t

he

reference

in

surfAce

treAtment

International

Surface

T

echnologies

istsurface.com

7

DCM100 to 330 Dust Collector - Instruction Manual & Parts

INSTALLATION CONT’D

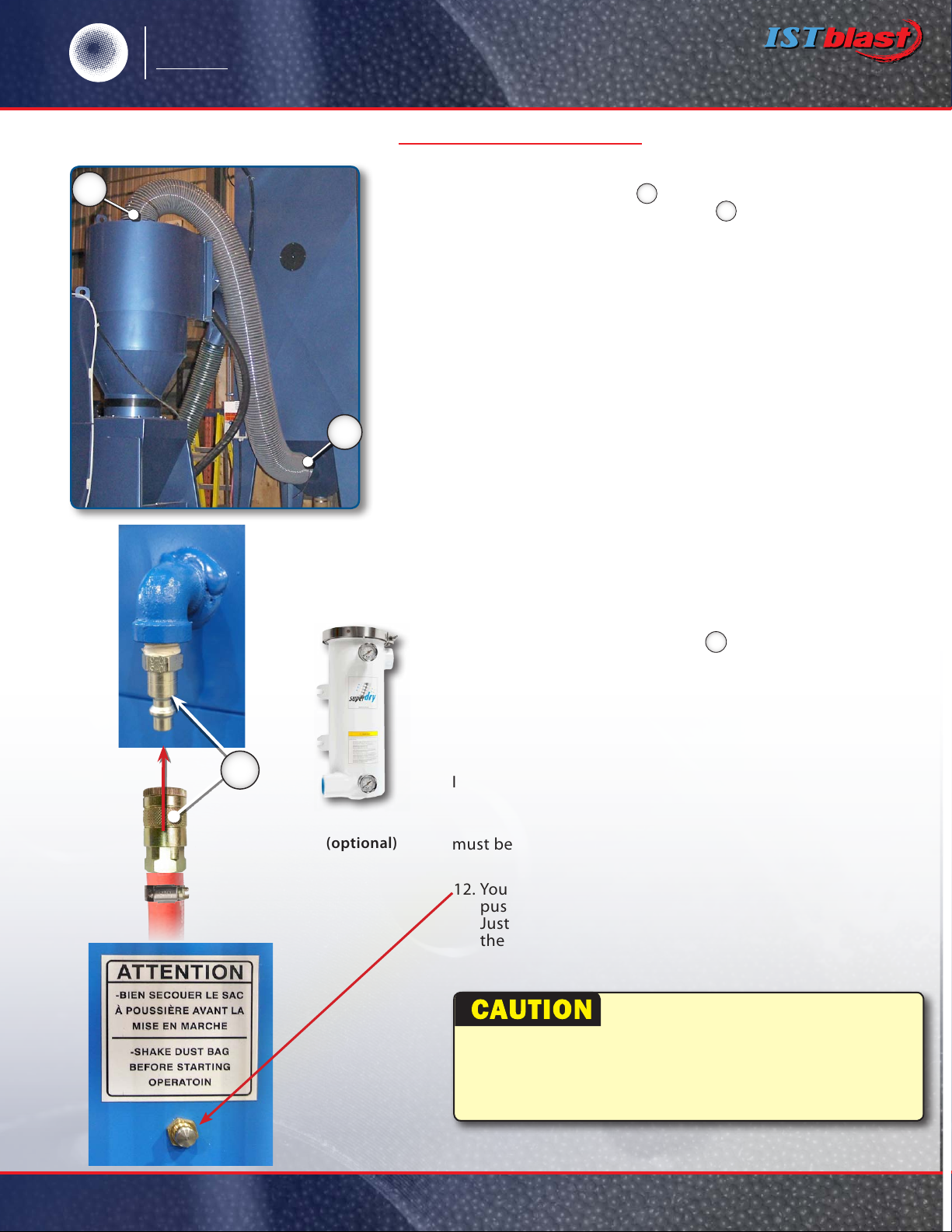

6. Connect one end of the tubular transport of abrasive at

the exit of recycling

1

and the other end at the entrance

at the bottom of the scrubber

2

. Secure each end of the

hose with clamps included with the hose.

7. The wire is removed on the rst 2 or 3 inches. Be careful

not to damage the hose. The wire helps dissipate static

electricity inside the hose. For the static is dissipated, each

segment must be in contact with the metal of which must

have a rm grounding installed.

8. For dust collector with the dust collecting drum option,

make sure that the drum is properly located under the dust

collector and that it has been correctly secured to it.

10. For dust collectors equipped with a muffler option you must

install it directly to the air outlet of the fan. Simply bolt it on

the adapter. To ensure right air circulation, it is essential to

keep 18 inches of clearance in front of the air outlet of the

muffler. See details in section MUFFLER INSTALLATION on

pages 8 & 9.

11. Connect your shop’s air supply line to the dust collector air

inlet. Your air supply is coupled to the air inlet with a ¼ inch

male quick connect coupling 6A (see details page 8).

To properly operate, your IST system must use clean, dry air.

Use proper filters, air dryers, and air purifying systems to ensure

clean and dry air is supplied.

An isolating valve should be installed at the source of air (Air

Inlet of cabinet) to depressurize the system for maintenance.

If you use a rigid conduit for your air duct, a flexible section

must be installed to allow the opening of the door.

12. You need a maximum of 80 psi air supply for the standard,

push button, pneumatic dust bag shaker of your equipment.

Just press (more or less 10 times) the button on the side of

the service door before starting operation.

Air dryer

(optional)

1

2

IF YOU USE INTERLOCKING

CONNECTIONS, SECURE THEM WITH PINS.

A CONNECTION THAT DISCONNECTS UNDER

PRESSURE COULD CAUSE SERIOUS INJURY.

CAUTION

6A