Show Pro Industries Pro Cutter Cow Series User manual

SHOW PRO INDUSTRIES

P.O. Box 1235, Springtown, TX 76082 / (817)523-4055 / (817)220-5117 fax

Show Pro Industries would like to thank you for purchasing a Pro

Cutter. Every effort has been taken to provide you with a quality

product designed to provide years of trouble-free service.

Pro Cutter 1502

with Performance Package Upgrade

Packing List:

control box (steel box containing electronic components)

digital remote control w Stepper Technology

off-side pulley

installation instructions

Cow Model:

FLEX cow*

slide tubes w/snaps

kevlar cable (custom cut) & "tech" line

Flag Model:

flat braid rope (400’)

trainer flag

(4) heavy duty cable ties for mounting control box

Note: A black & white banner can be added that will interchange with cow.

INSTALLATION INSTRUCTIONS:

Cow Model:

1. Mount control box: Securely attach control box on one side of

arena. It should be mounted so pulleys on bottom of box are

approximately 45 inches from the ground.

2. Mount return pulley: Mount off-side return pulley on opposite side

of arena in horizontal position. It should also be mounted

approximately 45 inches from the ground. See attached

instructions for machines using a cable tensioner.

3. Install kevlar cable: Have an assistant hold cable in center of

arena. Take end of cable attached to slide tube around off-side

pulley, across arena, around both pulleys on bottom of control box,

and back to center. Be sure the straight slide tube slides freely

on the back part of the loop. Tie opposite end of cable to slide

tube and tighten removing as much slack as possible. Tie s knot

and cut off extra cable. Keep in mind that the objective is to form a

loop with the cable. The slide tube with two snaps supports the

cow’s head, and the slide tube with one snap (slides freely on back

part of loop) supports the cow’s shoulder.

4. Install "TECH" line: The tech line is static and supports the cow’s

hip. A slide tube is pre-installed on this line. Tie one end of tech

line to fence as close to control box as possible. There should be

no more than 2 –3 inches between the back part of the loop and

the tech line. Tie to fence on opposite side of arena and tighten.

Installing tech line close to shoulder line causes the cow to travel

flat, stop flat, and turn around smoothly.

5. Apply power: Plug Pro Cutter into grounded 120VAC, 3-prong

outlet. Always unplug unit when not in use. *EURO MODELS:

240VAC/50Hz

6. Attach cow: Following the included drawing, attach cow to slide

tubes on kevlar cable and tech line.

7. Power on Remote: A power button is located on the right side of

the remote control pouch. Press to turn ON.

Note: The power indicator light does NOT illuminate when power

is ON. It only illuminates when you press the directional switches

on the remote control or the Stepper switches.

(Refer to Performance Package instructions on page 9.)

3 inch spacing

Maintain 2 to

Pro Cutter

Off-side Idler Pulley

OVERHEAD VIEW - COW MODEL

Firmly fasten static Tech line to fence

(slides freely on static Tech line)

(fastened rope through center)

Slide tube w/ 2 snaps

(slides freely on second line)

Slide tube w/ 1 snap

Slide tube w/ 1 snap

INSTALLATION INSTRUCTIONS:

Flag Model:

1. Mount control box: Securely attach control box on one side of

arena. It should be mounted so pulleys on bottom of box are

approximately 45 inches from the ground.

2. Mount return pulley: Mount off-side return pulley on opposite side

of arena in horizontal position. It should also be mounted

approximately 45 inches from the ground.

3. Install flat-braid rope: To install flat braid rope, start in center of

arena. Take one end of rope around off-side pulley, across arena,

around pulleys on bottom of control box, and back to center. Tie

one end of rope to left side of flag and other end to right side of

flag while removing slack. Cut extra line.

4. Apply power: Plug Pro Cutter into grounded 120VAC, 3-prong

outlet. Always unplug unit when not in use. *EURO MODELS:

240VAC/50Hz

5. Power on Remote: A power button is located on the right side of

the remote control pouch. Press to turn ON.

Note: The power indicator light does NOT illuminate when power

is ON. It only illuminates when you press the directional switches

on the remote control or the Stepper switches.

(Refer to Performance Package instructions on page 9.)

FRONT VIEW - FLAG MODEL

GROUND

ends of flag

Fasten rope to

OVERHEAD VIEW - FLAG MODEL

Pro Cutter

5" Idler Pulley

FRONT VIEW

TOP VIEW

Pro Cutter Flag models with optional Cable Tensioner

GROUND

Pro Cutter

Fasten rope to

ends of flag

Cable

Tensioner

Cable

Tensioner

Operating Instructions:

Following is a brief description of the various switches and dials:

1. POWER: Flip POWER switch ON to energize control box.

Red POWER light will illuminate. The unit requires 5 seconds to

initialize. Avoid pressing any control buttons while unit initializes.

2. MANUAL: Operate control box left, right, and change speeds.

3. LOGIC: Switch reverses the direction that the cow or flag

travels.

Example: After the Pro Cutter is installed, attach remote control to

your wrist (wrist watch position) and button assembly on index

finger. Press left switch with your thumb. If cow or flag travels to

left, you’re ready to go. However, if cow or flag travels right

toggle LOGIC switch. This will cause the cow or flag to travel left

as you press left switch –and right as you press right switch.

4. FUSE: Power surges, faulty cord, or defective component may

cause a fuse to blow. When this happens, remove fuse and replace

using only 4 amp/250v AGC fuse, or permanent damage may

result.

NOTE: power indicator light will not illuminate when fuse is bad.

5. SPEED DIALS: Front face of control box

SPEED 1: The left speed dial is the starting speed. When the

control box is asked to run using either remote or manual

control switches, the cow or flag will begin moving at Speed 1

regardless of direction. To stop, simply release button or

switch.

SPEED 2: The right speed dial is second speed. To access

Speed 2, begin by pressing a run button on remote or manual

control. The cow or flag will begin moving at Speed 1. When

traveling at Speed 1, release button and re-press immediately.

Control box will shift to Speed 2.

EXAMPLE: Set Speed 1 (left dial) to "15", and Speed 2 to

"45". When a run button is pressed, the cow or flag will move

at SPEED 1. To shift to SPEED 2, start the cow moving at

SPEED 1, then release and instantly re-press run button. The

cow or flag will now travel at SPEED 2.

NOTE: When you stop, the unit automatically resets to

SPEED 1.

NOTE: If the unit fails to shift to SPEED 2, double-click

was not fast enough. User only has 100

milliseconds to cause speed change.

6. REMOTE CONTROL: The remote control can be worn in a variety

of ways depending on comfort and convenience. The most common

method is to strap the control pouch to your preferred wrist, and strap

the button assembly to your index (pointer) finger. The riders thumb

is then used to operate the run buttons.

7. PRACTICE: Attach remote control to your wrist by inserting your

hand through Velcro loop on pouch. Attach switch plate to index

finger and rotate buttons so they can be pushed by your thumb. Walk

to center of arena and practice operating machine. Make any

necessary adjustments. Once comfortable with the controls, you are

ready to introduce your horse to the Pro Cutter. We recommend

working at slow speeds until both horse and rider are acclimated.

ADDITIONAL FEATURES:

* Soft-start acceleration: Progressive acceleration ramp

* Superior radio system: Better range, less interference.

* Large drive system: Heavy-duty industrial components

* Weather-tight NEMA enclosure

*Dynamic braking

Thank you for choosing............

SHOW PRO INDUSTRIES

P.O. Box 1235, Springtown, TX 76082 / (817)523-4055 / (817)220-5117 fax

PERFORMANCE PACKAGE SYSTEM UPGRADE

Your Pro Cutter is now equipped with the all new Performance Package. This full

system upgrade enhances your training experience by giving the rider the ability to make

speed adjustments from horseback using STEPPER technology, and an ultra-high

performance remote control radio package. This new “state of the art” operator interface

provides many advantages over other remote control systems. These include user

programmable functions, instant response, extended range, reduced power consumption,

and a flush mount antenna system.

STEPPER TECHNOLOGY:

Stepper Technology refers to the process of changing speeds from horseback using the

wrist mounted remote control. After setting your base speeds on the Pro Cutter

CONTROL BOX, the rider can further adjust speed(s) by pressing the SPEED UP or

SPEED DOWN buttons located top of the

remote control pouch. Each press of either

button will result in a 10% CHANGE in speed;

with a total number of 10 STEPS available.

Cycling power ON/OFF on the Pro Cutter

CONTROL BOX will reset the STEPPER

back to a “0” setting.

REMOTE CONTROL:

The remote control includes an easily replaceable 9 volt alkaline battery and is ready to

operate once your Pro Cutter is installed. NOTE: Be sure to check the date stamp

when purchasing new batteries. As with any electronic device, the remote control

should be stored in a cool, dry location to enhance battery life and prevent corrosion.

Should the remote control become wet, damage may be prevented by immediately

removing the battery and leaving the battery door off in a warm, low humidity location

for several hours. The battery should also be removed during extended storage periods

exceeding 2 to 3 months. Direct replacement remote controls are readily available should

the original unit become lost or damaged.

A power button is located on the right side of the remote control pouch. The power

indicator light does NOT illuminate when power is ON. It only illuminates when you

press the directional switches on the remote control OR one of the Stepper switches.

Battery requires replacement if light is on continuously, or does not illuminate when

control buttons are pressed.

NOTE: ALWAYS turn power button “Off”

on remote control when not in use!

PAIRING (PROGRAMMING):

At times it is desirable to operate multiple Pro Cutters in close proximity without the

remote controls cross-communicating. This requires a simple PAIRING procedure to

shift the radio package to an alternate frequency. The following procedure outlines the

pairing (programming) process which requires opening the Pro Cutter drive box with

power applied. Care must be taken to avoid contact with live circuits or electric shock

may occur. Show Pro Industries accepts no responsibility for damage or injury resulting

from contact with live electrical circuits. PROGRAM RADIOS AT YOUR OWN

RISK.

1) Begin by opening the lid on the Pro Cutter drive box. This is accomplished using a

blade screw driver on the ¼ turn lid latch. Once open, the radio receiver is located in

the top-center of the control box (drawing 1). Using drawing 1 as a guide, identify

the black PAIR button located near the center of the receiver circuit board.

(drawing 1)

PAIRING

RF GOODBAT/RNGEPAIRING

ANT

RESET

RECEIVER

(HOLE)

PAIRING

BATTERY RESET

TRANSMITTER

1) Remove the wireless remote control from the canvas/Velcro pouch. Using drawing 2

as a guide locate the pairing hole in the upper left corner of the remote control case.

A small pin will be required to access the pairing switch.

2) With power applied to the Pro Cutter drive box, press and release the black PAIR

button on the radio receiver board. A yellow PAIR indicator will illuminate on the

receiver board indicating the receiver is searching for the remote control. Next, press

and release the PAIR button on the remote control using a small pin. You should

now see the yellow PAIR indicator flash and the green RF GOOD indicator

illuminate. Wait for both indicators to turn off before pressing any buttons or

switches.

Pairing is complete once both indicators turn off. Test for proper operation by

pressing the remote control RUN buttons. The green RF GOOD indicator should

illuminate each time a RUN button is pressed. Close Pro Cutter lid being careful to

fully engage lid latch to prevent possible damage from water/dirt entering control

box. Reinstall remote control case into Velcro pouch.

Important Safeguards:

1. Electrical enclosure (control box) should be protected with a non-metal roof

or shield. This not only protects the paint finish but also keeps rubber

components (gasket, boots, antenna, etc.) from drying out.

2. Warning: Electric shock or malfunction could occur if power cord or plug is

damaged in any way. Do not work Pro Cutter in rain –or allow cord or plug

to lie in water.

3. Always use properly grounded 120VAC electrical outlet.

4. Do not operate Pro Cutter if control box, or any of its components are

damaged in any way, or after malfunction.

5. Use Pro Cutter only as intended and described in literature.

6. Always unplug Pro Cutter when through working each day.

7. Do not allow flag to run into ends, or damage may occur to electronics, rope,

or both.

TROUBLESHOOTING

Problem: Solution:

1. Pro Cutter will not operate Make sure there is power to

using remote control or manual machine. Check 4A fuse.

switch.

2. Pro Cutter will operate using Check battery in remote

manual switch but not remote control. Be sure antenna &

control. receptacle aren’t damaged.

3. There’s a “clicking” noise Fuse is blown.

but Pro Cutter won’t run. replace fuse (4 amp, 250 v.,

fast blow).

NOTE: The remote control, worn on the rider’s wrist, has a 9-volt battery in the plastic

case inside the pouch. The battery must be changed on a regular basis.

LIMITED WARRANTY

SHOW PRO INDUSTRIES

P.O. Box 1235, Springtown, TX 76082 / (817)523-4055 / (817)220-5117 fax

The following warranty is in lieu of all

other warranties, expressed, implied or

statutory, including but not limited to any

implied warranty of merchantability or

fitness for a particular purpose.

All new products sold by Show Pro Industries are warranted

against defects in material and workmanship for two (2) years

from the date of original purchase. During the warranty period,

Show Pro Industries will repair, or at its option replace without

charge, any SPI product (excluding normal wear items), providing

it is returned to the factory, shipping prepaid, and is proven to be

defective during the subsequent factory inspection. The warranty

period for products repaired after expiration of new product

warranty, as stated above, is limited to the repair portion and is

valid for 90 days from date of reshipment to customer. All

warranties, expressed or implied, are void if product is damaged

by accident, misuse or modification in the absence of written

authority from Show Pro Industries.

This manual suits for next models

4

Table of contents

Popular Cutter manuals by other brands

DeWalt

DeWalt Klein Tools BAT20-G Series instruction manual

Huskie Tools

Huskie Tools REC-SB624CC Operation manual

Cembre

Cembre B-TC065-SC Operation and maintenance manual

Textron

Textron Klauke Mini+ ES 32-L instruction manual

Toro

Toro 03240 installation instructions

Thermal Dynamics

Thermal Dynamics COUGAR 125 Service manual

VONROC

VONROC TC501AC Original instructions

Lincoln Electric

Lincoln Electric Growth Series Assembly guide

BASETech

BASETech TO-6683673 operating instructions

EINHELL

EINHELL 43.011.63 Original operating instructions

Siding Tools Industries

Siding Tools Industries UK-12 owner's manual

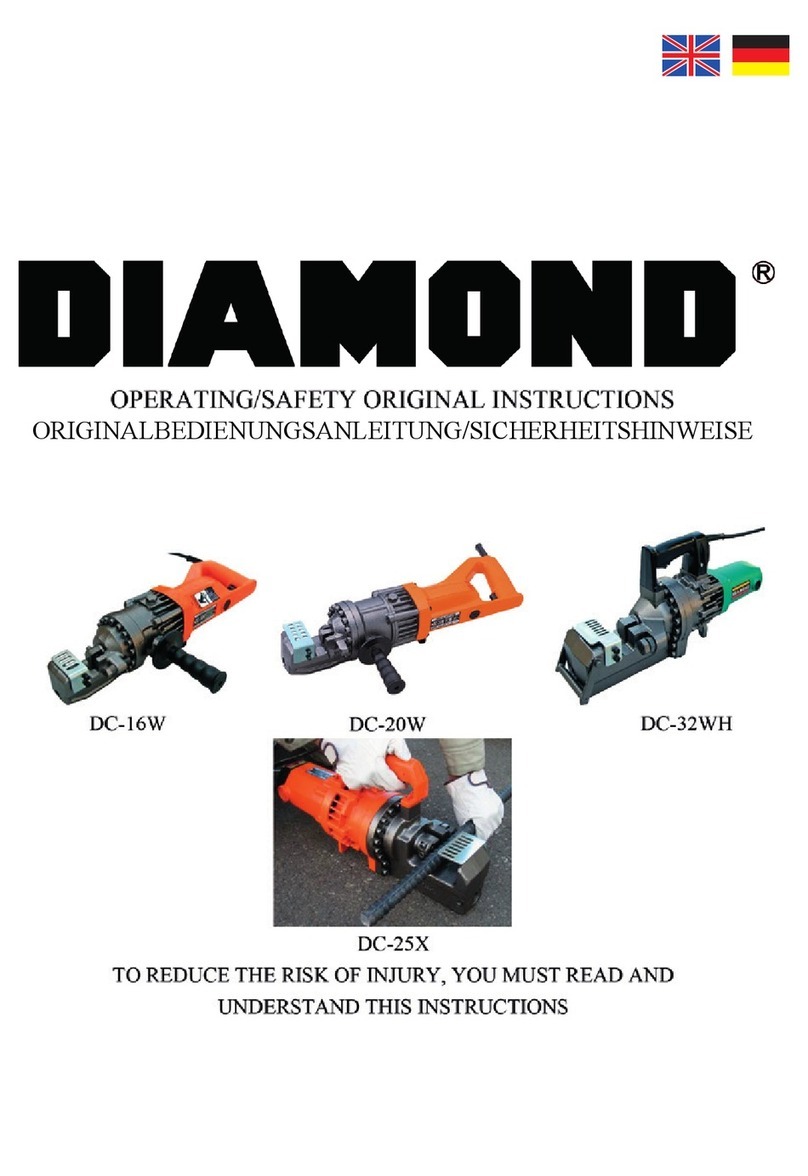

Diamond

Diamond DC-16W Operating / Safety Original Instrcutions