1

1. Important Notice

This manual contains important safety information and pre-

cautionary measures. It is impossible to list all potential hazards

associated with every dust collection system in each application.

Proper use of the equipment should be discussed with Parker

Hannifin. Operating personnel should be aware of, and adhere

to, the most stringent safety procedures.

EXPLOSION HAZARD

• Avoid mixing combustible materials such as alumi-

num, paper, wood or other organic dusts with dusts

generated from grinding materials. A fire hazard could

develop from sparks entering the dust collector.

When collecting flammable or explosive materials,

the dust collector should be located outdoors and

incorporate the appropriate safety measures and/or

accessories.

• When collecting emissions from spark-producing

processes, care must be taken to reduce any poten-

tial fire hazards. System design should include

methods to prevent sparks from entering the dust

collector. Dust collectors do not contain fire extin-

guishing equipment unless specifically ordered.

Experts in the field of fire extinguishing equipment

should be consulted for recommendations concern-

ing proper fire detection and suppression systems.

• Some dust collection systems require explo-

sion venting. Consult your insurance underwriter,

NFPA (National Fire Protection Association) man-

ual and your local fire authorities to determine the

requirements for explosion venting.

• Be careful and conscientious – consult national and

local fire codes, waste disposal, safety and other

appropriate authorities. Comply with their recom-

mendations for the proper installation and operation

of dust collection equipment.

• Your dust collector was selected for a particular

application. Consult Parker prior to making any

application or system changes.

• All explosion vent installations should be located to

allow full-unrestricted discharge when system pres-

sure exceeds the set pressure of the explosion vent.

An explosion vent should never be located where

the discharge from the vent will impact people or

plant equipment.

• Do not use the explosion vent as temporary work

surface for hand tools; i.e., wrenches, screw drivers,

etc. Such actions can cause premature failure to

occur via over stressing the explosion vent.

• All dust collectors handling hazardous or fire/

explosion risk dust, as determined by the user, are

recommended to be located outside the building in

non-traffic areas even though the dust collector is

equipped with an explosion vent.

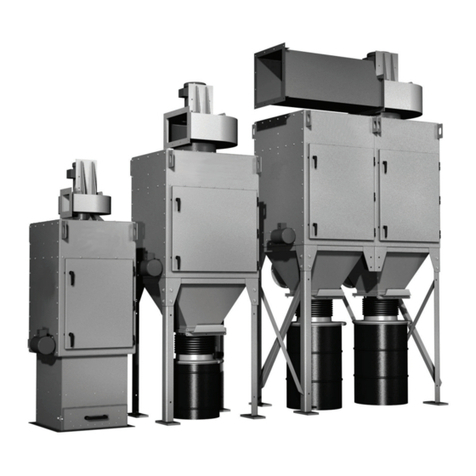

2. Introduction

Thank you for selecting Parker dust collection equipment to assist

you in your commitment to a clean and safe environment. We trust

that in purchasing our product, you have recognized our com-

mitment to continually offer air cleaning equipment engineered to

each dust collection need and manufactured to the highest stan-

dards. If at any time you have a question about dust collection,

please do not hesitate to call your local Parker representative.

The SFC is designed to collect process generated dusts.

The optimized pulse cleaning system coupled with the QuickSeal

filter access doors provide the most dependable and mainte-

nance friendly cartridge collector in the market.

The SFC dust collector should not be used for any purpose not

listed in this manual.

As you review this manual, refer to Figure 1 for assistance in iden-

tifying dust collector parts. The SFC Specification Table in Section

3 provides additional unit information.

2.1 Unit Nomenclature

Example: SFC8-2-H55

SFC = Model collector

8 = number of cartridge filters

2 = number of filter tiers

H55 = unit base arrangement

H55 - hopper with 44” (112 cm) clearance for

standard 55 gallon (208 liter) drum

SD - hopper with 28” (66 cm) clearance for

Parker-supplied 20 gallon (76 liter) drum

OB - open bottom construction

BV - custom bin vent unit with open bottom

DD - dust drawer

2.2 Description and Operation

The SFC is a high-efficiency cartridge dust collector designed to

eliminate airborne dust as it is generated. Contaminants are cap-

tured at the source(s), then conveyed through ducting to the car-

tridge filter section (dirty air section) where the dust is collected.

Clean air is then discharged from the unit through the clean air

discharge.

The dust collector is designed for on-line or downtime cartridge

filter cleaning by means of a customer-supplied compressed air

system.

The SFC is a high-efficiency, horizontally-oriented cartridge dust

collector equipped with 9.48” I.D. and 13.87” O.D. cartridge

filters. The larger diameter ProTura

®

Nanofiber cartridge filter

design allows for lower pressure losses through the dust col-

lector while increasing the amount of media contained in each

filter. SFC Series dust collectors have pre-engineered backward-

inclined or radial-type optional blower packages in 2, 3, 5, 7-1/2,

10, 15, 20, 25 and 30 hp (1.5, 2.2, 3.7, 5.5, 7.5, 11, 15, 18.8,

22.6 kW) assemblies.

There are two primary modes of operation — the air filtering

operation and filter cleaning cycle. Both modes of operation are

shown in Figure 1.

!DANGER