause" at the end. If you stored "No Pause", the program will start over again immediately.

NOTE: If the controller seems to refuse to run a program, it is probably because the first movement in the program has been

defined as "000.000" degrees. If this happens, go to EDIT MODE and check the program if the first block has been edited to

zero.

Old programs can be erased by holding down the [ 9 ] when the controller is turned off and turning it on. We recommend doing

this occasionally so you can start with a "clean slate."

CONTINUOUS MOTION

You can put the table into continuous motion by entering zero for the number of divisions in the Division Mode, or zero for the

number of degrees in the Degrees Mode. During continuous motion, the table will start moving at the SLOW speed setting, ramp

up to the FAST speed setting, and keep turning until you stop it with the [STOP] key. When the table goes into Continuous

Motion, the LCD screen will display something similar to:

Hit JOG to stop

Feed rate: 40

The first line serves to remind you how to stop the motion: by hitting the [JOG] key.

The second line shows you what the current setting of the FAST feed rate is. You can now change the speed of rotation with the

keypad while the table is turning. If you press the [ 7 ] key (labeled "Slow"), the feed rate will decrease. If you press the [ 9 ] key

(labeled "Fast"), the feed rate will increase. In this way, you can find the speed setting that works best for you. As the speed

changes, the new rate is assigned to the FAST speed setting and shown on the LCD screen.

As you decrease the FAST feed rate, if the value goes lower than the current setting for the SLOW feed rate, the SLOW setting

will also be reduced to the same value. (You can't have the SLOW setting be faster than the FAST setting.)

INTERFACE OPTIONS

There are two interface options for the controller. They both use the 8-pin mini-DIN connector at the top end of the controller

case. The interface options are:

• Step and direction signals for use with other motor controllers.

• Sense and acknowledge signals for handshaking with other CNC controllers.

STEP AND DIRECTION INPUT

If you have a motor controller that outputs STEP and DIRECTION signals for a fourth axis, you can use the Sherline CNC

rotary indexer to receive these signals and move the table. You'll need a cable to connect the STEP and DIRECTION signals of

your other controller to the proper pins of the interface connector on the end of the Sherline controller.

You must put the Sherline controller into a special "Slave Mode" to work with these signals. To do this, hold down the [ 1 ] key

on the keypad when you first turn on the controller. You should see a message that displays:

Slave Mode

In this mode the controller will wait for a low-going STEP command. As soon as it is found, the table will move .0125 degrees

clockwise if the DIRECTION input is high. If the DIRECTION input is low, the table will move .0125 degrees counterclockwise.

There are 28,800 steps in a full rotation of 360 degrees.

To stop using the slave move, turn the controller off, wait 5 seconds, and turn it on again.

SENSE AND ACKNOWLEDGE INPUT

Some CNC controllers support a SENSE and ACKNOWLEDGE (ACK) protocol for a fourth axis with a "M" command.

When the "M" command is executed the controller closes a relay and then waits for the "M-FIN" input line to go high (open

circuit) while the remote device is operating. When the remote device has finished, it must short the M-FIN line to ground to

acknowledge that the action is complete.

The Sherline controller supports this M protocol. There is a SENSE input line and an ACK output line in the interface connector.

The SENSE input is made active by shorting it to ground. It is left inactive by leaving it unconnected to ground, or by pulling it to

5 volts. The ACK output is an "open collector" drive signal. It can be used like a switch closure. When it is active, it will be

connected to ground. When inactive, it will be an open circuit. The ACK output will work with signals as high as 30 volts.

The SENSE input works just like the [NXT] key on the controller. In either of the motion modes (Positioning or Program) where

you can move the table by pressing the [NXT] key on the keypad, you can also move the table by shorting the SENSE input to

ground. You can use some other CNC controller to make the SENSE input low (for example, the M command}.

To connect your CNC controller to the Sherline controller, add a relay to your CNC machine. Connect the relay switch contacts

to the Sherline controller SENSE and GROUND lines. When your CNC control closes the relay, it will trigger the Sherline

controller.

Every time the [NXT] key or the SENSE input initiate a motion, the ACK output of the Sherline controller will be shorted to

ground. As soon as the Sherline controller has completed the motion, the ACK output will be opened (will not be shorted to

ground).

CABLE COLOR CODE

Colors of the wires inside the cable are not consistent from batch to batch, so we cannot provide a reliable color code. (You

would think in this day and age of standardization that they would be, but they are not.) Use a continuity checker and the pin map

shown in Figure 2 below to determine the color of the wire connected to each pin. Note the colors on a printout of Figure 2 or a

sketch for future reference.

FIGURE 2-Layout of the interface male connector viewed from the back side.

REMOTE TRIGGER SWITCH

The controller can be operated from a remote switch. This will allow you to keep the controller in a more "friendly" environment

and have a more durable switch used for starting a programmed sequence. To incorporate this feature, connect the remote trigger

switch that is in the normally open position to the SENSE INPUT and GROUND wires of the included 8-pin connector cord.

(NOTE: The first time a program is run, it must be initiated by hitting the [NXT] button on the keyboard. After that, it can be

initiated from either the keyboard or the remote switch.)

LIMIT SWITCHES

Although the use of limit switches would be unusual with rotary tables it is a feature that's built in for our CNC linear tables so we

thought we would bring it to your attention.

The Sherline Controller supports the use of limit switches to avoid running a cutter into a fixture or clamp. The limit switches

should be simple "normally open momentary contact" type switches. You can place a limit switch at each end of the table if you

wire them in parallel. Arrange the switches so they will be closed by the motion of the table when it gets too close to something

you don't want it to reach. The limit switches are wired into the 8-pin interface connector at the end of the controller. (See Figure

2.)

The limit switches will be active in all motion modes, including the JOG mode. When the controller moves into a limit switch, it will

remember that it cannot move any farther in that direction. The controller will consider the move complete. Any further commands

to move in that direction will also "pretend" to execute, but no actual motion will take place. Instructions to move in the opposite

direction will work fine.

This feature will allow you to start a programmed move from a known position with the use of a quality limit switch. The program

could drive the slide to the limit switch at a slow feed and then start its next move from where the limit switch stopped the

movement of the slide. You could program the last move to end against the limit switch but in doing so you would lose the

advantage of knowing that the program will always start from the same place. Be sure the move to the limit switch will have

enough extra travel to compensate in case an operator moved the hand wheels between cycles.

To incorporate this feature, connect the limit switches that have been wired in the "normally open" position to the two pins of the

included 8-pin connector cord noted as "LIMIT SWITCH" in Figure 2.

Once the controller has moved away from the limit switch, commands to move in that direction will again be honored.

LINKING TWO SHERLINE CONTROLLERS TOGETHER

The Sherline stepper motor controller has a unique feature that allows two controllers to be linked together and perform simple

programs in unison. This allows the controllers to perform operations that are much more complex than what a single controller

can do. They are linked together with an optional cord plugged into the back of each unit. It would be difficult to describe the

many combinations that could be generated using this method, so I'll give you a general "overview" of the rules and leave the rest

up to your imagination.

1. The Master controller that initiates the sequence may be in any motion mode. Note: the controllers may be either a linear or

rotary type or a combination of both. The difference between the two is they each have code written specifically to control

a linear slide or a rotary table.

2. The second controller (called the "Controllee") will start its program when the Master program comes to a block that is

terminated with a "Pause" command or, if it's a rotary controller, it has completed a Division Mode or Degree Mode

movement.

3. The Master will be restarted when the Controllee program comes to a block that is terminated with a "Pause" command or,

if it's a rotary controller, it has completed a Division Mode or Degree Mode movement.

4. When a programmed block is terminated with the "Stop" command (entered with the [ 8 ] key at the end of a program

block), the program will stop and not trigger the other controller. The operator must press [NXT] to continue. It would be

advisable to enter just one "Stop Command," and for it to be in a block in the Master controller. This keeps the operator

from having to press NXT on both controllers to run a program.

CUTTING A GEAR USING ALL THE FEATURES OF BOTH LINEAR AND ROTARY SHERLINE

CONTROLLERS

Example:

The following procedure gives you an idea of how easy it would be to program a complex set of operations to produce a 53-

tooth gear. I chose 53 teeth because it is a prime number and can't be produced with simple indexing.

Linear Controller Program:

1. Rapid feed up to gear blank from home position. No Pause

2. Slow feed across gear face with cutter. No Pause

3. Slow feed back across gear face for quality finish. No Pause

4. Rapid feed to home position. Pause

Sherline CNC Rotary Table Controller Program:

1. Using the Division Mode, enter the number 53

With five lines of code (keypad entries) you have now entered all the information needed to produce a 53-tooth gear. Think

about it. The slide will rapid up to the cutter, slow down and make a cut, feed back across the part at a programmed feed rate,

and rapidly return to its home position. The rotary table will then index, and initiate the next cut. This will be repeated until the

required 53 indexes have been made. After the last index, the program will stop and wait for an operator. This has been

accomplished inexpensively with a very clever design and program, and we at Sherline and Bryan and I are quite proud of it.

Two Linear controllers could be linked to produce any number of sequences for simple but useful movements. For example, one

controller could drive the mill table X-axis, and the other could drill with the Z-axis.

USING THE ROTARY TABLE IN MACHINING

By Joe Martin

The following instructions are included to give you some further insight into the fine points of using a rotary table for machining

operations. Sherline Products Inc. makes a wide variety of miniature machine tools, which now includes the CNC rotary table

(P/N 8700). For obvious reasons, the descriptions and illustrations use these machines as examples.

MOUNTING THE TABLE TO A FULL-SIZE MILL

Sherline machine tools have very limited work areas, and the tools and accessories manufactured by Sherline are designed to be

used in conjunction with one another to eliminate wasted space. If you plan to use this device on full-sized equipment I would

suggest mounting the table to a rectangular block of metal. There are three 10-32 tapped holes on the bottom of the table for this

purpose. The holes are 120° apart on a 3.2" (81.28mm) bolt circle. On a Sherline mill, the stepper motor mount overhangs the

table, but on a large industrial table, a riser block is needed to keep the motor mount from interfering with the table surface. When

mounted to an aluminum block of sufficient size, the entire assembly can be held in a vise in the horizontal or vertical position,

thereby making it easier to use. It can also be mounted on a standard Sherline tilting angle table (P/N 3750). Remember that

when operated in an industrial environment, the unit cannot be flooded with coolant.

FIGURE 3--Rotary table mounted to a riser block (P/N 8710)

FIGURE 4--Sherline's tilting angle table (P/N 3750) is designed to hold the rotary table and allows it to be tilted to any

angle from 0° to 90°. The thickness of its base provides the same function as the riser block shown in Figure 3.

Don't let the reasonable price mislead you into believing this is not a precision piece of equipment. During the past thirty years,

Sherline has specialized in designing and manufacturing equipment where you, the customer, get the "most bang for the buck".

The following instructions have been written to show what is involved in doing a complex job on a rotary table accurately. In

many cases these instructions have nothing to do with how the table is driven. A CNC-driven table can solve the problem of

tedious calculations, but it will never solve an error in logic. I believe if you truly understand the job I will describe in detail,

average jobs can be accomplished without filling your trash can with mistakes. Remember, there are not many people capable of

making the complex machined products used today, and if you can master the vertical mill and the rotary table combination, you

will have come a long way at becoming a good machinist. You will find erasers aren't much good and no one has come up with a

good "putting on" tool when it comes to metal parts. Complex parts are very difficult to make. When you are making "one-of-a-

kind" parts, don't worry about how long it takes. Spend your time planning and checking so you don't have to start over.

When a rotary table is put on a vertical mill, you end up with a machine that is theoretically capable of reproducing itself. Of

course, the size of the rotary table has to be considered, and the Sherline table would be too small to accomplish this on a full-size

milling machine. But having a rotary table means the capabilities of your mill will be greatly expanded, and only the size of the part

and the ingenuity of the operator will govern the complexity of the part. The purpose of these instructions is to give you an insight

into properly using this accessory. An inexpensive calculator with trig functions is a must for complex jobs.

Standard milling machine setups usually involve aligning the work with the table and then with the spindle. This is easily

accomplished because the table can be accurately moved with the handwheels.

DEALING WITH BACKLASH

When working with a rotary table, the term "backlash" must also be used. Backlash occurs in all rotary tables and exists between

the worm and worm gear just as it does in a leadscrew, so it must be considered. In the case of this particular table it amounts to

.2° to .3°. Setting the worm any closer to the gear will cause excessive drag and wear. The smaller the diameter you are working

with, the less the backlash error will effect you. When working on a diameter of 1" (25.4mm), the total backlash will be less than

0.002" (0.05mm), but at 4" (100mm), the error could be as high as 0.010" (.25mm). (See the "Maintenance" section on for

instructions on adjusting the worm gear backlash and the beginning of these instructions for the paragraph on setting the electronic

backlash compensation.)

When the rotary table is used with the right angle attachment, backlash has to be considered in a different way if an "off balance"

fixture is mounted. As the out-of-balance fixture is being lifted against gravity, the backlash remains normal, but after the fixture

goes past top dead center, the off-balance fixture will pull the backlash to the opposite side. This could give you an error equal to

the backlash. This is around .2° and must be considered. I realize this is an unusual occurrence, but it is a tough one to find, which

is why I mention it. If you believe this is a possibility, hold the backlash in the correct direction after the move is complete and

tighten the lock. Of course you could also add a counterbalance to eliminate this problem.

USING THE MILL AND ROTARY TABLE AS A LATHE

A machinist working with miniature tools may find it useful to use the rotary table to turn large diameter parts. The CNC table can

be set to run continuously and diameters can be cut using end mills rather than lathe tools.

LOCKING THE TABLE WHEN MAKING A CUT

If you are using the rotary table to cut a gear, the table lock should be used during the cutting process; however, I don't believe it

is necessary when cutting a small, fine pitch gear. As soon as you lock the table you stand a chance of forgetting to unlock it

before attempting to advance the table. This would result in losing your place, because the stepper motor system has no way of

recording whether or not it moved. When doing repetitive machine operations you have to be very methodical. Let your mind

wander and you stand a good chance of screwing it up. If you make this type of screw-up, all is not lost if you took the time to

write the exact handwheel setting down at the start so you can start over from exactly the same place. This is good insurance

before starting a series of cuts.

PRECAUTIONS REGARDING HOT CHIPS AND COOLANT

Care should be taken to prevent hot chips from landing on the computer and burning into the keypad. Also, the electronics can be

damaged if the motor is flooded with coolant. Sherline's one-year warranty does not cover this kind of damage because it is

caused by misuse. The 6' extension cable provided with your rotary table should be used to keep the keypad unit at a safe

distance from the machine and out of the range of flying chips.

MAKING ALLOWANCES FOR CUTTER DIAMETER

A close look at Figure 5 will start making you aware of the complexities of working with a rotary table. Unless you are doing a

hole layout, you very seldom can work with the angles and dimensions on your drawing because of the cutter diameter.

FIGURE 5--A demonstration of CPR or Cutter Path Radius

FIGURE 6--Cutter machining outside of part

FIGURE 7--Cutter machining inside of part

Figures 6 and 7 show the relation of cutter and part. Start considering what I refer to as CPR, which is where the center of the

cutter is from the center of the rotary table.

The next problem to be aware of is why the rotary table must be offset to cut segments. Study Figure 9 and it becomes obvious

that allowing for the cutter diameter at one end of the segment will not make any correction at the other.

EXAMPLE: CUTTING A WHEEL WITH SPOKES

When one of our customers purchases his first metal cutting tool, it is usually a lathe, and somewhere in that customer's mind is a

brass canon he has been wanting to build. When a customer buys his first rotary table, chances are he either wants to drill hole

patterns, which shouldn't require any instructions, or he wants to make some kind of wheel with spokes in it. Therefore, I will

describe how to "accurately" cut a wheel with spokes. I realize that in most cases it is not necessary to work to this degree of

accuracy to do a job of this nature, but to accurately make a precision part of this type is what a rotary table is all about. In most

cases, I will leave you to your own common sense as to the depth of cuts and how much to leave from roughing and finish cuts.

Remember, I have never seen a part scrapped from taking too light of a cut..

Make an accurate drawing at the start showing offsets and cutter paths (similar to Figure 10). The offsets can be calculated as

shown in the sample in Figure 10.

REMEMBER...the rotary table center must be precisely located below the spindle when you start. Only one half of the segment

may be cut from the calculated point, which is why only one half of the spoke width is considered. Look at the drawing again and

be sure you truly understand why you can only cut one half of the segment before proceeding, or your chances for success will be

dismal.

FIGURE 8--This example shows how easy it is to allow for the cutter diameter using trigonometry

FIGURE 9--Offsetting the rotary table to cut segments

Now we have the offsets calculated and the rotary table "indicated in" in relation to the spindle. We move the X-axis the amount

of the offset, moving the table to the left. Be sure to consider the backlash, and it may also be prudent to allow for roughing and

finish cuts. Now move the Y-axis and the Y offset in (towards the column). This will allow the first half of the segment to be cut so

that it looks like the diagram. Assuming the part is properly clamped to the rotary table and held in such a way that you can't

inadvertently cut into the table, it's time to start. The example has four equal segments, which means a spoke will be cut every

90°; therefore, a lot of confusion can be eliminated if you start with your table at 0° (see Figure 8). The center of the spokes will

now lay out at 0°, 90°, 180°, and 270°, and the halfway points will be at 45°, 135° etc. Allowance for the cutter was taken care

of when the offsets were calculated. It is not necessary to calculate the value of angle "A" or other angles because you are only

cutting half of the segment at a time.

A good rule now is to take a very light cut (.001") and convince yourself everything is correct. The real trick of machining is to do

something you have never done before the "first time", and you can't be too careful. A one-minute check versus three hours or

more to start over makes this a good investment in time. The cut along the spoke is accomplished by moving only the X-axis back

and forth using the calculated points until you get through the part. Again, I remind you it may be wise to take a roughing cut first.

Sometimes an undersize (resharpened) end mill is a good way to rough cut. Then change to a new end mill for finish passes. This

allows the same handwheel number used for roughing and finishing.

FIGURE 10--Drawing and calculations for cutter paths

The rotary cuts are made with the X-axis in its proper position, and the table rotated counterclockwise. One of the really neat

things in machining happens when using a rotary table to feed work into an end mill, and I believe it comes about because of the

slow and precise feed that can be obtained. If a hole you're cutting requires a bottom, great finishes can be had from end mills and

rotary tables. The rotary part of the segment only needs to be moved slightly past the half way point, for the remainder of the

segment will be cut with the Y-axis offset moved out from the column and the table rotated in a clockwise direction.

It is quicker to cut the first half of all four segments, then move the Y offset and complete the segments. If you are going to try

something like this for a first project, check your entire plan out with .001" cuts and be positive you are correct before making

cuts that could scrap your part. (See Figure 11.)

Table of contents

Popular Control System manuals by other brands

Kolbinger

Kolbinger ADAM-5000 Series user manual

Samsung

Samsung Wi-Fi Kit 2.0 User & installation manual

FAAC

FAAC J355HA M50 Translation of the original instructions

Techno

Techno TH387 Mounting & installation

Thermo King

Thermo King SR-2 SmartReefer2 Diagnostic manual

Siemens

Siemens SINUMERIK 840D sl Commissioning manual