Shop Tuff DB-5500LB User manual

5500 lb. Pallet Truck

OWNER’S MANUAL

WARNING:

Carefully read and understand all ASSEMBLY AND OPERATION

INSTRUCTIONS before operating. Failure to follow the safety rules and other

basic safety precautions may result in serious personal injury.

01272017

Model # DB-5500LB

Page of 9

2

Thank you very much for choosing this product! For future reference, please complete the owner’s

record below:

Model: __DB-5500LB____ Purchase Date: _______________

Save the receipt, the warranty, and these instructions. It is important that you read the entire manual

to become familiar with this product before you begin using it.

This product is designed for certain applications only. The manufacturer cannot be responsible for

issues arising from modification. We strongly recommend that this product not be modified and/or

used for any application other than that for which it was designed. If you have any questions relative

to a particular application, DO NOT use the product until you have first contacted us to determine if

it can, or should, be performed on the product.

For technical questions, please call 1-218-943-6296.

TECHNICAL SPECIFICATIONS

Item

Description

Capacity

5500 lbs.

Fork Dimensions

27” x 48”

Dimensions

63.5” x 47.8” x 27”

GENERAL SAFETY RULES

WARNING: Read and understand all instructions. Failure to follow all instructions listed

below may result in serious injury.

CAUTION: Do not allow persons to operate or assemble this pallet truck until they

have read this manual and have developed a thorough understanding of how the pallet truck

works.

WARNING: The warnings, cautions, and instructions discussed in this instruction

manual cannot cover all possible conditions or situations that could occur. It must be

understood by the operator that common sense and caution are factors that cannot be built into this

product, but must be supplied by the operator.

SAVE THESE INSTRUCTIONS

Page of 9

3

WORK AREA

•Keep work area clean, free of clutter, and well-lit. Cluttered and dark work areas can cause

accidents.

•Keep children and bystanders away while operating a pallet truck. Distractions can cause you

to lose control, so visitors should remain at a safe distance from the work area.

•Be alert of your surroundings. Using a pallet truck in confined work areas may put you

dangerously close to sharp tools and rotating parts.

PERSONAL SAFETY

•Stay alert, watch what you are doing, and use common sense when using a pallet truck. Do not

use a pallet truck while you are tired or under the influence of drugs, alcohol, or medication. A

moment of inattention while operating a pallet truck may result in serious personal injury.

•Dress properly. Do not wear loose clothing, dangling objects, or jewelry. Keep your hair,

clothing, and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught

in moving parts.

•Use safety apparel and equipment. Use safety goggles or safety glasses with side shields that

comply with current national standards or, when needed, a face shield. Use a dust mask if

working in dusty work conditions. This applies to all persons in the work area.Also use non-skid,

safety shoes, hard hats, gloves, dust collection systems, and hearing protection when

appropriate.

PALLET TRUCK USE AND CARE

•Do not modify the pallet truck in any way. Unauthorized modification may impair the function

and/or safety and could affect the life of the equipment. There are specific applications for which

the pallet truck was designed.

•Always check for damaged or worn-out parts before using the pallet truck. Broken parts

will affect the pallet truck operation. Replace or repair damaged or worn parts immediately.

•Do not exceed the pallet truck load capacity.

•Distribute the load evenly. Uneven loads may cause the pallet truck to tip, resulting in

personal injury to the operator or others.

•Use the pallet truck on flat and level surfaces capable of supporting the pallet truck and its

maximum load. Pulling or pushing a load on a slanted or uneven surface can result in loss of

control.

•Store idle pallet truck. When the pallet truck is not in use, store it in a secure place out of the

reach of children. Inspect it for good working condition prior to storage and before re-use.

Page of 9

4

ASSEMBLY

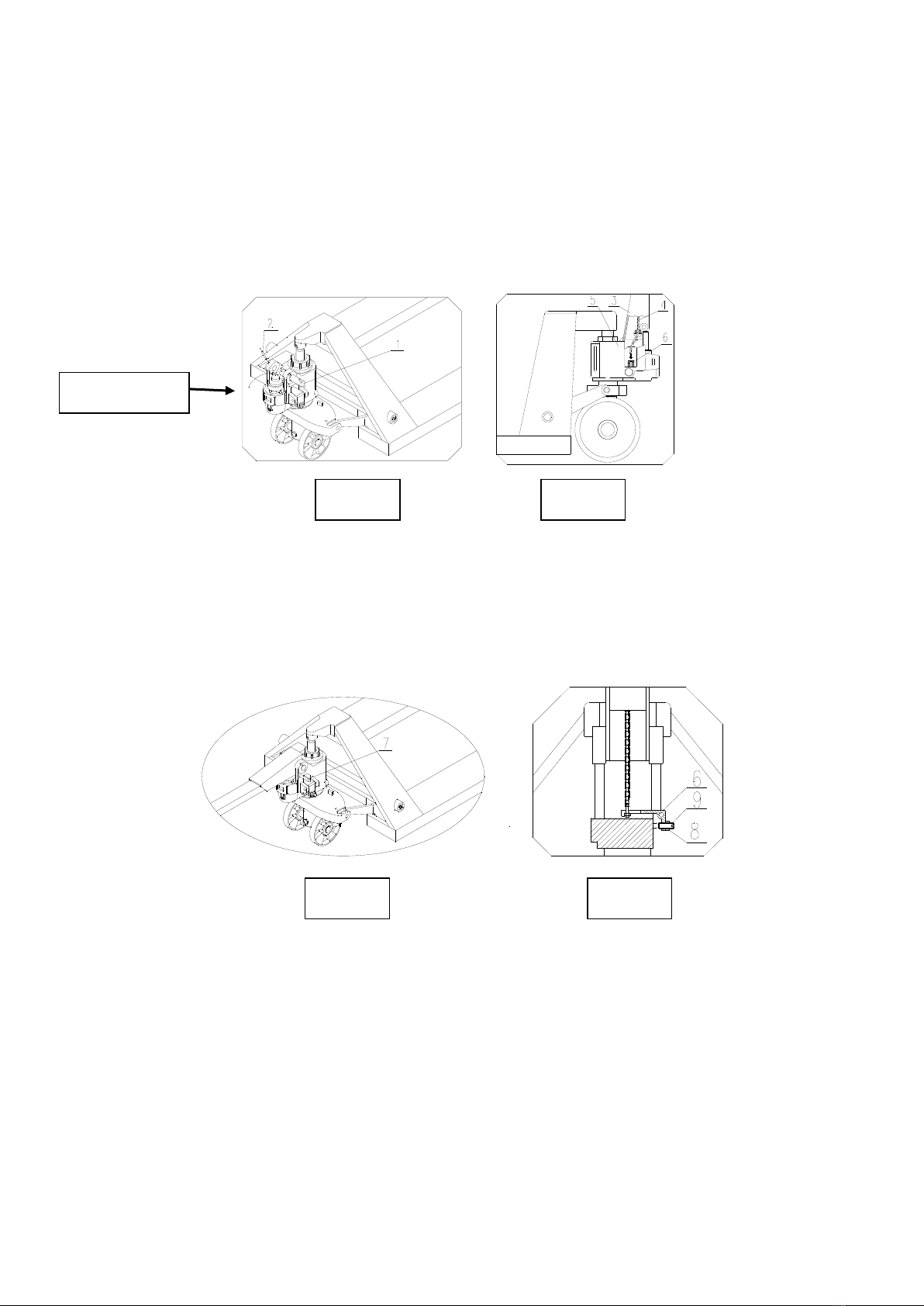

1. Pull out the Spring Pin (2) and remove the Pin Shaft (1) –see Figure 1.

2. Insert the Handle Tube (3) into Position A. Connect the Handle Tube (3) and the Pump Body (5)

using the Pin Shaft (1).

3. Insert the Spring Pin (2) into the Pin Shaft (1) to secure it.

4. Put the Chain (4) of the Handle Tube (3) through the hole of the Pin Shaft (1) –see Figure 2.

A

5. Put the screw and the nut at the end of the Chain (4) into the slot of the lever plate –see

Figure 2 and Figure 4.

6. Raise the Handle to a horizontal position –see Figure 3. Pull out the Pin (7) and keep it for

future use if handle needs to be replaced. The pallet truck assembly is complete.

Position A

Figure 2

Figure 3

Figure 4

Figure 1

Page of 9

5

OPERATION

Check before using

1. After the assembly is complete, move the Trigger (12) into the three different positions (see

below image). Be sure to check that the pallet truck operates in each position. Also trying

rocking the Handle from side to side to ensure it is properly aligned and secured.

下降

空档

上升

2. The Screw (9) (see Figure 4) is used for the adjustment of the truck. If the truck body drops

immediately after it is lifted, turn the Screw (9) slightly counterclockwise before trying the

truck again. If the truck body will not lower, turn the Screw (9) slightly clockwise. Then try to

operate the truck again till the truck is able to lower normally.

3. The Hex Nut (8)(see Figure 4) functions as a lock. This needs to be loosened before any

adjustments can be done. Be sure to tighten after adjustments have been completed.

WARNING:

1. Lift the Trigger up slightly when lowering the truck by controlling the Trigger to make the

truck lower slowly. Never release the Trigger quickly. Rapid descent will damage the truck

and the cargo.

2. Do not exceed the truck load capacity.

3. The center of gravity of the goods should be positioned in the middle of the two forks –see

Figure 5.

4. Do not use with loose or unstable cargo.

5. Do not place cargo on the pallet truck body for long periods of time.

Lowering position

Neutral position

Raising position

Figure 5

Table of contents

Other Shop Tuff Truck manuals