Trio MC4N-RTEX Instruction Manual

Other Trio Control System manuals

Popular Control System manuals by other brands

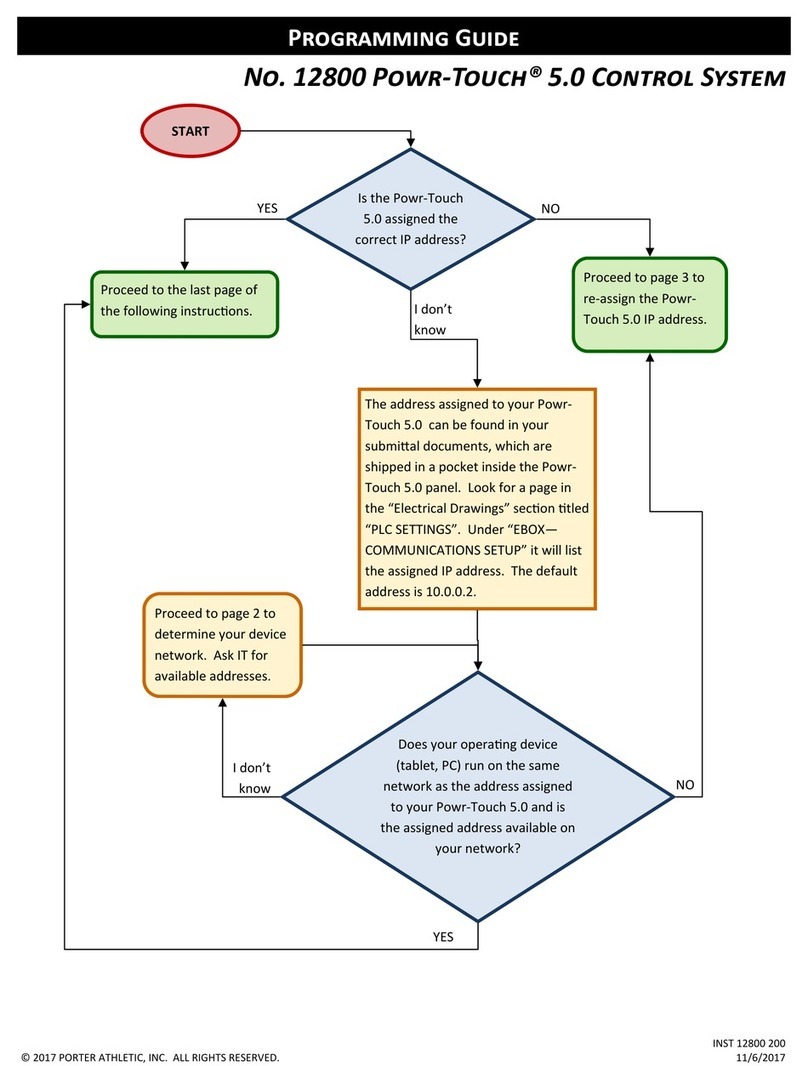

Porter Athletic

Porter Athletic Powr-Touch 5.0 Programming guide

Siemens

Siemens SINUMERIK 828D Turning Commissioning manual

Mitsubishi Electric

Mitsubishi Electric AE-200A Instruction book

SILENT KNIGHT

SILENT KNIGHT 2820 installation manual

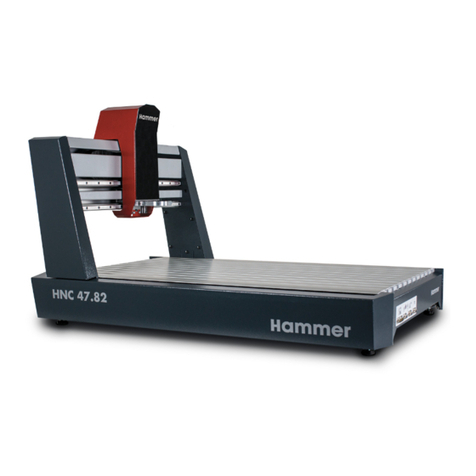

Felder

Felder Hammer HNC 47.82 Translation of the original operating instructions

Quick

Quick THRUSTERS COMMAND Manual for use and installation

Coelbo

Coelbo SPEEDCENTER S101040 operating instructions

ZKTeco

ZKTeco BG1000 Series user manual

DAVIS TECHNOLOGIES

DAVIS TECHNOLOGIES Profiler user guide

Racal Instruments

Racal Instruments 1260 VXI manual

Liberty Pumps

Liberty Pumps SX34-3-131 Installation Instructions and Operation/Troubleshooting Manual

Rehau

Rehau REH FC-BMS3 user manual