Shihlin electric PD301 User manual

PD301 Instruction Manual

Profibus DP communication expansion card

V 1.00

This instruction manual is only for the Shihlin communication expansion card Profibus DP. Please refer to

EN50170 for the detailed description on Profibus DP communication.

Content

1、OVERVIEW............................................................................................................................................ 1

1.1 Profibus standard............................................................................................................................. 1

1.2 PD-301 function ............................................................................................................................... 1

2、PRE-OPERATION INSTRUCTIONS..................................................................................................... 2

2.1 Delivery check.................................................................................................................................. 2

2.2 Specification..................................................................................................................................... 2

2.2.1 Inverter option specifications ................................................................................................. 2

2.2.2 Communication specification................................................................................................. 2

3、INSTALLATION ....................................................................................................................................... 3

3.1 Pre-installation instructions .............................................................................................................. 3

3.2 Node address setting ....................................................................................................................... 3

3.3 Node communication baud rate setting ........................................................................................... 3

4、WIRING.................................................................................................................................................... 4

4.1 DB9 connector .................................................................................................................................4

4.2 Wiring ............................................................................................................................................... 4

5、INVERTER SETTING.............................................................................................................................. 5

5.1 Parameter setting list ....................................................................................................................... 5

5.2 Operation mode setting ................................................................................................................... 5

5.3 Serial baud rate, communication protocol, frame format ................................................................ 6

5.4 Operation at communication error occurrence ................................................................................ 6

6、GSD FILE................................................................................................................................................. 7

6.1 GSD file description ......................................................................................................................... 7

6.2 User parameter setting ..................................................................................................................13

7、COMMUNICATION FUNCTION............................................................................................................14

7.1 Profidrive communication protocol ................................................................................................ 14

7.1.1 The control word and the status word ................................................................................. 14

7.1.2 Given values ........................................................................................................................14

7.1.3 Actual values .......................................................................................................................15

7.2 Communication information ...........................................................................................................15

7.2.1 Service Access Points (SAPs) ............................................................................................15

7.2.2 PPO message types ............................................................................................................19

7.2.3 Parameter handling .............................................................................................................20

7.2.4 Parameter transport example .............................................................................................. 22

7.3 PD-301 response time ................................................................................................................... 25

8、FAULT TRACING AND TROUBLESHOOTING....................................................................................25

8.1 LED indications .............................................................................................................................. 25

8.1.1 NET LED indication ............................................................................................................. 25

8.1.2 SP LED indication................................................................................................................25

8.2 INV indication error ........................................................................................................................25

9、PROFIBUS LINK SPECIFICATION ......................................................................................................26

Profibus COMMUNICATION EXPANSION CARD(PD-301) USER MANUAL ........................................... 27

OVERVIEW

1

1、OVERVIEW

This chapter contains a short description of the Profibus standard and PD-301 communication expansion

card information.

1.1 Profibus standard

Profibus is an open serial communication standard that enables data exchange between all kinds of

automation components. Profibus There are three main variations of PROFIBUS: Profibus FMS (Fieldbus

Message Specification), Profibus DP (Decentralized Periphery) and Profibus PA (Process Automation).

The physical transmission medium of the bus is a twisted pair cable (according to the RS-485 standard).

The maximum length of the bus cable is 100 to 1200 meters, depending on the selected transmission rate.

Up to 31 nodes can be connected to the same PROFIBUS network segment without the use of repeaters.

With repeaters, it is possible to connect 127 nodes (including repeaters and master station) to the

network.

In PROFIBUS communication, the master station (usually a PLC) polls the nodes which respond and take

the actions requested by the master. It is also possible to send a command to several nodes at the same

broadcast; in this case the nodes do not send a response message to the master. The PROFIBUS

protocol family is specified in the EN 50170 standard. For further information on PROFIBUS, refer to the

EN 50170 standards.

1.2 PD-301 function

PD-301 is an optional communication expansion device for Shihlin new type inverter which enables the

connection of Shihlin inverter to a PROFIBUS network. The PD301 is considered as a slave on the

PROFIBUS network. Through the PD301, it is possible to:

1、give control commands to the inverter(Start, Stop, Target frequency, Forward/Reverse rotation,

etc.)

2、Send the target frequency

3、Read status information and actual values from the inverter.

4、Read and change the inverter parameter values.

5、Reset at inverter fault.

PRE-OPERATION INSTRUCTIONS

2

2、PRE-OPERATION INSTRUCTIONS

Please read this chapter carefully before connecting PD-301 to ensure the normal use of PD-301.

2.1 Delivery check

Each PD-301 has been checked thoroughly before delivery, and is carefully packed to prevent any

mechanical damage. The package should contain the following objects:

A PD-301;

A simple installation guide;

Two screws.

Note: If the PD-301 is different from the objects above, please contact with the agent or distributor.

2.2 Specification

2.2.1 Inverter option specifications

Type Inverter inboard option

Number of node occupied

One inverter occupies one node

Connection cable For 12.0Mbps communication (compliant with EIA-485 (RS-485) standard)

2.2.2 Communication specification

Communication

speed

Wiring length 1200m maximum 9600bps, 19.2Kbps, 93.75Kbps

Wiring length 600m maximum 187.5Kbps

Wiring length 200m maximum 500Kbps, 1.5Mbps

Wiring length 100m maximum 3.0Mbps, 6.0Mbps, 12.0Mbps

INSTALLATION

3

3、INSTALLATION

3.1 Pre-installation instructions

Make sure that the input power of the inverter is off.

Note: With input power on, do not install or remove the plug-in option. Otherwise, the inverter and plug-in

option may be damaged.

3.2 Node address setting

Set the node address between "1 to 125" by using node address switches on the PD-301. For the setting

larger than 125, the address will be forced to transmitted to 125 by PD-301. When the address is 0,

Profibus slave station node address is invalid. The setting is reflected only when power turns on next time.

Please refer to the following table for address setting:

Switch number (1-8) Actual physical address

01111101~11111111

125

…… ……

00000010

2

00000001

1

00000000 0(invalid)

Note: The number is “0” when pressing the switch.

3.3 Node communication baud rate setting

PD-301 can auto detect the baud rate on Profibus without user’s setting.

WIRING

4

4、WIRING

4.1 DB9 connector

PD-301 adopts DB9 connector to connect to Profibus network, shown as the following:

6789

45 3 2 1

Refer to the table below for the definition of a connect.

Pin No.

Function name

Description and function

1

--

--

2 -- --

3

RXD/TXD-P

Profibus data +

4

CNTR-P

Profibus request signal

5 DGND 5V earth and data

reference earth

6 VP Positive voltage

7

--

--

8

RXD/TXD-N

Profibus data -

9

--

--

4.2 Wiring

(1) Use the network connection cable which supports 12.0Mbps communication.

Strip off the sheath of the Profibus communication dedicated cable and wind wires and shield cables

to use. If the length of the sheath pealed is too long, a short circuit may occur among neighboring

wires. If the length is too short, cables and shield cables might come off.

(2) Loosen the terminal screw and insert the cable into the terminal.

Tighten each cable with fixing screws to the recommended tightening torque.

Wire the stripped cable after twisting it to

prevent it from becoming loose.

In addition, do not solder it.

Use a bar type terminal as required.

INSTALLATION

5

Screw size Tightening torque Cable size Screwdriver

M2 0.22N⋅m-0.25N⋅m 0.3mm2-0.75mm2

Small flat-blade screwdriver (Tip thickness:

0.4mm /tip width: 2.5mm)

Note:

After wiring, wire offcuts must not be left in the inverter. They may cause an error, failure or malfunction.

5、INVERTER SETTING

5.1 Parameter setting list

After connecting PD-301 to the inverter correctly, PD-301 can’t work immediately. User should first

confirm the parameter value below.

Parameter

Number

Name Setting

range

Factory

value

Remark Setting

value

79 Operation mode

selection 0-8,99999 0 Valid

52

Number of

communication

retries

0-10 1 Valid

53 Communication

check time interval

0、9999、

0.1-999.8 9999

0-999.8: Use the set value for the

communication overtime test.

9999: No communication overtime test.

Valid

153 Communication

error handling 0、1 0 0: Warn and call to stop.

1: No warning and keep running. Valid

5.2 Operation mode setting

The inverter mounted with PD-301 has three operation modes.

(1) PU operation............Controls the inverter from the key of the operation panel mounted on the

inverter.

(2) External operation...Controls the inverter by switching on/off external signals connected to the

control circuit terminals of the inverter. (The inverter is factory-set to this

mode.)

(3) Network operation…Controls the inverter with instructions from the network via the communication

option.

INVERTER SETTING

6

Before switching the operation mode, check that:

(1) The inverter is at a stop.

(2) The P.79 Operation mode selection setting is correct.

(3) P.79 cannot be modified during communication.

5.3 Serial baud rate, communication protocol, frame format

PD-301 and the inverter adopt the Modbus format communication data. Communication speed is

9600bps, communication frame format is 1,8,N,2 (1 bit is the start bit, 8 data bits, no parity check and 2

stop bits). PD-301 is regarded as the inverter Modbus master station.

5.4 Operation at communication error occurrence

(1) Number of communication retries

P.52 is used to set the number from when a communication line error occurs until it is recognized as a

communication error. The value of P.52 determines the way of communication error displaying.

Parameter number

Name

Setting range

Initial value

52

Number of communication retries

0 ~10

1

(2) Communication check time interval

P.53 is used to set the communication check time between PD-301 and the inverter communication. After

exceeding the time, the inverter will do the corresponding processing.

Parameter number Name Setting range Initial value

53

Communication check time interval

0, 9999, 0.1-999.8

9999

(3) Communication error handling

P.153 is used to set the handing mode after detecting the error. If you want to stop the inverter after

communication error occurrence, you can set the value to 0.

Parameter number Name Setting range Initial value

153

Communication error handling

0、1

0

GSD FILE

7

6、GSD FILE

6.1 GSD file description

GSD file is designed to recognize the features and functions of Profibus-DP. GSD file is a text file which

can identify Profibus-DP device (master station or slave station). GSD file contains the necessary data

information on the standard DP master station equipped with a DP slave station. GSD file contains the

vendor information, support of communication transmission speed, timing information, support features

and accessories and available I/O signal. GSD file is the basic structure of the master station parameter

record. When editing this file, use a text editor. For installation instructions, refer to the instruction manual

of the Profibus-DP configuration software. The following is the GSD text used by PD-301 and the text

name is SEEC0D0F.GSD. User can copy the text to save it to .GSD file for use.

Also, user can download it from http://www.shihlin-elec.com/down.asp

==========================================================

; GSD-File for Shihlin INV Profibus DP Adapter

;

; Auto_Baud_supp, 12MBaud

;

;===========================================================

#Profibus_DP

ExtUserPrmData = 1 "dpv1 status 1"

Unsigned8 0 0-0

EndExtUserPrmData

ExtUserPrmData = 2 "dpv1 status 2"

Unsigned8 0 0-0

EndExtUserPrmData

ExtUserPrmData = 3 "dpv1 status 3"

Unsigned8 0 0-0

EndExtUserPrmData

ExtUserPrmData = 4 "Data Input 1"

GSD FILE

8

Unsigned16 0x1001 0-65535

EndExtUserPrmData

ExtUserPrmData = 5 "Data Input 2"

Unsigned16 0x1002 0-65535

EndExtUserPrmData

ExtUserPrmData = 6 "Data Input 3"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 7 "Data Input 4"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 8 "Data Output 1"

Unsigned16 0x1001 0-65535

EndExtUserPrmData

ExtUserPrmData = 9 "Data Output 2"

Unsigned16 0x1003 0-65535

EndExtUserPrmData

ExtUserPrmData = 10 "Data Output 3"

Unsigned16 0x1004 0-65535

EndExtUserPrmData

ExtUserPrmData = 11 "Data Output 4"

Unsigned16 0x1005 0-65535

EndExtUserPrmData

GSD FILE

9

ExtUserPrmData = 12 "Reserved 1"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 13 "Reserved 2"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 14 "Reserved 3"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 15 "Reserved 4"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 16 "Reserved 5"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

; Unit-Definition-List:

GSD_Revision = 1

Vendor_Name = "Shihlin Electronics"

Model_Name = "INV Profibus DP Adapter"

Revision = "Rev. 1"

Ident_Number = 0x0D0F

Protocol_Ident = 0 ; Profibus DP

Station_Type = 0 ; DP-slave

FMS_supp = 0

Hardware_Release = "V1.0"

Software_Release = "V1.0"

Redundancy = 0

GSD FILE

10

Repeater_Ctrl_Sig = 2

24V_Pins = 0

; Supported baudrates

9.6_supp = 1

19.2_supp = 1

45.45_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6 = 60

MaxTsdr_19.2 = 60

MaxTsdr_45.45 = 60

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

; slave specific values

OrderNumber = "Shihlin Profibus DP-301"

Slave_Family = 1@TdF@Shihlin INV Drivers

Implementation_Type = "VPC3+C"

Bitmap_Device = "SA3 DP"

Bitmap_SF = "SA3 DP"

Freeze_Mode_supp = 1

Sync_Mode_supp = 1

Fail_Safe = 1

GSD FILE

11

Auto_Baud_supp = 1

Set_Slave_Add_supp = 0

Min_Slave_Intervall = 6

; Module-Definitions:

Modular_Station = 1

Max_Module = 1

Modul_Offset = 0

Max_Input_Len = 32

Max_Output_Len = 32

Max_Data_Len = 64

Max_Diag_Data_Len = 16

WD_Base_ims_supp = 1

Publisher_supp = 0

;specify the user parameters:

Max_User_Prm_Data_Len = 29

Ext_User_Prm_Data_Const(0) = 0x00,\

0x00,\

0x00,\

0x10,0x01,\

0x10,0x02,\

0x00,0x00,\

0x00,0x00,\

0x10,0x01,\

0x10,0x03,\

0x10,0x04,\

0x10,0x05,\

0x00,0x00,\

0x00,0x00,\

0x00,0x00,\

0x00,0x00,\

0x00,0x00

GSD FILE

12

Module = "4 PKW, 2 PZD (PPO 1) " 0xF3,0xF1

EndModule

Module = "0 PKW, 2 PZD (PPO 3) " 0x00,0xF1

EndModule

Module = "4 PKW, 4 PZD " 0xF3,0xF3

EndModule

Module = "0 PKW, 4 PZD " 0x00,0xF3

EndModule

Ext_User_Prm_Data_Ref(0) = 1

Ext_User_Prm_Data_Ref(1) = 2

Ext_User_Prm_Data_Ref(2) = 3

Ext_User_Prm_Data_Ref(3) = 4

Ext_User_Prm_Data_Ref(5) = 5

Ext_User_Prm_Data_Ref(7) = 6

Ext_User_Prm_Data_Ref(9) = 7

Ext_User_Prm_Data_Ref(11) = 8

Ext_User_Prm_Data_Ref(13) = 9

Ext_User_Prm_Data_Ref(15) = 10

Ext_User_Prm_Data_Ref(17) = 11

Ext_User_Prm_Data_Ref(19) = 12

Ext_User_Prm_Data_Ref(21) = 13

Ext_User_Prm_Data_Ref(23) = 14

Ext_User_Prm_Data_Ref(25) = 15

Ext_User_Prm_Data_Ref(27) = 16

;============ END of GSD file for INV =====================

GSD FILE

13

6.2 User parameter setting

In GSD file, user parameter is used in Profibus network configuration. For the description, please refer to

the table below.

Item Name Description Factory setting

1 Data In 1 Modbus communication address, the first character of cyclic

output data PZD will be sent to this address. 0x1001

2 Data In 2 Modbus communication address, the second character of

cyclic output data PZD will be sent to this address. 0x1002

3 Data In 3 Reserve 0x0000

4 Data In 4 Reserve 0x0000

5 Data Out 1

Modbus communication address, PD-301 will monitor this

address and copy the return data to the first character of cyclic

input data PZD.

0x1001

6 Data Out 2

Modbus communication address, PD-301 will monitor this

address and copy the return data to the second character of

cyclic input data PZD.

0x1003

7 Data Out 3

Modbus communication address, if "4 PKW, 4 PZD" module is

selected, PD-301 will monitor this address and copy the return

data to the third character of cyclic input data PZD.

0x1004

8 Data Out 4

Modbus communication address, if "4 PKW, 4 PZD" module is

selected, PD-301 will monitor this address and copy the return

data to the fourth character of cyclic input data PZD.

0x1005

Parameter 1~8 sets the Modbus address for PD-301 monitoring the inverter parameter. When user sets

these values, the corresponding PPO will adopt this Modbus address to set the parameter values for

PD-301 monitoring the inverter. The detailed setting methods varied from different PC configure software.

The instruction here is not described for details.

COMMUNICATION FUNCTION

14

7、COMMUNICATION FUNCTION

7.1 Profidrive communication protocol

Communication protocol means the way of transmitting control order (control word, status word, given

value and actual value) between the master and the slave. PD-301 adopts Profidrive dpv0 protocol. The

following introduces the control word, status word, given value and actual value in Profidrive

communication protocol. PD-301 doesn’t adopt the control word and status word stated in Profidrive. It

gives a detailed description on the status word and its structure in PD-301.

7.1.1 The control word and the status word

The control word is the principal means for the master station controlling the slave station from a fieldbus

system. It is sent by the fieldbus master station to the inverter, the PD-301 module acting as a gateway.

The inverter switches between its states according to the bit-coded instructions on the control word, and

returns status information to the master in the status word. The structure of the control word and the

status word adopted by PD-301 is shown as the figure below, and the corresponding inverter Modbus

address is: 0x1001.

Control word STW: Status word ZSW:

b0

Reserve

b0

In rotation

b1

Forward rotation

b1

Forward rotation

b2

Reverse rotation

b2

Reverse rotation

b3 Low speed b3 Frequency arrival

b4

Medium speed

b4

Over load

b5 High speed b5 End of parameter restored to

default value

b6

The second function

b6

Frequency detection

b7 Inverter sudden stop b7 Abnormal occurrence

b15-b8

Reserve

b15-b12

Reserve

7.1.2 Given values

Shihlin inverter can receive control information from multiple sources including external terminal analog

signal given, PU panel given and communication module given, etc. For Profibus controlling the inverter,

PD-301 should be defined as given controlling information source. At this point, Profibus bus passing

speed given value will be mapped to the corresponding Modbus communication address, the value is

0x1002.

COMMUNICATION FUNCTION

15

7.1.3 Actual values

Actual Values are words containing information on the operation of the inverter. The functions to be

monitored are selected by a PC network with configuration software. PC gets the present inverter

operation status through reading the value. The monitoring Modbus address is 0x1003.

7.2 Communication information

The PD-301 supports the Profibus DP (DP-V0) protocol according to IEC 61784 and EN 50170 standard.

Profibus DP-V0/DP-V1 is a distributed I/O system which enables the master to use a large number of

peripheral modules and field devices. The data transfer is mainly cyclic: the master reads the input

information from the slaves and sends the output information back to the slaves. The PD-301 uses

so-called PPO (Parameter/Process Data Objects, i.e. parameter / process data object) in cyclic

communication, supporting standard message1, message2. It also adopts custom expansion message

structure.

7.2.1 Service Access Points (SAPs)

The services of the Profibus data link layer (Layer 2) are used by Profibus-DP through Service Access

Points (SAPs). Precisely defined functions are assigned to individual SAP. For further information on

Service Access Points, please refer to the EN 50170 and IEC 61784 standards. The following introduces

SAP in Profibus.

SAP No. Short name Name

Default SAP

Data_Exch

Transfer Input and Output Data

SAP 55 Set_Slave_Address Set Slave Address (Not supported)

SAP 56

Read_Inputs

Read Out Inputs

SAP 57 Read_Outputs Read Out outputs

SAP 58

Global_Control

Global Control Service

SAP 59 Get_Cfg Get Configuration Data

SAP 60

Slave_Diag

Read Slave Diagnostic Information

SAP 61

Set_Prm

Send Parameter Data

SAP 62

Chk_Cfg

Check Configuration Data

COMMUNICATION FUNCTION

16

SD2 is usually used to DP communication in Profibus. The structure of a piece of SD2 message is as the

table below:

DP header

DP tailer

SD LE LEr SD DA SA FC *DSAP *SSAP DU FCS ED

68h

x

x

68h

xx

xx

x

xx

xx

x…

xx

16h

SD = Start Delimiter

LE = Length

LEr = Length Repeated

DA = Destination Address

SA = Source Address

FC = Function Code

*DSAP = Destination Service Access Point

*SSAP = Source Service Access Point

DU = Data Unit for DP services

FCS = Frame Checking Sequence

ED = End Delimiter

* For SAP 0, no item.

7.2.1.1 SAP 0 (Data_Exchange)

Profibus allows the master to send output data to a slave station and to simultaneously request input data

from the same station.

Outp_Data (Output Data)

DU Length: 4 to 28 (depending on the selected PPO information / standard message type)

Inp_Data (Input Data)

DU Length: 4 to 28 (depending on the selected PPO information / standard message type)

Note: Except SAP 0, any data can use “Read_Inputs” (SAP 56) and “Read_Outputs” (SAP 57) message

to read I/O data on any slave at any time. Besides DSAP and SSAP, these messages are the same as

cyclic data exchange messages. In these messages, MSB of DA and SA is set to 1 to show the

DSAP/SSAP in message header.

COMMUNICATION FUNCTION

17

7.2.1.2 SAP 58 (Global_Control)

This SAP is used to send special command to single slave, a group of special slaves or send once to all

slaves (broadcast).

Global_Control data type: Octet String consists of 8 octets / Length: 2

DU (Byte)

Description

0

GC_Command

MSB

0

0

X1

X2

X3

X4

X5

0

LSB

0: Reserve

X1: Clear data(0 = Not clear output, 1 = clear output)

X2-x3: Unfreeze - freeze (00 = No function; 10 = Activate; x1 = Forbid)

X4-x5: Sync(00 = No function; 10 = Activate; x1 = Forbid)

1 Group_Select

0 to 255.This value should correspond to the Group Identification of SAP 61 (DU byte 6).

7.2.1.3 SAP 61 (Set_Prm)

This SAP is used to set the parameters of the slave.

Byte Character Function

7

6

5

4

3

2

1

0

0 Lock

Req

Unlo

Req

Sync

Req

Free

Req

WD

on

Res Res Res Station status

1

WD_Fact_1

2 WD_Fact_2

3

MinTSDR

4 Ident_Number_High

5

Ident_Number_Low

6

Group_Ident

7 0 0 0 0 0 0 0 0 dpv1 status 1

8

0

0

0

0

0

0

0

0

dpv1 status 2

9 0 0 0 0 0 0 0 0 dpv1 status 3

10-243

User_Prm_Data

The extended parameter data bytes are configured via the PROFIBUS network configuration tool. The

functions are defined in the GSD file.

Table of contents

Popular Computer Hardware manuals by other brands

Intel

Intel PXA27 Series Design guide

Maple Systems

Maple Systems iR-ETN Series Installation instruction

Samoa

Samoa U-net 383300 Parts and technical service guide

Panasonic

Panasonic Future Electronics BULLSEYE quick start guide

RCA

RCA COSMAC user manual

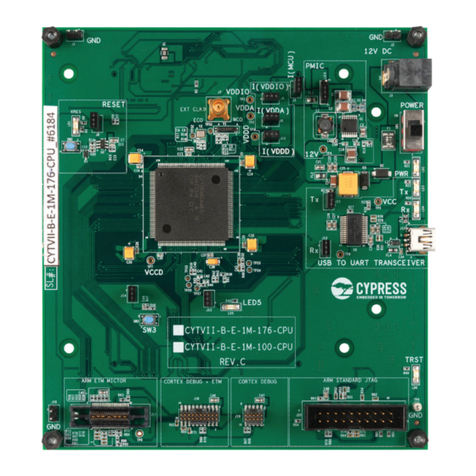

Cypress Semiconductor

Cypress Semiconductor CY62138FV30 Specification sheet

Noctua

Noctua NH-U12S chromax.black installation manual

TECSYSTEM

TECSYSTEM T154 Series manual

Automationdirect.com

Automationdirect.com Productivity 1000 P1-540 manual

Digital Equipment

Digital Equipment VAX 4000 Series Installation

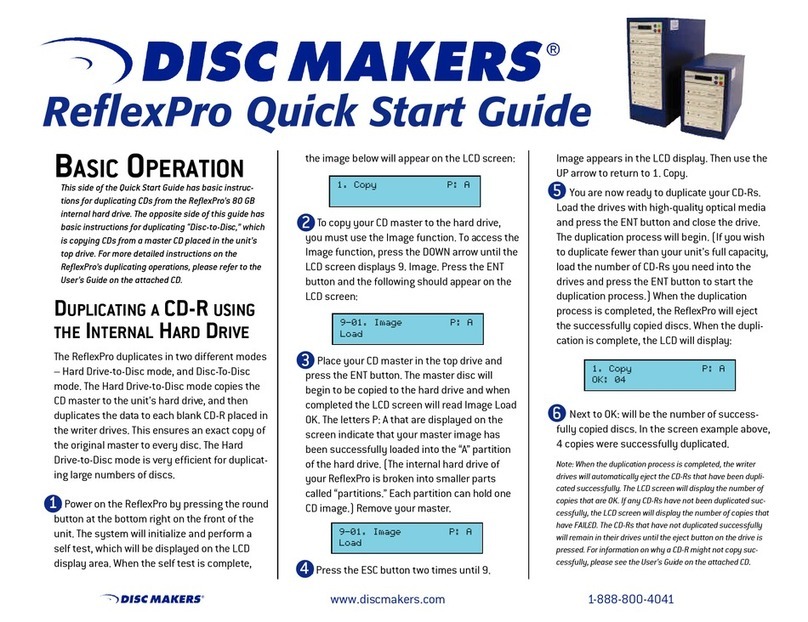

Disc Makers

Disc Makers ReflexPro4 quick start guide

Infineon

Infineon TRAVEO II quick start guide