2614 Texoma Drive Denison, TX 75020 • 980 Contract St. Suite 110 Lexington, KY

Phone: 903-462-7700 or toll free 800-899-5655 • Fax: 800-966-6834

2

PRECAUTIONS IN USE

•For safety concern, please always hold the cutter firmly from the bottom when moving it.

Do not move the cutter by clasping the depression area on both sides.

• Do not shake or drop the blade holder,

a blade tip maybe fly out.

• During operation, keep away from any

moving parts of the cutter (such as the

carriage, drums). Also be careful that your

clothing and hair do not get caught.

• Always connect the power cable to a

grounded outlet.

• Always use the accessory power cable

provided. Make sure the power cable

isn’t crimped or caught between objects.

• Do not connect the power cable to

branching outlet to which other machines

are also connected, or use an extension

cable. There is danger of overheating and of misoperation of the machine.

• Keep the tools away from children where they can reach.

• Always put the pinch rollers within position of the white marks.

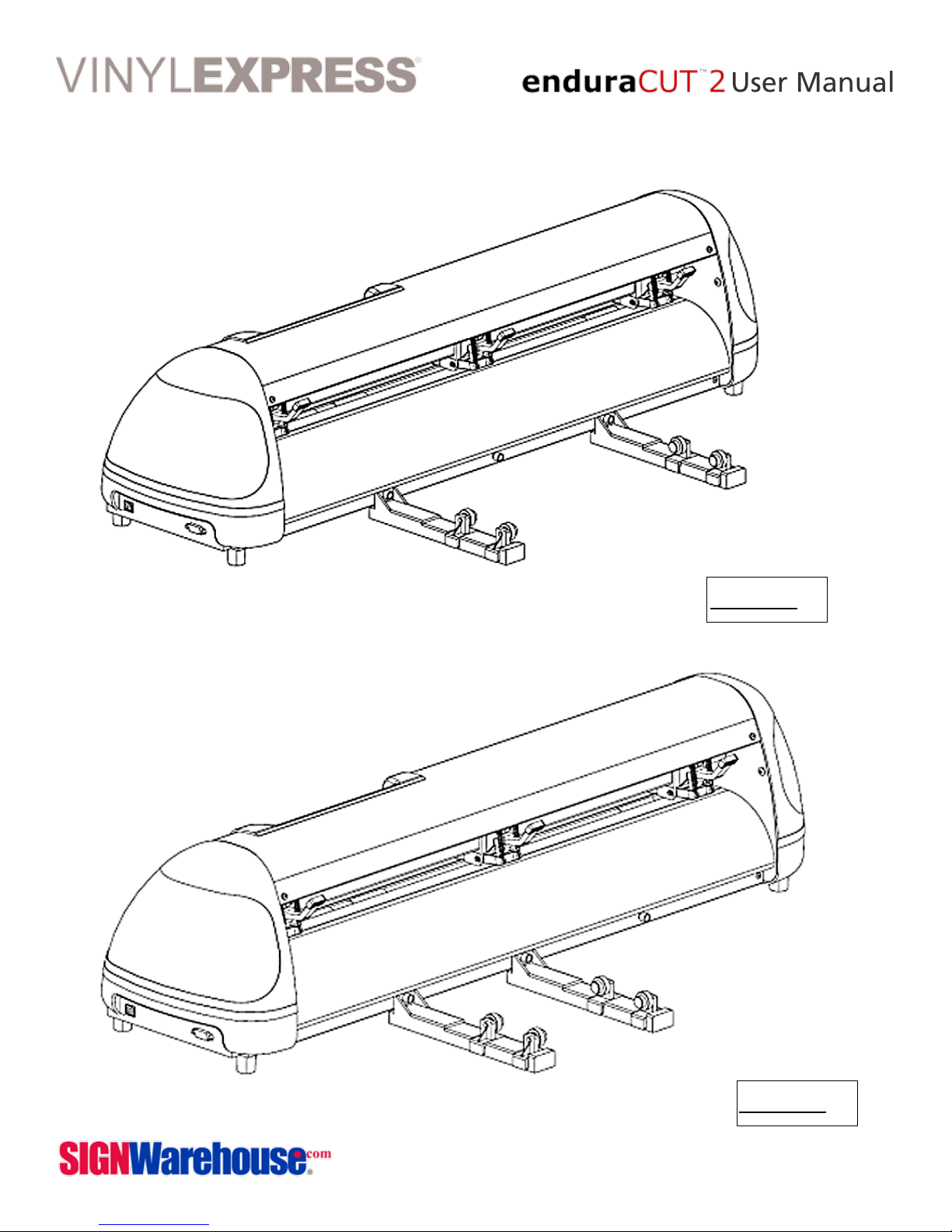

IMPORTANT INFORMATION

Thank you for your purchase of Vinyl Express EnduraCUT2 Cutting Plotter.

For your safety and to optimize the performance of the EnduraCUT 2, please read the user

manual completely and keep it in a correct location.