Shimaden SD16A Series User manual

MSD16A-E01-A

May. 2006

Digital Indicator

SD16A Series

Instruction Manual

Please ensure that this instruction manual is given to the final user of the

instrument.

Preface

Thank you for purchasing Shimaden products.

Please check that the delivered product is the correct item that you

ordered.

This instruction manual is meant for those who will be involved in the wiring,

installation, operation and routine maintenance of the SD16A series, and

describes about cautions, mounting, wiring, functions, and operation.

Please observe the contents, and always keep the manual close at hand

when handling this instrument.

The following headings give a description of matters requiring user

attention concerning safety, damage to machines and equipment,

additional explanations and commentaries are described under the

following headings.

WARNING

Items concerning matters that may lead to

an accident producing human injury or

death, if the warning is not observed.

CAUTION

Items concerning matters that may lead to

an accident producing damage to machines

or equipment, if the caution is neglected.

Note

Note

Additional explanations and commentaries.

Contents

Preface..................................................................................................... 1

Contents................................................................................................... 1

Safety Cautions........................................................................................ 1

1. Introduction .......................................................................................... 2

1-1. Check before use......................................................................... 2

1-2. Notes for use ............................................................................... 2

2. Installation and wiring........................................................................... 2

2-1. Installation site (environmental conditions)................................... 2

2-2. Mounting...................................................................................... 2

2-3. External dimensions and panel cutout ......................................... 2

2-4. Wiring .......................................................................................... 2

2-5. Terminal arrangement .................................................................. 3

3. Names and functions for front panel..................................................... 3

3-1. Names ......................................................................................... 3

3-2. Functions ..................................................................................... 3

4. Measuring range code table ................................................................. 3

5. Error messages.................................................................................... 3

6. Instruction for each screen ................................................................... 4

6-1. Screen sequences ....................................................................... 4

6-2. Power ON Screen Group............................................................. 5

6-3. Mode 0 Screen Group.................................................................. 5

6-4. Mode 1 Screen Group.................................................................. 5

7. Optional features overview ................................................................... 7

7-1. Alarm output ................................................................................ 7

7-2. Analog output............................................................................... 7

7-3. Sensor power supply ................................................................... 7

8. Specification......................................................................................... 8

Safety Cautions

WARNING

•The SD16A Series indicator is designed to indicate temperature,

humidity and other physical data for general industrial equipment. Do

not apply this instrument to other objects in a way that may cause

grave effects on human safety.

•In using this product, be certain to house it, for example, in a control

panel, so that the terminals cannot come into contact with personnel.

•Do not take this instrument out of its case or put your hand or any

conductor inside the case. Such conduct may lead to an accident that

endangers life or causes serious injury due to electric shock.

CAUTION

•To avoid damage to the connected equipment, facilities or the product

itself due to a fault of the product, safety countermeasure must be

taken before usage, such as proper installation of the fuse and the

overheating protection device.

•An alert symbol is printed on the terminal nameplate attached to

the case. It warns not to touch the electrical charging parts when the

power is being supplied, so as to avoid the risk of electrical shock.

•Install a switch or breaker on the external source power circuit

connecting to the source power terminal as a means to shut down the

power.

The switch or breaker should be installed adjacent to the instrument

in a position that allows the operator easy access.

•Regarding the fuse:

Since this instrument has no built-in fuse, make sure to install a fuse

in the electric circuit connecting to the source power terminal.

Install the fuse in a position between the switch or breaker, and the

instrument and attach it to the L side of the source power terminal.

Fuse Rating: 250V AC 1.0A/Time-lag (T) or Medium Time-lag (M)

•The load of voltage and current to be applied to the output terminal

(analog output) and the alarm terminal must be within the rated

range. If the range is exceeded, the instrument will overheat causing

the risk of the instrument being damaged and its life reduced.

As for the rating, please refer to "8. Specification."

The unit connected to the output terminal should conform to the

requirements of IEC61010-1.

•Do not apply over-rated voltage or current to the input terminal. That

will cause the risk of the instrument being damaged and its life

reduced.

As for the rating, please refer to "8. Specification."

In case the input type is voltage (mV or V) or current (4 ~ 20mA), the

unit connected to the output terminal should conform to the

requirements of IEC61010-1.

•Take care to prevent metal or other foreign matter from obstructing

the ventilating hole for heat radiation. It will cause damage to the

instrument and may even result in fire.

•Do not block the ventilating hole. Also avoid dust accumulation. Any

rise in temperature or insulation failure may result in a risk of the

instrument being damaged and its life reduced. As for the clearance

space for installing the instrument, refer to "2-3 External dimensions

and panel cutout."

•Repeating withstanding tests on voltage, noise, surging may lead to

the deterioration of the instrument, so please be careful.

•Strictly refrain from remodeling and using the instrument improperly.

Copyright © SHIMADEN CO., LTD. All rights reserved.

1

SD16A Instruction Manual

1. Introduction Note The environmental conditions fall under installation category

II of IEC 60664, and the pollution degree is "2".

1-1. Check before use

2-2. Mounting

Although the instrument passes thorough quality checks before shipment,

when the instrument is delivered, please confirm the type code number,

check the external conditions and the list of accessories to make sure that

there is no apparent damage or discrepancy.

1 Cut a fitting hole by referring to the panel cutout dimensions in section

2-3. The applicable thickness of the panel is 1.0 ~ 4.0mm.

2 Insert the indicator into the hole from the front of the panel, as it has

catching claws to fix it in position.

Confirmation of the type code

Note As the SD16A is a panel installation type indicator, use it by

mounting on a panel.

Check the type code printed on the label on the packing case with the

following table to confirm that the delivered goods meet your order.

Item Code Specifications

1. Series SD16A- 48 × 96 DIN size Digital Indicator

8

Universal-input

Thermocouple

R.T.D. (Pt100, JPt100)

Voltage (Input impedance

500 kΩmin.)

0~10mV DC

0~5, 1~5, 0~10V DC

Refer to "4. Measuring

range code table" for

details.

In case voltage input,

scaling/reverse scaling is

available.

(Note 2)

2. Input (Note 1)

4

Current 4~20mA DC

An external receiving resistor is

provided.

Scaling/reverse scaling

available (Note 2)

90- 100~240V AC ± 10% (50/60Hz)

3. Power supply

08- 24V AC (50/60Hz) /DC ±10%

0 None

4. Alarm output (option)

1

Separate setting/separate output 2-point (a-contact,

"COM" used commonly)

Contact rating 240V AC 1.5A/resistive load

0 None

3 0~10mV DC Output resistance 10Ω

4 4~20mA DC Load resistance 300Ω

max.

6 0~10V DC Load current 1mA max.

Scaling/reverse

scaling available

(Within

measuring

range)

5. Analog output

or sensor power supply

(option) (Note 3)

8 Sensor power supply 24V±3V DC 25mA max.

0 None

5 RS-485

6. Communication function

(option)

7 RS-232C

0 Without

7. Remarks

9 With

2-3. External dimensions and panel cutout

External dimensions

Unit: mm

Panel cutout

Note 1 The instrument supports full universal input; however please select one of two

codes, as an external receiving resistor (250Ω) is supplied for current input. If

no external receiving resistor is required, a code 8 specification product can

be used for current input.

Note 2 Scaling range: -1999 ~ 9999 Unit

Span: 10 ~ 10000 Unit

Note 3 When the 08 power supply code (24V AC/DC) is selected, the sensor power

supply cannot be selected.

Accessory list check

•Unit label seal 1 sheet

•Instruction Manual 1 copy

•Communication Interface Manual (in case the optional communication

option is selected) 1 copy

Note

e-mail for any problems about the product, accessories or

related items.

1-2. Notes for use

•Avoid operating the front panel keys with hard or sharp objects. Lightly

touch the operating keys with your fingertips for operation.

•When cleaning, do not use a solvent such as a thinner. Wipe the

instrument with a dry cloth lightly.

2. Installation and wiring

2-1. Installation site (environmental conditions)

CAUTION

Do not install the instrument in such environmental conditions as those

listed below. Otherwise, damage may be caused to the instrument, even

resulting in fire.

•Flammable or corrosive gas, oil soot or dust that deteriorates the

insulation is generated or abundant.

•Ambient temperature is below −10°C or above 50°C.

•Ambient humidity is higher than 90% RH, or below dew point.

•Strong vibrations or impacts are generated or transferred.

•High-voltage power lines exist in the neighborhood, or induction

interference.

•Exposure to direct sunlight or dew drops.

•The elevation is above 2000m.

Unit: mm

2-4. Wiring

WARNING

•When wiring the unit, be sure to cut the power supply OFF, or there

will be a risk of electric shock.

•Make sure the protective conductor terminal ( ) is grounded.

Otherwise, a serious electric shock may result.

•After completing the wiring, do not touch the terminals and electrically

charged parts while the power is ON.

•Make wiring according to the layout in "2-5. Terminal arrangement."

•Use ring tongue terminals of 7mm or narrower width to meet M3.5

screws.

•In case of thermocouple input, use a compensation wire with the type

of thermocouple selected. The external resistance should be100Ωor

less.

•In case of R.T.D. input, the resistance value per lead wire should be 5Ω

or less, and all three wires should have the same resistance value.

•Avoid arranging the input signal line to pass through the same conduit

or duct with high-voltage power lines.

•The shield wire (one-point grounding) is effective to eliminate

electrostatic induction noises.

•An effective way to eliminate the magnetic induction noises is to twist

the input wire in short and equal intervals.

•For the source power connection, use a wire or cable having a

cross-section of 1mm

2

or larger, and a performance capacity equivalent

to 600V vinyl insulation wire.

•The grounding wire should have a cross-section of 2mm

2

or larger, and

the grounding work should ensure a ground resistance of 100Ωor less.

•The symbol expresses the functional earth terminal. Please connect

it to the ground as much as possible to avoid the adverse impact from

noise.

•Screw the terminal connection securely.

Tightening torque 1.1 · Nm (11kgf · cm)

•Noise filter

In case the instruments are affected by the power supply noise, install a

noise filter to avoid operational errors.

Mount the noise filter on the grounded panel and connect the noise

filter output and the power supply terminal of the indicator with the

minimum possible distance.

Make wire with the mini-

mum possible distance

100~200V AC

100~200V AC

50/60 Hz

Noise filter SD16A

Grounding

Recommended noise filter:

ZMB2203-13 from TDK

2

SD16A Instruction Manual

2-5. Terminal arrangement

Note Do not connect other than the specified input

type to terminal.

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

11 12 13

COM AL1 AL2

SG

SG SD

RS-232C

RS-485

RD

Com

15 16 17 1918

Power supply

100~

240V AC

50/60Hz

LN LN

123

24V

AC/DC

123

Inputs

TC

67 667

RTD Voltage (V) Voltage (mV) Current (mA)

AB B

697567 5 7

1918

3. Names and functions for front panel

3-1. Names

Front panel

3-2. Functions

[1] Monitoring LEDs

•AL1 (Alarm 1) output monitoring LED (red)

The LED lights when the assigned alarm is ON.

•AL2 (Alarm 2) output monitoring LED (red)

The LED lights when the assigned alarm is ON.

•SET (parameter setting) monitoring LED (green)

The LED lights when the screen displayed is not the basic screen (0-0).

•COM (communication) monitoring LED (green)

The LED lights when the communication mode is on remote control.

[2] LED display for measured value (red)

•The current PV value is displayed on the basic screen (0-0).

•The type of parameters is displayed on each parameter display screen.

•The set value is displayed on each parameter setting screen.

[3] Key switches

Parameter key

•On a display screen, shifts the screen to the next.

•Switches from Mode 0 screen group/Mode 1 screen

group to Mode 1 screen group/Mode 0 screen group.

By pressing this key for two seconds or longer on

screen 0-0 or screen 1-0, shifts to the screen 1-0 or to

the screen 0-0 respectively.

Down key

•On a setting screen, decrements the value. The last

digit decimal point blinks until the value is registered by

pressing the Entry key.

Up key

•On a setting screen, increments the value. The last digit

decimal point blinks until the value is registered by

pressing the Entry key.

Entry key

•On a setting screen, registers the value that is modified

by the Up/Down key. The last digit of the decimal point

blinks until this registration by pressing the Entry key.

•Shifts between a display screen and the setting screen.

In this case, the light of the last digit of decimal point

goes out.

4. Measuring range code table

Input type Code Measuring range

(°C)

Measuring range

(°F)

Note

B01 0 ~ 1800 0 ~ 3300 Note 2

R02 0 ~ 1700 0 ~ 3100

S03 0 ~ 1700 0 ~ 3100

04 -199.9 ~ 800.0 -300 ~ 1500

K

05 0 ~ 1200 0 ~ 2200

E06 0 ~ 700 0 ~ 1300

J07 0 ~ 600 0 ~ 1100

T08 -199.9 ~ 300.0 -300 ~ 600 Note 3

N09 0 ~ 1300 0 ~ 2300

U10 -199.9 ~ 300.0 -300 ~ 600 Note 3

L11 0 ~ 600 0 ~ 1100

Thermocouple

WRe5-26 12 0 ~ 2300 0 ~ 4200

31 -199.9 ~ 600.0 -300 ~ 1100 Note 4

Pt

32 -100.0 ~ 100.0 -150.0 ~ 200.0

33 -199.9 ~ 500.0 -300 ~ 1000 Note 4

R.T.D

JPt

34 -100.0 ~ 100.0 -150.0 ~ 200.0

0 ~ 10mV 71

0 ~ 5V 81

1 ~ 5V 82

Universal Input (Note 1)

Voltage

0 ~ 10V 83

Current 4 ~ 20mA 95

0.0 ~ 100.0 Scaling available

Scaling range : -1999 ~ 9999 Unit

Span : 10 ~ 10000 Unit

Note 1 In case universal input type is selected, K (Code 05, 0 ~ 1200°C) is set at

factory default.

Note 2 The accuracy of 400°C or below of thermocouple B is ±5%FS.

Note 3 The accuracy of thermocouple T or U is ±0.5%FS at above -100°C and

0°C or below, and ±1%FS at -100°C or below.

Note 4 In case of Pt (Code 31) or JPt (Code 33), scale over occurs at -240.0°C

(-400°F).

[1] Monitoring LEDs

[2] LED display

for measured value [3] Key switches

5. Error messages

One of the following error messages is displayed on the basic screen (0-0):

When the thermocouple or A of R.T.D. is burnt out. Also

indicated when the PV value exceeds the higher-limit of

the measuring range by about 10%

When the B of R.T.D. (terminal No.7) is burnt out. When

the PV value is below the lower-limit of the measuring

range by about 10%, for such a reason as the reverse

polarity of the input wiring type.

When the cold junction (CJ) is abnormal on the higher

side in the thermocouple input.

When the cold junction (CJ) is abnormal on the lower

side in the thermocouple input.

When the B of the R.T.D. (terminal No.9) is burnt out, or

two or more wires of A, B, B are broken.

3

SD16A Instruction Manual

6. Instruction for each screen

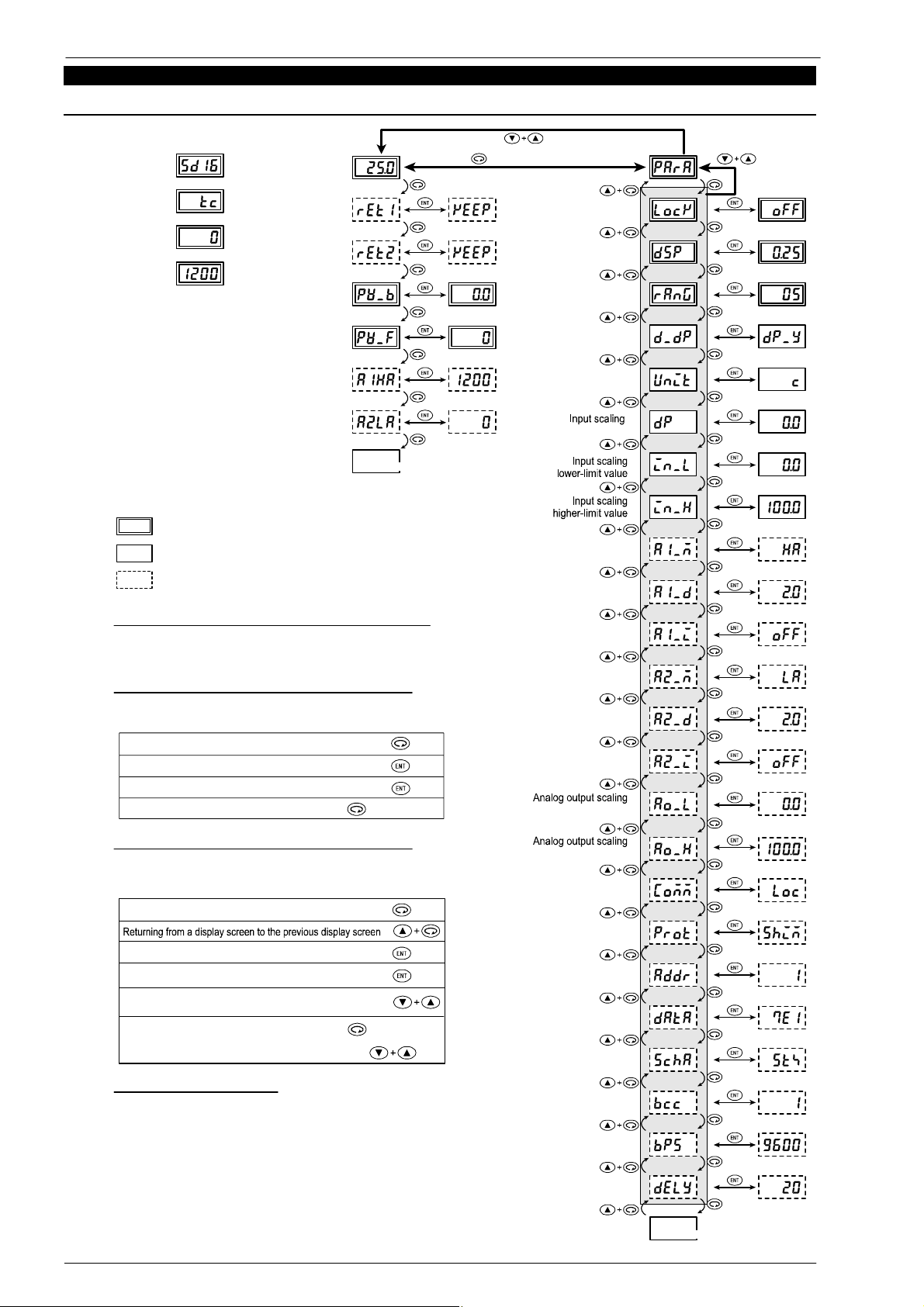

6-1. Screen sequences

1-4

1-1

0-0 1-0

1-17

1-18

1-19

1-20

1-21

1-22

1-23

1-24

1-2

1-3

1-5

1-6

1-7

1-8

1-9

1-10

1-11

1-12

1-13

1-14

1-15

1-16

0-1

0-2

0-3

0-4

0-5

0-6

0-0

1-0

to

Basic screen

to

1-0 screen

Basic screen

Model name

Input type

Measuring range

lower-limit value

Measuring range

higher-limit value

PV filter

Alarm 2

latching release

Alarm 1

latching release

Alarm 1

setting value

Alarm 2

setting value

PV bias

lower-limit value

higher-limit value

Communication

mode

Communication

protocol

Communication

address

Communication

data format

Communication

speed

Communication

delay

Communication

start character

Communication

BCC operation

Alarm 1

code

Alarm 1

hysterisis

Alarm 1

inhibit

Alarm 2

code

Alarm 2

hysterisis

Alarm 2

inhibit

Mode 0

Screen Group Mode 1

Screen Group

Power ON

Screen Group

For approx. two secs

Key lock

Display

update cycle

Measuring range

Decimal places

Input unit

decimal places

Screens always displayed.

Screens displayed or not displayed

depending on some conditions.

Screens displayed when any option is added.

Each screen is classified by the screen frame as follows.

Key operations on screens of Power ON Screen Group

No key operation is required as screens alter automatically

within Power ON Screen Group.

Key operations on screens of Mode 0 Screen Group

Mode 0 Screen Group consists of screens that are often used under

control operation. The commonly-used key operations are as follows:

Shifting a display screen to the next display screen

Shifting a display screen to the setting screen

Returning from a setting screen to the display screen

Shifting from 0-0 screen to 1-0 screen

approx. 2 secs.

Key operations on screens of Mode 1 Screen Group

Mode 1 Screen Group consists of screens that are used less often

than Mode 0 screens, and are required according to the input type or

controllability. The commonly-used key operations are as follows:

Shifting a display screen to the next display screen

Shifting a display screen to the setting screen

Returning from a setting screen to the display screen

Returning from any display screen of Mode 1

to 1-0 screen

Returning from 1-0 screen to 0-0 screen

Auto return feature

If no key operation is executed on any screen but the Basic screen

(0-0) for three minutes or more, the screen returns to

the Basic screen automatically.

approx. 2 secs.

or

4

SD16A Instruction Manual

5

6-2. Power ON Screen Group

The following information is displayed automatically.

Model name

The model name (SD16A) is displayed.

Input type

The input type is displayed.

The type is either TC (thermocouple), Pt (R.T.D.),

mV, V, or mA.

Measuring range, lower-limit value

The lower-limit value of the input is displayed.

Measuring range, higher-limit value

The higher-limit value of input is displayed.

6-3. Mode 0 Screen Group

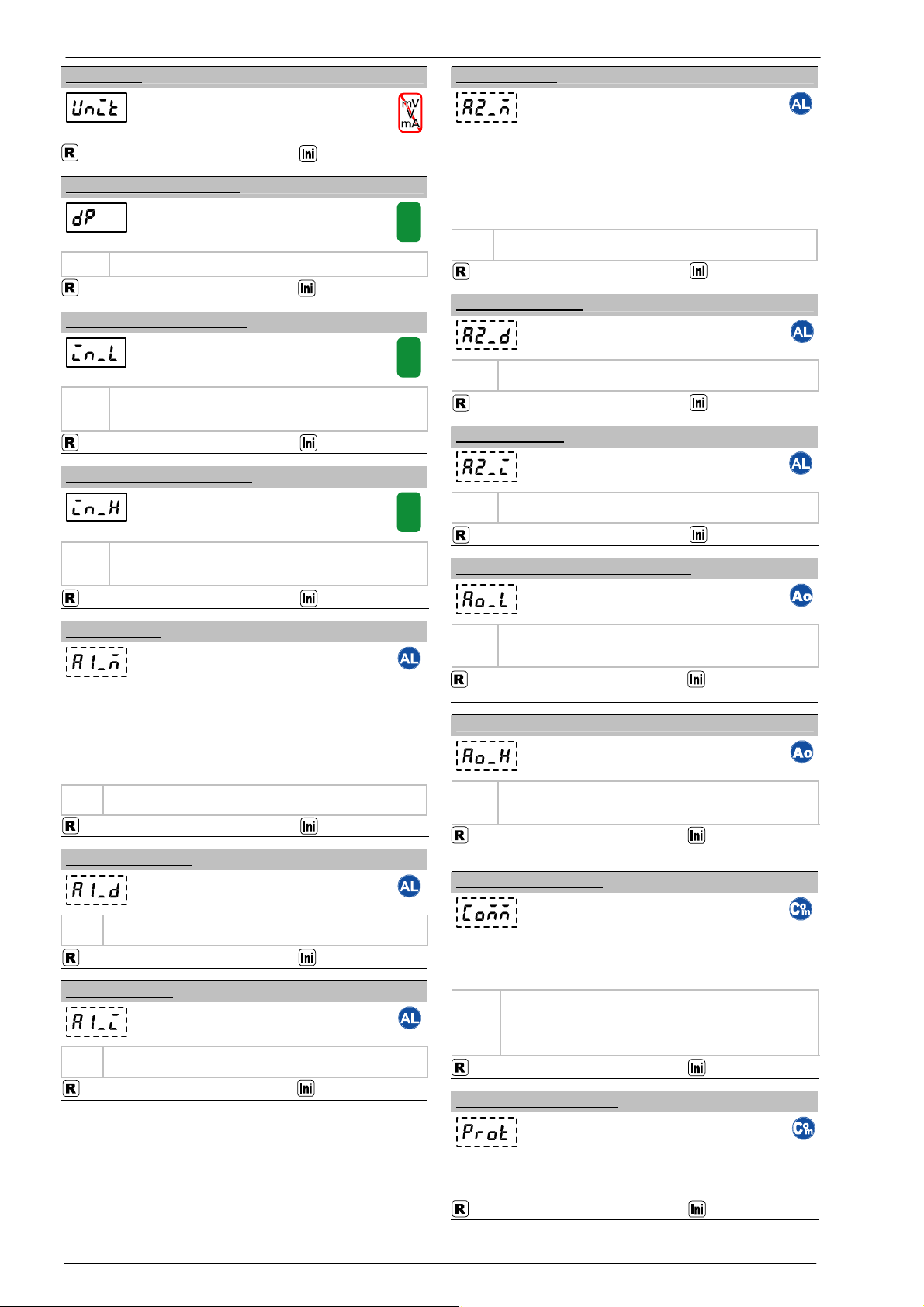

The following informational icons are used from this sub-section.

Setting/display is available

when the alarm option is

supported.

Setting/display is available when

the analog output option is

supported.

Setting/display is available

when the communication option

is supported.

Setting/display is available

when the voltage or current

input is specified.

Setting/display is not available

when the voltage or current input

is specified.

Setting range

Initial value

0-0 Basic screen

PV (measured value) is displayed.

Note

In case the Alarm 1 or 2 signal is output with the latching feature, use

key on this screen to release the Alarm 1 latching, or use

key on this screen to release the Alarm 2 latching.

0-1 Alarm 1 latching release

This screen is displayed when Alarm 1 is in the

latching state, and is used for releasing it from that

state.

This screen is displayed in case Alarm 1 code (1-1)

is selected from the one with latching, and when the

instrument is in the latching state. Set the parameter

RSET to stop the alarm output.

As for the latching feature, refer to "Latching feature"

of "7-1. Alarm output."

KEEP : Alarm output is ON with latching feature.

RSET : Releasing the alarm with latching feature.

Note The Alarm 1 output signal with latching feature can also be set to OFF by

pressing

key on the Basic screen (0-0).

KEEP, RSET KEEP

0-2 Alarm 2 latching release

This screen is displayed when Alarm 2 is in the

latching state, and is used for releasing it from that

state.

This screen is displayed in case Alarm 2 code (1-12)

is selected from the one with latching, and when the

instrument is in the latching state. Set the parameter

at RSET to stop the alarm output.

As for the latching feature, refer to "Latching feature"

of "7-1. Alarm output."

KEEP : Alarm output is ON with latching feature.

RSET : Releasing the alarm with latching feature.

Note The Alarm 2 output signal with latching feature can also be set to OFF by

pressing

key on the Basic screen (0-0).

KEEP, RSET KEEP

0-3 PV bias

The PV bias value is displayed or can be set.

The value is used for compensating input errors by

the sensor, etc. When the value is set, the

compensated PV is displayed.

-1999 ~ 2000 Unit 0 Unit

0-4 PV filter

The PV filter time is displayed or can be set.

The value is helpful for reducing the adverse effect

of noise from a PV input.

Note The PV filtering is temporarily disabled when the instrument is recovering

from scale over.

0 ~ 100 seconds

100

0-5 Alarm1 setting value

Alarm 1 setting value is displayed or can be set.

One of the following Alarm 1 action types (1-9) is displayed on the screen.

A1HA :Higher-limit absolute value

A1LA :Lower-limit absolute value

A1H.A. :Higher-limit absolute value (with latching)

A1L.A. :Lower-limit absolute value (with latching)

Note This screen is not displayed when non or So (scale over) is selected on

Alarm 1 code screen (1-9).

Measuring range lower-limit to higher-limit value

Higher-limit value

0-6 Alarm 2 setting value

Alarm 2 setting value is displayed or can be set.

One of the following Alarm 2 action types (1-12) is displayed on the screen.

A1HA :Higher-limit absolute value

A1LA :Lower-limit absolute value

A1H.A. :Higher-limit absolute value (with latching)

A1L.A. :Lower-limit absolute value (with latching)

Note This screen is not displayed when non or So (scale over) is selected on Alarm

2 code screen (1-12).

Measuring range lower-limit to higher-limit value

Lower-limit value

6-4. Mode 1 Screen Group

1-0 Mode 1 initial screen

This is the heading screen of Mode 1 screens.

1-1 Key lock

Key lock status is displayed or can be set.

When the key lock is set to ON, parameter value

modification is not allowed.

OFF, ON

OFF

1-2 Display update cycle

The display update cycle of PV is displayed or can

be set.

0.25 ~ 5.00 secs. Set by 0.25 secs.

0.25

1-3 Measuring range

The input type is displayed or can be set. Refer to

"4. Measuring range code table" for input type

details.

01 ~ 12, 31 ~ 34, 71, 81 ~ 83, 95

05 (K, TC 0 ~ 1200°C)

1-4 Decimal places

The decimal place with/without status is

displayed or can be set.

dp_y : with decimal places

dp_n : without decimal places

Note

In case the measuring range that doesn’t support decimal places is specified,

this screen is not displayed.

Once this setting is modified from "with decimal places" to "without decimal

places", the values of input scaling, analog output scaling, alarm setting,

alarm hysterisis, and PV bias are rounded to the nearest integer. Then that

setting is modified to "with decimal places" again, the value after the decimal

places remains 0.

dp_y, dp_n dp_y

mV

V

mA

SD16A Instruction Manual

1-5 Input unit 1-12 Alarm

The input unit is displayed or can be set.

°C

°C, °F

1-6 Input sca acesling decimal pl

The scaling decimal places for voltage/current

layed or can be set.

Note han voltage/current system input, display only.

system input are disp

Other t

n.nnnnn. ~ n.nnn

1-7 Input scaling lower-limit value

The scaling lower-limit value for voltage/current

input is displayed or can be set.

le.

Note

Other than voltage/current input, display only.

The span between lower-limit and higher-limit is 10 ~ 10000.

Reverse scaling is availab

-1999 ~ 9999 Unit 0 Unit

1-8 In ueput scaling higher-limit val

The scaling hi

input is display

gher-l al

ed or can be

Other than voltage/current input ay only.

tween the lower-limit and the higher-limit is 10 ~ 10000.

ling is available.

imit v ue for voltage/current

set.

Note The span be

Reverse sca

, displ

-1999 ~ 99 1000 Unit99 Unit

1-9 Alarm 1 code

As for action t

Alarm output."

The Alarm 1 action type is displayed or can be

set.

ypes, refer to "Action type" of "7-1.

: Lower-limit absolute value

Note h ues are initialized. However,

they are LA_L.

non : none

HA : Higher-limit absolute value

LA

HA_L: Higher-limit absolute value (with latching)

LA_L : Lower-limit absolute value (with latching)

So : Scale over

e alarm code is changed, the preset valOnce t

not initialized when the code is changed HA<->HA_L, or LA<->

non, HA, HALA, HA_L, LA_L, So

1-10 Alarm 1 hysterisis

The Alarm 1 hysterisis is displayed or can be set.

hen non or So (scale over) is selected on the

Note This screen is not displayed w

Alarm 1 code screen (1-9).

1 ~ 999 Unit

20 Unit

1-11 m 1 iAlar nhibit

Note This scr the

Alarm 1

The Alarm 1 inhibit status is displayed or can be

set.

een is not displayed when non or So (scale over) is selected on

code screen (1-9).

OFF, ON

OFF

ode2 c

tion type" of "7-1.

utput."

non : none

HA : Higher-limit absolute value

LA : Lower-limit absolute value

Note Once the eset values are initialized. However,

L.

The Alarm 2 action type is displayed or can be

set.

As for action types, refer to "Ac

Alarm o

HA_L: Higher-limit absolute value (with latching)

LA_L : Lower-limit absolute value (with latching)

So : Scale over

alarm code is changed, the pr

they are not initialized when the code is changed HA<->HA_L, or LA<->LA_

no , LA_L, So LAn, HA, LA, HA_L

1-13 Alarm 2 hysterisis

The Alarm 2 hysterisis is displayed or can be set.

Note This scre ected on the

Alarm 2

en is not displayed when non or So (scale over) is sel

code screen (1-12).

1 ~ 999 Unit 20 Unit

1-14 Alarm 2 inhibit

set.

The Alarm 2 inhibit status is di ed or can be

Note This scr ed

Alarm 2 r

splay

een is not displayed when non or So (scale over) is select on the

code sc een (1-12).

OFF, ON OFF

1-15 Analog output scaling lower-limit value

output scaling lower-limit value is

the lower-limit value and the higher-limit

.

The analog

displayed or can be set.

Note

Reverse scaling is available.

The same value cannot be set for

value (on screen 1-16)

Measuring range lower-limit value to

value

Lower-limit

higher-limit

value

1-16 Analog output scaling higher-limit value

The analog output scaling higher-limit value is

Reverse

value cannot be set for the lower-l reen 1-15) and

her-limit value.

displayed or can be set.

Note The same

the hig

scaling is available.

imit value (on sc

Measuring range lower-limit value to

t v

Higher-limit value

higher-limi alue

1-17 Communication mode

LOC : Lo

The communication mode is di n be

set.

cal mode. Data can be read out via

dified to

ront panel keys. How

om COM to LOC is available.

r to the separated Communication Interface Instruction

Manual.

splayed or ca

communication.

COM : Communication mode. Data can be set

and read out via communication.

Note modification fr

For details, refe

Once the communication mode is mo

setting can no longer be made with f

COM via communication, the

ever, the

LOC, COM LOC

1-18 Communication protocol

The communication protocol is displayed or can

RTU

be set.

SHIM : Shimaden protocol

ASC : MODBUS ASCII

RTU : MODBUS RTU

SHIM, ASC, SHIM

mV

V

mA

mV

V

mA

mV

V

mA

6

SD16A Instruction Manual

Inhibit action

1-19 Communication address

When the alarm or 1-14),

the inhibit action wer on is performed, as follows.

Latc

output inhibit action is set to ON (on screen 1-11

at po

hing feature

The communication address is displayed or can

be set.

1 ~ 100 1

1-20 Communication data format

The communication data format is displayed or

can be set.

The setting value is composed of three

character : Data length (b r

dle character : Parity. E (even) or N (

Right character : Stop bit. 1 or 2

f the 7-bit format types. The default value

For MOD lt value is

8E1.

alphanumerical characters.

Left

Mid

its). 7 o 8

none)

Note

For MODBUS ASCII, specify one o

is 7E1.

BUS RTU, specify one of the 8-bit format types. The defau

7E1, 7E2, 7N1, 7N2, 8E1, 8E2, 8N1, 8N2 7E1

1 Co-21 mmunication start character

The start character of communication data is

can be set.

Start character STX (02H

Text en d ETX (03H)

DH)

Note MODBUS ASCII/RTU doesn’t use a start character.

displayed or

STX )

End character CR (0

ATT Start character @ (40H)

Text en d : (3AH)

End character CR (0DH)

TXS , ATT STX

1-22 Co tionmmunication BCC opera

1

The BCC operation method is displ .

: ADD operation from the start character to the

text-end character

2

3 R operation from after the start character to the

4

Note MODBUS

ayed or can be set

: 2’s complement after ADD operation from the start

character to the text-end character.

: XO

text-end character.

: BCC operation is not performed.

ASCII/RTU doesn’t use BCC.

1 ~ 4 1

1-23 Communication speed

The communication speed is displayed or can be

set.

Note displayed on eeIn case of 19200 bps, "1920" is the scr n.

1200, 2400, 4800, 9600, 19200 bps 9600

1-24 Communication delay

The delay time by communication, between time

of receiving a command and sending the reply, is

displayed or can be set.

1 ~ 100 msec 20

7. Optional features overview

7-1. Alarm output

The instrument supports two points of alarm optionally.

Action type

The f rm output action types (scree supported.

he lower-limit absolute value alarm

ollowing ala n 1-9 or 1-12) are

T

The higher-limit absolute value alarm

Scale over

The latching feature outputs the alarm signal constantly once PV is

region, even if PV is out of the alarm action

detected in the alarm action

region later.

Note

When PV is in the alarm action region, latching cannot be

released. To release the latching, refer to the description of

screen 0-0, 0-1, or 0-2.

The latching feature is disabled.

ng feature is enabled.

The latchi

7-2. Analog output

Analog output is ltage or

analog current. B t scaling lower-limit value

(screen 1-15) or higher-limit value (1-16), the analog output signal can be

gained by pecified measuring range.

A

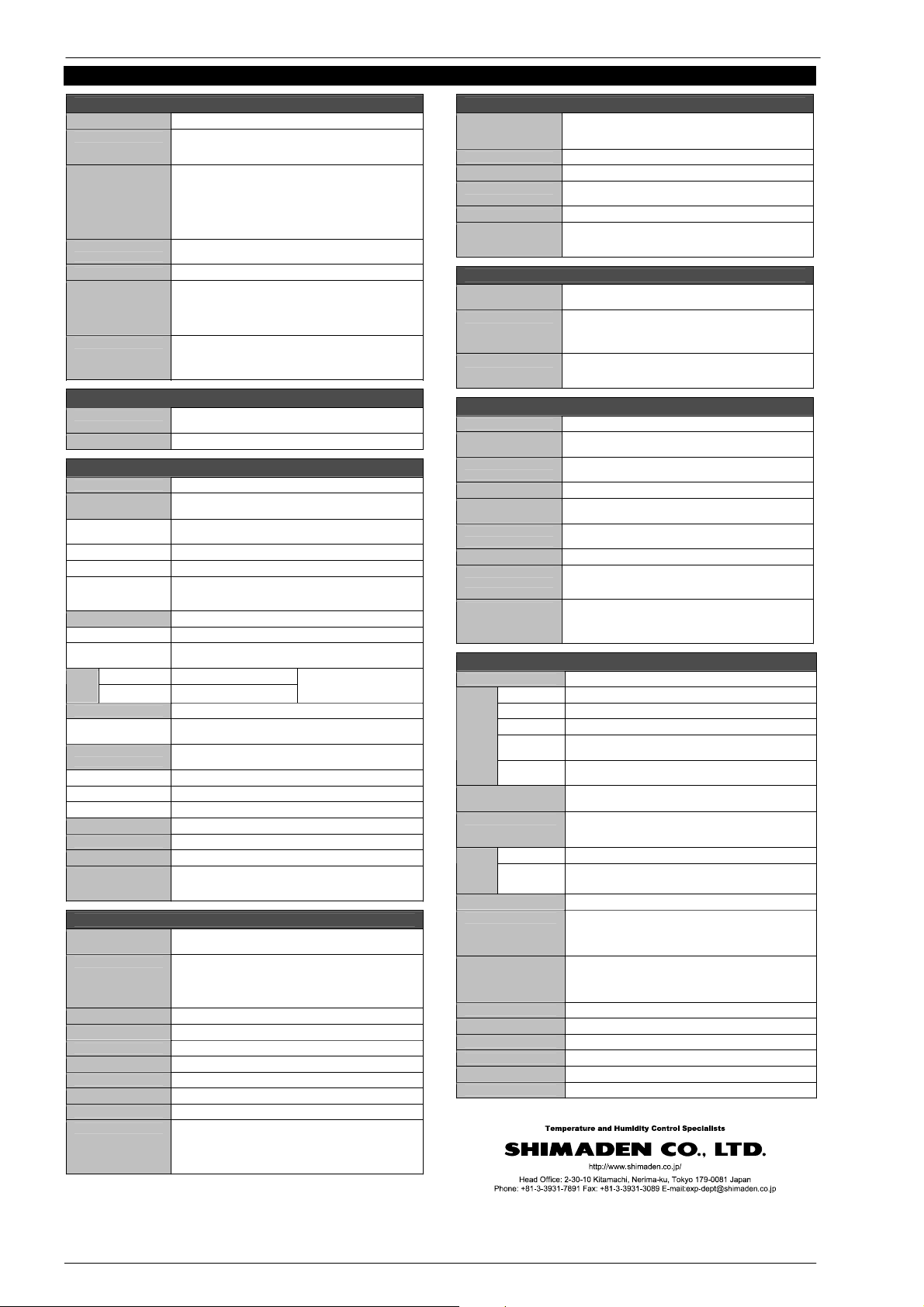

7-3. Sensor po

a feature that outputs PV value-based analog vo

y setting the analog outpu

PV value-base within a s

Ao_L < o_H Ao_L > Ao_H (reverse scaling)

wer supply

In case the optio cted,

the instrument can be us series.

Note that i

sensor p

W g

nal DC sensor power supply (24V DC 25mA) is sele

ed with the Humidity Sensor H71/TH71

f 08 of power (24V AC/DC) from type code is selected, the

ower supply cannot be specified.

irin example using with Humidity Sensor H71/TH71

0%

Alarm setting value

100%

Hysterisis

ON

OFF

0%-10% 100% 110%

ON ON

OFF OFF

A

larm

0%

Alarm setting value

100%

Hysterisis ON

OFF

A

larm signal

Hysterisis

A

Alarm standby

larm setting v

PV

(measured val

alue

ue)

Power ON

ON

Time

OFF

A

larm

setting value

PV

(measured val

Alarm action region

Time

ON ON

ue)

OFF OFF

A

lar

Hysterisis

m signal

0%

10

A

0%

Measuring range

o_L Ao_H

A

nalog output

Ao_H Ao_L

0%

100%

Measuring range

A

nalog output

IN/OUT

H71/TH71

SD16A

19

11 12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

1

567

18

POWER

DC

For voltage (V) Input

24V DC 25mA

OUT

H71/TH71

For current (mA) Input

SD16A

19

11 12 13 14 15 16 17 18 19 20

12345678910

567

18

DC

Time

A

larm

setting value

ea

PV

(m sured value)

Alarm region

A

larm signal

Hysterisis

A

llowed

Release of latching

A

llowed

Operation of

latching release

ON

OFF

Alarm action region

7

SD16A Instruction Manual

8

8. Specification

Display

Digital display Measured value (PV), 7-segment, Red 4-digit LED

Action indication SET (green) : lit when parameter value is displayed

COM (green) : lit when communication mode is set

AL1/AL2 (red) : lit when alarm signal is output

Display accuracy ± (0.3%FS + 1 digit) within measuring range

Excluding cold junction temperature compensation accuracy

of thermocouple input.

± 5%FS for temperature below 400°C (752°F) of

thermocouple B.

Accuracy of thermocouple T or U is ±0.5%FS at above -100°C

and 0°C or below, and ±1%FS at -100°C or below.

Display accuracy

maintaining range 23°C±5°C (18 ~ 28°C)

Display resolution Differs depending on the measuring range (

0.001, 0.01, 0.1, 1

)

Measured value

display range

-10 ~ 110% of measuring range (Accuracy is only guaranteed

when the value is within the measuring range).

For R.T.D. input of -199.9 ~ 600.0°C: -240.0 ~ 680.0°C

-199.9 ~ 500.0°C: -240.0 ~ 570.0°C

For thermocouple K of -199.9 ~ 800.0°C: -273.1 ~ 900.0°C

Display update cycle 0.25 ~ 5.00 secs (0.25 secs step)

When 0.50 secs or more is set, a difference may occur among

the displayed value, the analog output, and the

communication data.

Setting

Setting method Using four key switches on the front panel

Setting protection feature by key lock ON/OFF is provided.

Setting range Same as the measuring range.

Input

Input type Thermocouple, R.T.D., voltage (mV/V). Universal-input

Thermocouple B, R, S, K, E, J, T, N {U, L (DIN43710)}, WRe5-26

For details, refer to the Measuring range code table.

Lead wire tolerable

resistance 100Ω max.

Input impedance 500kΩ min.

Burnout Standard feature (up-scale)

Cold junction

compensation

accuracy

±1°C (within accuracy maintain range (18 ~ 28°C))

±2°C (ambient temperature 5 ~ 18°C, 28 ~ 45°C)

R.T.D JIS Pt100 3-wire type, JPt100 3-wire type

Amperage Approx. 0.25mA

Lead wire tolerable

resistance 5Ω max./wire (each wire should have the same resistance)

mV 0 ~ 10mV DC

-

l

o

V

e

g

a

t

V0 ~ 5, 1 ~ 5, 0 ~ 10V DC

Input impedance 500kΩ

min.

Current 4 ~ 20mA DC

External receiving

resistor 250Ω (supplied if specified)

Input scaling

function

Available in case of voltage (mV/V) or current (mA) input.

Reverse scaling can be set.

Scaling range -1999 ~ 9999 counts

Span 10 ~ 10000 counts

Decimal places None, 0.0, 0.00, 0.000

Sampling cycle 0.25 secs

PV bias -1999 ~ 2000

PV filter 0 ~ 100 secs (PV filter is set to OFF when 0 sec)

Isolation Isolated between input and analog output (sensor power

supply), or between input and communication.

Not isolated between input and system.

Alarm output (option)

Number of alarm

points

2 points (AL1 and AL2), normally open, COM is commonly

used.

Alarm type One of the following six types can be assigned to each alarm.

None, higher-limit absolute value alarm (with latching),

higher-limit absolute value alarm (without latching), lower-limit

absolute value alarm (with latching), lower-limit absolute value

alarm (without latching), Scale over

Setting range Within measuring range or within scaling range

Alarm action ON-OFF action

Hysteresis 1 ~ 999 Unit

Inhibit action ON/OFF can be selected for each alarm output.

Output type Contact 1a (COM is commonly used)

Rating 240V AC 1.5A (resistive load)

Output update cycle 0.25 secs

Isolation Isolated between alarm output and input, between alarm

output and analog output (sensor power supply), between

alarm output and communication, or between alarm output

and system.

Not isolated between alarm output 1 and alarm output 2.

Analog output (option)

Analog output type 0 ~ 10mV (Output resistance 10Ω)

0 ~ 10V (Load current 1mA max.)

4 ~ 20mA (Load resistance 300Ω max.)

Output resolution Approx. 1/14000

Output accuracy ±0.3%FS of display value

Scaling Within measuring range or within input scaling range (reverse

scaling can be set).

Output update cycle 0.25 secs

Isolation Isolated between analog output and input, between analog

output and alarm output, between analog output and

communication, or between analog output and system.

Sensor power supply (option)

Output rating 24V ± 3V DC 25mA max.

Depending upon instrument’s power ON-OFF status.

Isolation Isolated between sensor power supply and input, between

sensor power supply and alarm output, between sensor power

supply and communication, or between sensor power supply

and system.

Restrictions Sensor power supply can't be selected when the analog

output is selected. Sensor power supply can’t be selected

when the power supply 24V is selected.

Communication (option)

Communication type RS-232C, RS-485

Communication

system Half duplex asynchronous communication method

Communication

speed 1200, 2400, 4800, 9600, 19200 bps

Data format 7E1, 7E2, 7N1, 7N2, 8E1, 8E2, 8N1, 8N2

Communication

address 1 ~ 100

Number of

connectable devices 31 devices max. (for RS-485)

Delay 1 ~ 100 msec

Communication

protocol

Shimaden standard protocol, MODBUS ASCII, MODBUS

RTU (start character and BCC operation method can be

selected for Shimaden standard protocol).

Isolation Isolated between communication and input, between

communication and alarm output, between communication

and analog output (sensor power supply), or between

communication and system.

Miscellaneous

Data storage By nonvolatile memory (EEPROM).

Temperature -10 ~ 50°C

Humidity 90%RH max. (no dew condensation)

Height 2000m above sea level or lower

Installation

category II

s

n

o

i

t

idn

o

c

tn

e

ibm

A

e

s

u

r

o

f

Degree of

pollution 2

Power supply voltage

(frequency)

100 ~ 240V AC ± 10% (50/60Hz)

24V AC (50/60Hz) /DC ±10% (option)

Power consumption 11VA (100 ~ 240V AC)

8VA (24V AC)

5W (24V DC)

Safety IEC61010-1, EN61010-1

-i

l

p

pA

elb

ac

dr

a

dn

a

t

s

EMC EN61326:1997+A1:1998, A2:2001, A3:2003

EMC testing display accuracy ±3%FS

Dust proof /drip proof IP66 equivalent

Isolation resistance Between all input/output terminals and power terminal:

500V DC 20MΩ min.

Between all input/output terminals and ground terminal:

500V DC 20MΩ min.

Dielectric strength Between all input/output terminals and power terminal:

2300V AC for one minute.

Between power terminal and ground terminal:

1500V AC for one minute.

Case material Black PPO resin molding (equivalent to UL94V-1)

External dimensions H48 x W96 x D111 mm (inside of panel: 100mm)

Mounting Push-in panel (one-touch mount)

Panel thickness 1.0 ~ 4.0 mm

Panel cutout H45 x W92 mm

Weight Approx. 250g

The contents of this manual are subject to change without notice.

Any questions should be directed to your local agent, or send an e-mail to exp-dept@shimaden.co.jp.

Printed in Japan

Table of contents