Throughout this manual are special

“attention statements”.

WARNING!

A statement preceded by the

triangular attention symbol and the

word “WARNING” contains

information that should be acted

upon to prevent serious bodily

injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information

that should be acted upon to

prevent mechanical damage.

IMPORTANT!

The operational procedures described

in this manual are intended to help

you get the most from your M230

Multipurpose Tool Carrier as well as

to protect you and others from harm.

These procedures are guidelines for

safe operation under most conditions,

and are not intended to replace any

safety rules and/or laws that may be

in force in your area. If you have

questions regarding your 230-series

power tool, or if you do not under-

stand something in this manual, your

Shindaiwa dealer will be glad to assist

you. You may also contact Shindaiwa,

Inc. at the address printed on the back

of this Manual.

Attention Statements

SAFETY

2

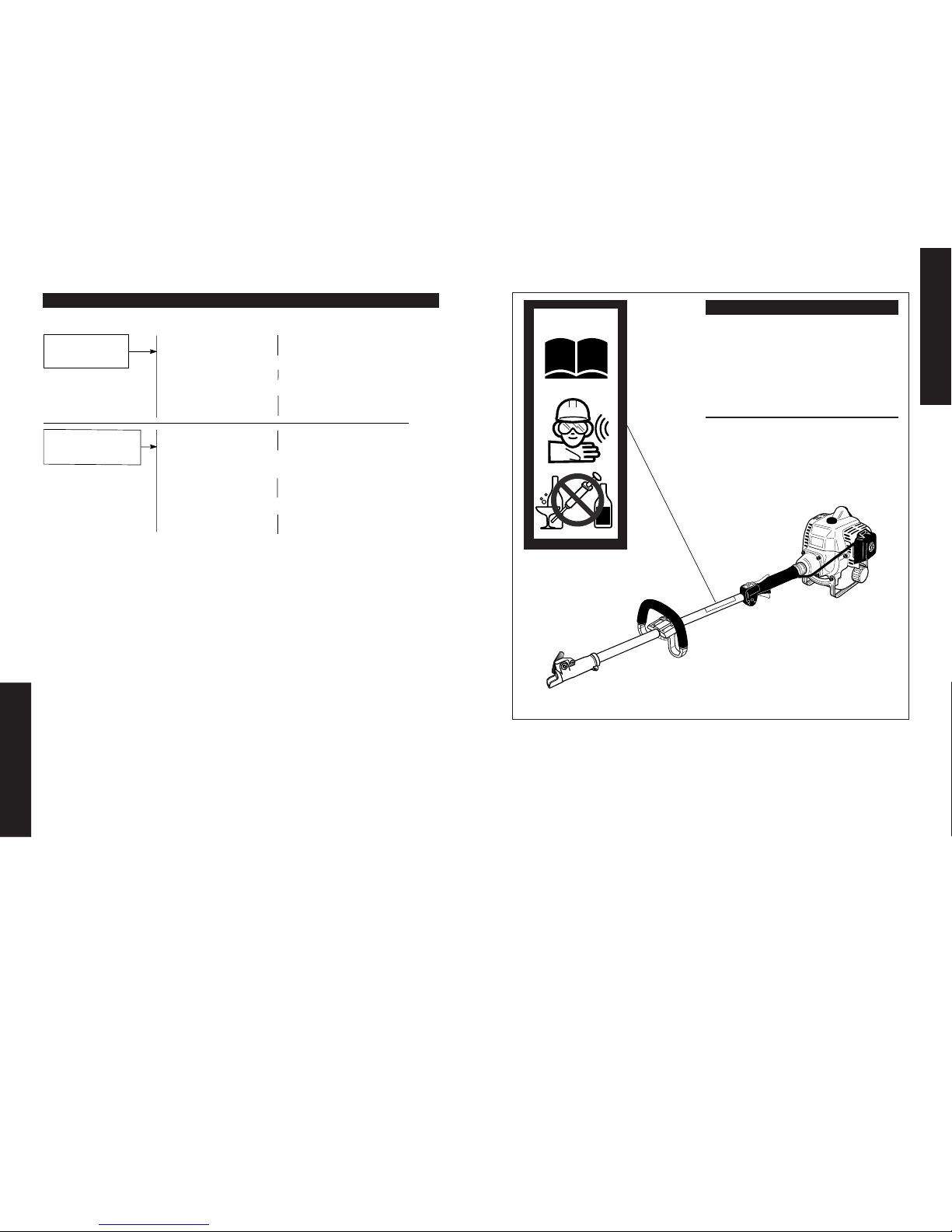

Read and follow this

manual. Failure to do

so could result in

serious injury.

Wear eye and hearing

protection at all times

during the operation

of this unit.

Keep bystanders

at least 50 Feet (15 m)

away during operation.

Beware of thrown or

ricocheted objects.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word

“NOTE” contains information that is

handy to know and may make your

job easier.

Shindaiwa Kogyo Co., Ltd.

Federal Emission Design And Defect Limited Warranty

Utility And Lawn And Garden Engines

Shindaiwa Kogyo Co., Ltd. warrants to the initial purchaser and each subsequent owner, that this

utility equipment engine (herein engine) is designed, built and equipped to conform at the time of

initial sale, to all applicable regulations of the U.S. Environmental Protection Agency (EPA), and

that the engine is free of defects in materials and workmanship that would cause this engine to fail

to conform with EPA regulations during its warranty period. This emission warranty is applicable in

all States, except the State of California.

For parts listed under PARTS COVERED, the dealer authorized by Shindaiwa Kogyo Co., Ltd.

will, at no cost to you, make the necessary diagnosis, repair, or replacement of any defective

emission-related component to ensure that the engine complies with applicable U.S. EPA regula-

tions.

MANUFACTURERS WARRANTY COVERAGE

When sold within the U.S., this engine’s emission control system is warranted for a period of two

(2) years from the date this product is first delivered to the original retail purchaser.

OWNER’S WARRANTY RESPONSIBILITIES

As the engine owner, you are responsible for the performance of the required maintenance listed

in your owner’s manual. Shindaiwa Kogyo Co., Ltd. recommends that you retain all receipts

covering maintenance on your engine, but Shindaiwa Kogyo Co., Ltd. cannot deny a warranty claim

solely for the lack of receipts or for your failure to ensure the performance of all scheduled

maintenance.

As the engine owner, you should however be aware that Shindaiwa Kogyo Co., Ltd. may deny

your warranty coverage if your engine or a part has failed due to abuse, neglect, improper

maintenance or unapproved modifications.

You are responsible for presenting your engine to the nearest dealer authorized by Shindaiwa

Kogyo Co., Ltd. when a problem exists.

If your Shindaiwa Dealer is unable to answer questions regarding your warranty rights and

responsibilities, you should then contact your Shindaiwa Distributor.

For the name and telephone number of the Shindaiwa Distributor in your area, please call

Shindaiwa Inc. at (503) 692-3070 between the hours of 8:00 AM and 5:00 PM Pacific Standard Time.

PARTS COVERED

Listed below are the parts covered by the Federal Emission Design and Defect Warranty. Some

parts listed below may require scheduled maintenance and are warranted up to the first scheduled

replacement of that part. The warranted parts include:

1. Carburetor Internal Components

• Valve Assembly-throttle, Jet, Metering Diaphram

2. Ignition System Components

• Ignition Coil

• Flywheel Rotor

The emission control system for your particular Shindaiwa engine may also include certain related

hoses and connectors.

LIMITATIONS

The Federal Emission Design and Defect Warranty shall not cover any of the following:

(a) conditions resulting from tampering, misuse, improper adjustment

(unless they were made by the dealer or service center authorized by

Shindaiwa Kogyo Co., Ltd. during a warranty repair), alteration, accident, failure to use the

recommended fuel and oil, or not performing required maintenance services,

(b) the replacement parts used for required maintenance services,

(c) consequential parts used for required maintenance services,

(d) diagnosis and inspection fees that do not result in eligible warranty

service being performed, and

(e) any non-authorized replacement part, or malfunction of authorized

parts due to use of non-authorized parts.

The following statement only applies to United States and its territories

25