HRW HPD0460BN V402 Manual 150622.docx E. & O. E. / Subject to change without notice Page 3 of 33

OPERATION OVERVIEW ....................................................................................................................................4

BACNET OBJECT INSTANCES ..........................................................................................................................5

BACNET PRIORITY ARRAY ...............................................................................................................................5

USER INTERFACE .................................................................................................................................................6

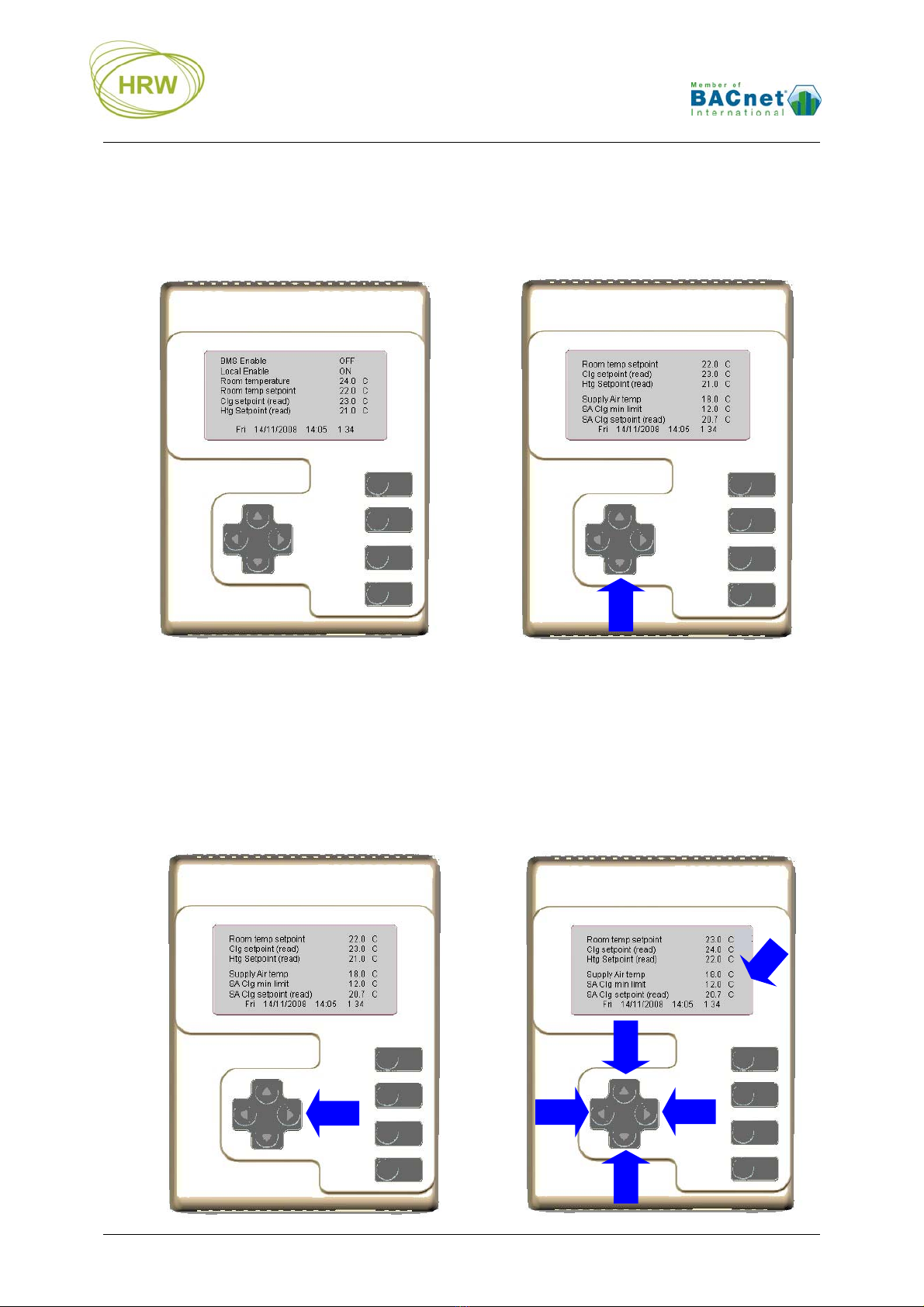

INTERFACE OPERATION ..........................................................................................................................................7

LARGE FONT DISPLAY ...........................................................................................................................................8

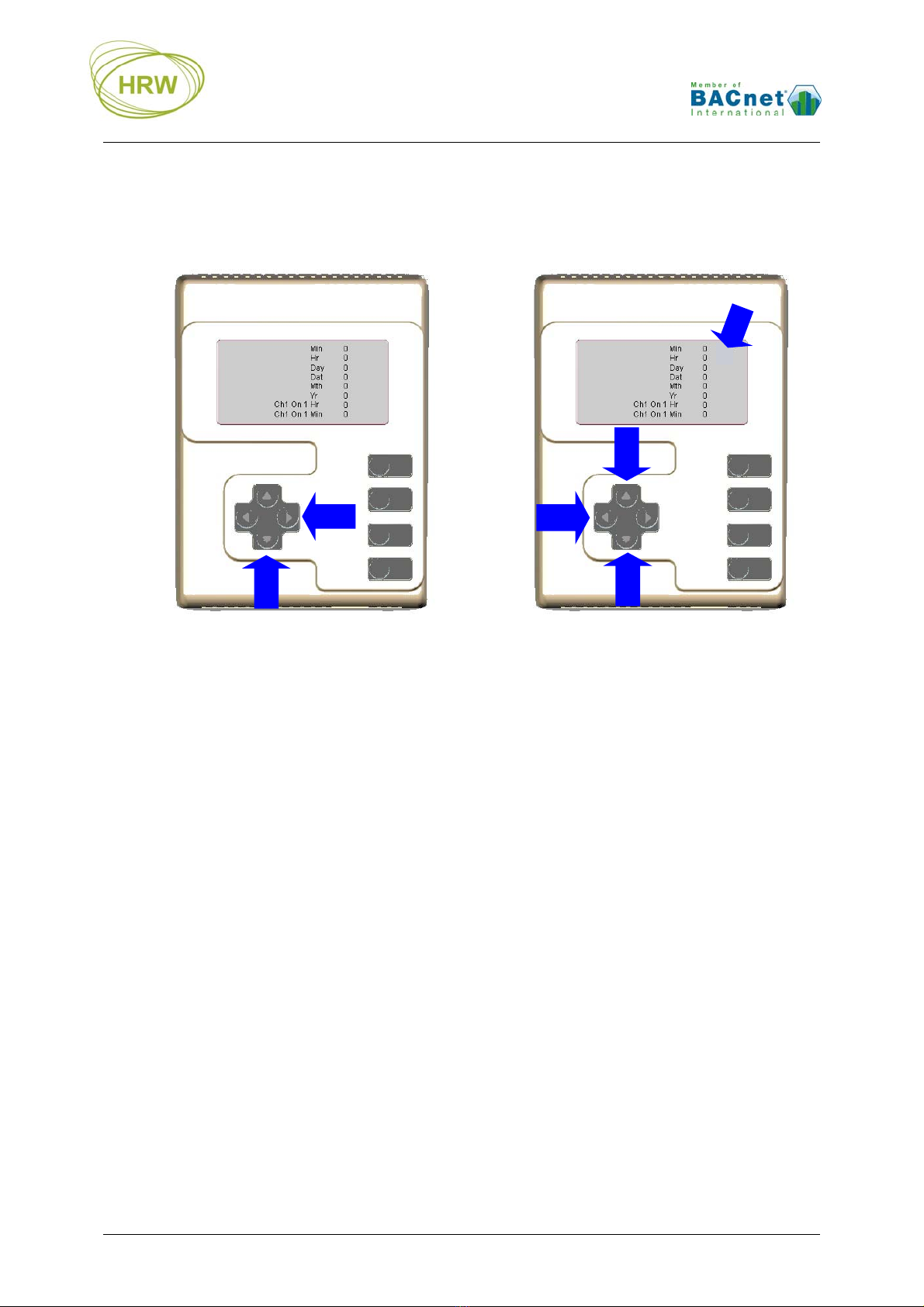

CLOCK & TIME-SWITCH SETTING ...........................................................................................................................8

FUNCTION BLOCK OBJECTS & SUB-PARAMETERS ................................................................................ 10

TERMINAL MODE .............................................................................................................................................. 13

HYPERTERMINAL SETTINGS ................................................................................................................................. 13

Additional Settings..........................................................................................................................................14

Connecting at 76800 Baud Rate.....................................................................................................................14

Saving HyperTerminal Settings......................................................................................................................14

Changing Baud Rate.......................................................................................................................................14

BREAK IN TO TERMINAL MODE ............................................................................................................................ 15

ADMINISTRATION COMMANDS ............................................................................................................................. 1 6

DISPLAY NAVIGATION ......................................................................................................................................... 17

SUMMARY SCREEN & LCD SETTING ................................................................................................................... 17

MANUAL OVERRIDE / RELEASE............................................................................................................................ 18

OPERATIONAL DISPLAYS ............................................................................................................................... 19

USER SUMMARY SCREEN ..................................................................................................................................... 19

DOWNLOAD TEXT FILE ........................................................................................................................................ 20

‘MAIN’ PHYSICAL I/O DISPLAY ........................................................................................................................... 21

POINT LIST DISPLAY ............................................................................................................................................ 21

CONTROL LOOP (CL) DISPLAY ............................................................................................................................ 22

DIGITAL LOGIC (DL) & ANALOGUE LOGIC (AL) DISPLAY .................................................................................. 23

NETWORK INTERFACE OBJECT (NIO) DISPLAY.................................................................................................... 24

RESET TO FACTORY DEFAULT ..................................................................................................................... 25

UPLOAD TEXT FILE ........................................................................................................................................... 25

UNIVERSAL INPUTS ........................................................................................................................................... 26

LINEARISATION TABLE ................................................................................................................................... 27

FACTORY DEFAULT SENSOR TYPES ..................................................................................................................... 27

ACTIVE SENSOR SCALINGS .................................................................................................................................. 27

PASSIVE SENSOR DEFINITION ............................................................................................................................... 28

RESET TO FACTORY DEFAULT .............................................................................................................................. 28

INSTALLATION & COMMISSIONING ........................................................................................................... 29

CONNECTIONS .................................................................................................................................................... 30

DIMENSIONS ........................................................................................................................................................ 30

TECHNICAL DATA ............................................................................................................................................. 31

ORDERING INFORMATION ............................................................................................................................. 32

ACCESSORIES ....................................................................................................................................................... 32

OTHER HP_BN SERIES DEVICES .......................................................................................................................... 32

DOCUMENT UPDATE HISTORY ..................................................................................................................... 33