About blasting

1. Preparations before blasting. All parts to be pa-

inted must be free of oil, grease and moistured.

Make sure that the parts are dry before blasting

them.

2. Pressure. Normal working pressure is between

3.5 to 5.5 bar. Up to 8.6 bar can be used, but

such high pressure destroys certain blasting

materials such as glass balls. Normally the

pressure is set to 5.5 bar, this is suitable for

most materials, for materials such as steel,

aluminum or fragile surfaces you start at a lower

pressure and increase if necessary until you

reach a desired effect.

3. The angle and distance of the blasting gun.

Aim the gun at a 45° to 60° angle towards the

object. Let the ricochets be directed away from

the object. Do not hold the gun at a 90° angle to

the object as the blasting material then bounces

back against the gun and reduces the blasting

jet. It also wears on the parts of the gun. Keep

the gun at a distance of about 15 cm.

Warning. The pistol must always point away from

the operator towards the object to be blasted.

Always remove the air connection during

maintenance and service of the appliance.

4. Blasting agents. The blasting agent must

always be of good quality and dry. Moisture

causes the blast material to ow less and clog

intake pipes, hoses and containers.

5. Nozzle size. By increasing the diameter of the

nozzle, the felling can be increased signicantly,

but this requires increased air ow (the

compressor must be able to provide this).

Maintenance

1. The blasting gun. After 10-12 hours of use,

check the nozzle. If the nozzle wears unevenly,

turn it 1/4 turn after 10 hours of use.

2. Lump formation of blasting agents. Lump

formation is caused by moisture in the air

supply or from parts that are greasy or oily.

Ifleft untreated, the blasting agent will ow

unevenly and eventually clog the intake manifold

or gun. Check the air supply, install an effective

moisture trap if necessary. Degrease parts to be

blasted properly before blasting them.

3. The blast gun drops in pressure. Set the

regulator pressure to 5.5 bar, activate the blast

gun and check the pressure gauge, if the

pressure drops signicantly it indicates that the

air supply is not sucient. This may be because

the hose has too small a diameter, a reducing

quick coupling, a clogged lter or a compressor

that does not provide sucient ow. The air

hose should be 1/2 ”or larger.

4. Poor ow of blasting agents. Check for

moisture, install microlters if necessary,

replace damp blasting agent and clean hoses

and nozzles. Look for any holes in the hoses,

replace if necessary.

Dirt in the blasting agent, be careful not to put any

paper in the agent, this easily causes nozzles and

hoses to become clogged. Replace or sift the

blasting agent.

Sandblasting

WARNING: Always wear a blower hood and

approved protection, goggles, heavy gloves, shoes

and clothing. Inspect each connection and make

sure all are tight and well sealed.

WARNING: This machine is not intended for use

with silicon-based abrasives. Silicon-based

abrasives have been linked to severe respiratory

diseases.

Filling the abrasives

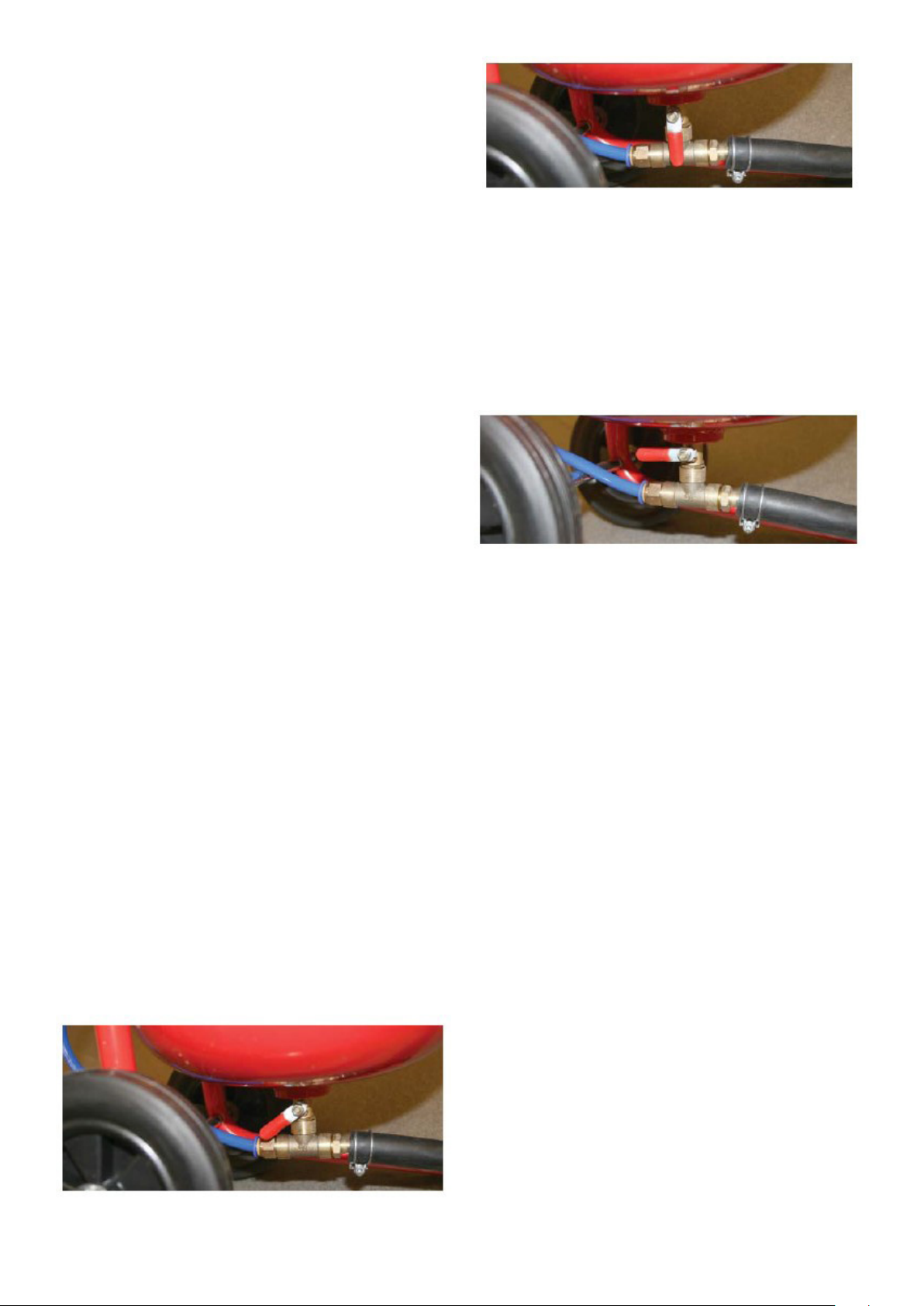

1. Loosen the compressed air connection hose.

Before opening the tank, make sure that it is

not pressurized and the air pressure gauge is

set to ”0”.

2. To release the pressure from the tank, push in

the blower gun lever until all air is released.

3. Check that the abrasive is dry and clean so that

it does not clog valves and hoses.