Shibaura ST318 User manual

ST318/ST321/ST324

MODEL

Electro-magnetic Interference (EMC)

This tractor complies strictly with the European Regulations on electro-magnetic emissions. However,

interference may arise as a result of add-on equipment which may not necessarily meet the required

standards. As such interference can result in serious malfunction of the unit and/or create unsafe situations,

you must o serve the following:

Ensure that eac h piece of non-SHIBAURA equipment fitted to the tractor ears the

CE mark.

The m ax im um power of em ission equipment(r adio,tele phones,etc.) must not exceed

the limits imposed y the national authorities of the countr y wher e you use the

tractor.

The electro-magnetic field genera ted y the add-on system should no t exceed

24V/m at any tim e and at a ny location in the prox imity of electronic com ponents.

Failur e to com ply with these rules will render the SH IBAURA warranty null and void.

Printed in Japan

S318,321,324 300812560 050002-003F

1

GENERAL INFORMATION

PLEA SE R EAD CAR EF ULLY :

For a complete lis t of the pre-deliver y service ch ecks performed b y your dealer, r efer to

the PR E-DELIVER SERVICE check list fo und at th e back of this m anual. Keep one c opy

as your rec ord of the s ervic e perform ed. The other should be r emoved from the m anual

and kept by your dealer. MAKE SU RE THAT BOTH COPIES ARE CO MPLETED AND THAT

OU AND THE DEALER SIGN BOTH COPIES .

After you have operated your t ractor for fifty hours, tak e this manual and your tracto r to

your d ealer. He will then perf orm the factor y rec ommended 50-HOUR SERVICE as li sted

on the lo wer portio ns at t he back of this manual - without char ge - exc ept for

lubricant, oil, or f ilters replaced as part of norm al m aintenance. MAKE SURE THAT OU

AND THE DEALER SIGN BOTH COPIES .

A PRODUCT IDENTI FICATION PLATE is locate d on the right-hand side of the front fram e.

The numbers on the plate are important should your tractor re quire future service. For

your convenience, have your dealer recor d the num bers in t he appropri ate spaces bel ow.

SHIBAUR A po licy is one of continuo us i mprovement, an d the right to c hange prices,

specification or equipment at any time without notice is reser ved.

All data given in th is manua l is subjec t to produc tion variations . Dim ensions an d weights

are approx im ate o nly and the illus trations do not n ecessaril y s how tractors in s tandard

condition. For exact information about an y particular tractor please consult your

SHIBAUR A Tractor Dealer.

2

CONTENTS

GENERAL INFORMATION····················································································································1

INTERNATIONAL S MBOLS················································································································3

SAFET PRECAUTIONS ···············································································································4 - 7

CONTROLS, INSTRUMENTS AND OPERATION ···································································· 8 - 29

SEAT, SEAT BELT AND ROPS ·································································································· 8 - 9

LIGHTING··········································································································································10

INSTRUMENT PANEL, KE SWITCH ··················································································· 11 - 12

STARTING THE ENGINE ················································································································12

STOPPING THE ENGINE················································································································13

BREAK-IN PROCEDURES ··············································································································13

THROTTLE CONTROLS ·················································································································14

BRAKE CONTROLS·························································································································15

TRANSMISSION, FOUR-WHEEL DRIVE AND PTO ···························································· 16 - 20

FOUR-WHEEL DRIVE ··················································································································16

MECHANICAL TRANSMISSION··························································································16 - 17

H DROSTATIC TRANSMISSION ······················································································ 17 - 18

CLUTCH PEDAL····························································································································18

DIFFERENTIAL CONTROL·································································································· 18 - 19

PTO CONTROLS AND OPERATION··················································································19 - 20

TOWING THE TRACTOR················································································································20

HOOD LUTCH···································································································································21

THREE POINT LINKAGE·················································································································21

H DRAULIC LIFT S STEM ···································································································· 22 - 25

DRIVING THE TRACTOR················································································································26

WHEEL TREAD SETTINGS ············································································································27

TRACTOR WEIGHTING ·········································································································· 28 - 29

TIRE PRESSURES ··························································································································29

LUBRICATION AND MAINTENANCE ························································································30 - 52

LUBRICATION AND MAINTENANCE CHART ··············································································30

FUEL AND LUBRICANTS········································································································ 31 - 33

FUEL AND LUBRICANT SERVICE PROCEDURES·····························································33 - 38

GENERAL MAINTENANCE ·····································································································38 - 50

TRACTOR STORAGE·············································································································· 51 - 52

GENERAL TORQUE SPECIFICATION TABLE·············································································53

SPECIFICATIONS························································································································ 54 - 56

SAFET AND INSTRUCTION DECALS ····················································································57 - 59

PREDELIVER AND 50-HOUR SERVICE ················································································ 61 - 63

SAFETY PRECAUTIONS

The following precautions are suggested to help pre ent accident

4

PERSONAL SAFETY

Throughout this manual and on machine decals,

you will find precautionary statements

( “CAUTION , WARNNG , and “DANGER ) fol-

lowed by specific instructions. These specifica-

tions are intended for the personal safety of you

and those working with you. Please take the time

to read them.

The word “CAUTION is used where a

safe behavioral practice according to

operating and maintenance instruc-

tions and common safety practices will

protect the operator and others from

accident involvement.

The word “WARNING denotes a po-

tential or hidden hazard, which has a

potential for serious injury. It is used

to warn operators and others to exer-

cise every appropriate means to avoid

a surprise involvement with machinery.

The word “DANGER denotes a for-

bidden practice in connection with a

serious hazard.

Failure to follow the “CAUTION , “W ARNING ,

and “DANGER instructions may result in bodily

injury or death.

MACHINE SAFETY

Additional precautionary statements

(“ATTENTION , and “IMPORTANT ) are followed

by specific instructions. These statements are

intended for machine safety.

ATTENTION

: The word “ATTENTION is use to

warn the operator of potential machine damage if

a certain procedure is not follows.

IMPORTANT

: The word “IMPORTANT is used

to inform the reader of something he needs to

know to prevent minor machine damage if a cer-

tain procedure is not follows.

A careful operator is the best operator. Most ac-

cidents can be avoided by observing certain pre-

cautions. Read and take the following precau-

tions before operating this tractor to help prevent

accidents. Equipment should be operated only by

those who are responsible and instructed to do

so.

SAFETY AND THE TRACTOR

1. Read the Operator’s Manual carefully be-

fore using the tractor. Lack of operating

knowledge can lead to accidents.

2. Use an approved Roll bar and Seat Belt for

safe operation. Overturning a tractor with-

out a roll bar can result in death or injury. If

your tractor is not equipped with a rollbar

and seat belt, see your SHIBAURA Tractor

Dealer.

3. Use the handholds and step plates when

getting on and off the tractor to prevent

falls. Keep steps and platform cleared of

mud and debris.

4. Do not permit anyone but the operator to

ride on the tractor. There is no safe place

for extra riders.

5. Keep all safety decals clean of dirt and

grime, and replace all missing, illegible, or

damaged safety decals. See the list of de-

cals in the Decal section of this manual.

SERVICING THE TRACTOR

1. The cooling system operates under pres-

sure, which is controlled by the radiator cap.

It is dangerous to remove the cap while

system is hot. Always turn cap slowly to the

first stop and allow the pressure to escape

before removing the cap entirely.

2. Do not smoke while refueling the tractor.

Keep any type of open flame away. Wait for

engine to cool before refueling.

SAFETY PRECAUTIONS

The following precautions are suggested to help pre ent accident

5

3. Keep the tractor and equipment, particularly

brakes and the steering, maintained in a re-

liable and satisfactory condition to ensure

your safety and comply with legal require-

ments.

4. Keep open flame away from battery or cold

weather starting aids to prevent fires or ex-

plosions. Use jumper cables according to

instructions to prevent sparks, which could

cause explosion.

5. Stop the engine before performing any ser-

vice on the tractor.

6. Escaping hydraulic/diesel fluid under pres-

sure can penetrate the skin causing serious

injury. If fluid is injected into the skin, ob-

tain medical attention immediately or gan-

grene may result.

* DO NOT use your hand to check for leaks.

Use a piece of cardboard or paper to search

for leaks.

* Stop engine and relieve pressure before

connecting or disconnecting lines.

* Tighten all connections before starting en-

gine or pressurizing lines.

7. Do not modify or alter or permit anyone

else to modify or alter this tractor or any of

its components or any tractor function

without first consulting SHIBAURA Tractor

Dealer.

8. The fuel oil in the injection system is under

high pressure and can penetrate the skin.

Unqualified persons should not remove or

attempt to adjust a pump, injector, nozzle

or any other part of the fuel injection sys-

tem. Failure to follow these instructions can

result in serious injury.

9. Continuous long term contact with used en-

gine oil may cause skin cancer. Avoid pro-

longed contact with used engine oil. Wash

skin promptly with soap and water.

10. Some components on your tractor, such as

gaskets and friction surfaces (brake linings,

clutch linings etc.), may contain asbestos.

Breathing asbestos dust is dangerous to

your health. You are therefore advised to

have any maintenance of repair operations

on such components carried out by an au-

thorized SHIBAURA Tractor Dealer. If

however, service operations are to be un-

dertaken on parts that contain asbestos,

the essential precautions listed below must

be observed:

* Work out of doors or in a well-ventilated

area.

* Dust found on the tractor or produced during

work on the tractor should be removed by

extraction not by blowing.

* Dust waste should be dampened, placed in a

sealed container and marked to ensure safe

disposal.

* If any cutting, drilling, etc., is attempted on

materials containing asbestos, the item

should be dampened and only hand tools or

low speed power tools used.

OPERATING THE TRACTOR

1. Apply the parking brake, place the PTO

lever in the “OFF position, the lift control

lever in the down position, the remote con-

trol valve levers in the neutral position, and

the transmission in neutral before starting

the tractor.

2. Do not start the engine or operate controls

while standing beside the tractor. Always sit

in the tractor seat when starting the engine

or operating controls.

3. Do not bypass the neutral start switches.

Consult your SHIBAURA Tractor Dealer if

your neutral start controls malfunction. Use

jumper cables only in the recommended

manner. Improper use can result in tractor

runaway.

4. Avoid accidental contact with the gear shift

levers while the engine is running. Unex-

SAFETY PRECAUTIONS

The following precautions are suggested to help pre ent accident

6

pected tractor movement can result from

such contact.

5. Disengage PTO, shut off the engine and

apply the parking brake before getting off

the tractor.

6. Do not park the tractor on a steep incline.

7. Do not operate the tractor engine in an en-

closed building without adequate ventilation.

Exhaust fumes can cause death.

8. If power steering or engine ceases operat-

ing, stop the tractor immediately.

9. Pull only from the drawbar or the lower link

drawbar in the down position. Use only a

drawbar pin that locks in place. Pulling from

the tractor rear axle or any point above the

axle may cause the tractor to upset.

10. If the front end of the tractor tends to rise

when heavy implements are attached to the

three-point hitch, install front end or front

wheel weights. Do not operate the tractor

with a light front end.

11. Always set the hydraulic selector lever in

position control when attaching equipment

and when transporting equipment. Be sure

hydraulic couplers are properly mounted

and will disconnect safety in case of acci-

dental detachment of implement.

12. Do not leave equipment in the raised posi-

tion.

13. Use the Flasher/Turn Signal Lights and

SMV signs when traveling on public roads

both day and night unless prohibited by

law.

14. Be sure tractor lights are adjusted to pre-

vent blinding an oncoming vehicle operator.

DRIVING THE TRACTOR

1. Watch where you are going especially at

row ends, on roads, around trees and low

hanging obstacles.

2. To avoid upsets drive the tractor with care

and at speeds compatible with safety, es-

pecially when operating over rough ground,

when crossing ditches or slopes, and when

turning corners.

3. Lock tractor brake pedals together when

transporting on roads to provide two wheel

braking.

4. Keep the tractor in the same gear when

going downhill as used when going uphill.

Do not coast or free wheel down hills.

5. Any towed vehicle whose total weight ex-

ceeds that of the towing tractor must be

equipped with brakes for safe opera ion.

6. When the tractor is stuck or tires are frozen

to the ground, back up the tractor to pre-

vent upset.

7. Always check overhead clearance, espe-

cially when transporting the tractor.

8. When operating at night, adjust lights to

prevent blinding an oncoming driver.

OPERATING THE PTO

9. When operating PTO driven equipment,

shut off the engine and wait until the PTO

stops before getting off the tractor and dis-

connecting the equipment.

10. Do not wear loose clothing when operating

the power take off, or when near rotating

equipment.

11. When operating stationary PTO driven

equipment, always place both gear shift

levers in neutral, apply the tractor parking

brake and block the rear wheels front and

back.

12. To avoid injury, do not clean, adjust, unclog

or service PTO driven equipment when the

tractor engine is running.

SAFETY PRECAUTIONS

The following precautions are suggested to help pre ent accident

7

13. Make sure the PTO master shield is in-

stalled at all times and always replace the

PTO shield cap when the PTO is not in use.

SAFETY PRECAUTIONS

The following precautions are suggested to help pre ent accident

8

DIESEL FUEL

1. Under no circumstances should gasoline,

alcohol or blended fuels be added to diesel

fuel. These combinations can create an in-

creased fire or explosive hazard. Such

blends are more explosive than pure gaso-

line in a closed container such as a fuel

tank. Do not use these blends.

2. Never remove the fuel cap or refuel with the

engine running or hot.

3. Do not smoke while refueling or when

standing near fuel.

4. Maintain control of the fuel filler pipe nozzle

when filling the tank.

5. Do not fill the fuel tank to capacity. Allow

room for expansion.

6. Wipe up spilled fuel immediately.

7. Always tighten the fuel tank cap securely.

8. If the original fuel tank cap is lost, replace it

with a SHIBAURA approved cap. A

non-approved, proprietary cap may not be

safe.

9. Keep equipment clean and properly main-

tained

10. Do not drive equipment near open fires.

11. Never use fuel for cleaning purposes.

12. Arrange fuel purchases so that summer

grade fuels are not held over and used in

the winter.

SAFETY FRAME (ROPS)

If your SHIBAURA Tractor is equipped with a

safety frame it must be maintained in a service-

able condition. Be careful when driving through

doorways or working in confined spaces with low

headroom.

Under no circumstances:

1. modify, drill or alter the safety frame in any

way as doing so could render you liable to

legal prosecution.

2. attempt to straighten or weld any part of the

main frame or retaining brackets which

have suffered damage. By doing so you

may weaken the structure and endanger

your safety.

3. secure any parts on the main frame or at-

tach your safety frame with other than the

special high tensile bolts and nuts speci-

fied.

4. attach chains or ropes to the main frame for

pulling purposes.

5. take unnecessary risks even though your

safety frame affords you the maximum pro-

tection possible.

CONTROLS, INSTRUMENTS AND OPERATIONS

8

SEAT, SEAT BELT AND ROPS

Seat Adjustment

Your SHIBAURA Tractor is equipped with an ad-

justable suspension seat as shown in Fi ure 1.

To adjust the seat fore and aft, move the release

lever ①, towards the fender, slide the seat to the

desired position, releasin the lever to lock.

The seat has seven hei ht position controlled by

the knob ②. While sittin in the seat, pull out the

knob movin it to the left to increase the hei ht, or

to the ri ht to reduce the hei ht.

To adjust the seat suspension for individual opera-

tors, pull out the lever ③, and twist until either the

(+)or(-)si n is uppermost. Operatin the

ratchet with the(+)uppermost will provide a firmer

ride, or with(-)uppermost, a softer the ride.

Figure 1 - Tractor Seat Adjustment

Seat Belt

To len then the seat belt, tip the buckle end down

and pull on the buckle until the ends can be joined.

To shorten the belt, buckle it, then pull on the loose

end until the belt is snu , Fi ure .

Use soap and water to clean the seat belt if nec-

essary. Do not use carbon tetrachloride, naphtha,

etc., as these substances will weaken the webbin .

Additionally, do not bleach or re-dye the webbin ,

as these products will also weaken the webbin .

Replace the seat belt if it becomes dama ed or

worn.

Two seat belt brackets have been provided, one

each fender, to han each end of the seat belt from

when it is not I use. This helps to keep the seat

belt clean, and also saves it from rubbin a ainst

the fender and scratchin the paint.

Figure - Seat Belt

Rear View Mirror

Mounted on a detented, sprin loaded arms, the

mirror can be quickly moved out of the way when

operatin in the orchards or amon st fruit vines.

By loosenin the screws on the clamp, the head

may be re-positioned on the arm to provide

maximum rearward vision.

Figure 3 - Rear View Mirror

CONTROLS, INSTRUMENTS AND OPERATIONS

9

ROLLOVER PROTECTIVE STRUCTURE(ROPS)

Your tractor is equipped with a foldin Roll Over

Protective Structure(ROPS). If, for some reason,

the recommended that you equip your tractor with

a ROPS.

ROPS are effective in reducin injuries durin

tractor overturn accidents. Overturnin tractor

without a ROPS can result in serious injury or

death.

Roll Over Protective Structure (ROPS), and seat

belts are available from your SHIBAURA Tractor

Dealer.

The safety offered by the roll bar and seat belt is

minimized if your seat belt is not buckled. Always

use your seat belt - they save lives.

WARNING:

::

: When improperly oper-

ated, a tractor can roll over.

For low clearance use only, the ROPS

may be lowered.

No protection is provided when the

tractor is operated with the ROPS in

the lowered position.

Always raise the ROPS immediately

after low clearance work. When a

tractor is driven from a low clearance

operation, the ROPS should be locked

in the raised position.

Figure 4 - Rollover Protective Structure (ROPS)

Folding the ROPS

A foldable ROPS is factory installed on your tractor.

Operate with ROPS in the raised position when-

ever possible. Use the ROPS in the folded position

only when absolutely necessary.

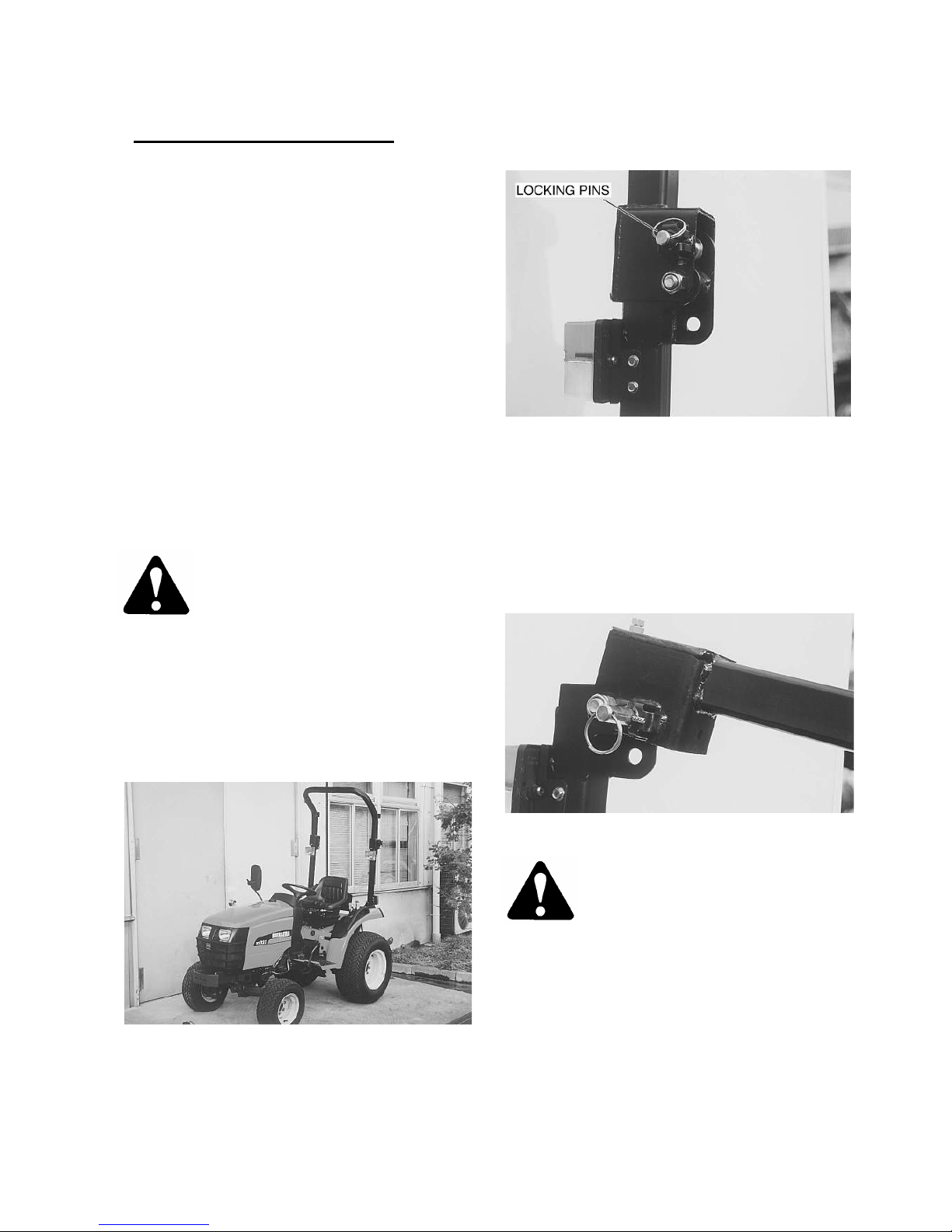

To fold the ROPS pull out the lockin pins, Fi ure 5,

and twist to lock in the released position. Lower

the upper section of the ROPS rearwards, releas-

in the lockin pins to anchor the ROPS firmly

once in position. To raise the ROPS reverse the

above procedure.

Figure 6 - ROPS, Folded Position

WARNING:

::

:Do not operate the tractor

with the ROPS folded as a standard

operatin mode. A folded ROPS does

not provide rollover protection.

If a seat belt is fitted, it must always be worn when

the tractor is operated with the ROPS in the raised

position. However, if the ROPS has been removed

from the tractor, or if operated in the folded position,

the seat belt should not be used.

Always pull from the tractor the drawbar. Do not

attach chains or ropes to the ROPS for pullin pur-

poses, as the tractor can tip backwards.

Figure 5 - ROPS, Raised Position

CONTROLS, INSTRUMENTS AND OPERATIONS

10

LIGHTING

HAZARD FLASHER WARNING LIGHTS AND

COMBINATION SWITCH

Your SHIBAURA tractor is equipped with hazard

li ht, Fi ure 7. The li ht switch must be turned to

the “ON” position before the hazard li ht will oper-

ate.

Figure 7 - Hazard Flasher and Turn Signals Lights

Lighting Switches

Your tractor is equipped with a combination switch

①,operatin turn si nals, hazard li hts and the

horn. The main li htin switch ②, is mounted on

the left side of the instrument console.

Figure 8 -

--

-1.Combination Switch, .Main Lighting

Switch

Combination Switch

The turn si nal li hts are activated by movin the

switch to the left or ri ht as required. The turn si -

nal switch is not self-cancelin . To operate the

hazard function, move the hazard flasher switch,

clockwise to activate all four indicator li hts.

Depressin the center button will sound the horn.

Figure 9 - Combination Switch

MAIN LIGHTING SWITCH

The main li htin switch, shown in Fi ure 10, is a

pull-push type switch. Its positions are :

1st position・・・・・・・・・・・・・・・・・・・・・・・Li hts “OFF”

2nd position・・・・・・・・・・Side and Tail Li hts “ON”

3rd position・・・・・・Side, Tail and Headli hts “ON”

(Low Beam)

4th position・・・・・・Side, Tail and Headli hts “ON”

(Hi h Beam)

Trailer Turn Indicator Light

The warnin li ht, Fi ure 10, will flash in union with

tractor/trailer turn si nals if trailer is attached.

CONTROLS, INSTRUMENTS AND OPERATIONS

11

Figure 10 – Trailer Turn indicator Light

CONTROLS, INSTRUMENTS AND OPERATIONS

12

INSTRUMENT PANEL

Instrument Panel

①

①①

①

Engine Oil Pressure Warning Light - Illumi-

nates with the key switch in the “ON” or “HEAT”

positions and remains lit for a short period of

time after the en ine is started. The li ht indi-

cates oil pressure only and oes out when suf-

ficient oil pressure is present at the oil sender.

If the bulb becomes lit durin operation, stop

the tractor en ine immediately and investi ate

the cause.

②

②②

②

Cold Starting Indicator Light - Illuminates

when the key switch is turned to the “HEAT”

position. It remains lit for approximately 5 sec-

onds when the key is held in position, durin

which time the low plu s are heatin the

pre-combustion chambers.

③

③③

③

Battery Charge Warning Light - Illuminates

when the key switch is in the “ON” or “HEAT”

positions and oes out when en ine is started.

If this bulb becomes lit durin operation, it indi-

cates the char in system is not operatin

normally. As the battery can become fully dis-

char ed under these conditions, the problem

should be investi ated as soon as possible.

④

④④

④

Proof Meter - Records the hours and portions

of hours that your tractor has been operated

based on an avera e en ine speed of 1883

RPM. Use the proof meter as a uide to deter-

mine hourly service maintenance intervals.

⑤

⑤⑤

⑤

Tachometer- Re isters en ine RPM (Revolu-

tions Per Minute). The au e is marked in in-

crements of 100 and will return to zero when

the en ine is not runnin .

⑥

⑥⑥

⑥

High Beam Indicator - Illuminates when the

head-li hts are switched to main beam.

⑦

⑦⑦

⑦

Parking Brake Light - Illuminates if the parkin

brake is en a ed when the key switch is turned

from “OFF” position.

⑧

⑧⑧

⑧

Fuel Gauge - Indicates the amount of diesel

fuel when the key switch is in the “ON” or

“HEAT” positions. It will re ister empty with the

key switch in the “STOP” position.

⑨

⑨⑨

⑨

Turn Indicator Warning Lights - Flash in un-

ion with the turn si nal warnin li ht when the

level is moved to the ri ht-hand or left-hand.

⑩

⑩⑩

⑩

Temperature gauge - Indicates coolant tem-

perature. If the activated when the key switch is

turned to the “ON” or “HEAT” positions. The

au e will re ister cold with the key switch in

the “STOP” position. If the needle re isters in

the reen ran e, this indicates a normal oper-

atin temperature. If the needle moves to the

red portion of the au e, this indicates an

overheated condition. Stop the tractor en ine

immediately and investi ate the cause.

⑪

⑪⑪

⑪

Rear PTO Speed - Determined by the portion

of the needle on the tachometer. The tachome-

ter is marked to indicate 540 PTO RPM. En ine

RPM should remain close to this mark while

usin the rear PTO; runnin the en ine faster

than this results in a dan erous over speed

condition.

⑫

⑫⑫

⑫

Hazard Indicator Warning Lights - Flash in

union with the hazard warnin li ht when the

lever is moved clockwise.

CONTROLS, INSTRUMENTS AND OPERATIONS

13

KEY SWITCH

The key switch is shown in Fi ure 11.

Turnin the key to the ri ht to the “ON” position will

activate the indicator li hts and instruments.

Turnin the key further ri ht to the “HEAT” position

will active the cold-start aid.

Turnin the key to the fully clockwise to the

“START” position will start the en ine. Upon re-

lease, the key will sprin return to the “ON” posi-

tion.

To stop the en ine, turn the key to the “OFF” posi-

tion.

Figure 11- Key Switch

IMPORTANT:

::

:The key switch must remain in the

ON position while operatin the en ine. The warn-

in li hts and battery char in system will not func-

tion with the switch in the OFF position.

PRE-HEATING THE ENGINE

Your tractor has a diesel en ine. Before startin a

cold en ine, the pre-combustion chambers must be

heated.

To preheat the en ine, turn the key switch to the

“HEAT” position, Fi ure 11 and hold the key in this

position for approximately 5 seconds. The low

plu s heat the combustion chambers durin this

time, and the en ine will now be ready to start.

NOTE: When ambient temperature are colder, a

lon er preheat time may be necessary. Even after

the cold start indicator li ht has one out, the low

plu s will continue to heat if the key is held in the

“HEAT position.

WARNING:

::

:Do not use ether with the

thermostat startin aid.

STARTING THE ENGINE

The safety key switch allows activation of the start-

in motor only when:

1. The rear PTO is in the “OFF” position.

2. The mid PTO is in the “OFF” position.

3. The ran e lever in the “NEUTRAL” position.

4. The clutch pedal is fully depressed.

Always safety practices when startin your tractor.

Position the hand throttle rearward so that it is one-

fourth to one-third open when startin the tractor.

After startin return the throttle to the idle position

and allow the en ine to idle for 1 minute before op

eratin the tractor.

IMPORTANT:

::

:Do not en a e the startin motor

continuously for more than 30 seconds ; doin so

may cause startin motor failure.

NOTE:

::

:A coolant immersion heater which provides

for easier startin in temperatures below 0° F

(-17.7℃) by warmin the en ine oil and coolant,

is available as a dealer installed option.

STARTING THE TRACTOR WITH

JUMPER CABLES

WARNING:

::

:Start en ine only from

the operator’s seat.

If it is necessary to use jumper cables to start the

CONTROLS, INSTRUMENTS AND OPERATIONS

14

tractor, follow the instructions below.

1. Shield eyes.

2. Connect one end of the jumper cable to the

tractor battery positive (+) terminal and the

other to the auxiliary battery positive (+) termi-

nal. Connect one end of the other cable first to

the auxiliary battery ne ative (-) terminal, and

the other end to the tractor starter round ter-

minal. Follow the startin procedures indicated

previously above.

Idle the en ine and turn on all electrical equipment

(li hts, etc.), then disconnect the cables in reverse

order of the connectin procedure above. This will

help protect the alternator from dama e due to

extreme load chan es.

WARNING:

::

:Batteries contain sulfuric

acid and produce explosive ases.

Follow the instructions below to pre-

vent personal injury.

Wear eye and skin protection.

Keep sparks and flame away.

Always have adequate ventilation while char -

in or usin the battery.

Follow the battery manufacturer’s instruction

switch are shown on the battery.

STOPPING THE ENGINE

Pull the hand throttle fully rearward and turn the

key switch, Fi ure 11, to the “OFF” position to stop

the en ine.

IMPORTANT:

::

:Failure to turn the key switch to the

“OFF” position after the en ine has stopped will al-

low the warnin li hts to remain on, causin the

battery to dischar e.

BREAK-IN PROCEDURES

Your SHIBAURA Tractor will provide lon and

dependable service if iven proper care durin the

50 hour break-in period. Durin the first 50 hours

of operation :

1. Avoid “lu in ” the en ine. Operatin in too

hi h a ear under heavy load may cause en ine

“lu in ”, which is indicated when the en ine

will not respond to a throttle increase.

2. Use the lower ear ratios when pullin heavy

loads and avoid continuous operation at con-

stant en ine speeds. You will save fuel and

minimize en ine wear by selectin the correct

ear ratio for a particular operation. Operatin

the tractor in low ear with a li ht load and hi h

en ine speed will waste fuel.

3. Avoid prolon ed operation at either hi h or low

en ine speeds without a load on the en ine.

4. Check the instruments frequently and keep the

radiator and oil reservoirs filled to their recom-

mended levels. Daily checks include :

En ine oil level

Radiator coolant

Air cleaner

5. After the first 50 hours of use, be sure to per-

form the maintenance chart ,on Pa e 30.

WARNING:

::

:Never attempt to start the

en ine while standin beside the trac-

tor always sit in the seat when startin

the en ine.

CONTROLS, INSTRUMENTS AND OPERATIONS

15

ELECTRICAL SOCKET for Traile

r

A standard seven pin socket, Fi ure 1 , is provided

mounted on the left side of the tractor at the rear.

With reference to the picture inset, the socket

connections (as viewed from the rear of the tractor)

are as follows;

Pin No. Wire Colour Circuit

①

Green/Red L.H. Turn Si nal

② Not Used

③ Black Earth(Ground)

④ Green/White R.H. Turn Si nal

⑤ Red R.H. Parkin Li ht

⑥ Green/Purple

Stop Li hts

⑦ Red/Black L.H. Parkin Li ht

Figure 1 - Seven Pin Electrical Socket

THROTTLE CONTROLS

HAND THROTTLE AND ENGINE STOP

CON-

TROL

The hand throttle is shown in Fi ure 13. Push the

throttle rearward to increase en ine rpm. Pull the

throttle forward to decrease en ine rpm.

Figure 13 - Hand throttle

FOOT THROTTLE

(Only mechanical transmission, 9x3)

The foot throttle, shown in Fi ure 14, can be used

separately, or in conjunction with the hand throttle.

With the hand throttle control lever set at a selected

en ine rpm, the foot throttle can be used to in-

crease en ine rpm to its maximum speed.

Upon release of the foot throttle, the en ine speed

will return to the rpm at which the hand throttle has

been set, or idle if the hand throttle is not at a

pre-set position.

Figure 14 - Foot throttle and Brake Controls

CONTROLS, INSTRUMENTS AND OPERATIONS

16

BRAKE CONTROLS

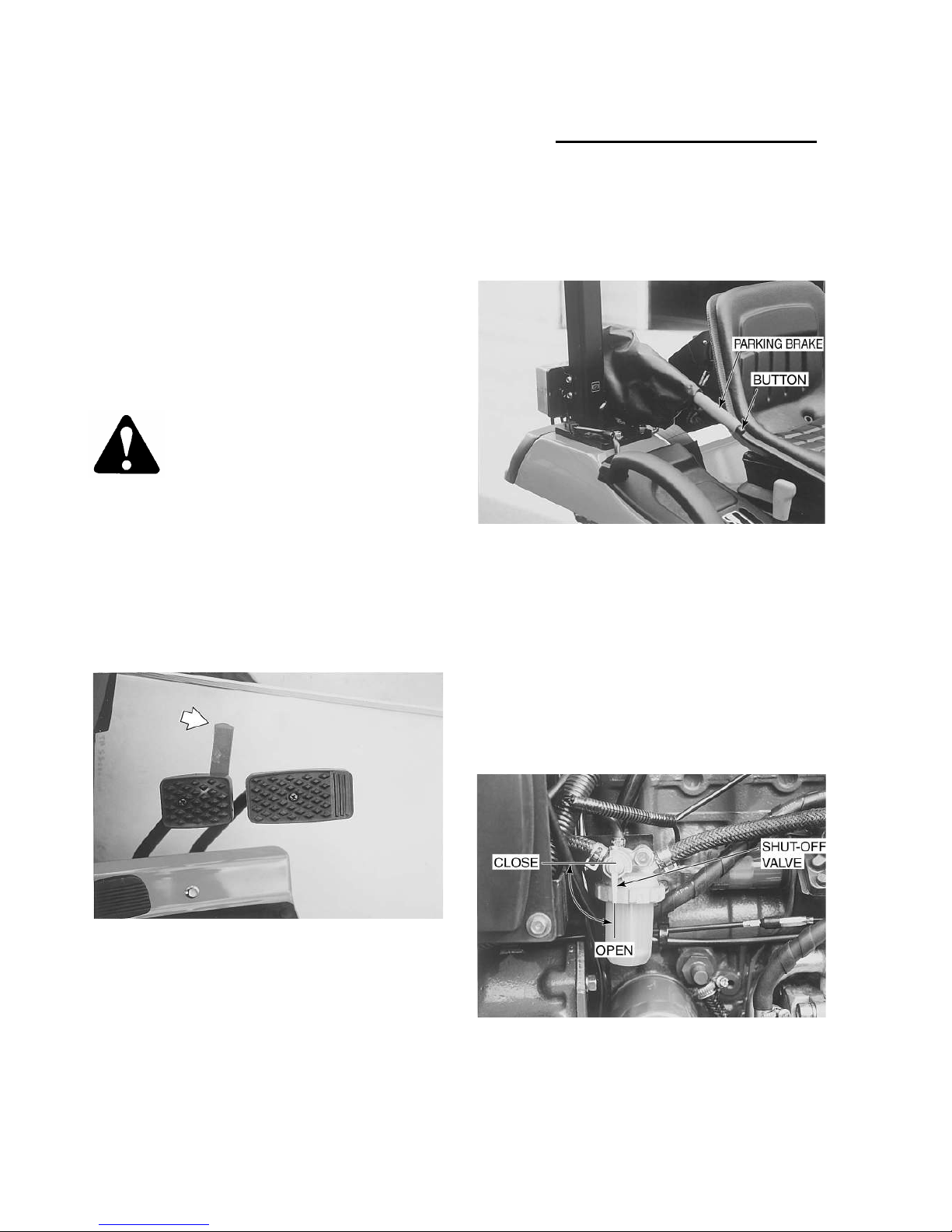

BRAKE PEDALS

The brake pedals are shown in Fi ure 15. The ri ht

brake pedal is used to brake the ri ht rear wheel.

The left pedal is used to brake the left rear wheel.

Depress both pedals simultaneously to stop the

tractor.

To assist in makin sharp turns at slow speed, de-

press the ri ht or left brake pedals as required.

WARNING:

::

:When operatin the tractor

at hi h speeds, never attempt to make

sharp turns by usin the brakes.

BRAKE PEDAL LOCK

The brake pedal lock, shown in Fi ure 15, is used

to secure the brake pedals to ether.

Lock the pedals to ether whenever the tractor is

operated at hi h speeds and at any time the tractor

is used on the hi hway.

Figure 15 - Brake Pedal Locking

PARKING BRAKE CONTROL

The parkin brake, shown in Fi ure 16, is used for

lockin the brake pedals in the applied position.

The parkin brake should be applied whenever the

tractor is parked.

Figure 16 - Parking Brake Control

FUEL SHUTOFF VALVE

The fuel shutoff valve is shown in Fi ure 17.

To open the fuel shutoff valve, move the handle so

that it points strai ht up and down.

To close the fuel shutoff valve, move the handle to

the horizontal position. Always shut off the valve

when servicin any portion of the fuel system.

Figure17 - Fuel Shutoff Valve

CONTROLS, INSTRUMENTS AND OPERATIONS

17

FOUR-WHEEL DRIVE

The shift lever for the four-wheel drive is located

on the ri ht-hand of the seat, Fi ure 18.

Full upward, the lever disen a es the four-wheel

drive(OFF). Full downward, it en a es the four-

wheel drive(ON).

Figure18 - Four - Wheel Drive Lever

To en a e the four-wheel drive, depress the clutch

pedal fully and move the four-wheel drive lever full

downward. To disen a e, move the lever full up-

ward.

IMPORTANT :

::

:The front wheel drive should be

used when additional traction is required while op-

eratin in loose soil, wet, slippery conditions or on

slopes.

For normal operation on firm soil, level hard sur-

faces and roadin the unit at hi h speeds, front

wheel drive should be disen a ed to maximize tire

and line life and fuel economy.

MECHANICAL TRANSMISSION MODELS

(9x3 TRANSMISSION)

TRANSMISSION GEARSHIFT LEVERS

The transmission main shift lever ① and ran e

selector lever ②, are shown in Fi ure 19.

A dia ram showin the shift pattern is on the bezel

around the earshift lever.

Three forward and one reverse speeds are pro-

vided for each of the two ran es. This provides a

total of 6 forward and 2 reverse speeds.

With a nine speed transmission the ran e lever

provides three ran es. This provides a total of 9

forward and 3 reverse speeds.

Ground speeds for the various ear ratios can be

found on pa e 56.

IMPORTANT:

::

:Do not attempt chan e ears while

the tractor is movin . The mechanical transmission

is not synchronized. The clutch pedal must be de-

pressed and tractor motion stopped to chan e ear

ratios with the main shift lever or the ran e shift

lever.

Figure 19 - Transmission Controls

SPEED RANGE MAIN

1 L 1

2 2

3 3

4 H 1

5 2

6 3

R

1

L R

R

2

H R

Other manuals for ST318

1

This manual suits for next models

2

Table of contents

Other Shibaura Tractor manuals