1

Table of Contents

1. Safety Instructions .......................................................................... 2

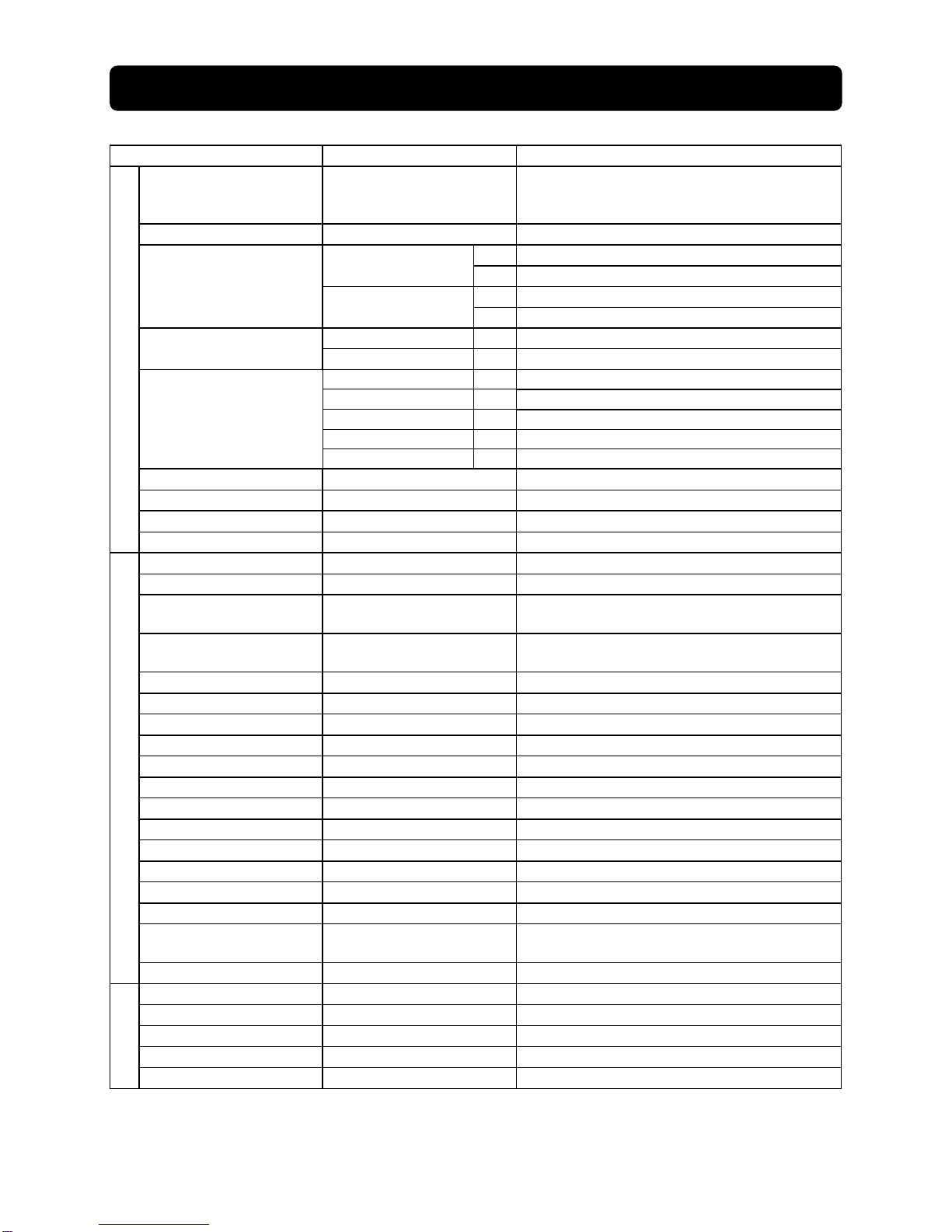

2. Specifications .................................................................................. 5

2-1. Specifications............................................................................5

2-2. Ambient Conditions...................................................................6

3. Applications.....................................................................................6

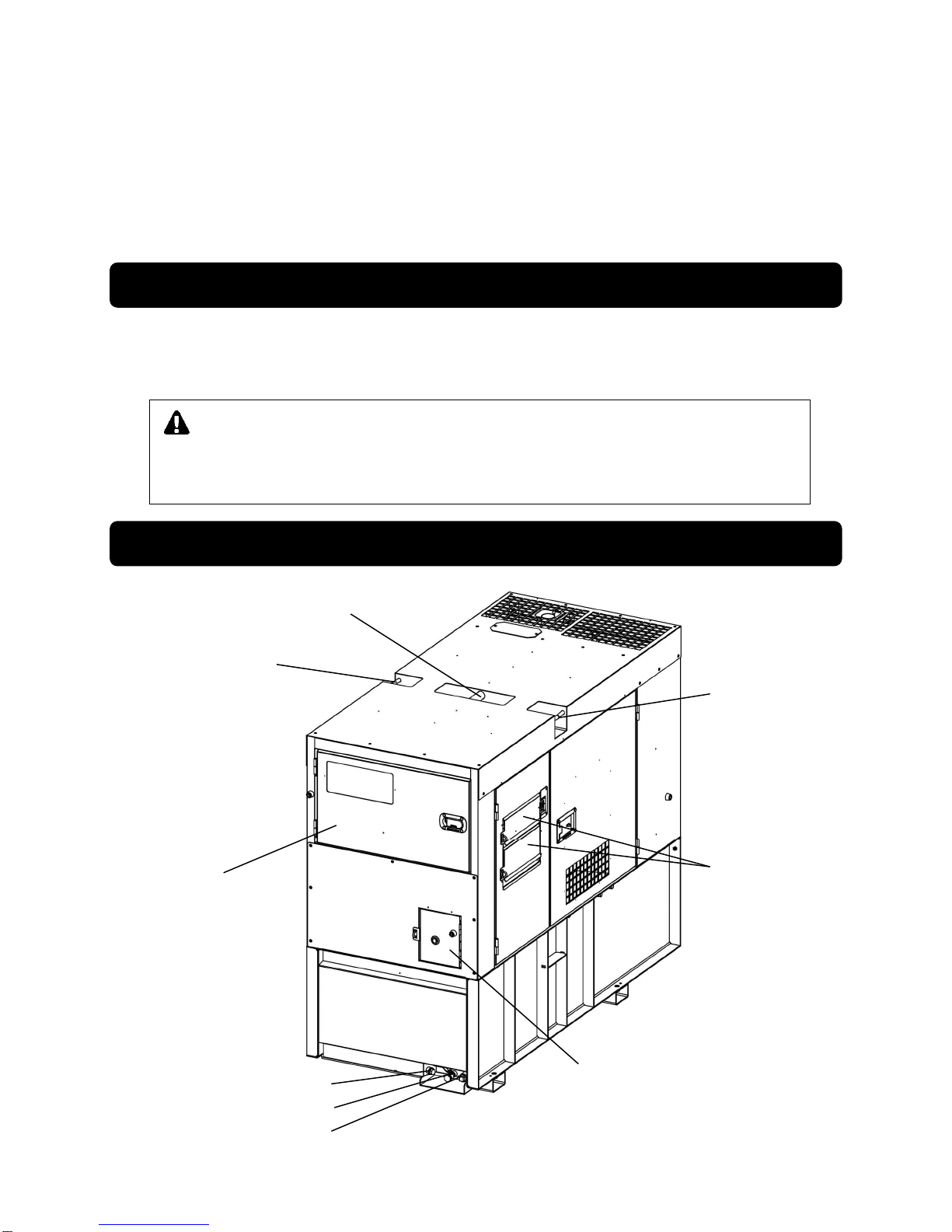

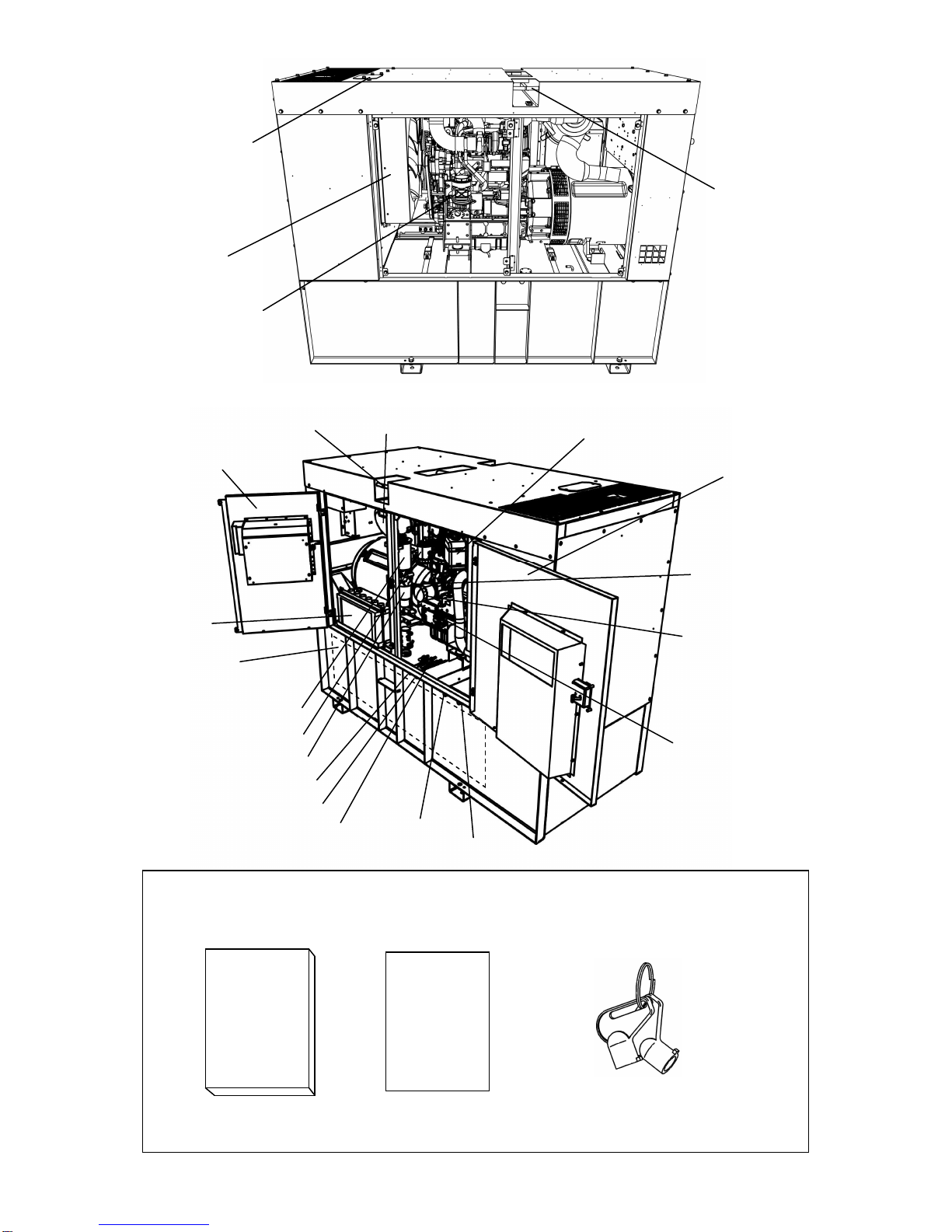

4. Part Names.......................................................................................6

4-1. External View/Part Names ........................................................ 6

4-2. Operation Panel Part Names ....................................................8

5. Equipment........................................................................................9

5-1. Available Output Monitor...........................................................9

5-2. Warning Indicators ....................................................................9

5-3. Meters and Gauges................................................................. 11

5-4. Spill Containment ....................................................................14

5-5. Fuel Piping Switch (3Way Fuel Valve).....................................14

6. Transporting/Installing..................................................................15

6-1. Transport Procedures..............................................................15

6-2. Installation Procedures............................................................16

7. Load Connections ......................................................................... 17

7-1. Load Cable Selection..............................................................17

7-2. Connecting Load Cables......................................................... 18

8. Pre-Operation Inspection.............................................................. 21

8-1. Checking Engine Oil................................................................21

8-2. Checking Coolant....................................................................22

8-3. Checking the Fan Belt.............................................................23

8-4. Checking the Fuel ...................................................................23

8-5. Checking the Spill Containment ..............................................24

8-6. Checking for Fuel, Oil and Coolant Leaks...............................24

8-7. Checking the Battery...............................................................25

9. Operating Procedures................................................................... 26

9-1. Initial Startup/Pre-Check..........................................................26

9-2. 240/480-V Switching Function................................................. 27

9-3. Procedures during Operation..................................................28

9-4. Stopping Operation .................................................................28

9-5. Protective Functions................................................................29

9-6. Connecting with External Fuel Tank........................................30

10. Inspection/Maintenance................................................................ 31

11. Long-Term Storage........................................................................39

12. Troubleshooting............................................................................. 40

13. Generator Circuit Diagram............................................................ 43

14. Engine Electrical Circuit Diagram................................................ 44