Toro 03240 User manual

FormNo.3446-292RevA

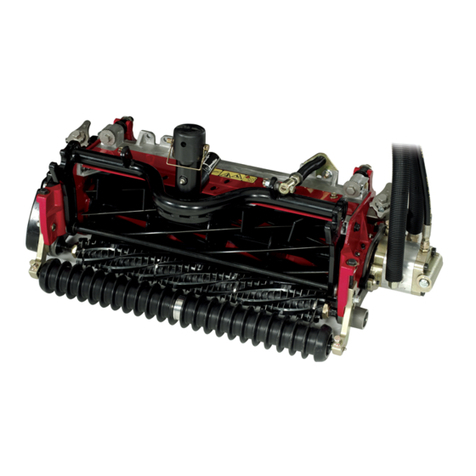

UniversalGroomerDriveKit

Reelmaster®3100-DEdgeSeries™27-inchCuttingUnits

ModelNo.03240—SerialNo.321000000andUp

InstallationInstructions

Introduction

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheDeclarationof

Incorporation(DOI)atthebackofthispublication.

Important:Beforeinstallingthiskit,ensurethat

youhaveacompatiblecuttingunit:

03240isdesignedforuseon27-inchReelmaster

DPACuttingUnits.

Refertothefollowingtableforfurtherdetail:

Universal

Groomer

DriveKit

CompatibleCutting

Units

IncompatibleCutting

Units

03240Allaluminumsideplate

cuttingunits,Model

Numbers:03188,

03189,03190

Paintedredsideplate

DPAcuttingunits,

ModelNumbers:03180,

03181,03183

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comforproductandaccessory

information,helpndingadealer,ortoregisteryour

product.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

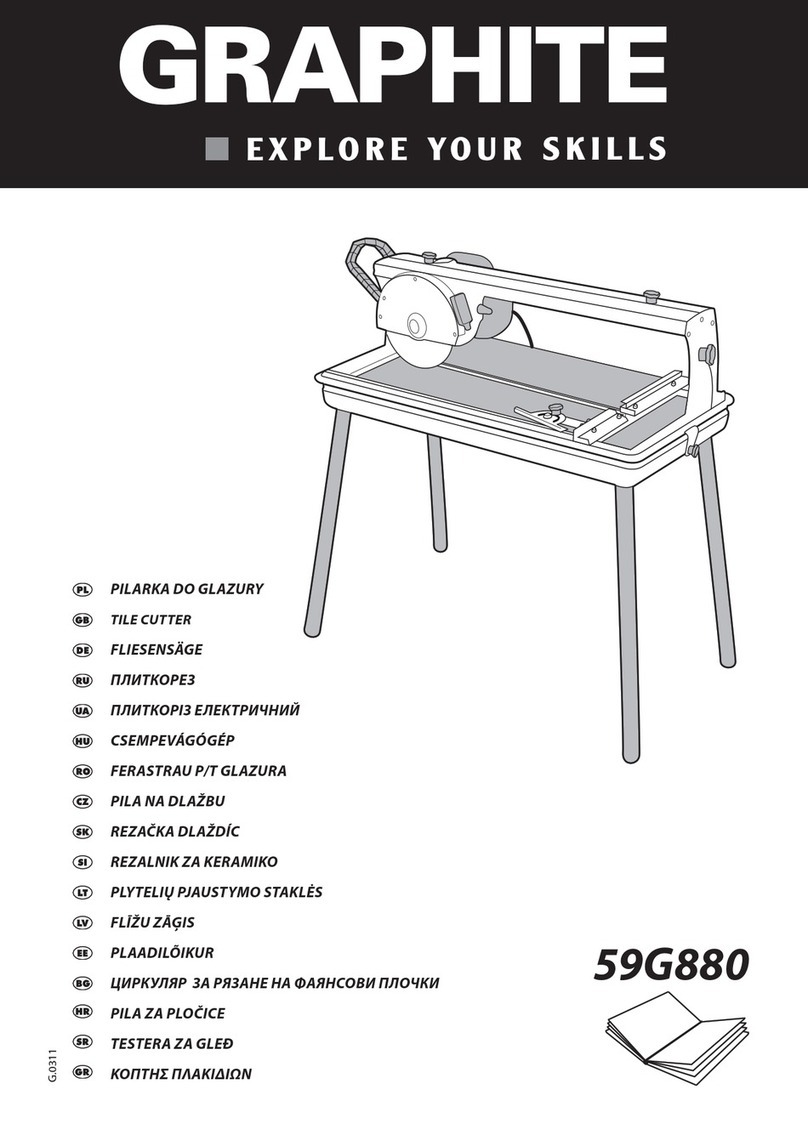

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g357127

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved*3446-292*

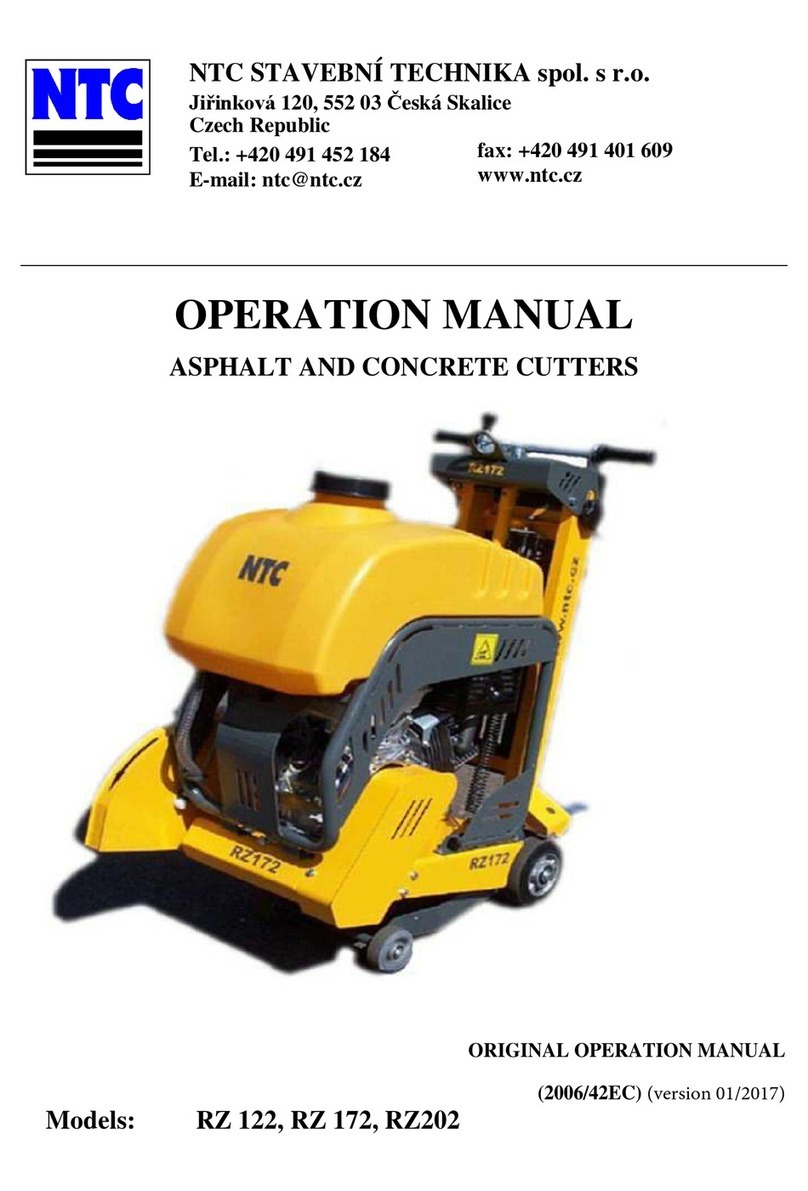

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

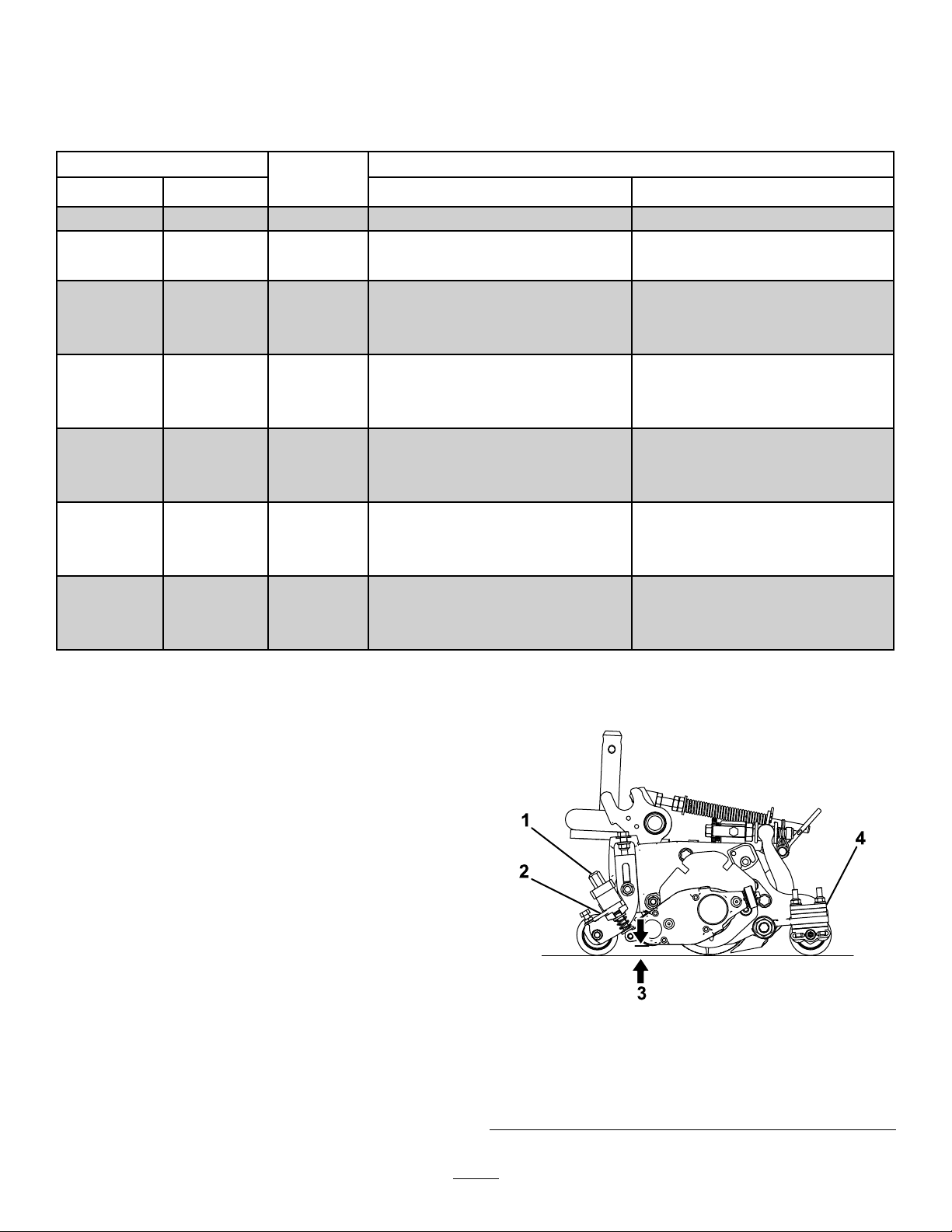

ProcedureDescriptionQty.Use

1Nopartsrequired–Preparethemachine.

2Torquewrench(Notincluded)–Gatherthetoolsrequiredforsetup.

3Nopartsrequired–Determinethegroomergearbox

position.

Extendedsplinedinsert(right-hand

threads)2

4Extendedsplinedinsert(left-hand

threads)1

Preparethecuttingunit.

Weightbracket3

Hex-socket,button-headbolt(3/8x3/4

inch)6

Groomerdrivebox(leftdrive)2

5

Groomerdrivebox(rightdrive)1

Installtheweightbracketandgroomer

drivebox.

Idlerassembly(left)1

Idlerassembly(right)2

O-ring3

Pivothub3

Socket-headscrew(3/8x3/4inch)6

6

Locknut(3/16—thin)6

Installtheidlerassembly.

Shoulderbolt6

Hardenedwasher3

LeftHOCbracketassembly3

RightHOCbracketassembly3

7Flangelocknut(3/8inchwith5/8inch

hex)6

InstalltheHOCbracketassembliesand

thefrontroller.

8

Cap(foruniversalgroomerassemblies

withnorearrollerbrushkitinstalled

only)

3Installthegroomerdrivecap.

Bolt(1/4x1-1/2inches)12

Jamnut12

Shaftclamp12

9Groomingreel(orderseparately)3

Installthegroomerassembly(ordered

separately)andoptionalbroomerkit.

10Washer(PartNo.3256-24,notincluded)–Adjustthegroomerspringforce.

Carriagebolt(5/16x3-1/2inches)6

Spacer6

Flangenut(5/16inch)6

11Weight18

Installtheweights(groomeronly,with

orwithoutfrontgrassbasketsandrear

cuttingunitwithoutreargrassbasket).

Carriagebolt(5/16x3-1/2inches)6

Spacer6

Flangenut(5/16inch)6

12Weight12

Installtheweights(withgroomerand

rearrollerbrush).

2

ProcedureDescriptionQty.Use

Carriagebolt(5/16x2-1/4inches),Part

No.3230-7—soldseparately1

Carriagebolt(5/16x3-1/4inches),Part

No.3230-13—soldseparately1

Carriagebolt(5/16x4-1/2inches),Part

No.3230-30—soldseparately1

Spacer2

Flangenut(5/16inch)1

Locknut(5/16inch),PartNo.

3296-47—soldseparately2

Weight2

13

Smallweight(PartNo.

132-0734-03—soldseparately)6

Installtheweights(rearcuttingunitwith

groomeronly,withreargrassbasket).

14Nopartsrequired–FinishinstallingtheUniversalGroomer

DriveKit.

1

PreparingtheMachine

ForCuttingUnitsInstalledonthe

Machine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Lowerthecuttingunits.

4.Shutofftheengine,removethekey,andwaitfor

allmovingpartstostop.

5.Removethecuttingunitsfromthemachine;refer

totheOperator’sManualforthetractionunit.

2

GatheringtheTools

RequiredforSetup

Partsneededforthisprocedure:

–Torquewrench(Notincluded)

Note:Ensurethatthetorquewrenchesarecapable

oftorquingbothclockwiseandcounterclockwise.

•T orquewrench—5.2to6.8N∙m(46to60in-lb)

•T orquewrench—16to22N∙m(12to16in-lb)

•T orquewrench—20to26N∙m(15to19in-lb)

•T orquewrench—115to129N∙m(85to95ft-lb)

•T orquewrench—135to150N∙m(100to110ft-lb)

•Reeldriveshafttool,PartNo.TOR4074

•Long-handledprybar(3/8x12inches)

ServiceTools

Oilsyringe(included),PartNo.137-0872;referto

ChangingtheGearboxLubricant(page19).

Driveshafttool(optional),PartNo.137-0920;refer

toyourtractionunitServiceManualorcontactyour

authorizedT orodistributor.

3

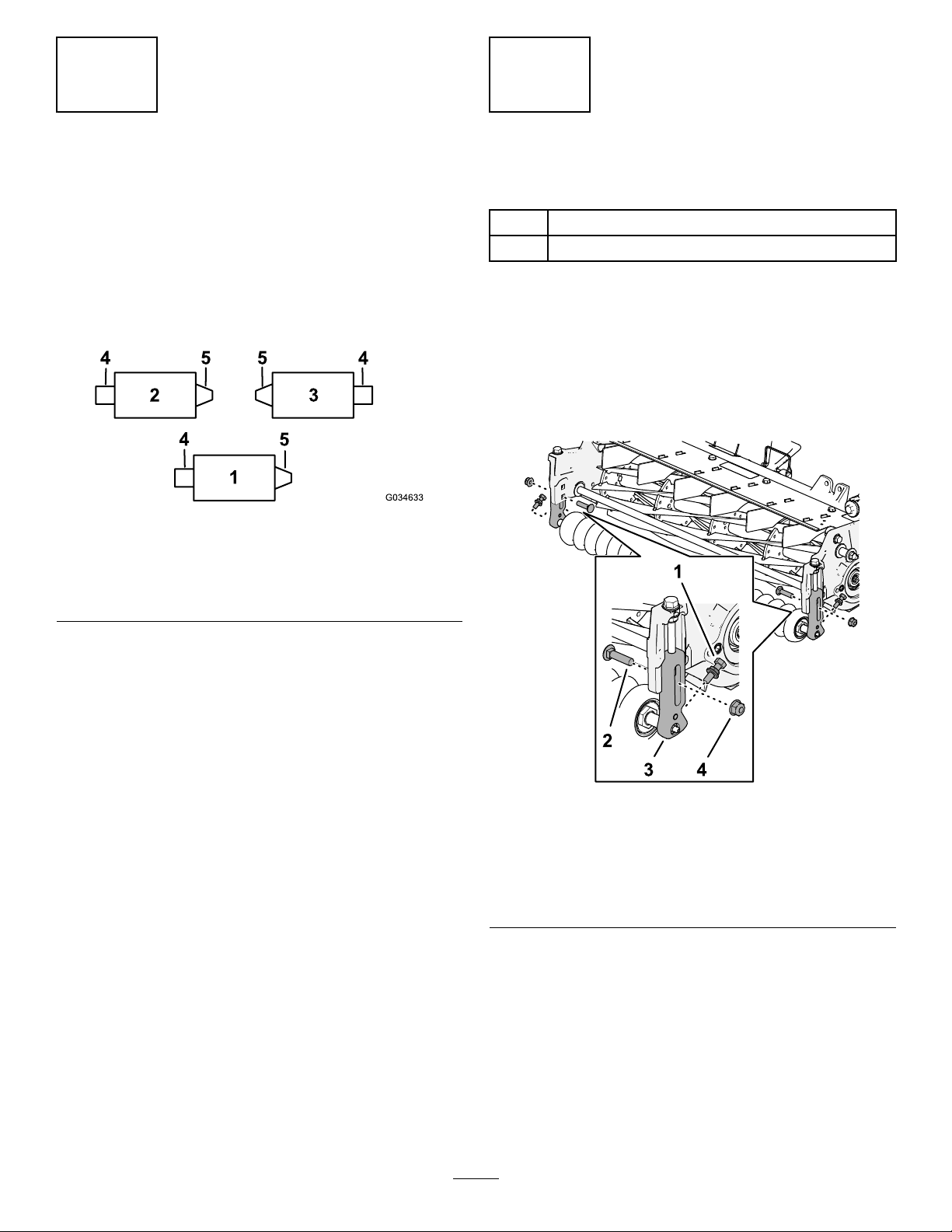

3

DeterminingtheGroomer

GearboxPosition

NoPartsRequired

Procedure

Usethefollowingdiagramtodeterminethepositionof

thegroomergearboxandreelmotors.

g034633

Figure2

1.Cuttingunit14.Groomergearboxposition

2.Cuttingunit25.Reelmotorposition

3.Cuttingunit3

Note:Ifyouareinstallingagroomerkitandyouare

installingtherearroller-brushkitontothecuttingunits,

installthegroomerkitrst.

4

PreparingtheCuttingUnit

Partsneededforthisprocedure:

2Extendedsplinedinsert(right-handthreads)

1Extendedsplinedinsert(left-handthreads)

RemovingtheFrontRollerand

HeightofCutBrackets

1.Loosenthe2angenuts(5/16inch)and2

capscrews(5/16x1-1/4inches)andsecuring

front-rollershafttothe2height-of-cutbrackets

(Figure3).

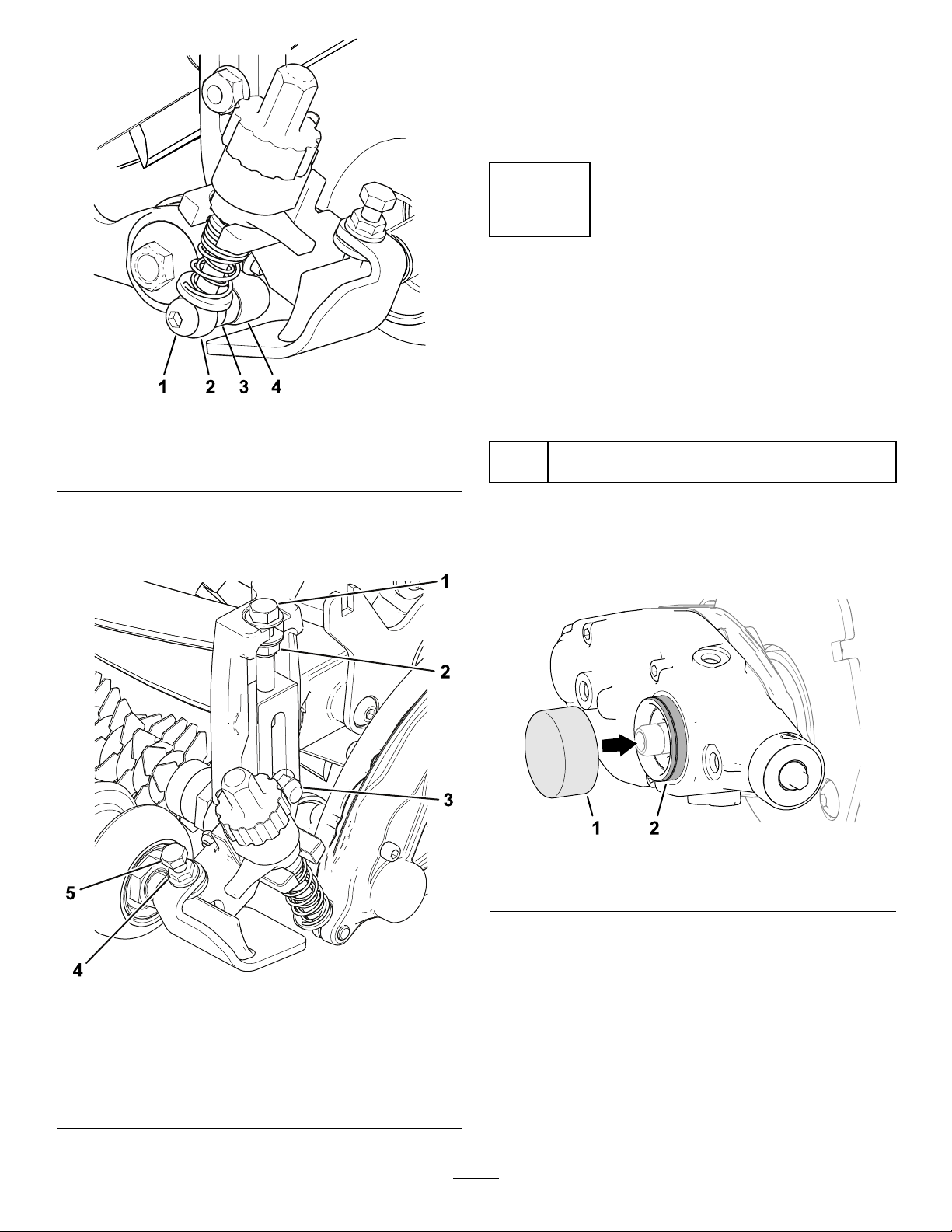

g356734

Figure3

1.Capscrew(5/16x1-1/4

inches)andangenut

(5/16inch)

3.Height-of-cutbracket

2.Carriagebolt(3/8x1-1/2

inches)

4.Flangelocknut(3/8inch)

2.Removetheangelocknut(3/8inch)and

carriagebolt(3/8x1-1/2inches)securingthe

height-of-cut(HOC)brackettothecutting-unit

sideplate(Figure3).

Note:Retainthecarriagebolt(3/8x1-1/2

inches).

Discardtheangenut(5/16inch),capscrew

(5/16x1-1/4inches),andangelocknut(3/8

inch).

4

3.Loosentheangelocknut(3/8inch)and

capscrew(3/8x3-7/8inches)intheheight-of-cut

bracket(Figure4).

g356733

Figure4

1.Sideplate4.Height-of-cutbracket

2.Flangelocknut(3/8inch)5.Shaft(roller)

3.Capscrew(3/8x3-7/8

inches)

4.Removetheheight-of-cutbracketfromthe

sideplate,andremovetherollerfromthe

height-of-cutbrackets.

Note:Retainthefrontroller.

Discardtheangelocknut(3/8inch),capscrew

(3/8x3-7/8inches),andheight-of-cutbracket.

5.Repeatsteps2and3attheothersideor

thecuttingunit,andremovetheheight-of-cut

bracketformthesideplate.

RemovingtheSupportRod

Removethe2ange-headboltsandwasherssecuring

thesupportrod,andremovethesupportrod(Figure

5).

Note:Discardthesupportrodandange-headbolts.

g192295

Figure5

1.Flange-headbolts(2)3.Washer(2)

2.Supportrod

5

RemovingtheSplinedInsert

Lockingcompoundsolvent:Loctite®768™solvent

(59ml(2oz)HenkelPartNo.768X-NMS)

1.Restrainthereeltoremovetheexistingsplined

insert;refertoRestrainingtheReelforRemoving

ThreadedInserts(page21).

2.Usingthereeldriveshafttool(ToroPartNo.

TOR4074),removeanddiscardtheexisting

splinedinsertsfromeachendofthereel

driveshaft(Figure3).

Important:Thesplinedinsertattheleftside

ofthecuttingunithasleft-handthreads.The

splinedinsertattherightsideofthecutting

unithasright-handthreads.

g356735

Figure6

1.Reeldriveshaft2.Splinedinsert

3.UseLoctite768solventandawirebrushtoclean

thethreadsineachendofthereeldriveshaft.

4.Drythereel-driveshaftthreads.

AssemblingtheExtendedSplined

Insert

HydraulicMotorSide

Note:Thesplinedinsertattheleftsideofthecutting

unithasleft-handthreads.Thesplinedinsertatthe

rightsideofthecuttingunithasright-handthreads.

1.Restrainthereeltoinstalltheextendedsplined

insert;refertoRestrainingtheReelforInstalling

ThreadedInserts(page22).

2.Applymedium-strengththread-locking

compound(suchasBlueLoctite®243)tothe

threadsinthehydraulicmotorendofthereel

driveshaft.

g356732

Figure7

1.Extendedsplinedinsert2.Reeldriveshaft

3.Assembletheextendedsplinedinsertintothe

endofthereeldriveshaft(Figure7).

4.Torquetheinsertto115to128N∙m(85to95

ft-lb).

5.Allowthethread-lockingcompoundtocurefor

15minutes.

6

5

InstallingtheWeight

BracketandtheGroomer

DriveBox

Partsneededforthisprocedure:

3Weightbracket

6Hex-socket,button-headbolt(3/8x3/4inch)

2Groomerdrivebox(leftdrive)

1Groomerdrivebox(rightdrive)

AssemblingtheWeightBracketto

theCuttingUnit

1.Atthesideofthecuttingunitoppositeofthe

extendedsplinedinsert,aligntheholesinthe

weightbracketwiththeholesinthesideplate

(Figure8).

g356787

Figure8

1.Sideplate3.Socket-headscrew(3/8x

3/4inch)

2.Weightbracket

2.Assembletheweightbrackettothesideplate

withthe2socket-headscrews(3/8x3/4inch).

3.Torquethescrewsto37to45N∙m(27to33

ft-lb).

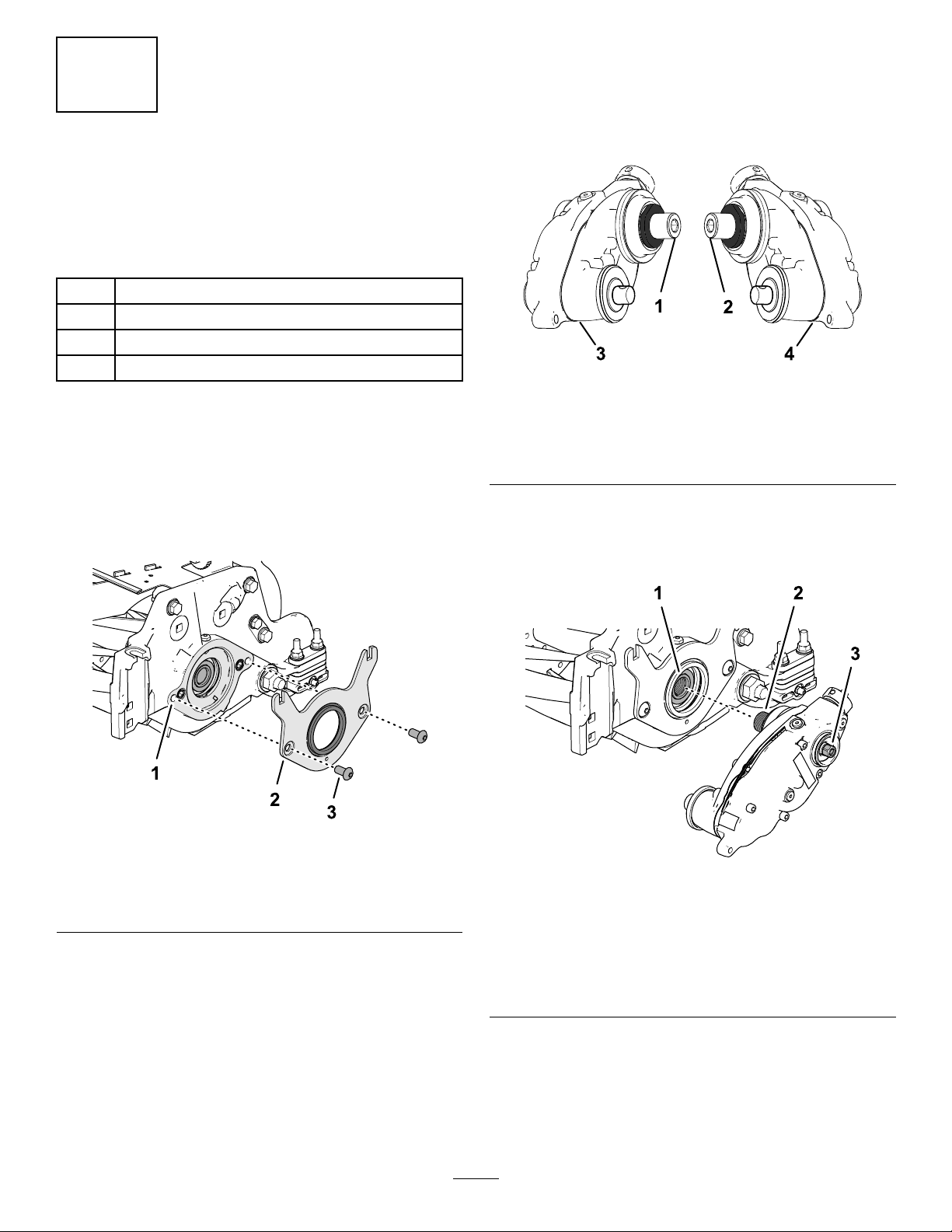

AssemblingtheGroomerGearbox

totheCuttingUnit

1.Identifytheleftdrivegroomerdriveboxesand

theright-drivegroomerdriveboxes;referto

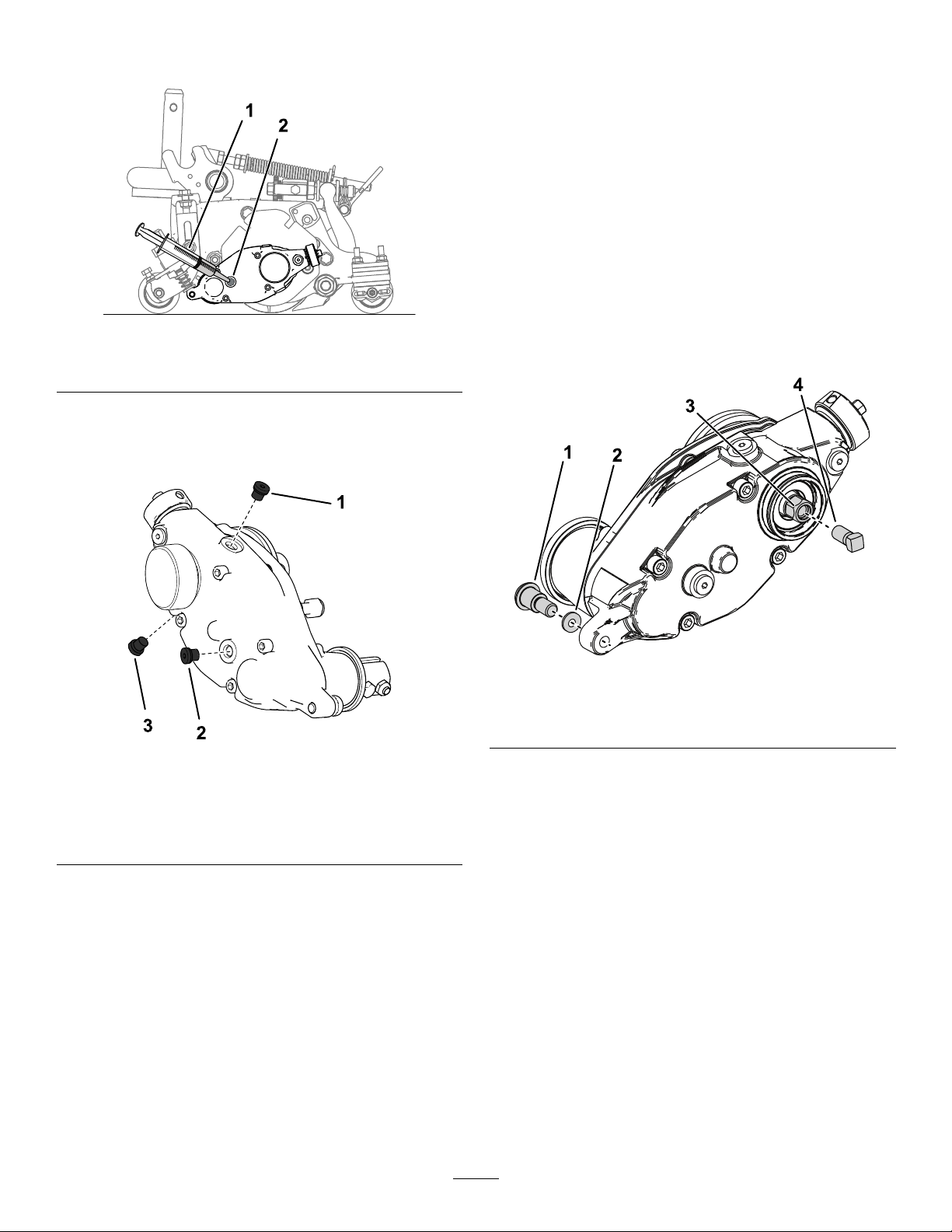

Figure9.

g346922

Figure9

1.Right(yellow)adapter3.Groomerdrivebox—right

drive

2.Left(green)adapter4.Groomerdrivebox—left

drive

2.Applyacoatofmedium-strengththread-locking

compound(suchasBlueLoctite®243)tothe

threadsintheendofthereeldriveshaft(Figure

10).

g356786

Figure10

1.Reeldriveshaft3.Hex-head(gearbox

driveshaft)—torqueto

135to150N∙m(100to

110ft-lb)

2.Driveshaftadapter

(groomergearbox)

3.Alignthedriveshaftadapterwiththeendofthe

reeldriveshaft,andthethreadtheadapterinto

thereeldriveshaftbyturningthehex-headof

thegearboxdriveshaft.

7

Important:Thereelthreadsontheleftside

ofthecuttingunitareleft-handed,andthe

reelthreadsontherightsideofthecutting

unitareright-handed.

4.Restrainthecuttingreel;refertoRestrainingthe

ReelforInstallingThreadedInserts(page22).

5.Torquethehex-headofthegearboxdriveshaft

to135to150N∙m(100to110ft-lb).

Important:Youmustusea6-pointsocket

withheavywall.

Important:Donotuseanimpactwrenchfor

thisstep.

6.Allowthethread-lockingcompoundtocurefor

15minutesbeforecontinuingtheprocedure.

7.Ifyouareinstallingthegroomerattheleftsideof

themachine,performthefollowing(Figure11):

A.Removethehex-socketscrewthatsecures

theclutchknobtotheactuatorshaft.

B.Removetheclutch-knobassemblyandip

itover(Figure11).

C.Assembletheclutchknobtotheactuator

shaftwiththehex-socketscrew.

g298196

Figure11

1.Hex-socketbolt2.Clutch-knobassembly

8.Ifyouareinstallingarearrollerbrush,installthe

rearrollerbrushdrive;refertotheRearRoller

BrushKitInstallationInstructions.

6

InstallingtheIdler

Assembly

Partsneededforthisprocedure:

1Idlerassembly(left)

2Idlerassembly(right)

3O-ring

3Pivothub

6Socket-headscrew(3/8x3/4inch)

6Locknut(3/16—thin)

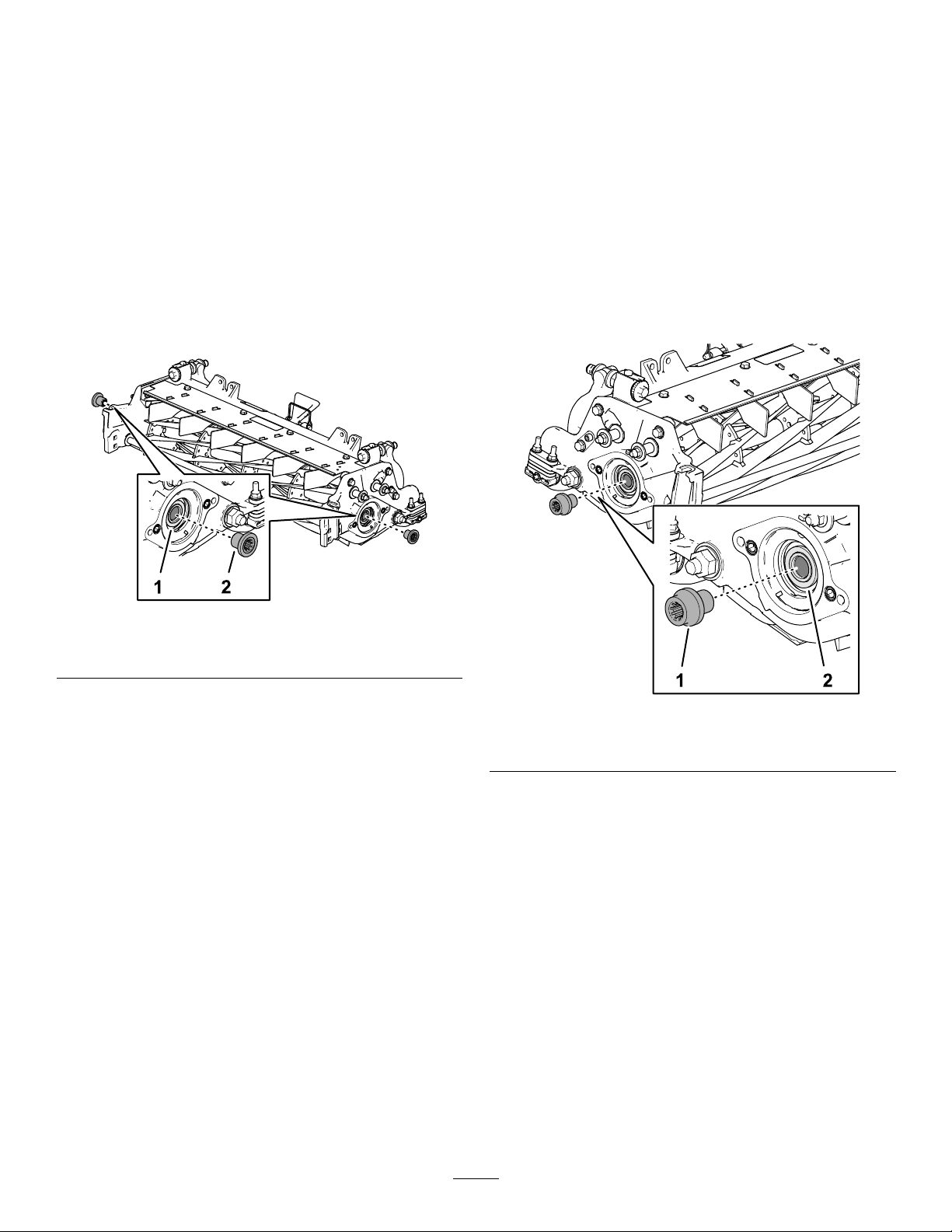

AssemblingtheIdlertotheCutting

Unit

1.AssembletheO-ringontothepivot-hub(Figure

12).

g356810

Figure12

1.Cuttingunit(hydraulic

motorside)

4.Pivot-hub(applyanti-seize

tothehuboutside

diameter)

2.Idlerassembly5.Socket-headscrew(3/8x

3/4inch)

3.O-ring6.Locknut(3/16—thin)

2.Applyacoatofanti-seizecompoundtothe

outsidediameterofthepivot-hub.

3.Positiontheidlerassemblyatthehydraulic

motorsideofthereel(oppositeofthegroomer

gearbox).

4.Insertthepivothubintotheidler,andassemble

thehubandidlertothecuttingunit(Figure12)

with2socket-headscrews(3/8x3/4inch).

8

5.Torquethesocket-headscrewsto37to45N∙m

(27to33ft-lb).

6.Looselyinstallthe2locknutsonthepivothub.

7

InstallingtheHOCBracket

AssembliesandtheFront

Roller

Partsneededforthisprocedure:

6Shoulderbolt

3Hardenedwasher

3LeftHOCbracketassembly

3RightHOCbracketassembly

6Flangelocknut(3/8inchwith5/8inchhex)

Procedure

1.LooselyinstalltheleftandrightHOCbracket

assembliesandthefrontrollerassemblytothe

cutting-unitsideplatesusingthepreviously

removedcarriagebolts(Figure13).

g246878

Figure13

1.RightHOCbracket

assembly

4.Carriageboltandange

locknut(3/8with5/8inch

hex)

2.Frontrollerassembly5.Washers

3.LeftHOCbracket

assembly

2.Applymedium-strengthcylindricalbonding

retainingcompound(suchasBlueLoctite242®)

totheshoulderboltspriortoinstallingthe

adjusterarmstothegroomerdriveboxandthe

idlerassembly.

3.Onthegroomerboxside,positionthe

adjuster-armrodoftheHOCbracketonthe

insideofthegroomerdriveboxandsecureit

withashoulderboltandahardenedwasheras

showninFigure14;torquetheshoulderboltto

16to22N⋅m(12to16ft-lb).

Note:Theshoulderboltmustbeinstalledfrom

theinsideofthemachinetotheoutsideofthe

machine.

g346924

Figure14

1.Shoulderbolt3.Hardenedwasher

2.Adjuster-armrod4.Groomerdrivebox

4.Ontheidlerassemblyside,alignthe

adjuster-armrodoftheHOCbracketwiththe

adjustercollarontheidlerassemblyandsecure

itwithashoulderboltasshowninFigure12;

torquetheshoulderboltto20to26N⋅m(15to

19ft-lb).

9

g346925

Figure15

1.Shoulderbolt3.Adjustercollar

2.Adjuster-armrod4.Idlerassembly

5.Tightenthecarriageboltsandlocknutssecuring

theHOCbracketassembliestothesideplates

(Figure16).

g346926

Figure16

1.Adjustingbolt4.Flangenut

2.Locknut5.Capscrew

3.Carriageboltandange

locknut(3/8with5/8inch

hex)

6.TightenthelocknutontheHOCadjusterbolt,

thenbackoffthelocknut1/2turn(Figure16).

7.CenterthefrontrollerbetweentheHOCbracket

assembliesandlockitinplacewiththecap

screwsandangenuts(Figure16).

8

InstallingtheGroomer

DriveCap

ForCuttingUnitswithoutaRear

RollerBrushKitOnly

Partsneededforthisprocedure:

3Cap(foruniversalgroomerassemblieswithnorear

rollerbrushkitinstalledonly)

Procedure

1.Cleanthemountingareaonthegearbox(Figure

17).

g355416

Figure17

1.Groomerdrivecap2.Mountingarea

2.ApplyalightcoatofLoctite609retaining

compound(green)tothemountingarea.

3.Installthegroomerdrivecapontothemounting

area(Figure17).

10

9

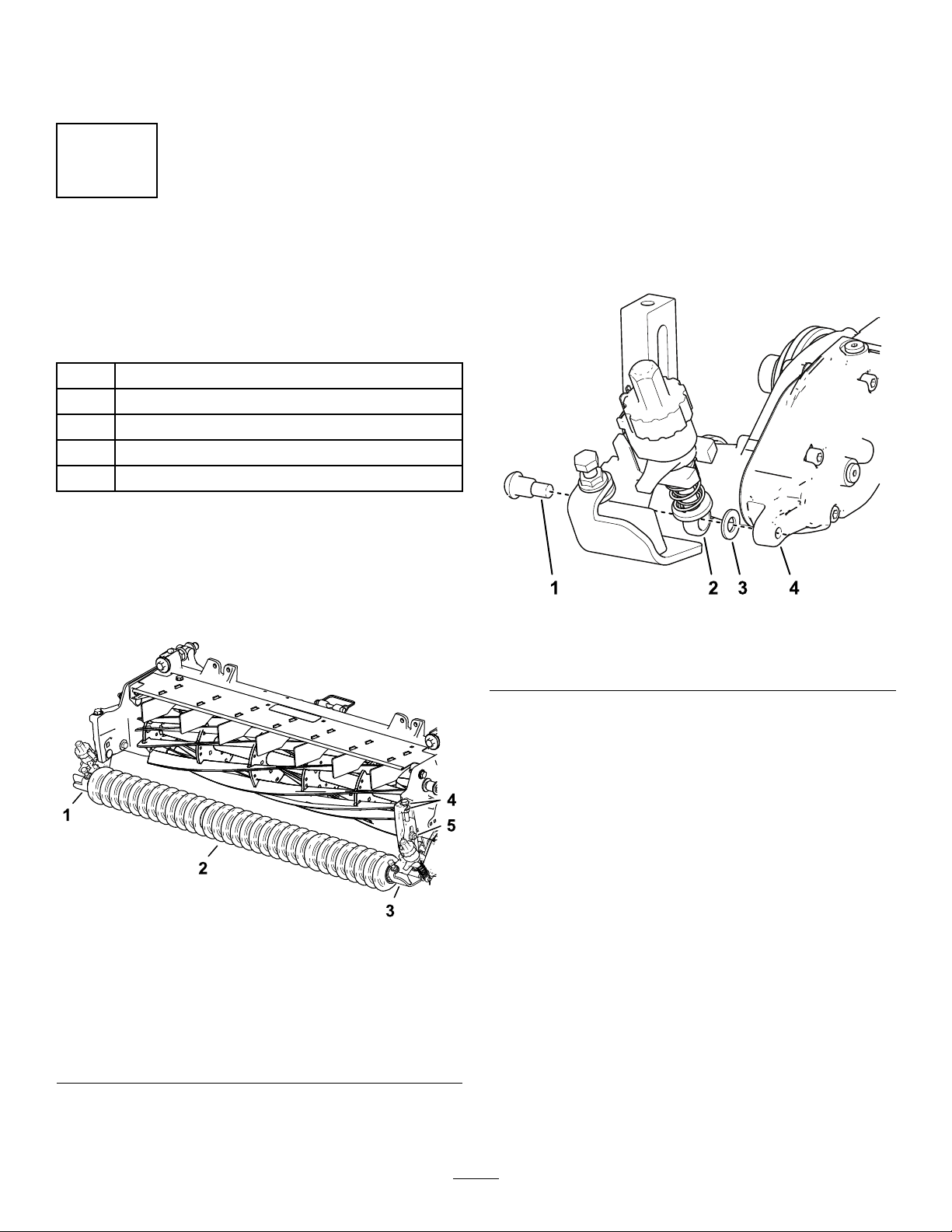

InstallingtheGroomer

AssemblyandOptional

BroomerKit

GroomerandBroomerKitsCome

Separately

Partsneededforthisprocedure:

12Bolt(1/4x1-1/2inches)

12Jamnut

12Shaftclamp

3Groomingreel(orderseparately)

InstallingtheOptionalGroomer

Kit

OrderedSeparately

ModelNumberGroomer

0324127-inchGroomerBladeCartridgeKit

1.Obtainagroomerbladecartridgekitorabrush

kitappropriateforyourneedsandcuttingunit;

refertothetableabove.

2.Lineupthegroomerassemblywiththe

drive-stubshaftsofthegroomerdriveboxand

idlerassembly(Figure18).

g240752

Figure18

1.Drive-stubshaft4.Shaftclamp(4)

2.Groomerassembly5.Bolt(4)Torqueto5to7

N∙m(46-60in-lb)

3.Jamnut(4)

3.Securethegroomertothemachineasshownin

Figure18using4bolts(1/4x1-1/2inches),4

jamnuts,and4shaftclamps.

4.Torquetheboltsto5to7N∙m(46to60in-lb).

InstallingtheOptionalBroomerKit

PartNumberBroomerKit

133-822227-inchBroomerKit

1.Obtaintheoptionalbroomerkitforgroomer

bladecartridgesappropriateforyourneedsand

cuttingunit;refertothetableabove.

2.Loosenthegroomerblade-retainingnutson

eachendofthegroomershaft(Figure19).

11

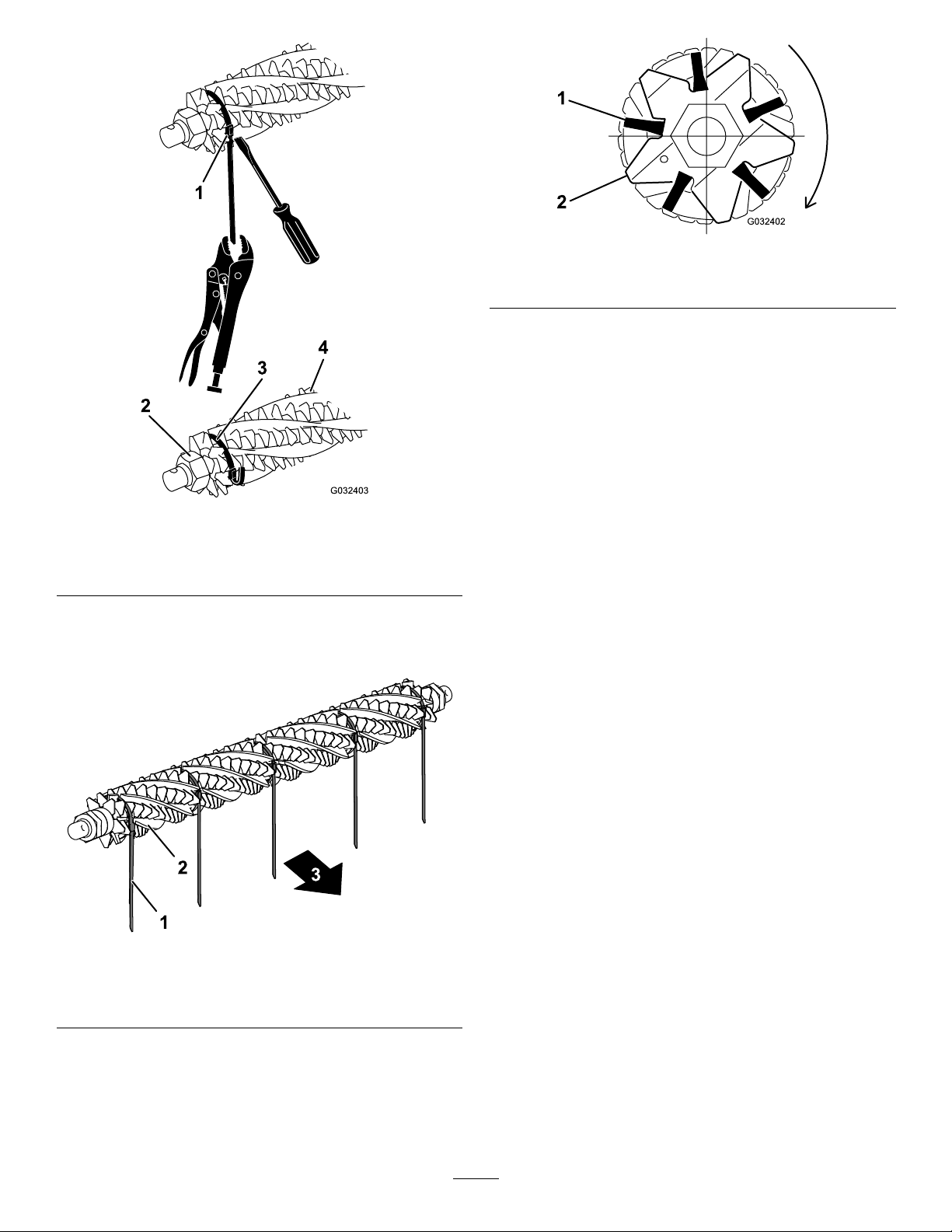

g032403

Figure19

1.Strapbuckle3.Strap

2.Retainingnut4.Brush

3.From1sideofthegroomerreel,slideabrush

intoeachgroovearoundthefulllengthofthe

groomerreel(Figure20).

g232518

Figure20

1.Strap3.T owardrearofmachine

2.Brush

4.Verifythatthebrushesareseatedinthegroomer

bladeslots(Figure19andFigure21).

g032402

Figure21

1.Brush2.Blade

5.Looselywrapthestraps,asshowninFigure

19,aroundthegroomerreelshaftandbrushes

insertingthestrapsinthegroovesinthebrushes

Figure21.

Positionthebrushessothatthestrapsare

betweenthefollowingblades:2and3;12and

13;23and24or24and25;35and36,and45

and46.

Important:Youmustwrapthestrapsaround

thegroomerbladeandbrushassemblyinthe

primaryrotatingdirection.Figure20shows

thestrapsinstalledforforwardrotation.

Note:Ifthebroomerbrushesarenot

seatedproperlyinthebladeslots,loosenthe

groomer-bladeretainingnutsoneachendofthe

groomershaft,positionthebroomerbrushes

properlyinthebladeslots,andtightenthe

groomer-bladeretainingnuts(Figure19).

6.Tightenthegroomerbladeretainingnuts;torque

themto45.2N∙m(400in-lb).

7.Whilepushingascrewdriveragainstthestrap

buckle,graspthestrapwithalockingpliersand

pullthestrapstightuntiltheylockintothebrush

grooves(Figure19).

8.Trimthestrapsothatitis6mm(1/4inch)from

thebuckleandfoldtheexcessstrapoverthe

buckle.

12

10

AdjustingtheGroomer

SpringForce(Optional)

Partsneededforthisprocedure:

–Washer(PartNo.3256-24,notincluded)

Procedure

Forlowheight-of-groomsetupswhereadditional

springforceisrequired(onlyifspringlengthis

above3/4inches),installadditionalwashers(Part

No.3256-24)totheeyebolttocompressthe

height-of-groomspringsatalowheightofgroom.

1.Setthedesiredcuttingunitheightofcut;referto

yourcuttingunitOperator’sManual.

2.Setthedesiredheightofgroom;referto

AdjustingtheGroomerHeight(page17).

3.Ensurethatthegroomeradjustersarein

theengaged(operating)position;referto

TransportingtheMachine(page19).

4.Measurethedistancebetweenthewashers(the

currentspringlength)asshowninFigure22.

g357750

Figure22

1.Topwasher4.Desiredspringlengthwith

optionalwashers–0.75

inches(19mm)

2.Additionalwashers(Part

No.3256-24)

5.Bottomwasher

3.Originalspringlength

(distancebetweentopand

bottomwashers)

5.Subtractthedesired(.75inchor19mm)spring

lengthfromthecurrentspringlength,anddivide

thisdifferenceby0.06inchestodeterminehow

manywashersyouneedtoaddtoachievethe

desiredspringlength.

6.Addorremovewashersbetweenthetopwasher

andthetopoftheeyeboltspringasfollows:

A.Fullyunthreadandremovetheadjusternut.

B.Removetheshoulderbolt(Figure14).

C.Lowertheeyebolt,removethetopwasher,

andadd/removewashersontopofthe

springasdesired.

Note:Boththeidlerandthegroomerboxsides

shouldhavethesamespringlengthandamount

ofwashers.

13

11

InstallingtheWeights

GroomerOnly,withorwithout

FrontGrassBasketsandRear

CuttingUnitwithoutRearGrass

Basket

Partsneededforthisprocedure:

6Carriagebolt(5/16x3-1/2inches)

6Spacer

6Flangenut(5/16inch)

18Weight

Procedure

Forcuttingunitswithonlythegroomerkitinstalled

(norearrollerbrushkitandnoreargrassbasket

installed),refertoFigure23.

g192300

Figure23

Groomeronly

1.Bolts(5/16x3-1/2inch)3.Flangenut—5/16inch(2)

2.Spacer(2)4.Weight(6)

12

InstallingtheWeights

GroomerandRearRollerBrush

Installed

Partsneededforthisprocedure:

6Carriagebolt(5/16x3-1/2inches)

6Spacer

6Flangenut(5/16inch)

12Weight

Procedure

Forcuttingunitswiththegroomerkitandtherear

rollerbrushkitinstalled,refertoFigure24.

Note:Thekitincludes6weightsforeachcutting

unit,however,thissetuprequiresonly4weightsper

cuttingunit.

g192302

Figure24

Groomerwithrearrollerbrushkitinstalled

1.Bolts(5/16x3inches)3.Flangenut—5/16inch(2)

2.Spacer(2)4.Weight(4)

14

13

InstallingtheWeights

RearCuttingUnitwithGroomer

Only,withRearGrassBasket

Partsneededforthisprocedure:

1Carriagebolt(5/16x2-1/4inches),PartNo.

3230-7—soldseparately

1Carriagebolt(5/16x3-1/4inches),PartNo.

3230-13—soldseparately

1Carriagebolt(5/16x4-1/2inches),PartNo.

3230-30—soldseparately

2Spacer

1Flangenut(5/16inch)

2Locknut(5/16inch),PartNo.3296-47—sold

separately

2Weight

6Smallweight(PartNo.132-0734-03—soldseparately)

Procedure

Forarearcuttingunitwiththegroomerkitandthe

reargrassbasketinstalled(norearrollerbrushkit),

refertoFigure25.

Alsoinstalltheweightsonthefrontcuttingunits.

Note:Forfrontcuttingunitswiththegroomerkitand

thefrontgrassbasketsinstalled(norearrollerbrush

kit),refertoFigure23.

Note:Thecentercuttingunitdoesnotworkwithboth

therearrollerbrushkitandthereargrassbasketkit.

g192301

Figure25

Rearcuttingunitwithgroomerandreargrassbasket

installed

1.Bolt(5/16x4-1/2inches),

soldseparately

5.Weight(2),suppliedwith

thekit

2.Bolt(5/16x2-1/4inches),

soldseparately

6.Locknut(5/16inch),sold

separately

3.Bolt(5/16x3-1/4inches),

soldseparately

7.Flangenut(5/16inch),

soldseparately

4.Spacer(2),soldseparately8.Smallweight(4),sold

separately

14

FinishingInstallingthe

UniversalGroomerDrive

Kit

NoPartsRequired

Procedure

1.Setthedesiredheightofgroomforeach

cuttingunit;refertoHeight-of-Cut(HOC)and

Height-of-Groom(HOG)Settings(page17)and

AdjustingtheGroomerHeight(page17).

2.Installthecuttingunits;refertotheOperator’s

Manualforyourmachine.

15

Operation

Introduction

Groomingisperformedintheturfcanopyabovethe

soillevel.Groomingpromotesverticalgrowthofgrass

plants,reducesgrain,andseversstolons,producing

adenserturf.Groomingproducesamoreuniform

andtighterplayingsurfaceforfasterandtrueraction

ofthegolfball.

Groomingshouldnotbeconsideredasareplacement

forverticutting.Verticuttingisgenerallyamore

rigorousandperiodictreatmentthatcantemporarily

damagetheplayingsurface,whilegroomingisa

routineandgentlertreatmentdesignedtomanicure

theturf.

g006671

Figure26

1.Grassrunners(stolons)2.Thatch

Groomingbrushesarelessintrusivethanconventional

groomingbladeswhenadjustedtolightlycontactthe

turfcanopy.Brushingmaybebetterfortheultra-dwarf

cultivars,sincethesegrasstypeshaveanupright

growthpatternanddonotllinwellthroughhorizontal

growth.Brushescaninjureleaftissueiftheyareset

topenetratetoodeeplyintothecanopy.

Groomerbladesshouldneverpenetratethesoil.They

areeffectiveincuttingrunnersandremovingthatch.

Becausegroominginjuresleaftissue,avoidgrooming

duringperiodsofhighstress.Coolseasonspecies,

suchascreepingbentgrassandannualbluegrass,

shouldnotbegroomedduringhigh-temperature(and

high-humidity)periodsinmidsummer.

Manyvariablesaffecttheperformanceofgrooming,

includingthefollowing:

•Thetimeoftheyear(i.e.,thegrowingseason)and

theweatherpattern

•Thegeneralconditionofthegrass

•Thefrequencyofgrooming/cutting—bothhow

manycuttingsperweekandhowmanypasses

percutting

•Theheight-of-cutsettingonthemainreel

•Theheight/depthsettingonthegroomingreel

•Howlongthegroomingreelhasbeeninuse

•Thetypeofgrass

•Theoverallmanagementprogram(i.e.,irrigation,

fertilizing,spraying,coring,overseeding,etc.)

•Trafc

•Stressperiods(i.e.,hightemperatures,high

humidity,unusuallyhightrafc)

Thesefactorscanvaryfromfairwaytofairway.

Inspectthemowingareafrequentlyandchangethe

groomingpracticeasneeded.

Note:Usingthegroomerreelimproperlyortoo

aggressively(i.e.,toodeeportoofrequentgrooming)

mayunnecessarilystresstheturf,causingsevereturf

damage.Usethegroomercautiously.

Note:Continuechangingthedirectionofcut

wheneveryouusethegroomer.Thisenhancesthe

effectsofthegrooming.

Note:Operatethegroomerinastraightlineasmuch

aspossible.Usecautionwhenturningwhileoperating

thegroomer.

16

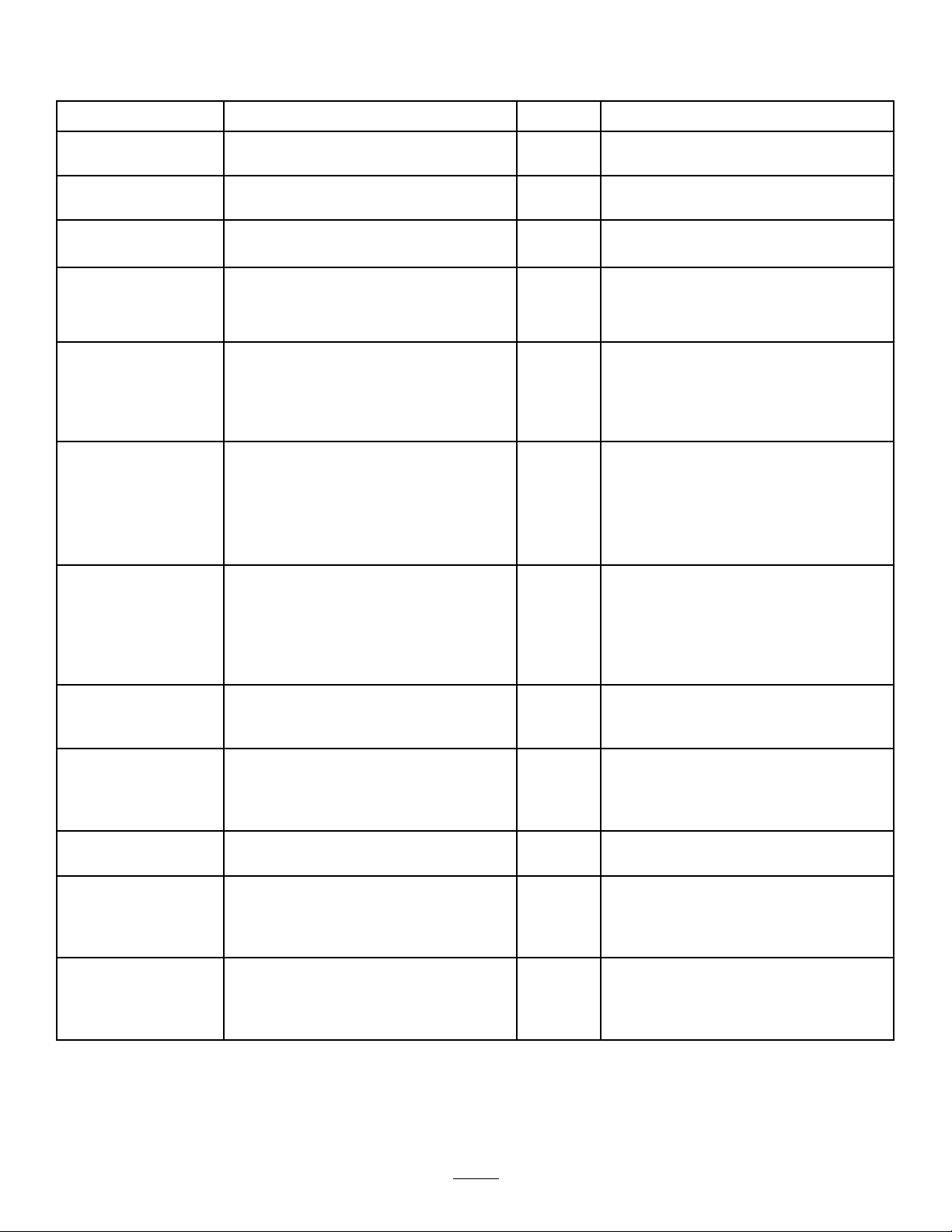

Height-of-Cut(HOC)andHeight-of-Groom(HOG)Settings

UsetheHeight-of-Cut(HOC)andHeight-of-Groom(HOG)tabletodeterminetherecommendedengagement

ranges.

HOCandHOGRecommendedRangeTable

Height-of-CutRecommendedHOG=HOCGroomerEngagement

(mm)(inch)

Numberof

RearRoller

Spacers(mm)(inch)

6.30.25003.1to6.30.125to0.250

9.50.37504.7to9.50.187to0.375

9.50.37514.7to9.50.187to0.375

12.70.50006.3to12.70.250to0.500

12.70.50016.3to12.70.250to0.500

12.70.50026.3to9.50.250to0.375

15.80.62509.5to15.80.375to0.625

15.80.62519.5to15.80.375to0.625

15.80.62529.5to12.70.375to0.500

19.00.750112.7to19.00.500to0.750

19.00.750212.7to19.00.500to0.750

19.00.750312.7to15.80.500to0.625

22.20.875115.8to22.20.625to0.875

22.20.875215.8to22.20.625to0.875

22.20.875315.8to19.00.625to0.750

25.41.002*19.0to25.40.750to1.00

25.41.00319.0to25.40.750to1.00

25.41.00419.0to22.20.750to0.875

Note:MaximumHOGrecommendedishalftheHOCto6mm(1/4inch)maximumengagement

*Movethegroomerfrontheight-of-cut(HOC)brackettothebottom(cuttingunitlocation)side-platehole.

AdjustingtheGroomer

Height

1.Parkthemachineonacleanandlevelsurface,

lowerthecuttingunitscompletelytotheground,

shutofftheengine,engagetheparkingbrake,

andremovethekey.

2.Makesurethattherollersarecleanandthe

cuttingunitissettothedesiredheight-of-cut

(seeyourcuttingunitOperator’sManual).

3.Rotatethequick-uplevers(Figure27)tothe

ENGAGEDposition(thehandlepointstowardthe

frontofthecuttingunit.

Important:UsetheHeight-of-Cut(HOC)

andHeight-of-Groom(HOG)recommended

rangetableforsettingthegaugebar;refer

toHeight-of-Cut(HOC)andHeight-of-Groom

(HOG)Settings(page17).

g346928

Figure27

1.Heightadjusterknob3.Groomerheight(HOG)

2.Quick-uplever4.Numberofrearroller

spacers(belowsideplate

pad)

17

4.Attheendofthegroomerreel,measurethe

distancefromthelowesttipofthegroomerblade

totheworkingsurface(Figure27).Turnthe

heightadjusterknob(Figure27)toraiseorlower

thegroomerbladetiptothedesiredheight.

5.Repeatstep4attheoppositeendofthe

groomer,thencheckthesettingontherstside

ofgroomer.

Theheightsettingonbothendsofthegroomer

shouldbeidentical.Adjusttheheightas

required.

ChangingtheGroomer

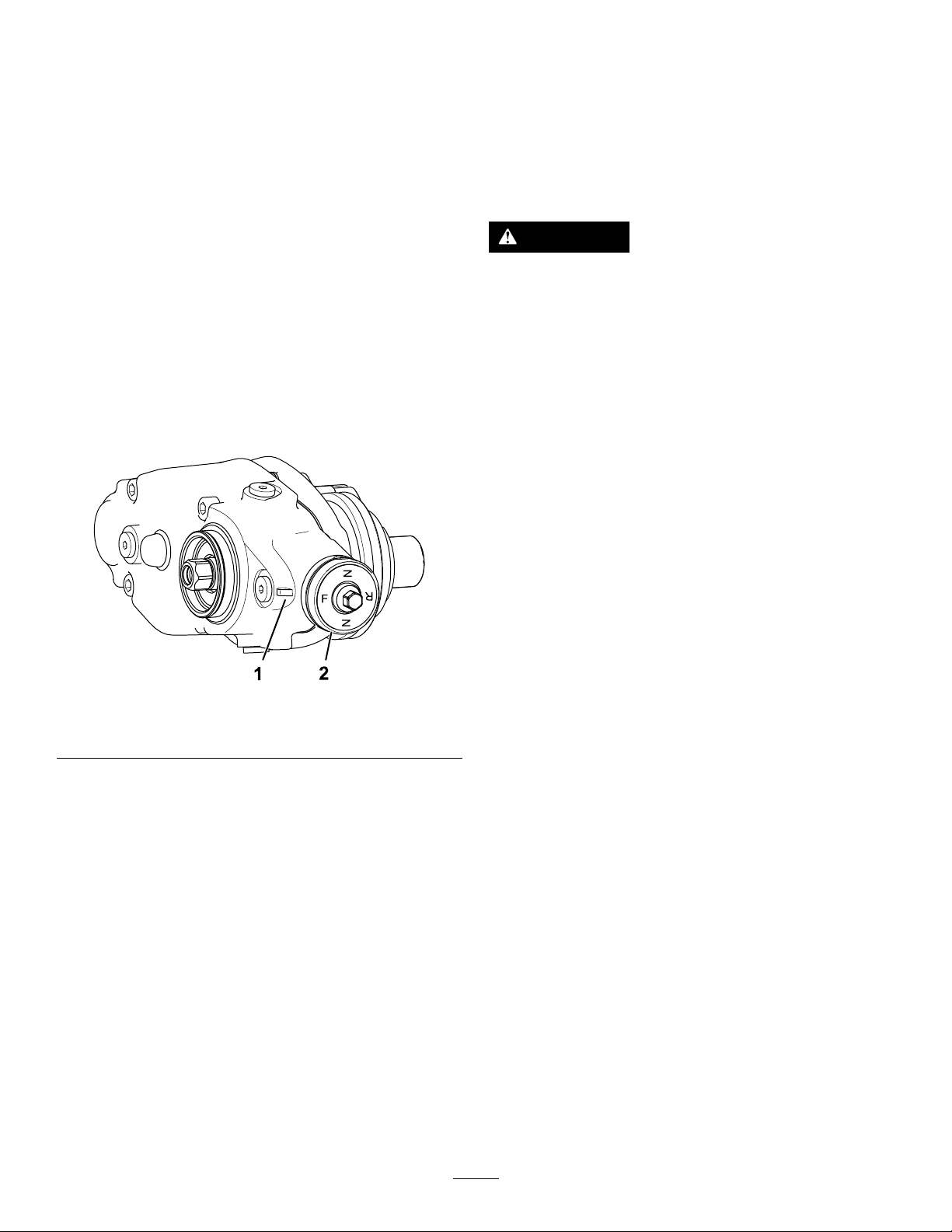

OperatingDirection

Thegroomerhas3settings:NEUTRAL,FORWARD,and

REVERSE.Tochangethedirectionofthegroomer,turn

theknobattheendofthegroomerdriveboxandalign

thedesiredpositionwiththeadjustmentnotch.

g246866

Figure28

1.Adjustmentnotch2.Knob

TestingtheGroomer

Performance

Important:Improperorover-aggressiveuseof

thegroomingreel(i.e.,toodeeportoofrequent

grooming)maycauseunnecessarystressonthe

turf,leadingtoseveredamage.Usethegroomer

cautiously.

DANGER

Contactwiththereelsorothermovingparts

canresultinpersonalinjury.

•Beforemakinganyadjustmentstothe

cuttingunits,disengagethereels,setthe

parkingbrake,shutofftheengine,and

removethekey.

•Keepyourhandsandclothingawayfrom

thereelsorothermovingparts.

Itisimportanttodeterminetheperformanceofthe

groomerbeforeputtingitintoregularuse.

1.Setthemaincuttingreelstotheheight-of-cut

settingthatyouwouldnormallyusewithoutthe

groomingreel.UseaWiehlerolleronthefront

andafullrollerontherear.

Theamountofgrassremovedisakeyindicator

indeterminingtheheight/depthsettingofthe

groomingreel.

2.Seteachofthegroomingreelstothedesired

heightsetting.

3.Examinethetestareaanddetermineifthe

groomedareasproducesthedesiredresults.

Ifnot,increaseordecreasetheheightofthe

groomersandmakeanothertestpass.

Checkthetestarea2or3daysaftertherst

groomingforgeneralconditionanddamage.Ifthe

groomedareasareturningyellowandbrown,andthe

non-groomedareasaregreen,thenthegroomingwas

tooaggressive.

18

TransportingtheMachine

Whenyouwishtomowwithoutthegroomerorneed

totransportthemachine,movethequick-upleverto

theTRANSPORTposition(Figure29).

Note:Thismovesthegroomerreelintoaraised

position.

g287375

Figure29

1.TRANSPORTposition2.OPERATIONposition

Maintenance

ChangingtheGearbox

Lubricant

ServiceInterval

Aftertherst100hours

Every500hours/Yearly(Whichevercomesrst)

1.Cleantheexternalsurfacesofthegroomer

housing.

Important:Ensurethatthereisnodirtor

clippingsontheoutsideofthegroomer

housing;ifdebrisgetsinsideofthegroomer

gearbox,damagemayoccur.

2.Removethedrainplugonthebottomofthe

housing(Figure32).

3.Removethellplugonthesideofthehousing

andloosentheair-ventplugonthetopsoair

canpassthrough(Figure32).

4.Alignasuitablecontainerbeneaththeoil-drain

porttocatchdrainedoil.

5.Tipthecuttingunitbackontothekickstand

untilthedrainportisatthebottomtoensure

completedrainage(Figure30).

g346929

Figure30

1.Removethedrainplug

fromthedrainport.

3.Loosentheair-ventplug.

2.Removethellplugfrom

thellport.

6.Rockthecuttingunitbackandforthtoensure

completedrainage.Whentheoiliscompletely

drained,placethecuttingunitonalevelsurface.

7.Installthedrainplug.

19

8.Useasyringe(PartNo.137-0872)tollthe

driveboxwith80-90Woil(approximately90cc).

g346931

Figure31

1.Syringewith80-90Woil2.Fillport

9.Installthellplugandtightentheair-ventplug.

10.Torqueallplugsto3.62to4.75N∙m(32to42

in-lb).

g346930

Figure32

Rightsidegroomerboxshown

1.Air-ventplug3.Drainplug

2.Fillplug

RemovingtheGroomer

DriveBox

Note:Retainallremovedpartsforlaterinstallation

unlessotherwisestated.

Important:Ifyouhaveanyissuesremovingthe

groomerdrivebox,refertoyourtractionunit

ServiceManualorcontactyourauthorizedToro

distributor.

1.Removethecapfromthegroomer.

2.Removetheclampboltsconnectingthegroomer

tothedrivebox(Figure18).

3.Removetheshoulderboltandhardenedwasher

connectingthegroomerdriveboxtotheadjuster

arm(Figure33).

g346932

Figure33

1.Shoulderbolt3.Groomerdrivehex-head

2.Hardenedwasher4.Reinforcementscrew

4.Restrainthereelforremoval;refertoRestraining

theReelforRemovingThreadedInserts(page

21).

5.Installthereinforcementscrew(PartNo.

1-803022—soldseparately)totheinternal

threadsofthegroomerdrivehexheadand

torqueto13.5N⋅m(120in-lb)asshownin

Figure33.

6.Removethegroomerdriveboxfromthecutting

reelbyturningthegroomerdrivehex-head

(Figure33).

Important:Ifthegroomerdriveboxis

installedontherightsideofacutting

unit,turnthegroomerdrivehex-head

counter-clockwise(right-handthread)to

removethedrive-boxshaftfromcuttingunit.

Important:Ifthegroomerdriveboxis

installedontheleftsideofacuttingunit,

20

Other manuals for 03240

1

Other Toro Cutter manuals