- 1 -

Table of Contents

1. Safety Precautions ........................................................................................2

2. Specifications ................................................................................................8

3. Applications ...................................................................................................9

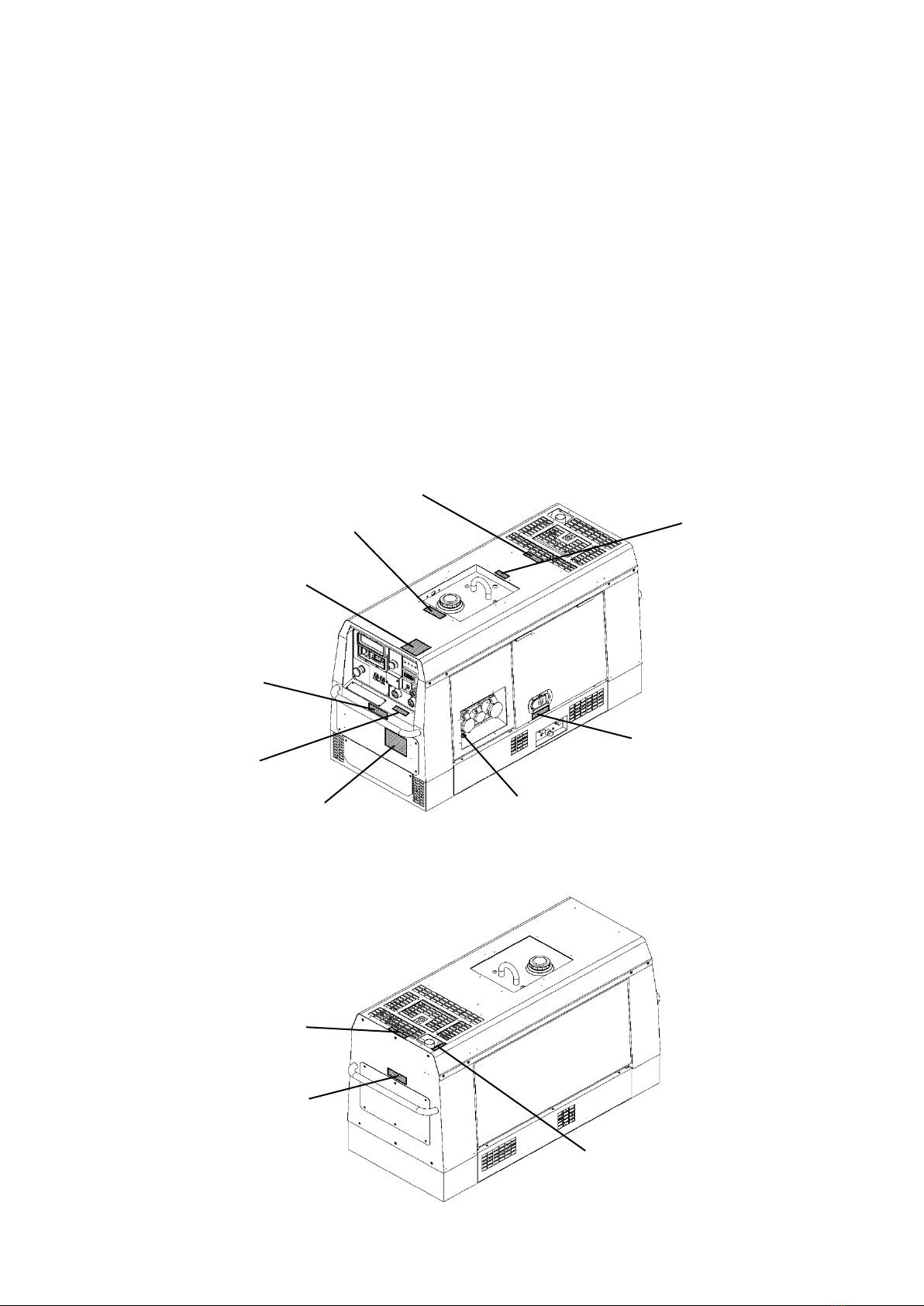

4. Parts Names...................................................................................................9

5. Equipment....................................................................................................12

5-1. Idle Control ...........................................................................................12

5-2. Display..................................................................................................12

5-3. Monitor Lamp .......................................................................................13

5-4. Earth Leakage Circuit Breaker and Grounding ....................................14

5-5. Emergency Stop Switch .......................................................................15

6. Transporting ................................................................................................16

7. Pre-Operation Inspection ...........................................................................16

7-1. Engine Oil Inspection ...........................................................................17

7-2. Coolant Inspection................................................................................17

7-3. Fuel Inspection .....................................................................................18

7-4. Inspection for Fuel/Oil/Cooling Water Leakage....................................19

7-5. Battery Inspection.................................................................................19

8. Operating Procedures.................................................................................20

8-1. Starting the Engine...............................................................................20

8-2. Stopping the Engine .............................................................................21

8-3. Emergency Stop...................................................................................22

9. Using as a Welder .......................................................................................22

9-1. Welding Cable Selection ......................................................................22

9-2. Welding Polarity ...................................................................................22

9-3. Welding Cable Connection...................................................................23

9-4. Duty Cycle ............................................................................................23

9-5. Welding Work .......................................................................................23

10. Using as a Generator ................................................................................24

10-1. Output Types and Ranges..................................................................24

10-2. Usable Device Capacities ..................................................................25

10-3. Operation............................................................................................25

11. Simultaneously Welding and Using as AC Power Source ....................26

12. Inspection/Maintenance............................................................................27

13. Long-Term Storage ...................................................................................31

14. Troubleshooting ........................................................................................32

15. Engine Wiring Diagram.............................................................................34

16. Generator Wiring Diagram........................................................................35