-5-

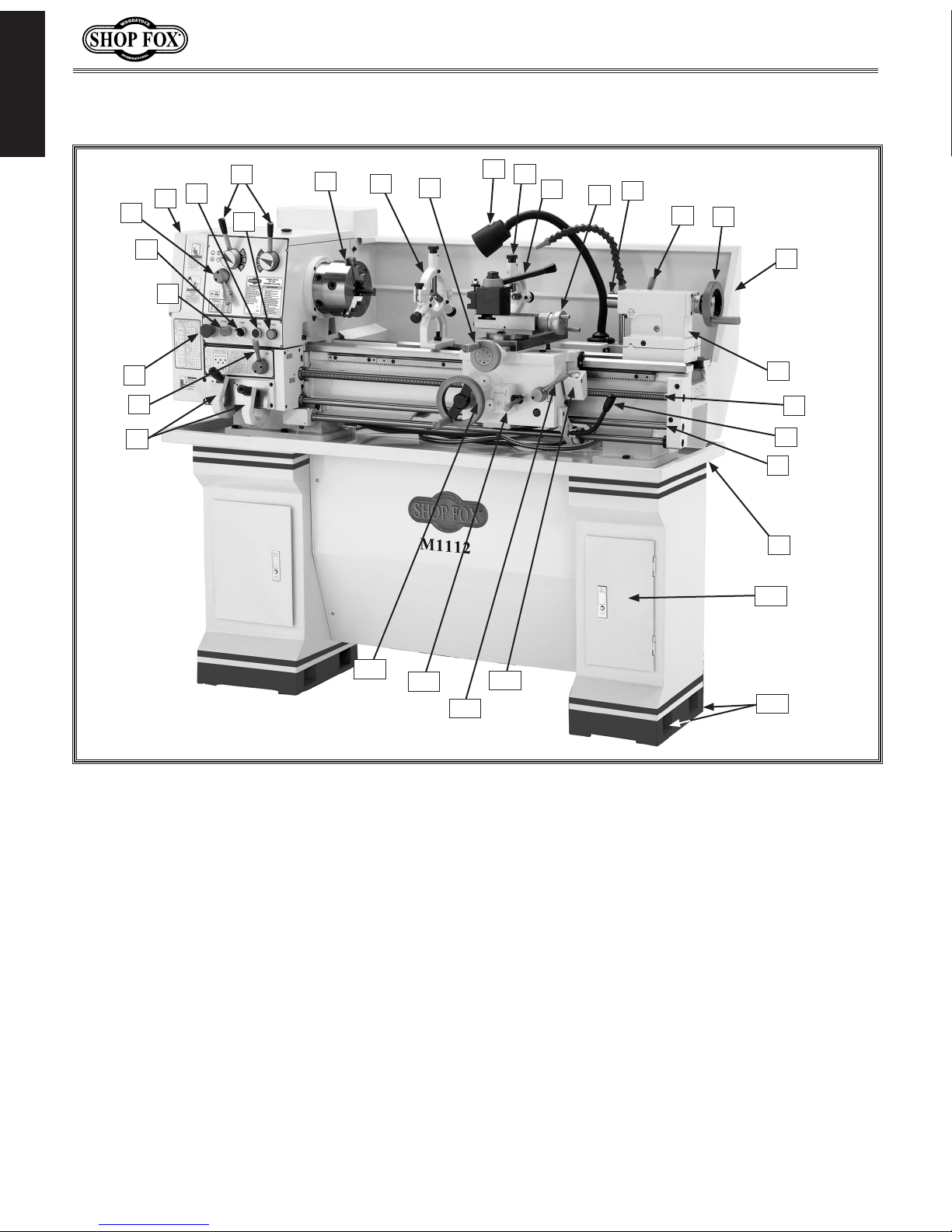

M1112 12" x 36" Gunsmithing Lathe

INTRODUCTION

Operation Information (continued)

Maximum Tool Bit Size................................................................................................... 5⁄8"

Compound Travel ........................................................................................................31⁄4"

Carriage Travel............................................................................................................ 29"

Cross Slide Travel........................................................................................................61⁄4"

Headstock Information:

Spindle Bore..............................................................................................................15⁄8"

Spindle Taper.......................................................................................................... MT #5

Number of Spindle Speeds ................................................................................................ 9

Range of Spindle Speeds ...................................... 70, 200, 220, 270, 360, 600, 800, 1000, 1400 RPM

Spindle Type..................................................................................................D1-5 Camlock

Spindle Bearings ........................................................................................... Tapered Roller

Tailstock Information:

Tailstock Travel ............................................................................................................ 4"

Tailstock Taper ........................................................................................................ MT #3

Tailstock Barrel Diameter ............................................................................................. 19⁄16"

Threading Information:

Number of Inch Threads..................................................................................................40

Range of Inch Threads........................................................................................... 4–112 TPI

Number of Metric Threads ...............................................................................................29

Range of Metric Threads ...................................................................................... 0.2–4.5mm

Number of Longitudinal Feeds ..........................................................................................40

Range of Longitudinal Feeds ......................................................................... 0.0011–0.0311 in.

Number of Cross Feeds ...................................................................................................40

Range of Cross Feeds ............................................................................ 0.0004–0.0105 in./rev.

Other Dimensions:

Bed Width.................................................................................................................71⁄4"

Leadscrew TPI.......................................................................................................... 8 TPI

Leadscrew Length ........................................................................................................44"

Leadscrew Diameter ..................................................................................................... 7⁄8"

Feed Rod Diameter..................................................................................................... 25⁄32"

Steady Rest Capacity ................................................................................................ 3⁄16"–2"

Follow Rest Capacity..................................................................................................1⁄4"–1"

Faceplate Size ............................................................................................................10"

Construction Information:

Stand............................................................................................................................................. CastIronandSteel

Headstock......................................................................................................................................................CastIron

HeadstockGears.......................................................................................................... FlameHardenedandGround

Bed............................................................................................................................InductionHardenedandGround

Body...............................................................................................................................................................CastIron

Paint.................................................................................................................................................... PowderCoated

Other Specifications:

Country of Origin..............................................................................................................China

Warranty....................................................................................................................... 2 Year

Serial Number Location ............................................................... Machine ID Label on Front Headstock

Features:

Easy To Use Lever Controls

Halogen Work Light

Coolant System

Full Length Splash Guard

1

5⁄8"Spindle Bore With 4 Brass Tipped Outboard Screws For Outboard Support

1⁄2"Square Drive Stud Tailstock Lock

Gears Flame Hardened And Ground