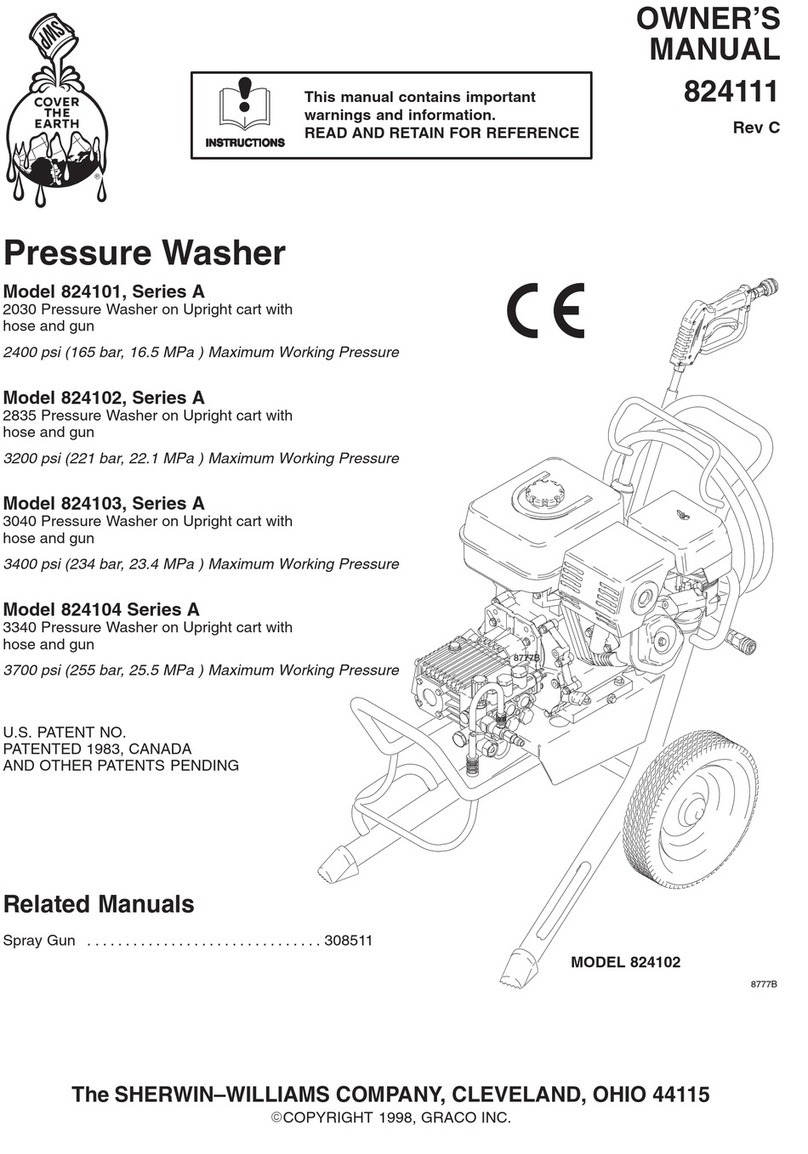

Sherwin-Williams 824102 User manual

824111

Rev. E

OWNER’S MANUAL

Pressure Washers

Model 824101, Series A

2030 Pressure Washer on upright cart with hose and gun

2400 psi (165 bar, 16.5 MPa) Maximum Working Pressure

Model 824102, Series A

2835 Pressure Washer on upright cart with hose and gun

3200 psi (221 bar, 22.1 MPa) Maximum Working Pressure

Model 824103, Series A

3040 Pressure Washer on upright cart with hose and gun

3400 psi (234 bar, 23.4 MPa) Maximum Working Pressure

Model 824104 Series A

3340 Pressure Washer on upright cart with hose and gun

3700 psi (255 bar, 25.5 MPa) Maximum Working Pressure

U.S. PATENT NO.

PATENTED 1983, CANADA

AND OTHER PATENTS PENDING

Related Manual

Hydra-CleanRGun 308511. . . . . . . . . . . . . . . .

Table of Contents

Warnings 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Service: 2030 Pressure Washer 10. . . . . . . . . . . . . . . . . . .

Pump Service: 2835, 3040, & 3340 Pressure Washers 12. . . . .

Parts: 2030 Pressure Washer 14. . . . . . . . . . . . . . . . . . . . . . . . . .

Parts: 2835, 3040, & 3340 Pressure Washers 16. . . . . . . . . . . .

Accessories 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sherwin-Williams Warranty 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Number 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The SHERWIN–WILLIAMS COMPANY, CLEVELAND, OHIO 44115

ECOPYRIGHT 1998, GRACO INC.

This manual contains important

warnings and information.

READ AND RETAIN FOR REFERENCE

Model 824102

8777B

8777B

2824111

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

WARNING

INJECTION HAZARD

Spray from the gun, leaks, or ruptured components can inject fluid into your body and cause serious

injury. Fluid splashed in the eyes or on the skin can also cause serious injury.

DFluid injected into the skin might look like just a cut, but it is a serious injury. Get emergency

medical attention.

DDo not point gun at anyone or at any part of body, and do not stop or deflect leaks with hand, body,

glove, or rag.

DDo not put hand or fingers over spray tip.

DTighten fluid connections before you start this equipment.

DEngage the gun trigger safety latch whenever you stop spraying.

DFollow Pressure Relief Procedure on page 3 if spray tip clogs and before you clean, check, or

service this equipment.

DRepair or replace worn or damaged parts immediately.

DCheck hoses, tubes, and couplings daily. Do not repair high-pressure couplings. Replace entire

hose. Fluid hoses must have spring guards on both ends to prevent kinks and rupture.

HAZARDOUS FLUIDS

Improper handling of hazardous fluids can cause serious injury or death due to splashing in eyes,

ingestion, or bodily contamination.

DKnow specific hazards of fluid being used.

DStore hazardous fluids in approved containers. Dispose of hazardous fluids per local, state, and

national guidelines.

DWear protective eye wear, gloves, clothing, and respirator as recommended by the fluid

manufacturer.

FUEL HAZARD

The fuel used in this pressure washer is combustible and when spilled on a hot surface can ignite and

cause a fire. Do not fill the fuel tank while the engine is running or hot.

EXHAUST HAZARD

The exhaust contains poisonous carbon monoxide which is colorless and odorless.

Do not operate this equipment in a closed building.

EQUIPMENT MISUSE HAZARD

Misuse of the pressure washer or accessories could cause them to rupture and result in fluid injection,

splashing in the eyes or on the skin, or other serious injury.

DDo not alter or modify any part or factory-set adjustment of this equipment.

DDo not exceed the maximum working pressure of any component or accessory in the system.

DDo not use any chemicals that are incompatible with the wetted parts as stated in Technical Data

on page 19.

DDo not alter throttle setting.

3824111

Setup

8777B

high-pressure hose

connection

hose rack

inlet water connection:

3/4-in. garden hose

gun

high-pressure hose

wand

Check for Shipping Damage

Check the pressure washer for shipping damage.

Notify the carrier immediately if there is any

damage.

Connect High-Pressure Hose and Gun

Connect the high-pressure hose to the high-pressure

hose connection and the gun. Both of these

connections are made with quick couplers.

CAUTION

Up to 100 ft (30 m) of high-pressure hose may

be used. Longer hoses could affect sprayer

performance and chemical injector performance.

Install Spray Tip

Install the appropriate spray tip on the wand. See

Installing and Changing Spray Tips on page 5.

If you are using a Sandblaster Kit, see its separate

manual for installation instructions.

Connect to Water Supply

CAUTION

Before you connect the garden hose to the pressure

washer, check your local plumbing code regarding

cross-connection to the water supply. If required,

install a backflow preventer.

If the inlet water pressure is over 60 psi (4.1 bar), a

regulating water valve must be installed at the

garden hose connection.

Do not exceed 160_F (70_C) inlet water

temperature.

Connect a hose with at least a 3/4-in. (19 mm) ID from

the water supply to the 3/4-in. garden hose inlet. The

supply hose should not be more than 50 ft (15 m) long.

NOTE: The water supply must have a minimum flow

rate equal to that of the pressure washer. See

Technical Data on page 19.

Pressure Relief

Procedure

WARNING

INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause serious injury. To reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the Pressure Relief Procedure

whenever you

DAre instructed to relieve the pressure

DStop spraying for more than 10 minutes

DCheck or service any of the system equipment

DInstall or clean the spray nozzle

1. Engage the gun trigger safety latch.

2. Turn the sprayer off, and remove the ignition cable

from the spark plug.

3. Shut off the water supply.

4. Disengage the trigger safety latch, and trigger the

gun to relieve pressure. Then engage the trigger

safety latch.

If you suspect that the spray tip or hose is clogged or

that pressure has not been fully relieved after following

the steps above: Disengage the trigger safety latch,

and trigger the gun to relieve pressure. Wrap a rag

around the hose end coupling, and VERY SLOWLY

loosen the coupling to relieve pressure gradually. Then

loosen it completely. Then clear the tip or hose.

4824111

Operation

Startup

Always use this start-up procedure to ensure that the pressure washer is started safely and properly.

DAlways engage the gun trigger safety latch when

you stop spraying even for a moment. This reduces

the risk of fluid injection or splashing in the eyes or

on the skin if the gun is bumped or triggered

accidentally.

DAlways observe the CAUTIONS in this section to

avoid costly damage to the pressure washer.

DIf you use the Sandblaster Kit, see the Sandblaster

Kit manual for detailed cleaning information.

1. Check the oil level.

NOTE: All pressure washers are equipped with a

low-oil sensor that shuts the engine off if the oil

level falls below a certain level. If the engine stops

unexpectedly, check both the oil and the fuel

levels. Check the oil level each time you refuel.

2. Check the fuel level.

WARNING

FIRE HAZARD

Do not refuel a hot engine. Refueling a

hot engine could cause a fire. Use only

fresh, clean regular or unleaded gasoline. Close

the fuel shutoff valve during refueling.

3. Turn on the water supply.

CAUTION

Never run the pressure washer without water.

Costly damage to the pump will result. Always be

sure the water supply is completely turned on

before you run the pressure washer.

4. Trigger the gun until water sprays from the tip,

indicating that the air is purged from the system.

5. Open the fuel shutoff valve. Be sure the spark plug

ignition cable is pushed firmly onto the spark plug.

Put the switch in the START position, and put the

throttle in the RUN position.

CAUTION

Do not allow the pressure washer to idle for more

than 10 minutes. Doing so could cause the

recirculating water to overheat and seriously

damage the pump. Turn off the pressure washer if

it will not be spraying at least every 10 minutes. If

heated inlet water is used, reduce this time more.

Do not operate the pressure washer with the inlet

water screen removed. The screen helps keep

abrasive sediment out of the pump, which could

clog the pump or damage the cylinders. Keep the

screen clean. Do not pump caustic materials; such

materials could corrode the pump components.

6. Pull the starter rope to start the engine. Brace one

foot on the pressure washer chassis, and pull the

starter rope out quickly. Pull and return the rope

until the engine starts.

CAUTION

Do not allow the starter rope to snap back against

the engine. Let the rope recoil gently to prevent

damage to the recoil.

NOTE: For easier starting, have one person start

the pressure washer while another person triggers

the gun.

If the engine is cold, start the engine with the

choke completely closed. In cool weather, you

might have to let the engine run with the choke

closed for the first 10 to 30 seconds. In warm

weather, open the choke completely as soon as

the engine starts.

If the engine is warm, start the engine with the

choke completely open or partially closed. When

the engine starts, open the choke completely.

5824111

Operation

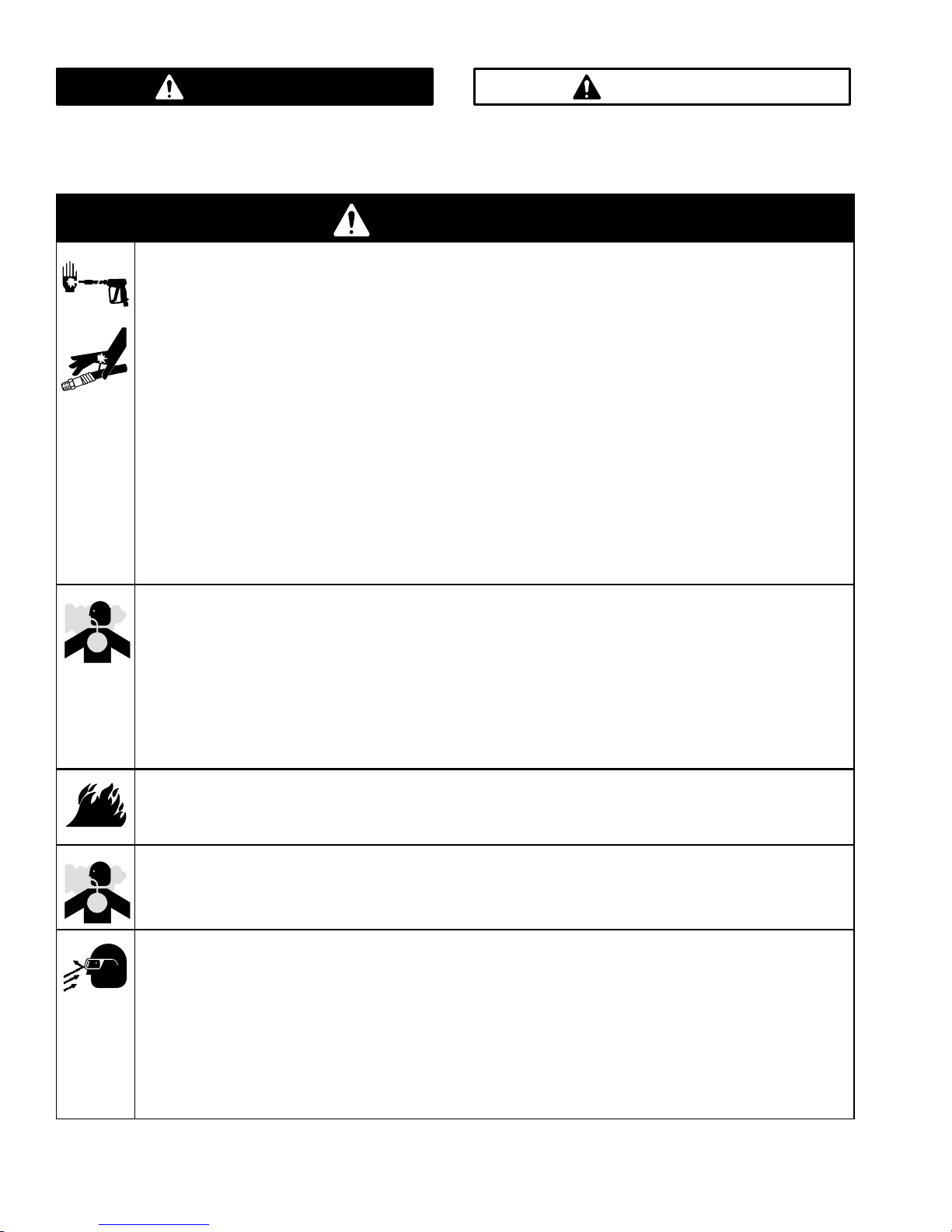

Trigger Safety Latch

WARNING

To reduce the risk of serious bodily injury, including

fluid injection and splashing in the eyes or on the

skin, always engage the trigger safety latch when

you stop spraying even for a moment. When

engaged, the trigger safety latch prevents the gun

from being triggered accidentally by hand or if it is

dropped or bumped. Be sure the latch is pushed

fully down, or it will not prevent the gun from being

triggered. See Fig. 1.

Fig. 1

engaged disengaged

04612

Trigger Safety Latch

Chemical Injector Operation

1. Relieve the pressure.

See page 3.

2. Insert the chemical filter (attached with clear tubing

to the chemical injector) into the container of

chemical.

3. Install the black large-orifice chemical tip. See

Installing and Changing Spray Tips at right.

This causes a drop in pressure that actuates the

chemical injector. Changing back to a small diameter

spray tip deactivates the chemical injector and

produces high pressure for rinsing. The chemical filter

can be left in the chemical container during high

pressure use. To regulate the flow rate of the chemical,

turn the chemical adjustment knob on the injector.

Maximum chemical flow is a full two turns

counterclockwise from the CLOSED (clockwise)

position.

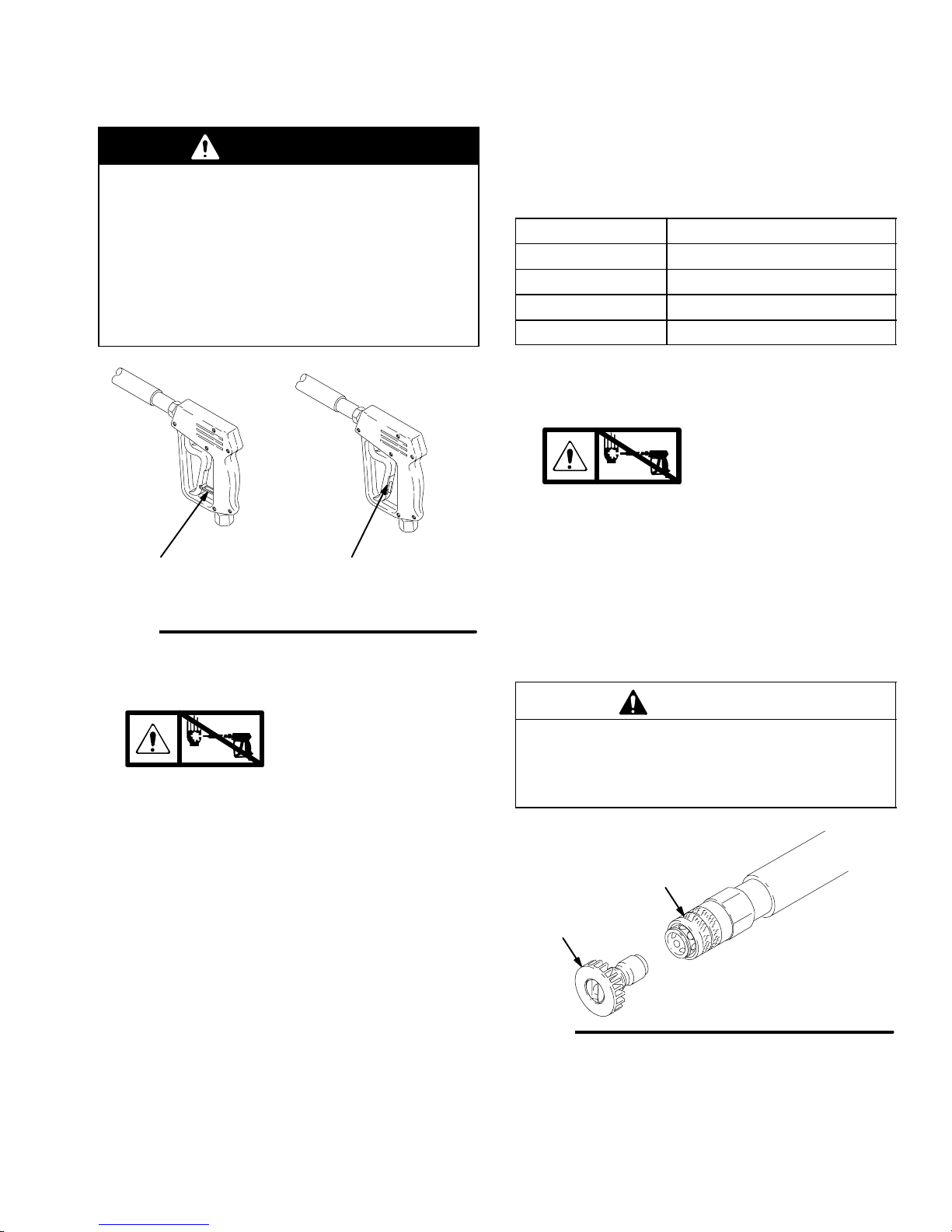

Installing and Changing Spray Tips

Spray tips have 4- or 5-digit numbers on them. The

first two digits are the spray angle. Select the spray tip

appropriate for your application. Tip holding holes are

provided on the chassis.

Spray Tip Number Spray Pattern Fan Angle

00XXX 0_blaster (red)

15XXX 15_(yellow)

25XXX 25_(green)

40XXX 40_(white)

NOTE: The chemical injector tip is brass and has a

large opening and a black plastic cap.

1. Relieve the pressure.

See page 3.

2. Point the gun and wand away from yourself and

anyone else.

3. Without holding your hand over the spray tip (A),

pull back the quick coupler ring (B). Remove the

current tip and/or install a different one, and then

push back the ring. See Fig. 2.

4. Pull on the tip to be sure it is secure before you

spray again.

CAUTION

To avoid blowing the O-ring out of the quick coupler

due to the high pressure in the system, never

operate the pressure washer without a tip securely

mounted in the quick coupler.

04929

Fig. 2

A

B

This manual suits for next models

3

Table of contents

Other Sherwin-Williams Pressure Washer manuals