ShopBot Invision Enclosure Quick setup guide

Invision Enclosure for Desktop DT3/DT1

Assembly and Use Guide

Table of Contents

1. Introduction to Assembly Methods (3-14)

2. Top Frame Assembly (15-52)

3. Base Assembly (53-71)

4. Door Installation (72-83)

5. Window Installation (84-92)

6. Additional Features (93-98)

Introduction to Assembly

Methods

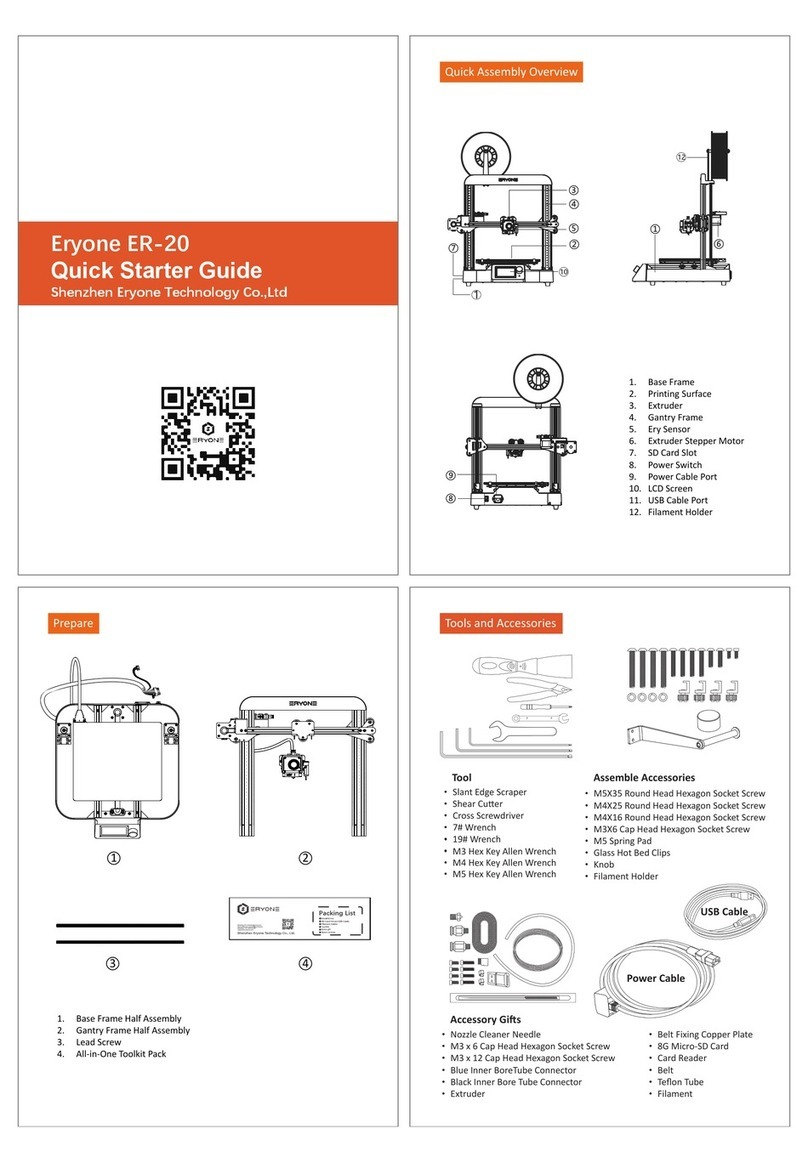

3

Callouts go here

The frame of your

enclosure is

constructed from

extruded, anodized

V-slot

Aluminum—sometimes

just called “extrusion”.

Extrusion is frequently

used for frames that

need to be rigid, but

quick to assemble and

modify.

Callouts go here

V - slot

The phrase V-slot refers to the shape of the slots

that result from the design of the die used when

extruding the aluminum. They can be used as

attachment points for plates or even other

pieces of extrusion. Certain types of screws can

be inserted directly into the V-slot where the

screws’ threads will engage the sharp edge of

the slot and hold tight.

4

5The assembly of this enclosure will make use of

many joints of this type.

6To make assembly even easier-we’ve

manufactured our own ShopBot-cut joinery for

V-slot extrusion. They will be referred to by the

letter of the alphabet that they most closely

resemble.

L (005983) x24

X

(005987) x1 T

(005986)

x10

I (005988) x1

7

Callouts go here

Callouts go here

You’ll just need to drop the joint into place on

the extrusion and tighten the bolt-heads to lock

the structure in place.

Lock!

Twist!

8Most of the joints have protruding “stops” to

ensure accurate positioning during assembly.

Just slide the extrusion in until it contacts the

corner stop and hold firm while you tighten the

bolts.

9Every connection will be made with at least two

screws. To ensure a tight fit, always tighten the

screw furthest from the corner first, this will pull

the extrusion into the corner. Once the outer

screws are tightened, the extrusion will be fixed

in place and the inner screws can be tightened.

10 Throughout this guide, we’ll use colors and

names to refer to each side of the enclosure to

help keep you oriented. The “front” of the

enclosure will be the side with the doors.

FRONT

LEFT

BACK

RIGHT

TOP

11 The extrusion for your enclosure is cut

to three lengths: 30.5”, 19.5” and

12.5”; These lengths will be identified

by colors...Yellow, Red and Blue

respectively.

30.5”

(005978)

x7

19.5”

(005979)

x15

12.5”

(005980)

x5

12 These are the four types of hardware that will be

used in the assembly of your enclosure.

#14 x ¾ Truss Head

(006109) x200 5/16-18 x 3/8

BHSCS

(006108) x150

#10 x ¾”

Flange Head

(006129) x10

#10 x 1.25 Flange Head

(005589) x50

13 Your assembly kit also includes all of the tools

that will be required to assemble your enclosure

Bit Driver

(006133)

x 1

3/16” Hex

Driver Bit

(006135)

x 1

No. 3 Phillips

Driver Bit

(006134)

x 1

Enclosure Top Frame Assembly

These are the parts that you will need for this

section.

15

L (005983) x24

X

(005987) x1

T

(005986)

x10

I (005988) x1

30.5” (005978) x7

19.5” (005979) x15

12.5” (005980) x5

#14 x ¾ Truss Head

(006109) x200

Interlock Sensor Assm

(006115) x1

16

Callouts go here

Callouts go here

This section of the assembly instructions will

guide you through the construction of the top of

the enclosure.

17

Callouts go here

Callouts go here

The top of the enclosure is constructed of 9x

19.5” sticks and 3x 12.5” sticks. Lay them out in

an open space according to the arrangement

shown in the diagram below.

18

Callouts go here

Callouts go here

Insert an X Joint into the center of the enclosure

top and fasten in place using the #14 x ¾ Truss

Head Screws.

19

Callouts go here

Callouts go here

Insert 4x T Joints around the perimeter of the

enclosure top and fasten in place.

20

Callouts go here

Callouts go here

Insert 4x L Joints on the corners of the

Enclosure Top and fasten in place.

21

Callouts go here

Callouts go here

For the next section, you’ll want to flip your

assembly over to provide easier access to the

area you’ll be working on.

22

Callouts go here

Callouts go here

Attach an two L Joints and a T Joint to the left

edge of the enclosure top.

23

Callouts go here

Callouts go here

Attach two L Joints and a T Joint to the back

edge of the enclosure top.

24

Callouts go here

Callouts go here

Attach two L Joints and a T Joint to the right

edge of the enclosure top.

25

Callouts go here

Callouts go here

Attach an two L Joint and an I Joint to the front

edge of the enclosure top.

26 Attach 7x 30.5” Sticks to the four corners of the

enclosure along with the 3 open slots on T

Joints around the frame.

27

Callouts go here

Callouts go here

For this next it will be easiest to look at the

enclosure “right-side-up”. You may want to

physically flip the enclosure assembly

right-side-up at this point as well.

28

Callouts go here

Callouts go here

We’ll now finish the enclosure frame with more

joinery and extrusion around the base of the

frame.

29

Callouts go here

Callouts go here

For this section, you will be facing the LEFT of

the enclosure.

30

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

31

Callouts go here

Callouts go here

Attach a T Joint to the base of the enclosure.

32

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

33

Callouts go here

Callouts go here

Attach a 19.5” stick and a 12.5” stick to the base

of the enclosure frame.

34

Callouts go here

Callouts go here

For this section, you will be facing the BACK of

the enclosure.

35

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

36

Callouts go here

Callouts go here

Insert a T Joint at the base of the enclosure.

37

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

38

Callouts go here

Callouts go here

Attach 2x 19.5” Sticks to the base of the

enclosure frame.

39

Callouts go here

Callouts go here

For this section, you will be facing the RIGHT of

the enclosure.

40 Attach an L Joint to the base of the enclosure.

41

Callouts go here

Callouts go here

Attach a T Joint to the base of the enclosure.

42

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

43

Callouts go here

Callouts go here

Attach a 19.5” stick and a 12.5” stick to the base

of the enclosure frame.

44

Callouts go here

Callouts go here

For this section, you will be facing the FRONT of

the enclosure.

45

Callouts go here

Callouts go here

Attach a L Joint to the Bottom Corner of the

enclosure

46

Callouts go here

Callouts go here

Attach an L Joint to the bottom corner of the

enclosure.

47

Callouts go here

Callouts go here

Attach 2x 19.5” Sticks to the L Joints on the

base of the enclosure frame.

48

Callouts go here

Callouts go here

In order to attach the I Joint to the enclosure

frame, you will need to temporarily remove the

sensor module. It is held in place by two #8

x1.25” Screws. Remove these screws and pull

the sensor module away from the I Joint. Do not

remove the wire connecting the sensor module

to the connector housing.

Connector

Housing

I Joint

Sensor

Module

49

Callouts go here

Callouts go here

Press the I Joint into place along the center base

of the enclosure frame and secure in place.

50

Callouts go here

Callouts go here

Reattach the Sensor Module to the I Joint using

the two #8x1.25” Screws. Be sure to pull the

wiring through the hole in the I connector as you

press the sensor module into place, so that there

is plenty of slack on the other side for the

connector housing.

Now, with the assistance of another person, raise

the enclosure frame up over the Desktop and

lower it into place around the tool.

51

Now attach the connector holder at the bottom

front of the enclosure frame to the front piece of

extrusion on the base frame using 2x #14 x ¾”

Truss Head Screws.

52

Locate the small connector for the safety interlock

on the corner of the tool nearest the power

switch.

53

Plug the matching end of the interlock sensor

cable into the wire on the tool.

54

Enclosure Base Assembly

These are the parts that you will need for this

section.

56

#14 x ¾ Truss Head

(006109) x12

#10 x 1.25

Flange Head

(005589) x44

Foot Spacer x4 Foot Cup x4

Edge Grip x4

Long Foot x2

Short Foot x2

Assemble two long risers as shown by first

connecting a foot spacer to a long foot using 4x

#10 x 1.25 Flange Head Screws; then attach a

foot cup to the foot spacer using 4 more screws.

57

Assemble two short feet in the same manner.

58

Getting the riser feet under the tool will require

tipping it up first on one side and then the other,

while sliding the feet into place. There should be

enough room inside the enclosure to allow the

tool to be tilted as shown.

59

Tilt up the left side of the tool and slide the short

risers into place under the two left feet. The

straight edge of the risers should be flush with the

inside edge of the enclosure frame.

60

Now, tilt up the right side of the tool and slide the

long risers into place under the two right feet.

Again the straight edge of the risers should be

flush with the inside edge of the enclosure frame.

61

Press an edge grip into the slot of the extrusion

stick adjacent to the short riser at the left rear of

the tool. Align the three holes in the edge grip

with the three holes on the riser. Insert 3x Flange

Head #10 x 1.25 screws to attach the edge grip

to the riser.

62

Secure the assembled edge grip to the extrusion

using 3x #14 x ¾” Truss Head Screws.

63

Repeat this process for the other risers.

64

65

66

67

68

69

If you find that the enclosure needs to be shifted

forward or backward -- simply remove the screws

attaching the edge grips to their extrusion sticks

and give the enclosure frame a nudge.

70

Enclosure Door Installation

These are the parts that you will need for this

section.

72

#14 x ¾ Truss Head

(006109) x6

Door Assembly

(006114) x2

#10 x 1.25

Flange Head

(005589) x8

#10 x ¾”

Flange Head

(006129) x2

73 This section will guide you through the

installation of the doors for your enclosure.