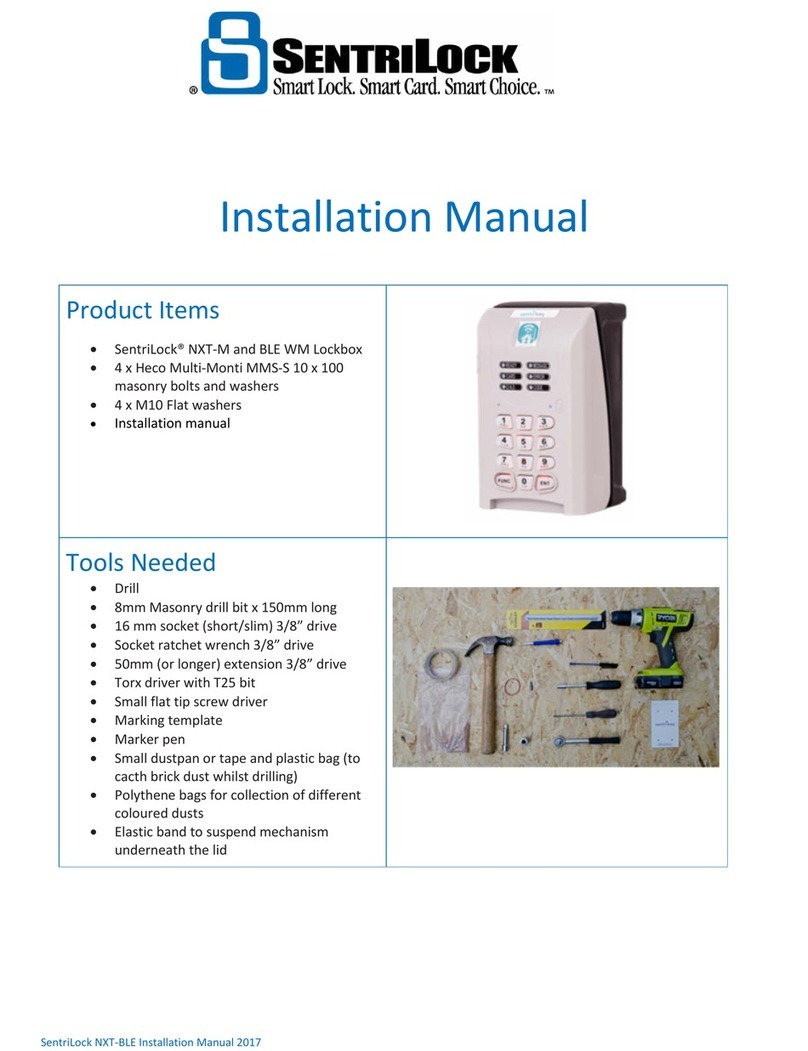

Installation Manual

SentriLock NXT-BLE Installation Manual – 2019 v3 Page 2 of 9

Before Starting

The SentriLock® NXT-M and BLE WM Lockboxes are designed to be mounted directly to a building or other secure

structure. The Lockboxes have been certified to Loss Prevention Standard (“LPS”) 1175, A10, B3 & C1 when mounted

using the following fasteners and substrates.

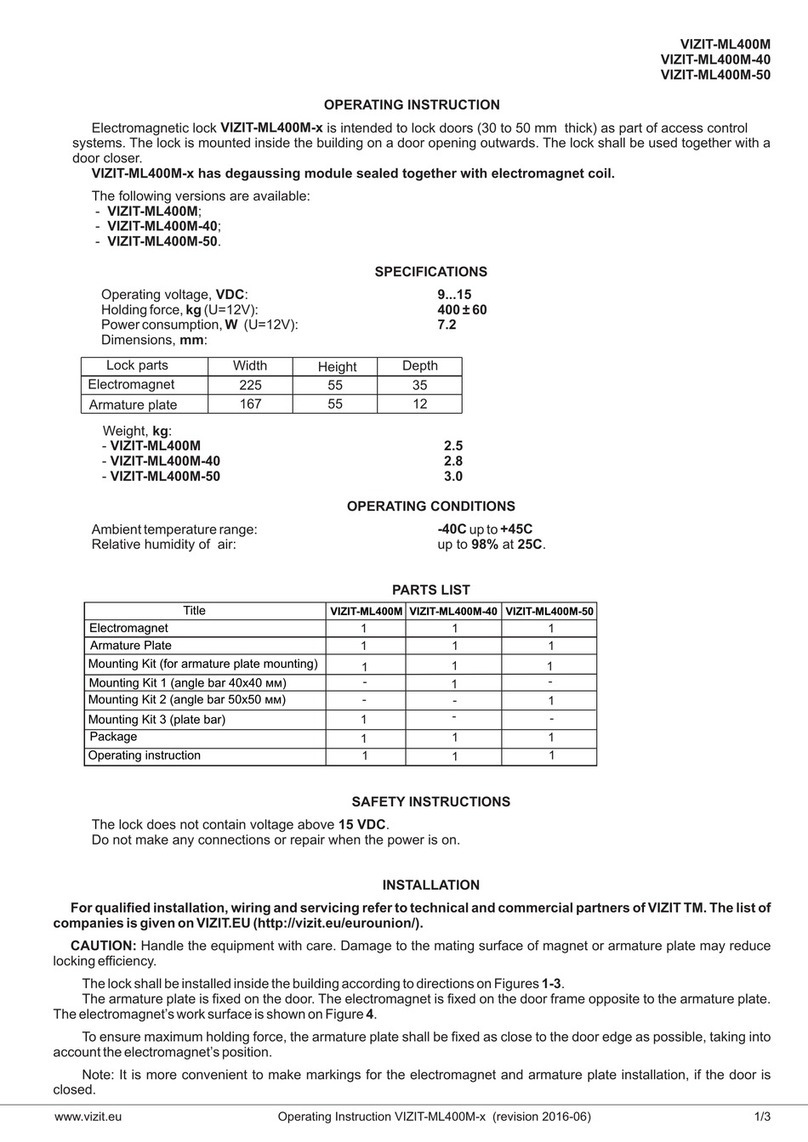

SUBSTRATE FASTENERS SECURITY RATING

Brickwork, concrete, stone 4 x Mungo MBK-STB 10 x 80mm masonry screws and

nylon plugs

A10, B3 & C1

Rendered substrate up to 20mm thick 4 x Mungo MBK-STB 10 x 100mm masonry screws

and nylon plugs

A10 & B3

Steel (minimum 4mm thick) 4 x M10 bolts (with tapped holes)

Or

4 x M10 bolts with M10 Security Shear Nuts

A10, B3 & C1

Mounting the lockboxes using any other mounting bolts or onto weaker wall structures will invalidate the security

rating.

It is important that the designated installer follows this instruction manual for the installation to retain the awarded LPS

certification. Should it be required to mount a lockbox on other than a conventional masonry wall, please contact

SentriLock to discuss suitability and the possible use of different specification mounting bolts.

This installation manual is a confidential document which is only issued to designated Installers. The purpose of this

manual is to act as a reference manual for the installation of a SentriLock® NXT-M and BLE WM Lockboxes. The

document remains the property of SentriLock, LLC.

Preparation

Position of Installation

It is recommended that the Lockbox be mounted in a position that makes attacks more difficult to reduce the

leverage an attacker can impart on the lockbox.

Surface

It is important that the mounting location is flat. If not, the pressure exerted by the mounting screws when

tightened will twist the Lockbox frame and may render it inoperable. Do not attempt to mount the lockbox on

any surface that is not flat.

On rendered walls ensure the use of Mungo MBK-STB 10x80mm masonry screws and nylon plugs as they will

maintain the LPS1175 A10 & B3 security rating.

Contact SentriLock to discuss suitability and the possible use of different mounting fasteners for non-standard

masonry surfaces.

Drilling the Mounting Holes into Brick Substrate

Where possible, all screws should fasten directly into the central part of a brick.

It is important the mounting holes are not in the mortar between bricks.

The drill holes must be at 90 degrees’ angle to the wall and to the specified depth.

Catch and save the dust from drilling to leave the area neat and tidy and to retain the dust for colouring filler

used to refill holes after de-installation.