Sherline Products 4417Z User manual

NOTE: These instructions accompany both the CNC

lathe already fitted with the locking system and the

retrofit kit for installing the lock on an existing lathe. If

you have a lathe already fitted with the system, only the

first part of the instructions regarding purpose and use

will be applicable.

The purpose of the leadscrew backlash lock

CNC machining operations require precise leadscrew

movement to producing a good part. The normal backlash

of.003"to.005"canbeunacceptableinthesesituationsand

a way was needed to reduce backlash to the .001" to .002"

range.ThissolutionwasdevelopedfortheZ-axisonthemill,

but it has been adapted here to work on the lathe as well.

BecauseIdesignedthislevertolockthecolumnleadscrew

acouple of yearsago, I neverthought of itas an optionthat

could be used to control backlash; however, early one

morningIfinallyrealizedhowtousethislockcouldbeused

inthisway,andwehadaprototypeworkingthenextdayand

were into production within a week. I’m also pleased to

report that the anti-backlash system can be added to every

Sherlinelatheever built!

By locking this lever against the saddle nut, it keeps the

leadscrewfrom turning oncetheheadstockis positioned at

theproperheightfortheoperation.Thisnewleverpositioning

system will allow you to position the locking lever in a

partiallylockedposition,removingasmuchbacklashasyou

desire, and then it can be locked in that position. As wear

occurs, the position of the locking lever can be adjusted.

Using the Z-axis lock on a CNC lathe

The locking arm is clamped in the lock plate for shipping.

Loosen the SHCS that holds it and remove the plastic arm.

Insert the pin in the end of the plastic lever into the hole in

the end of the brass Z-axis locking lever from the bottom

side.Alignthelockingarmwiththeslotinthelockplateand

slipitin.Movethebrasslockinglevertoprovidethedesired

amount of backlash. Tighten the thumbscrew to hold the

plasticarminposition.Donotovertightenthethumbscrew.

There is not a lot of force trying to move the arm. The arm

serves only to hold the locking lever in position once you

have adjusted it.

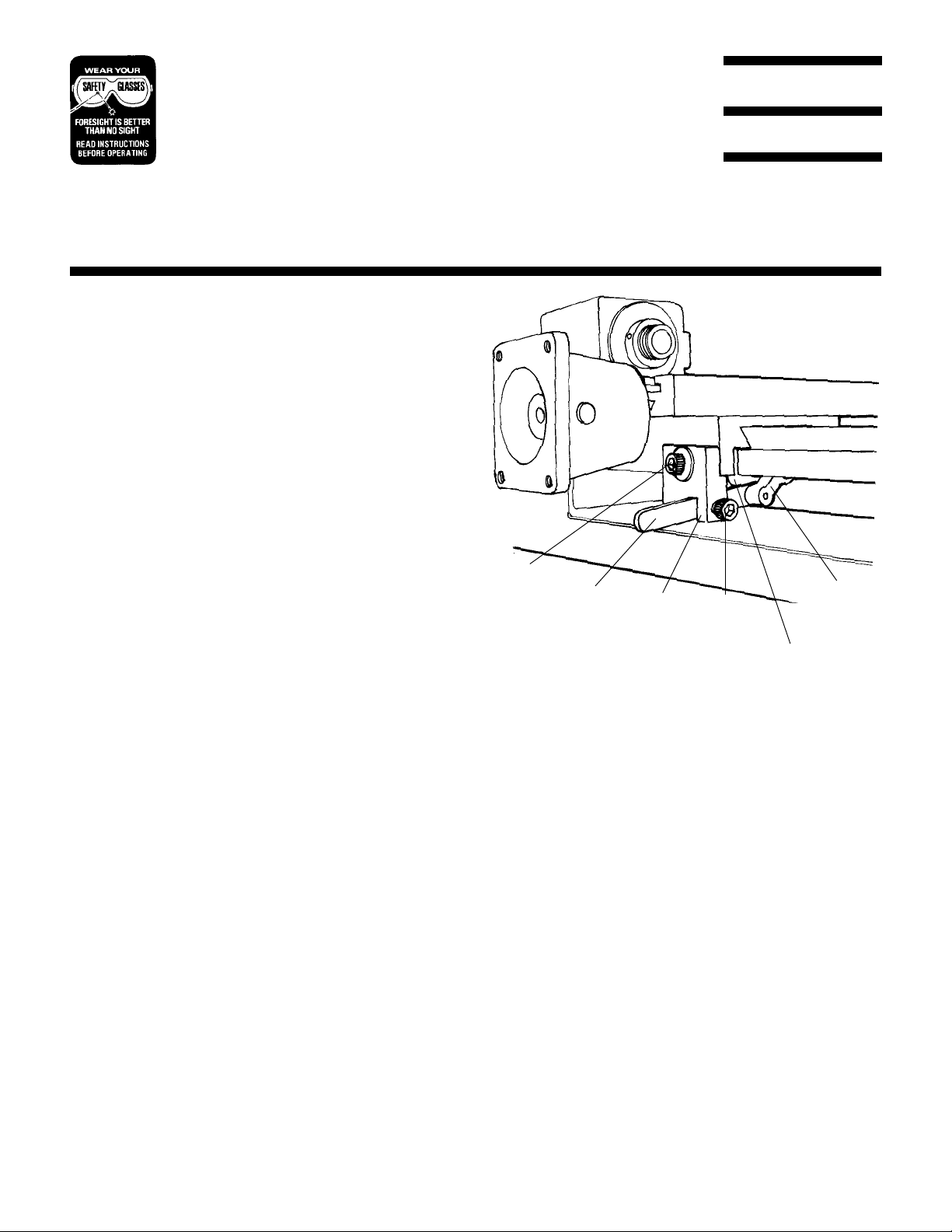

The brass locking lever is adjusted by hand as shown in

Figure 1, and then the positioning arm is locked in place.

Don't adjust the locking lever by moving the plastic arm

CNC Lathe Leadscrew Backlash Lock

P/N 4417Z/4417ZM

SHERLINE

PRODUCTS

INCORPORATED 1974

9/3/08

SHERLINEPRODUCTSINC.ˆ 3235ExecutiveRidge ˆ Vista ˆ California92081-8527ˆ FAX:(760)727-7857

TollFreeOrderLine:(800)541-0735 ˆ International,LocalorTech.Assistance:(760)727-5857 ˆ Internet:www.sherline.com

directly. You will have much better feel for the amount of

pressureneededbyadjustingthelockingleveritself,andthe

plastic pin that engages the hole in the locking lever is not

designed to exert a lot of pushing/pulling force.

Installing a new saddle nut and locking lever on a CNC

mill not currently fitted with a locking lever

Sherlinelatheshaveneverbeenfittedwithlockingleverson

the leadscrew. This system was developed specifically for

use on CNC machines. The new retrofit installation kit

includes a new locking lever and a new saddle nut without

aspring loadedball to holdit inthe unlocked position.The

positive locking arm allows partial locking of the lever to

reduce backlash to a minimum. The small detent in the

locking lever that was formerly used to engage a spring-

loaded ball has been retained to indicate the side of the

locking lever that should be facing the saddle nut. (If the

lockinglevershouldfailtolockagainstthesaddlenutwithin

theavailablearcinthebackofthemillcolumn,checktosee

if the lever has been installed backwards.) Install the new

saddle nut and lever as follows:

1. Remove the headstock and tailstock from the lathe.

LOCK PLATE

BODY

P/N44171

ADJUSTINGARM

P/N40173

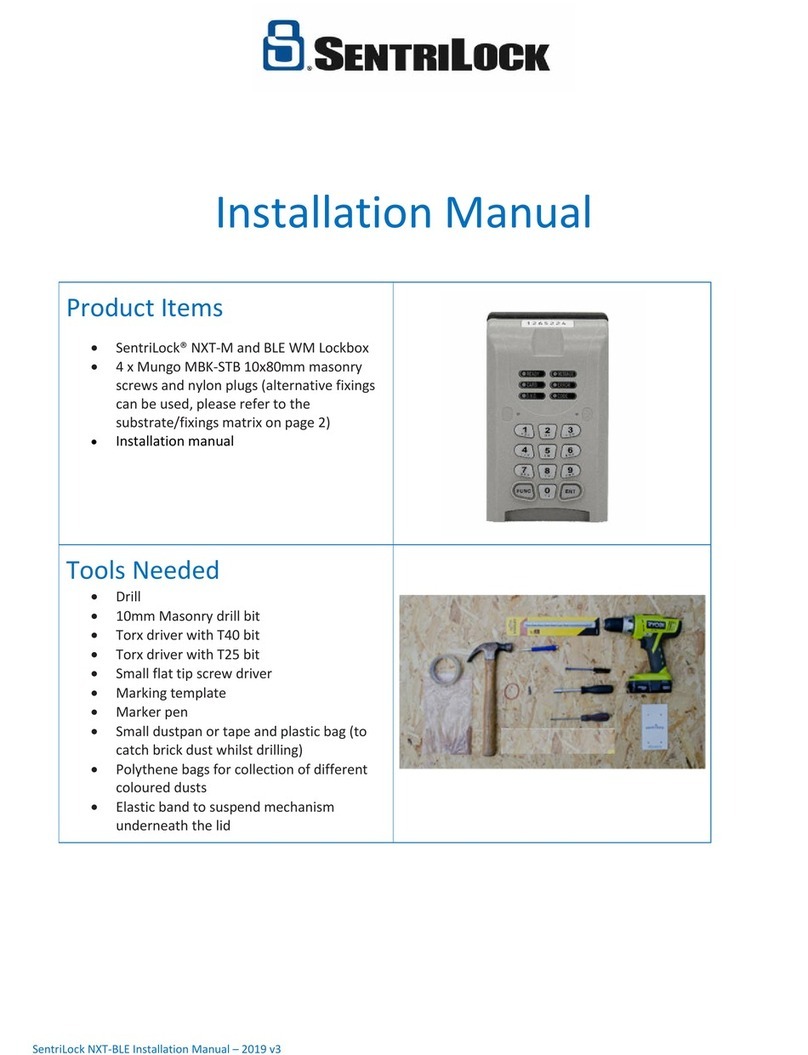

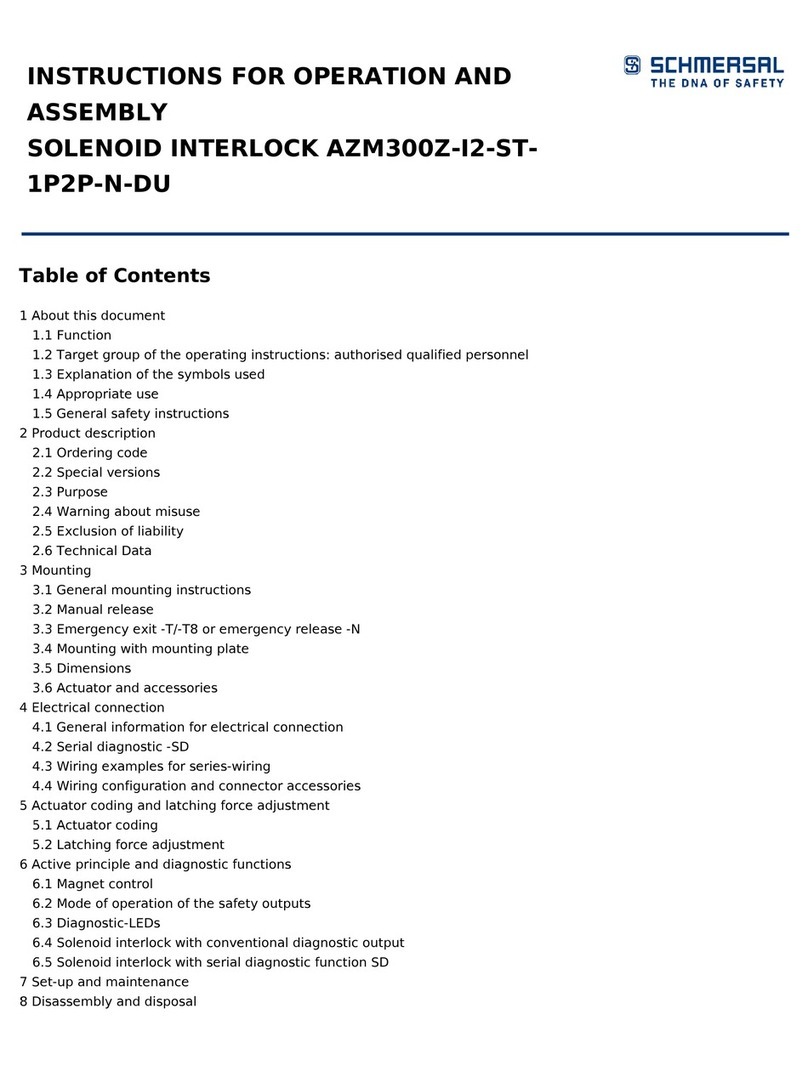

FIGURE 1—Components of the lever locking system as

they are now installed on new Sherline CNC lathes.

10-32x7/8"SHCS

P/N40740 BRASSLOCKING

LEVERP/N 44172/

44173

BRASSSADDLENUTP/N40174/41174

10-32x3/8"

SHCS

P/N40510

2. Remove the socket head cap screw that attaches the

saddle nut to the saddle.

3. Turn the lathe upside down and remove the single cap

screw at each end that holds the leadscrew thrusts to the

base.Notethenumberandlocationofanywasherspresent.

They are spacers and will need to be returned to the same

positionwhenreassembling.Turnbackoverandliftoffthe

bed, thrust and leadscrew assembly.

4. Crank the handwheel so the saddle nut moves to the end

of the leadscrew as far from the handwheel as possible.

5. Remove the countersunk screw in the bed that secures

thethrustatthehandwheelend.Thiswillallowyoutoslide

the leadscrew out of the other thrust and remove the

handwheel/leadscrew assembly from the bed.

6. Unscrew the old saddle nut from the leadscrew. Thread

the new locking lever first with the machined side or ball

detent side facing away from the handwheel. Then thread

the new saddle nut onto the leadscrew. Make sure the

saddlenutisinstalledfacinginthesamedirectionastheone

youpreviouslyremoved.Oncebothlockingleverandsaddle

nut are installed, screw them onto the leadscrew to the

approximatepositionoftheoldnutandleavethemjustlightly

touching each other but not locked.

6. In the reverse order from how you removed them,

reattach the leadscrew and thrust to the bed and then the

bedassemblytothebase.Remembertoreinstallanyspacer

washers in their original positions. Slide the saddle into

positionsotheholealignswiththeholeinthenewsaddlenut.

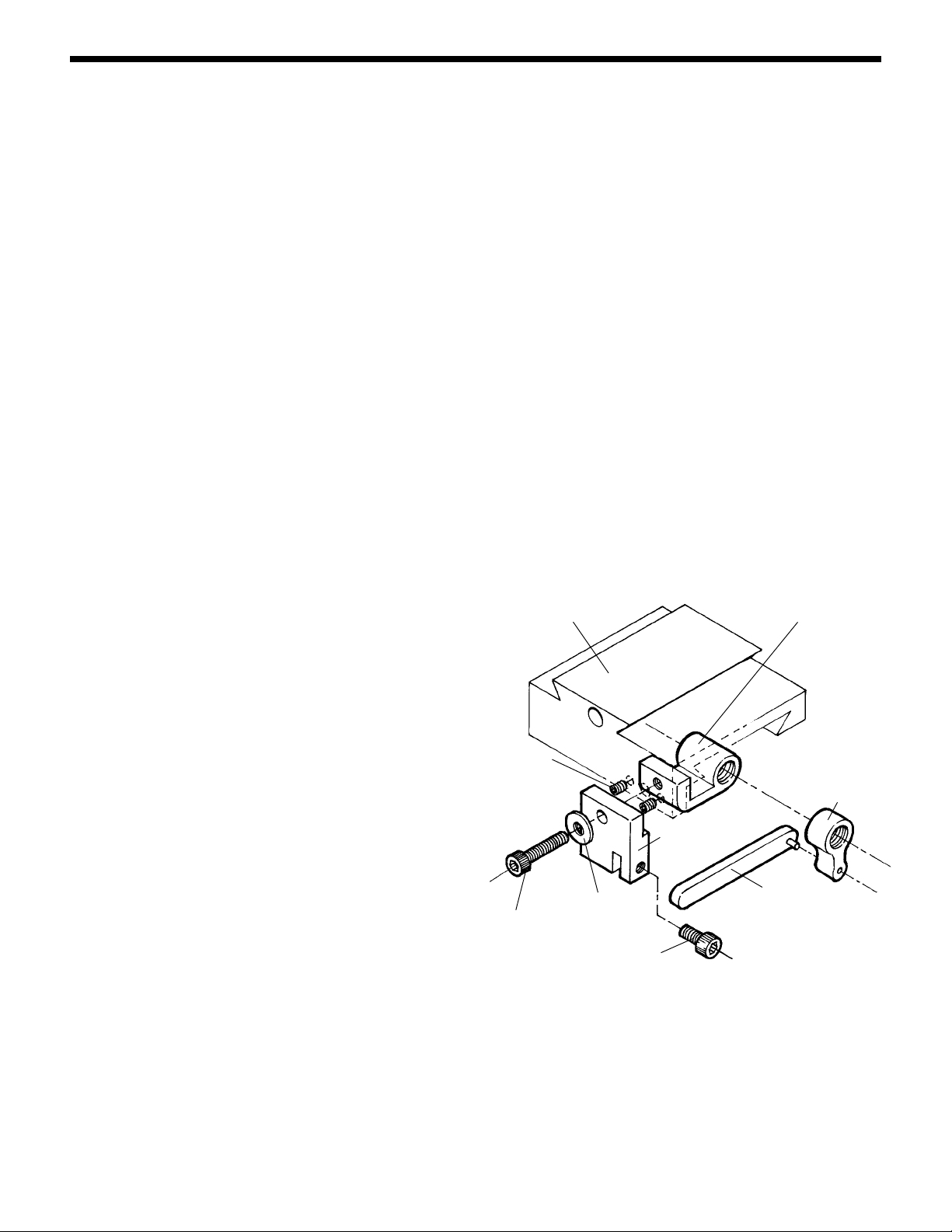

7. Using the new, longer socket head screw and washer

provided,feedthescrewthroughtheholeinthenewlocking

plate, through the hole in the saddle and into the threaded

hole in the saddle nut to reattach it. (See Figure 2.)

8.Insertthepinofthe plastic arm into theholeintheendof

the brass locking lever as shown in Figure 2. Slide the arm

into the slot on the bottom of the locking plate. Adjust it as

noted on side one of this sheet and secure it in the desired

position using the 10-32 x 3/8" SHCS.

Adjusting the saddle nut alignment

Whenyoureinstalled the new saddlenutinplace of the old

one,thetwoadjustingsetscrewswereleft in theirprevious

adjustmentpositions.Ifbindingoccursinthenewinstallation,

it will be necessary to readjust the new saddle nut on the

leadscrew using the two set screws on either side of the

attachment screw. To do this you will first need to remove

the locking plate to get access to these set screws. Then, to

adjustthesaddleitshouldfirstbepositionedattheendofits

travel as close to the handwheel as possible. Remove the

lockplateandlooselyinstalltheoriginalshorterscrewthat

attached the saddle to the old saddle nut. Bring each set

screw into light contact with the new saddle nut and

retighten the attaching screw. If binding occurs when you

turn the handwheel, readjust the two set screws until the

leadscrew moves freely. Then remove the old attachment

screw and reinstall the locking plate using the new, longer

screw.

Weare attemptingto adjustthe saddle nutso itrides on the

leadscrew with the minimum amount of drag. You can

check the drag by turning the leadscrew handwheel. If you

feel excessive drag, tighten or loosen a single set screw

while moving the saddle with the handwheel until the

handwheel turns freely, but keep the saddle close to the

handwheel. (If you adjust the saddle nut while it is in the

centeroftheleadscrew,itmaybeslightlyoffcenterbutwill

feelfreeuntilthesaddlegetsclosetoeitherendofitstravel.

Here, the leadscrew is supported and cannot deflect so it

willbindthemost.)Ifyoucan'teliminatethebinding,tapthe

saddle nut with a plastic hammer on the leadscrew side

while the saddle nut is tightly attached to the saddle and

readjust. Don't use the machine with a loose attachment

screw, as this will cause excessive wear and backlash.

Joe Martin, President and Owner

Sherline Products Inc.

4417Z, Page 2 of 2

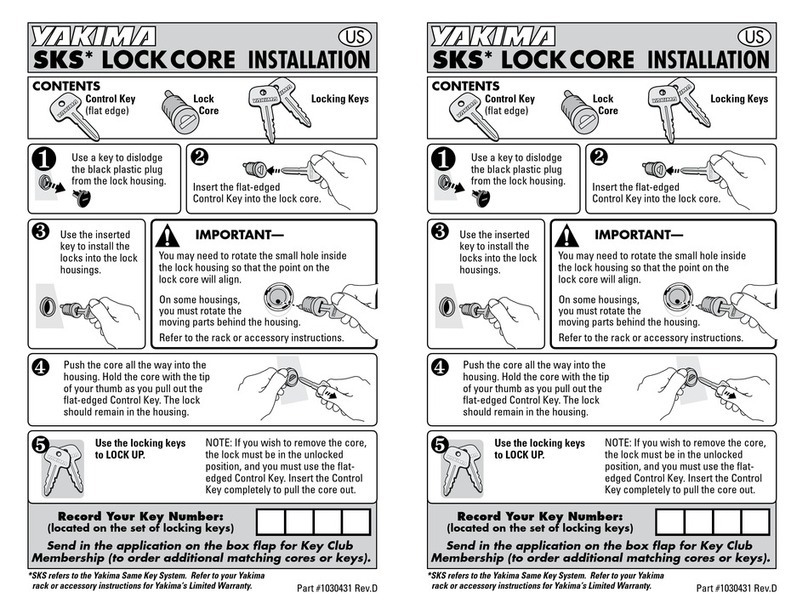

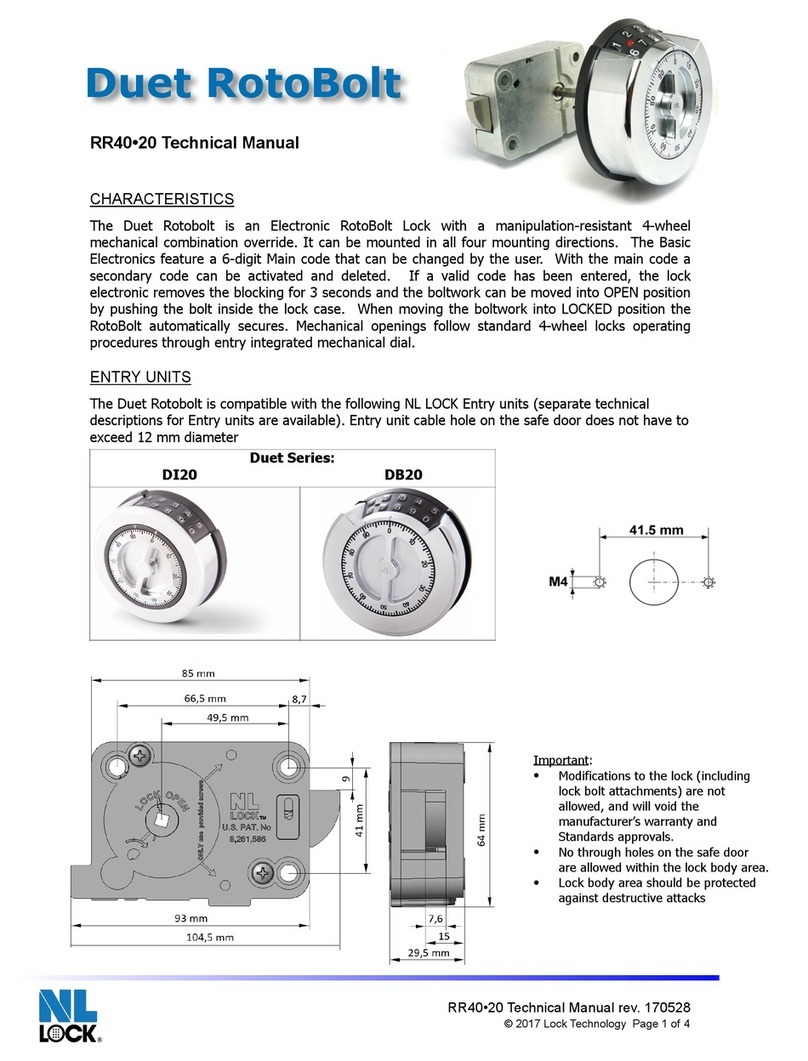

44171LOCK

PLATE BODY

4074010-32

x 7/8" SHCS

FIGURE 2—Exploded view shows saddle nut and locking

plate in relation to lathe saddle. Lever arm goes through

slot in lock plate body and is held in position by 3/8"

SHCS after adjusting.

40173

ADJUSTMENT

LEVER

44172/44173

BRASS LOCKING

LEVER

(Detent faces

saddle nut)

40174/41174 SADDLE NUT

40510 10-32 x 3/8" SHCS

406603/16"

WASHER

EXPLODED VIEW AND PARTS LIST

SADDLENUT

ADJUSTMENT

SCREWS

LATHE

SADDLE

This manual suits for next models

1