Showa Denki Dustresa CFA-110 User manual

YFAA21A-Y001E

Operation Manual for

Dustrésa

the Compact Dust Collector

CFA-110

CFA-215SC

CFA-215ST

CFA-220S

CFA-240S

SHOWA DENKI CO., LTD.

Introduction

Thank you for choosing our Dustrésa dust collector in the CFA series from among so many similar products

on the market.

Showa Denki, as a dedicated manufacturer of blowers and dust collectors, has supplied innovative products

developed by making the best use of its flow and rotary machine expertise. Compact, yet featuring high

performance and low energy consumption, your Dustrésa will serve you for long safe and sound as long as

you follow the instructions in this manual.

It is recommended that you keep the manual on hand for quick reference.

This manual contains all necessary information from installation to operation about the following varieties of

Dustrésa:

CFA-110 100 V, 50 & 60 Hz commonly used

CFA-215SC 100 V, 50 or 60 Hz exclusively used

CFA-215ST 200 V, 50 or 60 Hz exclusively used

CFA-220S 200 V, 50 or 60 Hz exclusively used

CFA-240S 200 V, 50 or 60 Hz exclusively used

Symbols used herein

The symbols and headwords found in this manual respectively have the following meaning:

Warning If failed to observe the relevant instructions, it could cause death

or serious injury.

Caution If failed to observe the relevant instructions, it could cause injury

or property damage.

indicates what must not be done.

indicates what requires the use of good care.

indicates what must be done.

Contents Page

Chapter 1 Cautions for safety - 1 -

Chapter 2 Outline of the dust collector - 2 -

Configuration - 2 -

Components - 2 -

Chapter 3 Installation - 3 -

Installation - 4 -

Electrical wiring - 4 -

Hood and connection of the duct - 4 -

Trial operation - 5 -

Chapter 4 Operation - 5 -

Routine operation - 5 -

How shake off the dust - 5 -

Caution - 6 -

Chapter 5 Maintenance - 6 -

What and when to inspect - 6 -

Replacing the filter cloth - 7 -

Adjusting tension of the shaking rope - 8 -

Replacement filter cloth sizes - 9 -

Troubleshooting - 10 -

Specifications - 10 -

- 1 -

Chapter 1 Cautions for safety

WARNING

Any Dustrésa must not suck the following things:

a lit cigarette or match, hot dust

sparks from a sander, a grinder, etc.

Combustible filter cloth of the dust collector can ignite and cause a fire.

flammable gases from petrol, thinner, etc.

Sparks from the incorporated electric components, static and contact of metals can cause an

explosion.

dust of aluminium, carbon and starch

It can cause a dust explosion.

Do not operate the Dustrésa with its maintenance door opened because it could be closed by

negative pressure inside catching your fingers and/or the motor overloaded.

Caution

The Dustrésa should not suck the following things which can cause it a failure:

Hot gas

The gas heated to 40C or more would deteriorate the insulation of electric components inside

the dust collector.

Water, oil, adhesives and adhesive dust

They would deposit on the filter cloth causing it blinding.

Work, tools and other solid objects than dust

They could damage the ducts and filter cloth.

Particulates (5 µ or smaller) of carbon and other materials

Use a high-performance filter cloth as the standard type can allow leaks.

Lightweight dust including feather, cotton dust, paper dust, polystyrene foam dust

They would adhere to the inside of the dust collector.

Do not ride on the Dustrésa because it could be deformed or you could fall.

Do not apply high pressure on the Dustrésa with a pressurizer.

Never increase the operation speed more than design speed using an inverter because it could

damage the incorporated blower.

- 2 -

スイッチ

取手

吸込口

吸込フタ

ろ布

ろ布押さえ

ダストパン

シェーキングハンドル

オプション

キャスター

排気口

スイッチ

シェーキング

ハンドル

吸込口

正面扉

吸込フタ

キャスター

ダストパン

ろ布止め金具

吊りボルト 排気口

シェーキング

ハンドル

吸込口

キャスター

正面扉

ろ布

吸込フタ

ダストパン

クランク

Chapter 2 Outline of the dust collector

Configuration

The dust-containing air sucked from the inlet port is dispersed and led to the filter cloth that purifies the air.

The purified air goes through the blower and released from the outlet in the machine roof into the atmosphere.

The dust caught on the filter cloth is shaken off with a shaker operated by a handle. The dust is collected in

the dust pan that is easily taken out from the front door.

Components

CFA-110

CFA-215S, 220S

CFA-240S

Switch

Handhold

A

ir inlet port

Inlet cover

Shaker handle

Caster

(option)

Filter cloth

Filter-cloth

retainin

g

dis

c

Dust pan

A

ir outle

t

Power switch

Shaker handle

A

ir inlet port

Inlet cover

Caster

Dust pan

Filter-cloth

metal fixe

r

Front door

Ring bolt

Front door

A

ir outle

t

Shaker handle

A

ir inlet port

Inlet cover

Caster

Crank

Filter

cloth

Dust pan

- 3 -

ガソリン シンナー

300

700

400

400

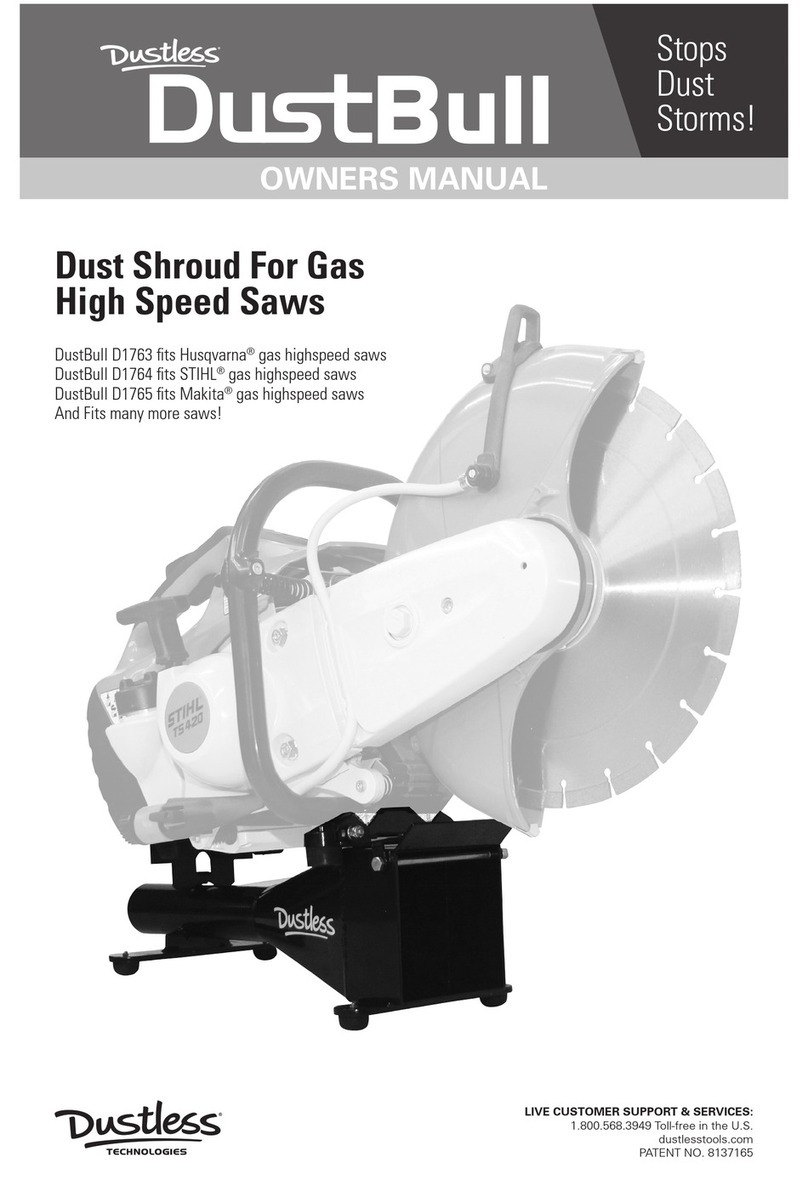

Chapter 3 Installation

Upon receiving the product, please examine its nameplate to see if the type, voltage and frequency indicated

on it conform with those of the ordered product. Also, check up the accessories for conformity.

In case of any damage to the product caused during transportation or a shortage of parts, please immediately

contact the relevant retailer or a nearby branch or sales office of Showa Denki.

Install the dust collector in a place fulfilling the following conditions:

Indoor places not get wet by rainwater

Dust collectors in the CFA series are designed

for indoor use.

For installation, avoid places liable to get wet

that may induce an electric shock and a

product failure.

No dew condensation at room temperature

Ambient temperature: 5C to 40C

Humidity: not higher than 80%

High temperatures and dew condensation

could cause an electric component failure

and/or an electric shock.

Horizontal places free from vibrations

Unusual vibrations could cause the product

topple over.

No hazardous chemicals stored around

Places close to stored petrol, thinner, and other

flammable chemicals have the possibility of an

explosion and/or a fire.

Places near the chemicals, like hydrochloric

acid and sulphuric acid, that produce a

corrosive gas could cause the product to

corrode.

Places easy for maintenance

Spaces as illustrated on the left must be

secured for dust discharge, filter cloth

replacement and purified-air release.

Unit: mm

Petrol Thinner

- 4 -

Installation

Although the dust collector, equipped with casters, can be readily moved, apply stoppers so it

may not move during operation. Avoid using the collector on a slope. When necessary, move

it slowly on a flat floor.

When lifting up the CFA-215S or 220S dust collector, hold its bottom, and not the plastic

portion, by two or more persons.

Ensure an enough space (twice or more as its air outlet diameter) around the dust collector so

it may display adequate suction power with its air outlet not blocked. Place nothing on the

machine.

Electrical wiring

Only qualified persons should work on the electrical wiring of the dust collector pursuant to

the Electrical Equipment Technical Standards and the Internal Wiring Regulations.

Make sure of the machine’s power supply as per its nameplate and use what is specified

therein. Operating the machine on a different power supply could be very dangerous causing

an operation failure.

Use an appropriate fuse (breaker) for the power supply that conforms with the start-up

current.

Be sure to earth the power supply connection.

Hood and connection of the duct

Dust collection method and suction air speed (controlled air speed) may vary depending on

the kind of dust and the condition of scattered dust. Generally, the suction air speed in the

hood opening vicinity should be designed to be 0.5 m/sec. or faster. Also, it is desirable that

the airflow in the duct is 15 m/sec. or higher.

The duct joints should be tightly sealed so no air may be sucked or leaked through them.

In case a flexible duct is used, it should not be bent too sharp or unnecessarily sagged so it

may keep a high suction power.

The air inlet port is on the right flank of the collector, viewed from its front door, in the

ex-factory configuration. It can be changed to the left flank and the port and the inlet cover

may thus be interchangeable.

Standard inlet diameter

CFA-110

CFA-215S CFA-220S CFA-240S

75 mm 97 mm 148 mm

- 5 -

Trial operation

Before a trial run of the dust collector, make sure:

• that the power supply cable, earth cable, insulation and voltage have been arranged as

specified;

• that there is no air leak at duct joints or no remaining material, bolt, nut or tool left behind in

the duct, and

• that the maintenance door and the dust pan are securely closed.

With the above points confirmed, turn on the power switch and turn it off quick and observe

the motor cooling fan through the air outlet on the ceiling. If it turns clockwise, it is alright. If it

turns counter-clockwise, then turn off the power supply and change the connections of 2

cables of the 3 power supply cables.

Chapter 4 Operation

Routine operation

Operation procedures: [1] Make sure that the front door is closed.

[2] Turn on the power switch to start operation.

End operation procedures: [1] Turn off the power switch.

[2] Wait about 2 minutes and then shake off the deposited dust on to the

dust pan and discharge.

Since continuous operation of the dust collector would blind the filter cloth and cause the

suction power to drop, stop operating the machine and go through the shaking-off and

discharge steps.

During operation, the shaking-off and discharge procedures are disabled.

Discharge of dust should be performed at the end of the day’s operation. During this

procedure, be sure to wear protective goggles and gloves and a dustproof mask.

How shake off the dust

CFA-110

Detach and clean the filter cloth.

If equipped with an optional shake-off device, turn

its handle to shake off the dust.

CFA-215–240

While holding the collector body by hand, pull the

shaker handle about 3 times. After use, return the

handle to its original position so it may not sag.

- 6 -

Caution

Although, in case of fine dust, a small amount can leak from the dust collector at its start, this

phenomenon will disappear when dust deposits on the filter cloth overall. If, however, the

leakage continues, replace the cloth with the optional high-performance type.

The dust pan, fixed in position with spring, can somewhat hitches on its casing when drawn in

or out. When returning the pan into position, push it in until it clicks fixed (except CFA-110).

Clean the pan before it accommodates too much dust.

The filter cloth’s life is one to two years on the average, which, however, depends on the

machine’s operation time and dust attributes and concentration. Replace the cloth with a new

one if the shake-off procedure fails to recover the suction power.

Although the filter cloth may not be damaged by usual operation, stop the machine operation

and replace the cloth with a new one if it is damaged. Using a damaged filter cloth could not

only allow dust to be released into the atmosphere but damage the built-in blower as well.

Chapter 5 Maintenance

Be sure to maintain the dust collector at regular intervals. This is important to prevent the

machine’s failure or accident and keep it serving you for many years to come. During the

maintenance work, always turn off the power supply to the machine and when replacing the filter

cloth use protective goggles and gloves and a dustproof mask.

What and when to inspect

What When Description

Front door Before operation Must be securely closed.

Motor load current Once a day Read the control panel ammeter, etc.

Exhaust air Dust must not leak.

Blower vibrations Once a week No vibrations or noise

Shaker No noise or operation error

Filter cloth application Once a month Cloth must not come off, loosen or damage.

Piping No bolt coming off or loosened or no worn-off packing

Ducting No dust deposits or clogs

Electrical wirings No poor insulation or loosened terminal

Inside of the machine One a year Clean the components of adhered dust.

The machine and its casing No corrosion or gap

- 7 -

ノブ

ろ布押さえ

ろ布

ガイド

パッチン 蝶ボルト

ダストパン

ロープ

押えねじ クランク

ロープ

フィルタケース

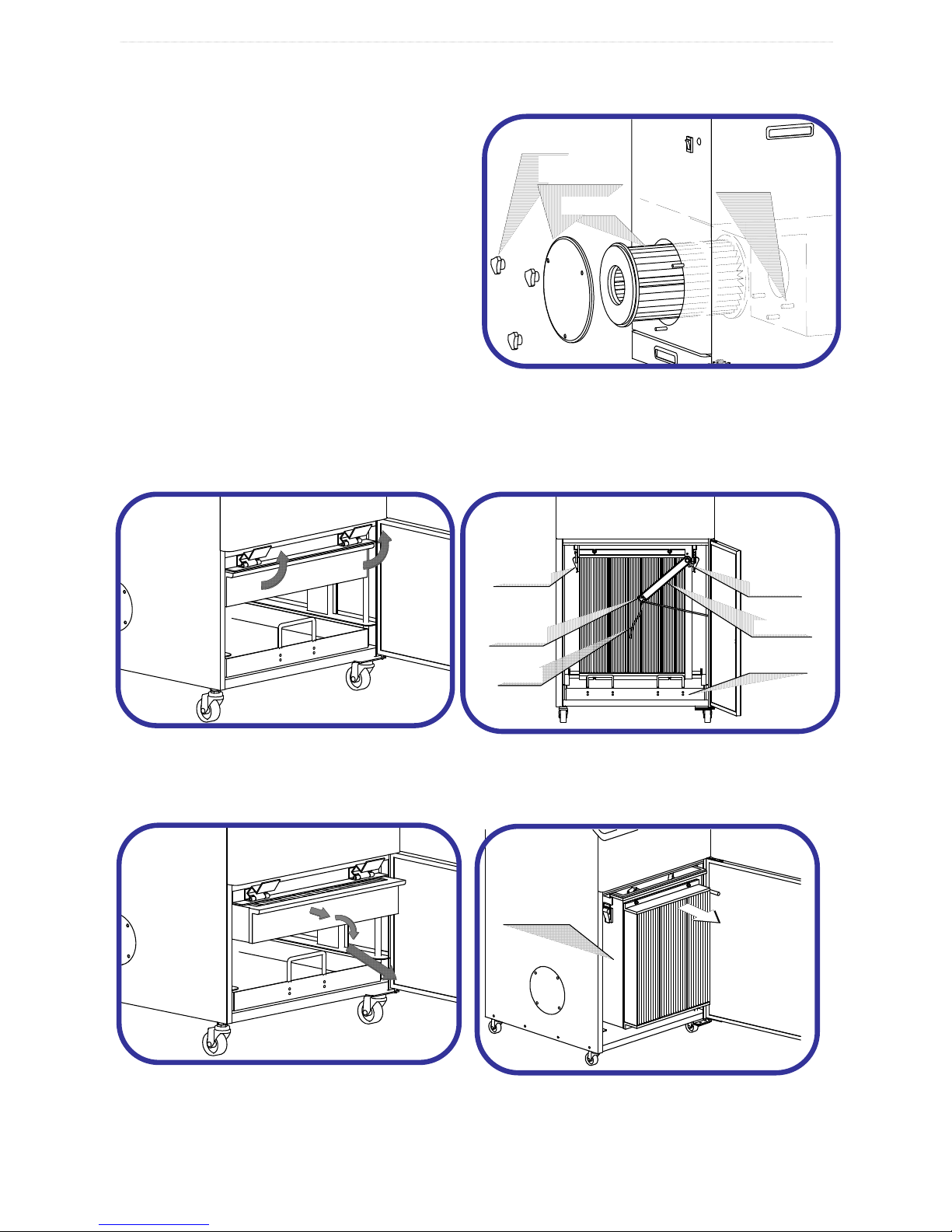

Replacing the filter cloth

CFA-110

(1) Remove the 3 knobs from the filter-cloth

retaining disc.

(2) Detach the retaining disc and remove the old

cloth.

(3) Insert a new cloth and fix the filter into the guide

pins.

(4) Secure the retaining disc with the 3 knobs.

CFA-215S, 220S CFA-240S

(1) Raise the filter-cloth metal fixers (1) Remove the crank by loosening the rope

retaining screw and the wing bolt. Draw out the

dust pan.

(2) Draw out the filter cloth to this side and take it

out.

(2) Unlock the snap locks located on both upper

sides of the filter case and pull out the case to

this side.

Knob

Filter cloth

retainin

g

disc

Filter cloth

Guide pin

Snap lock

Rope

retaining

screw

Rope

Wing bolt

Crank

Dust pan

Filter case

- 8 -

向きに注意 ナット、ワッシャ

(M6)

上の表示

ロープ

ロープ押さえ ロープ押さえ

ロープ

(3) Insert a new filter cloth in the direction as shown

in the figure below, make sure that the cloth is

inserted in the back groove and push it into

position completely.

(3) Loosen off the M6 nuts that fix the filter cloth and

remove the cloth.

(4) Pull up this side of the filter cloth and secure it in

position with metal fixers as it was.

(4) Attach a new cloth, with the ‘Topside’ marking

facing up, and assemble the whole thing

reversely to the procedures mentioned above.

Adjust the rope’s tension (See next page).

Adjusting tension of the shaking rope

Regulate the tension of the shaking rope if the shaker handle is loosened too much or when the filter cloth

is renewed.

(1) Loosen the 2 rope-retaining wing bolts and make the shaker handle closely contact the machine body.

CFA-215S/220S (Remove the filter cloth.) CFA-240S

(2) While pulling the rope end, turn the rope retainer by 2 to 3 cm in the arrow-marked direction.

(3) While pulling the rope, fasten the rope-retaining wing bolt.

Insert in the correct

direction. Nut and washer

‘Topside’

marking

Rope retainer Rope Rope retainer

Rope

- 9 -

Rope retainer in detail

Note: There can be a little air leak from the rope-pierced portions when the rope tension is regulated, which,

however, may not affect the machine’s performance.

In case the rope is broken or severely worn out, replace it with a new one.

Rope for replacement Starter rope (nylon solid braided) 4 mm ×50–60 cm

The rope is commercially available.

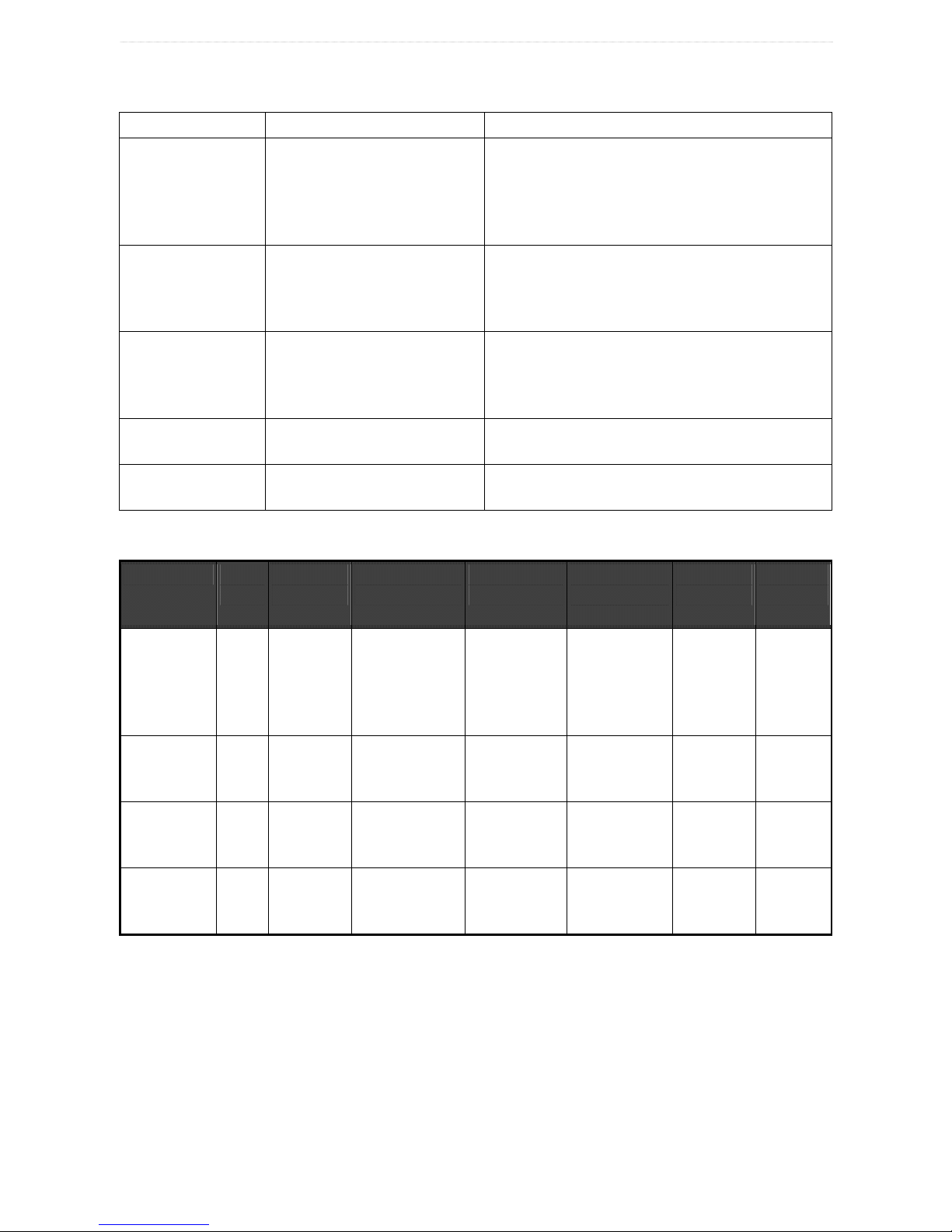

Replacement filter cloth sizes

Type Cloth size Number of cloths applied

CFA-110 150 mm 250 mm 1

CFA-215S 420 mm 420 mm 75 mm 1

CFA-220S 420 mm 420 mm 95 mm 1

CFA-240S 420 mm 540 mm 75 mm 2

Use our genuine filter cloths for replacement.

During replacement work, be sure to wear protective goggles and gloves and a dustproof mask.

- 10 -

Troubleshooting

Symptom Possible causes Remedies

Blower motor fails to

start.

• Power absent

• Thermostat activated

• Motor failure

• Turn on the power supply.

• Determine the cause(s), remove it (them) and

restart.

• Inspect and repair the motor (Consult the

manufacturer).

Blower noise,

unusual vibrations

• Motor bearings broken

• Foreign matter mixed

• Impeller out of balance

• Replace the bearings.

• Remove the foreign matter.

• Clean the impeller.

• Correct the imbalance (Consult the manufacturer).

Blown dust leakage • Filter cloth broken or out of

position

• Dust particles too fine

• Packing worn off

• Renew the cloth.

• Replace the filter cloth with a higher-performance

version.

• Replace the packing with a new one.

Poor suction power • Inlet piping clogged

• Filter cloth blinding

• Clear deposit from the piping.

• See the following item.

Filter cloth blinding • Filter cloth’s life

• Adverse dust attributes

• Replace the cloth with a new one.

• Effective measures should be taken separately.

Specifications

Type Motor

kW

Airflow rate

m3/min

Static pressure

kPa

Filtration area

m2

Dust container

capacity

L

Noise level

dB(A)

Mass

kg

CFA-110 0.2 4

0.8

(50 Hz)

1.18

(60 Hz)

0.8 3.1 64 25

CFA-215SC

CFA-215ST 0.4

4

5

6

1.96

1.57

0.98

1.5 6.9 64

44 (60 Hz)

47 (50 Hz)

CFA-220S 0.75

6

8

10

2.25

1.96

1.57

2 6.9 65 55

CFA-240S 1.5

12

16

20

2.55

2.35

1.96

4 16.9 68 135

Note: The noise levels were measured at 1.5 m from the machine’s front, which may vary depending on the

environment and condition in which to use the machine.

- 11 -

Notes :We are not responsible for any accident or breakdown caused by different/wrong use from this

manual, and improper repair or remodeling.

Business Promotion Dpt.

1-25 Shinden Kita-machi, Daito-city, Osaka, Japan 574-0052

Tel: +81-72-870-5708 Fax: +81-72-870-7243

http://www.showadenki.co.jp

This manual suits for next models

4

Table of contents

Other Showa Denki Dust Collector manuals

Popular Dust Collector manuals by other brands

MICRO-AIR

MICRO-AIR RP4 Installation and operation manual

Bucktool

Bucktool DC30A instruction manual

Oneida Air Systems

Oneida Air Systems Supercell XSK000035 owner's manual

Storch

Storch Cookie Monster manual

National Flooring Equipment

National Flooring Equipment 3472 instruction manual

Donaldson Torit

Donaldson Torit E-100 Installation and operation manual