Showa Denki Chiko CKU-060AT3-ACC User manual

チコーエアーテック株式会社

CHIKO AIRTEC CO., LTD.

•取扱説明書(以下、本書といいます)の『製品使用上のご注意』の内容をよく理解し、本書をよく読んでか

ら操作してください。

Please understand well the contents of "Cautions on Product Use" of Instruction Manual

(hereinafter referred to as “this manual”), and operate it after often reading this manual.

•本書はいつでも使用できるよう、大切に保管してください。

Please keep this manual carefully to be able to use it at any time.

日

本

語

English

ヒュームコレクタ

Fume Collector

型式/MODELS

CKU-060AT3-ACC (100V)

CKU-060AT3-ACC(-T)(200V)

CKU-060AT3-ACC(-CE)(220-230V)

取扱説明書

Instruction Manual

051(E)-A

■転載・複写について/Copyrights

•本書の著作権は、チコーエアーテック株式会社が所有しています。

CHIKO AIRTEC CO., LTD. owns the copyright of this manual.

•本書の内容の一部あるいは全部の無断転載や複写は固くお断りします。

Unauthorized reproduction or copying of part or all of the content of this manual is strictly prohibited.

•本書の内容は、将来予告なく変更することがあります。

The contents of this manual are to change without notice.

© 2020 CHIKO AIRTEC CO.,LTD.

■はじめに/Introduction

このたびは、お買い上げ頂き、誠にありがとうございます。

チコーエアーテック株式会社は「風の技術」を有効に利用し、コンパクトに空気をクリ-ンにすることをテ-マと

して努力しております。

この製品は、この風の技術をコンパクトにまとめた省エネ形のクリ-ン BOX です。

長期間故障なく安全にご使用いただくために、この取扱説明書をよくお読みいただき、本機の性能を十分に発

揮できますよう正しいお取扱いをお願いします。

We greatly appreciate that you have purchased our dust collector.

CHIKO AIRTEC CO., LTD. is working to achieve clean air with compact equipment while utilizing “air

technology” effectively.

This machine is an energy-saving-type clean box that realizes “air technology” in a compact body.

Please read this instruction manual thoroughly and handle this machine correctly so that you can use it

safely for a long time and enjoy its full performance.

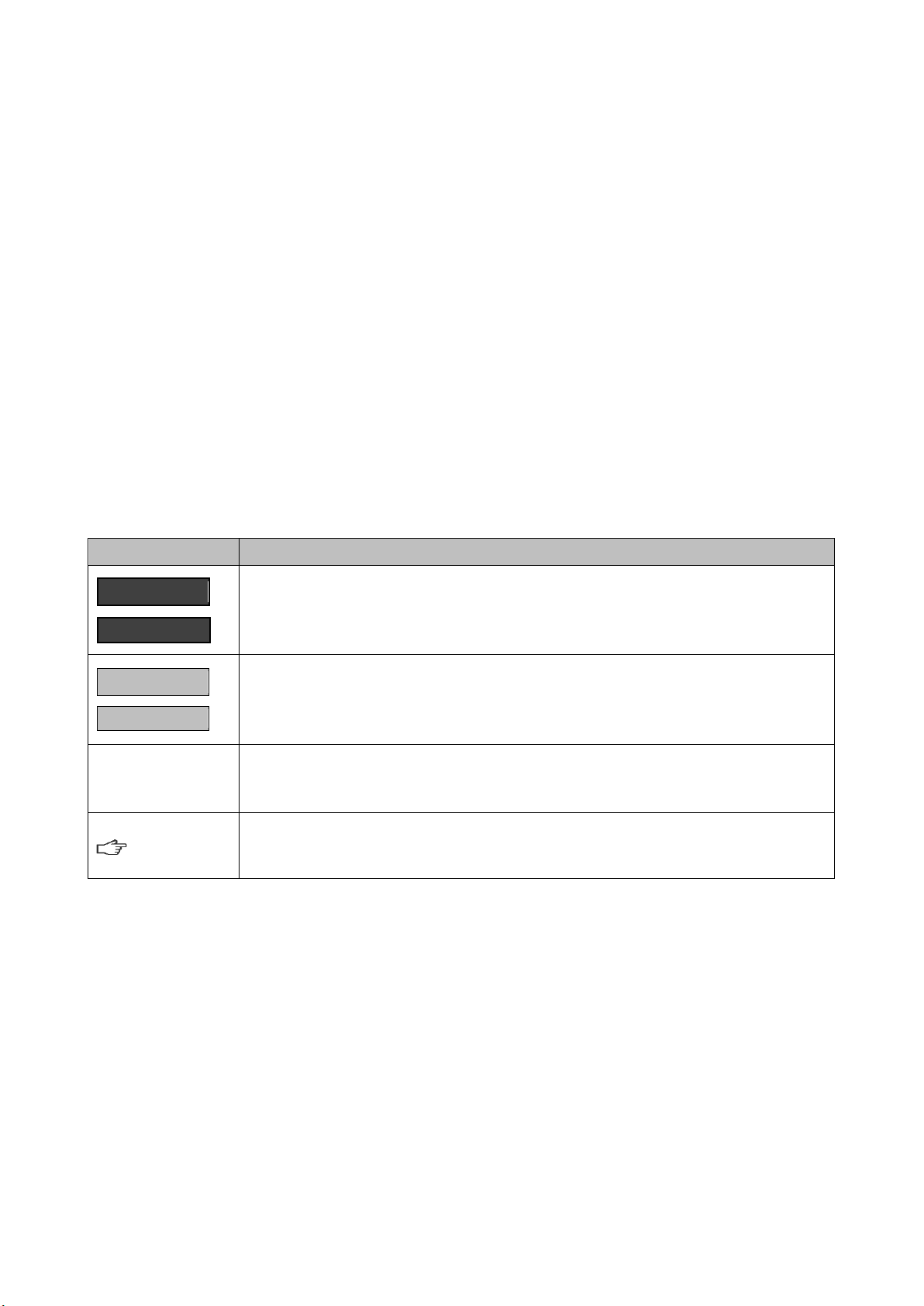

■本文中の表記について/About Notation

本書では、以下の表記に従って説明しています。

This manual explains according to the following notations.

表記/Notation

意味/Description

重要

IMPORTANT

本機の機能を十分に発揮するための情報や、本機の損傷を防ぐための情報を記載し

ています。

The information for fully exhibiting the function of this machine and the information

for preventing damage to this machine are indicated.

メモ

NOTE

参考となる情報を記載しています。

The information which is consulted is indicated.

1. 2. 3. ・・・

操作手順を記載しています。

The operating procedure is indicated.

参照先を記載しています。

The reference destination is indicated.

CMN011-006 原本 (Original instructions) 1

English

Table of contents

Chapter 1 Product Usage Precautions.............................................................................3

1.1 Safety Notations .............................................................................................................................. 3

1.2 Precautions for Transport, Storage, and Relocation

................................................................................ 3

1.3 Precautions for Installation.............................................................................................................. 3

1.4 Precautions for Operation ............................................................................................................... 4

1.5 Other Precautions ........................................................................................................................... 4

1.6 Safety Label Locations .................................................................................................................... 5

Chapter 2 Components Identification ..............................................................................6

2.1 Accessories ..................................................................................................................................... 6

2.2 Device Body .................................................................................................................................... 7

2.2.1 CKU-060AT3-ACC................................................................................................................... 7

2.3 AT3 Panel ........................................................................................................................................ 8

2.4 Display Indications .......................................................................................................................... 9

2.4.1 About Modes............................................................................................................................ 9

2.4.2 Indications During Stoppage ................................................................................................... 9

2.4.3 Indications During Operation................................................................................................. 10

Chapter 3 Operation ........................................................................................................11

3.1 Start-up Preparation.......................................................................................................................11

3.1.1 Installation ..............................................................................................................................11

3.1.2 Wiring and Piping .................................................................................................................. 12

3.2 Operation....................................................................................................................................... 12

3.3 Registering Initial Pressures ......................................................................................................... 13

Chapter 4 Configuring Settings (MODE SELECT Mode).......................................14

4.1 Screen Transitions in MODE SELECT Mode................................................................................ 14

4.2 Communication Format Setting Mode (When Equipped with Communication Function) ....... 14

4.3 Air Volume-Down Alert Timing Setting Mode ................................................................................ 15

4.4 Other Setting Mode ....................................................................................................................... 15

4.4.1 Clock Calibration Mode ......................................................................................................... 15

4.4.2 Accumulated Run Time Reset Mode..................................................................................... 16

4.4.3 Setpoint Reset Mode............................................................................................................. 16

4.5 Error History Mode ........................................................................................................................ 16

Chapter 5 Maintenance and Checkup ............................................................................17

5.1 Replacing Filters............................................................................................................................ 17

5.1.1 Replacing the Primary filter.................................................................................................. 17

5.1.2 Replacing the secondary filter............................................................................................... 18

5.1.3 Replacing the tertiary filter..................................................................................................... 18

5.2 Replacing Fuse.............................................................................................................................. 19

5.3 Replacing the Button Battery ........................................................................................................ 20

5.4 Daily Checkup ............................................................................................................................... 20

5.5 Errors/Warnings............................................................................................................................. 21

5.5.1 Action on Errors/Warnings..................................................................................................... 21

5.5.2 Error/Warning Table............................................................................................................... 22

5.6 Troubleshooting............................................................................................................................. 23

Chapter 6 Useful Utilization (Optional) ..........................................................................24

6.1 Remote Cable................................................................................................................................ 24

6.1.1 Electrical Diagram ................................................................................................................. 24

6.1.2 Pin Assignments.................................................................................................................... 26

6.1.3 Remote Operation ................................................................................................................. 27

6.2 Communication Function............................................................................................................... 27

6.2.1 RS485 Communication ......................................................................................................... 27

6.2.2 Ethernet ................................................................................................................................. 27

2

6.3 Removable Flange

............................................................................................................................ 27

Chapter 7 Appendix .........................................................................................................28

7.1 Specifications ................................................................................................................................ 28

7.2 Consumables List.......................................................................................................................... 28

7.3 Electrical Diagram ......................................................................................................................... 29

7.3.1 CKU-060AT3-ACC................................................................................................................. 29

Chapter 1 Product Usage Precautions

CMN011-006 原本 (Original instructions) 3

English

Chapter 1 Product Usage Precautions

1.1 Safety Notations

This instruction manual describes usage precautions with the below listed symbols.

Be sure to read the instructions.

Symbol

Meaning

WARNING

Indicates a hazardous situation which, if not avoided, could result in personal death or

serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result personal injury or

damage to the device.

Indicates a prohibited action (which MUST NOT be done).

Indicates a mandatory action (which MUST be done).

1.2

Precautions for Transport, Storage, and Relocation

WARNING

•Transportation must be done using at least two people.

Injury may result due to fall hazard.

CAUTION

•Relocation and storage must be done in a safe location within the

temperature range of -10°C to 60°C at relative humidity of 80% or less.

1.3 Precautions for Installation

WARNING

•Do not install the device in or around an area with flammable, explosive, or

corrosive mist, smoke, or gases.

CAUTION

•This device is designed for installation in a cleanroom or a clean factory.

Avoid installation in other areas, such as outdoors.

•Ensure a wide suction port.

If the device is used continuously with a narrow suction port (i.e., at high

pressure), the motor may become hot as it cannot be cooled.

•Install the device in a horizontal, vibration-free location as it contains rotating

equipment.

•Install the device at normal temperature (ambient temperature 0°C to 40°C, at

humidity 80% or less) without dew condensation.

High temperature or dew condensation may cause failure of electrical

components or electric shock.

•Beware that suction ambient temperature (temperature around the dust to

be collected) is low enough, because otherwise the motor may lead to

performance reduction or failure.

•The installation site should be at an altitude of 1,000 m or less.

Chapter 1 Product Usage Precautions

4

1.4 Precautions for Operation

WARNING

•Do not suck the following substances:

Flammable substances

...Gasoline, thinner, benzine, kerosene, paints, etc.

Explosive dusts ...........Aluminum, magnesium, titanium, zinc, epoxy, etc.

Sparky dust .................Dust containing sparks from high-speed cutting

machine, grinder, welding machine, etc.

Fire source ..................Cigarette, and liquid such as oil and chemical

Others..........................Liquid such as water, oil, chemical

•Do not use the device in or around an area with flammable, explosive, or

corrosive mist, smoke, or gases.

•Ensure secure connections, without bending or pulling cables with excessive

force.

Fire or electric shock may result.

•Ensure that the power supply conforms to the specifications of the device.

•Use the device to suck dry dust without potential dust explosion.

•Be sure to connect the ground wire.

CAUTION

•Do not move the device while in operation.

•Use the device in locations of pollution degree 2.

•Use a power supply of overvoltage category II.

•Turn off the main power switch in case of power outage.

Injury or device damage can occur when power returns.

•Ensure that filters are installed correctly.

If filters are missing, clogged, or broken, foreign matter may enter the motor,

causing failure.

1.5 Other Precautions

WARNING

•Do not disassemble or alter the device.

Failure to observe can cause electric shock or injury.

For internal checkup or repair, contact your dealer.

•Follow the information in the instruction manual when performing installation,

connection, starting, operation, checkup, and fault diagnosis.

Working in a wrong manner may lead to fire, electric shock, or injury.

CAUTION

•When discarding the device, dispose of it appropriately as an industrial

waste.

Chapter 1 Product Usage Precautions

CMN011-006 原本 (Original instructions) 5

English

1.6 Safety Label Locations

High voltage warning

label

“

Do not disassemble

” label

Nameplate

“Do not disassemble”label

High voltage

warning label

Nameplate

Chapter 2 Components Identification

6

Chapter 2 Components Identification

2.1 Accessories

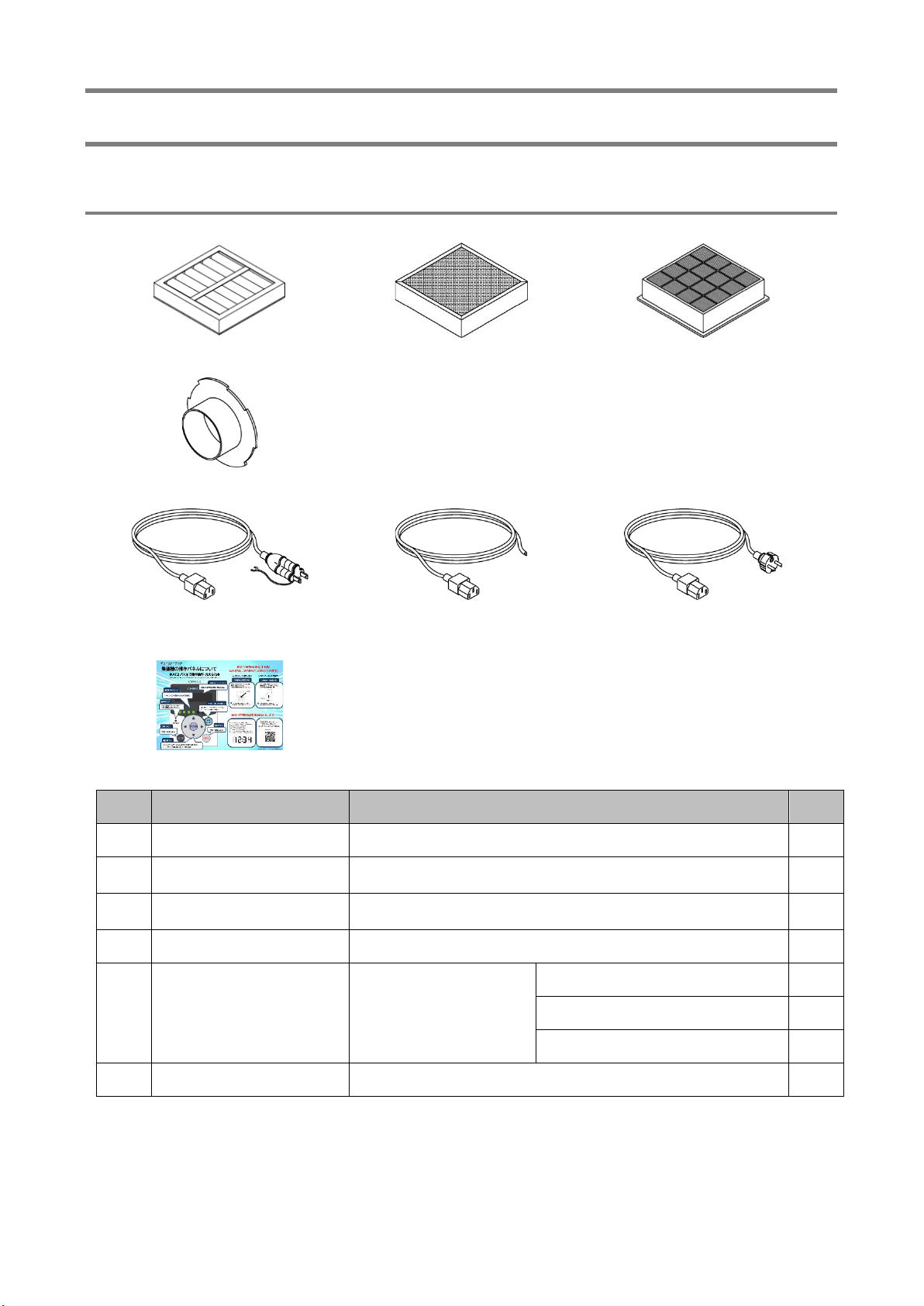

①②③

④

100V version 200V version(-T version)220-230V version(-CE version)

⑤

⑥

No.

Name

Function

Qty.

①

Primary filter

Collects/adsorbs dust.

1

②

Secondary filter

Removes odors by trapping fine particles through collision with

the activated carbon granules.

1

③

Tertiary filter

Prevents activated carbon particles from entering into the

blower.

1

④

Removable flange

Connects a suction duct.

1

⑤

Power cable (3 m)

Connects to the power

outlet.

Shaped differently

depending on power

supply specifications.

100V version*1

1

200 V version (-T version)

1

220/230 V version (-CE version)

1

⑥

Instruction manual

Provides instructions for using the device.

1

*1 Can be used in the area of 100-115V.

Chapter 2 Components Identification

CMN011-006 原本 (Original instructions) 7

English

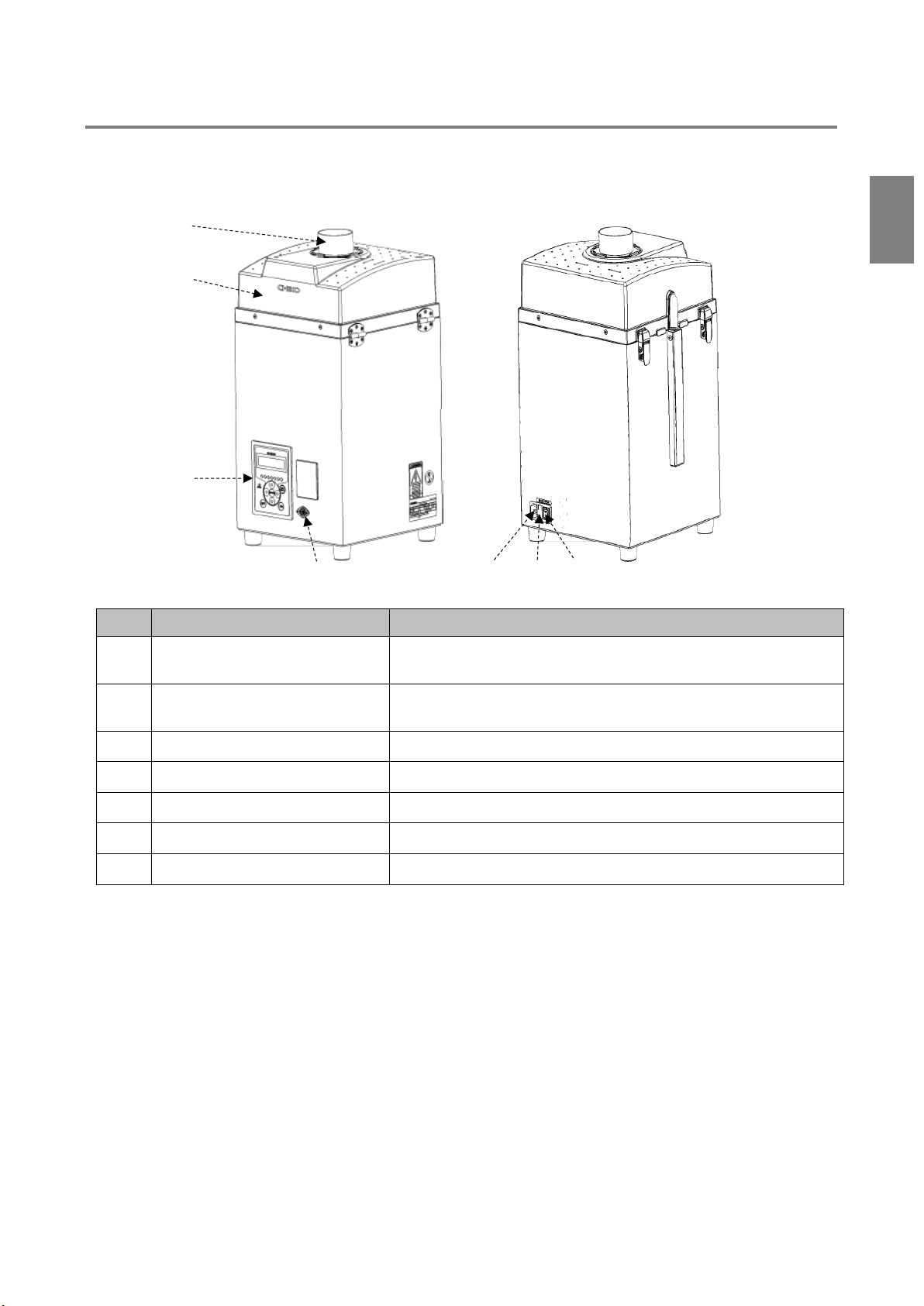

2.2 Device Body

2.2.1 CKU-060AT3-ACC

No.

Name

Function

①

Suction port

(Removable flange)

Connects a suction duct.

②

Suction-side filter case

Contains the primary filter, the secondary filter and

the tertiary filters.

③

AT3 panel (operation panel)

Operates the device.

④

Remote connector

Connects a remote cable (optional).

⑤

Power connector

Connects the power cable.

⑥

Fuse box

Contains a fuse.

⑦

Main power switch

Turns on/off power to the device.

①

②

③

④

⑤

⑥

⑦

Chapter 2 Components Identification

8

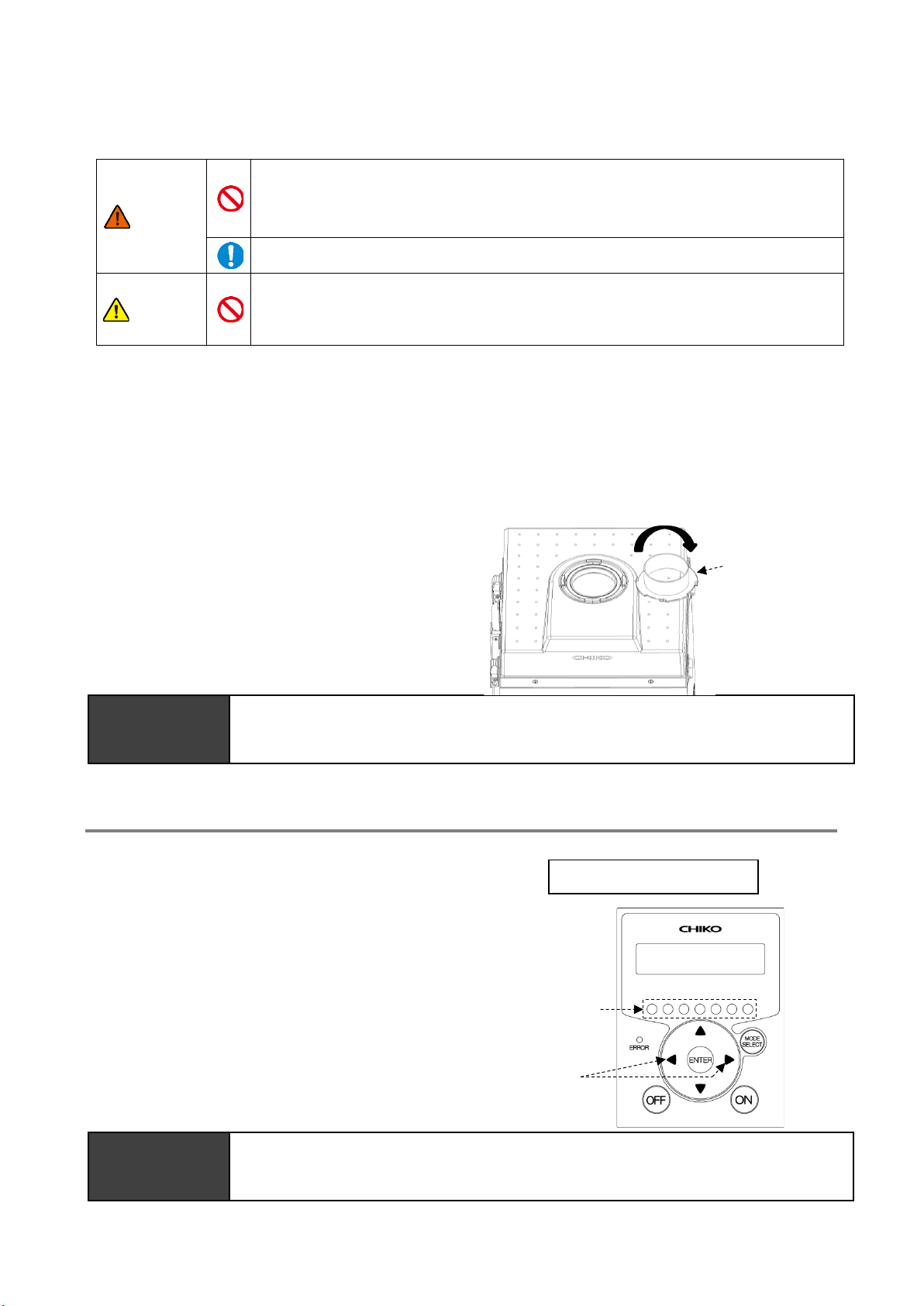

2.3 AT3 Panel

No.

Name

Function

①

Organic EL

(OLED) display

Displays the operating status and various settings.

Displays an error or warning number in case of an error or warning.

②

Suction power

level lamps

Green lamps indicate a suction power level (1 to 7).

③

Up/Down arrow

buttons

During stoppage or operation, switches among the content of the display.

“2.4

Display Indications” (page 9)

In MODE SELECT mode, cycles through parameters and changes numeric

data.

“Chapter 4 Configuring Settings (MODE

SELECT Mode)(page14)

④

ERROR lamp

The red lamp lights upon detection of an error that stops device operation.

The red lamp flickers upon detection of an error or warning that continues

device operation.

⑤

Left/Right arrow

buttons

During operation, each pressing of the Left (or Right) arrow button changes

the suction power to the next lower (or higher) level.

During MODE SELECT mode, each pressing of the Left (or Right) arrow

button moves the cursor left (or right) to the next position.

⑥

OFF button

Stops the operation.

During stoppage, holding this button down for three seconds clears the

registered initial pressure.

“3.3

Registering Initial Pressures

“

(page 13)

⑦

ON button

Starts operation.

⑧

ENTER button

During operation, holding this button down for three seconds causes

transition to initial pressure registration.

“3.3

Registering Initial Pressures” (page 13)

During SELECT MODE mode, determines the selected parameter and its

numeric data.

“Chapter 4 Configuring Settings (MODE

SELECT Mode)(page14)

⑨

MODE SELECT

button

During stoppage, transits to the MODE SELECT mode.

“Chapter 4 Configuring Settings (MODE

SELECT Mode)(page14)

During MODE SELECT mode, returns to the previous mode.

During an error/warning, transits to the error history mode or error clear mode.

l

①

②

④

⑥

③

③

⑤

⑦

⑤

⑨

⑧

Chapter 2 Components Identification

CMN011-006 原本 (Original instructions) 9

English

2.4 Display Indications

2.4.1 About Modes

2.4.2 Indications During Stoppage

The Up/Down arrow buttons cycle through indications.

Normal mode

ON button

OFF button

page 14

MODE SELECT button

Page 13

ENTER button

Held down for 3 sec

Main power

switch ON

Page 13

OFF button

Held down for 3 sec

During

stoppage

During

operation

Ver*.** ID.**

Battery ***%

Date: ****/**/**

Time: **:**:**

Program version, RS485 communication ID

Remaining battery level

Date

Time

Clock calibration mode ( Page 15)

Chapter 2 Components Identification

10

2.4.3 Indications During Operation

The Up/Down arrow buttons cycle through indications.

OP **.**kPa

SP **.**kPa

DP **.**kPa

EP **.**kPa

External pressure

Suction pressure

Differential pressure

Exhaust pressure

Blower ***.*°C

Temperature around blower

Motor *****rpm

Motor rotational frequency

Indicates the rotational frequency of the currently running motor.

Runtime ******h

Accumulated run time (resettable)

Indicates run time accumulated since the last resetting.

Accumulated run time reset mode ( Page

16)

Total ******h

Actual run time (not resettable)

Indicates the total run time.

Chapter 3 Operation

CMN011-006 原本 (Original instructions) 11

English

Chapter 3 Operation

3.1 Start-up Preparation

3.1.1 Installation

■Installation location

To ensure operating safety and deliver the full performance of the device, install the device in a location

that meets the following conditions:

Item

Description

Ambient temperature

0° to +40°C

Ambient humidity

80 RH% or lower (without dew condensation)

Ambient conditions

Indoors (not exposed to direct sunlight), free of corrosive/flammable gases,

oil mist, and dust.

■Removing the button battery insulating sheet

While removing the insulation sheet from the button battery, turn on the electricity.

1. Take out the primary filter, secondary filter

and the tertiary filters.

5.1

Replacing Filters

Page17

2. Pull out the insulating sheet off the battery

cover unit.

Note

•The button battery drains when the main power switch is OFF.

1 μA when main power is ON; 40 to 50 μA when main power is OFF

•The battery life (2 years, typical) depends on the usage. Take it as a guide value.

CAUTION

•It will cause a huge consumption of the battery, if the insulation sheet is

removed while the device is turned off.

Battery cover

Insulating

sheet

Chapter 3 Operation

12

3.1.2 Wiring and Piping

■Wiring

WARNING

•Perform wiring firmly, without bending or pulling cables with excessive force.

Fire or electric shock may result.

•Ensure that the power supply conforms to the specifications of the device.

•Be sure to connect the ground wire.

CAUTION

•Avoid multiple connections as they can cause voltage reduction.

At reduced voltage, the device may fail to operate normally, resulting in

failure.

The device is powered by a single-phase supply.

The tolerance of the supply voltage is 10%.

1. Connect the device attachment plug of the power cord to the power connector on the device.

2. Connect the power supply end of the power cord to the power outlet.

■Piping

1. Turn the removable flange clockwise until it is

secured on the suction port.

2. Connect the suction tube (to be prepared

separately) to the removable flange.

IMPORTANT

•Ensure appropriate piping during operation.

The piping should be as short as practicable, with the piping port diameter not too

small.

3.2 Operation

1. Turn on the main power switch.

The display indicates the program version

and the ID for RS485 communication.

2. Press the ON button on the AT3 panel.

The device starts operation.

3. Check that abnormal noise is not generated

and the suction is appropriate.

4. Set a desired suction power level by

pressing the Left/Right arrow buttons.

The suction power is indicated by the

suction power level lamps (1 to 7).

IMPORTANT

•Leave an interval of three minutes or more between on/off switching.Repeated

on/off switching at intervals of less than three minutes, in particular less than 30

seconds, may cause failure.

Ver*.** ID.**

Left/Right

arrow buttons

Suction power

level lamps

Removable

flange

Chapter 3 Operation

CMN011-006 原本 (Original instructions) 13

English

3.3 Registering Initial Pressures

Air volume reduction due to filter clogging is judged based on a registered initial differential pressure and

indicated as low air volume (WARN4). Register initial pressures through these steps:

1. Perform the wiring and piping of the device.

2. Start the device at a desired suction power level.

3. Press and hold down the ENTER button for three seconds.

The display shows “Initial DP Get Y”, prompting confirmation to register/update initial pressures.

4. To proceed with registration/update, press the ENTER button.

The device starts to acquire initial pressure.

If you do not want update, press the MODE SELECT button to return to normal operation.

5. The device runs through a sequence of suction power levels 1 to 7, to automatically acquire the

differential pressure for each level.

While the device is acquiring initial pressures, the display alternates between the “Initial DP Check”

message and the “suction power level and differential pressure” values.

6. When the registration completes, the display shows the “Initial DP Entry” message and the device

returns to normal operation.

IMPORTANT

•Ensure that the filters are new.

•Update registered initial pressures once again if piping is changed or all filters are

replaced (except for the exhaust filter) after registration of initial pressures.

•If initial pressures are not registered, an “initial pressure unregistered” warning

(WARN6) appears.

•The registered initial pressures can be cleared by holding down the OFF button for

three seconds when the device is in stop state.

●Clearing registered initial pressures

1. Hold down the OFF button for three seconds when the device is in stop state.

The display shows “Initial DP Clr Y”, prompting confirmation to clear registered initial pressures.

2. To clear them, press the ENTER button.

If you do not want to clear them, press the MODE SELECT button to return to normal operation.

3. When the clearing completes, the display shows the “Initial DP Clr” message and the device

returns to the stop state.

Chapter 4 Configuring Settings (MODE SELECT Mode)

14

Chapter 4 Configuring Settings

(MODE SELECT Mode)

4.1 Screen Transitions in MODE SELECT Mode

To move to the MODE SELECT mode, press the MODE SELECT button during stoppage.

The Up/Down arrow buttons cycle through parameters.

4.2 Communication Format Setting Mode

(When Equipped with Communication Function)

This mode sets the below listed items of serial communication format.

The settings are enabled after the main power switch is turned off and back on.

Item

Setting

Default

Communication station number

1 to 25

1

Baud rate

9600 bps, 19200 bps,

38400 bps, 57600 bps,

115200 bps

9600 bps

Bit length and parity

Bit length = 8 bits, with no parity

Bit length = 8 bits, odd parity

Bit length = 8 bits, even parity

Bit length = 9 bits, with no parity

Bit length = 8 bits, with no parity

Stop bit

Stop bit = 1 bit

Stop bit = 2 bits

Stop bit = 1 bit

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the communication format setting mode

(“Com Setting”).

3. Press the ENTER button.

The communication station number check screen appears, showing the current settings.

4. Press the Up/ Down arrow buttons to move to the item you want to set.

5. Press the ENTER button.

The setting screen appears.

6. Press the Up/Down arrow buttons to select the desired setting.

[Com Setting]

[Volume Down ST]

[Other Setting]

[Error Data]

Communication format setting mode

(

Page 14)

Air volume-down alert timing setting mode

(

Page 15)

Other setting mode

(

Page 15)

Error history mode

(

Page 16)

Chapter 4 Configuring Settings (MODE SELECT Mode)

CMN011-006 原本 (Original instructions) 15

English

7. Press the ENTER button to determine the setting.

8. To exit this mode, press the MODE SELECT button to return to normal mode.

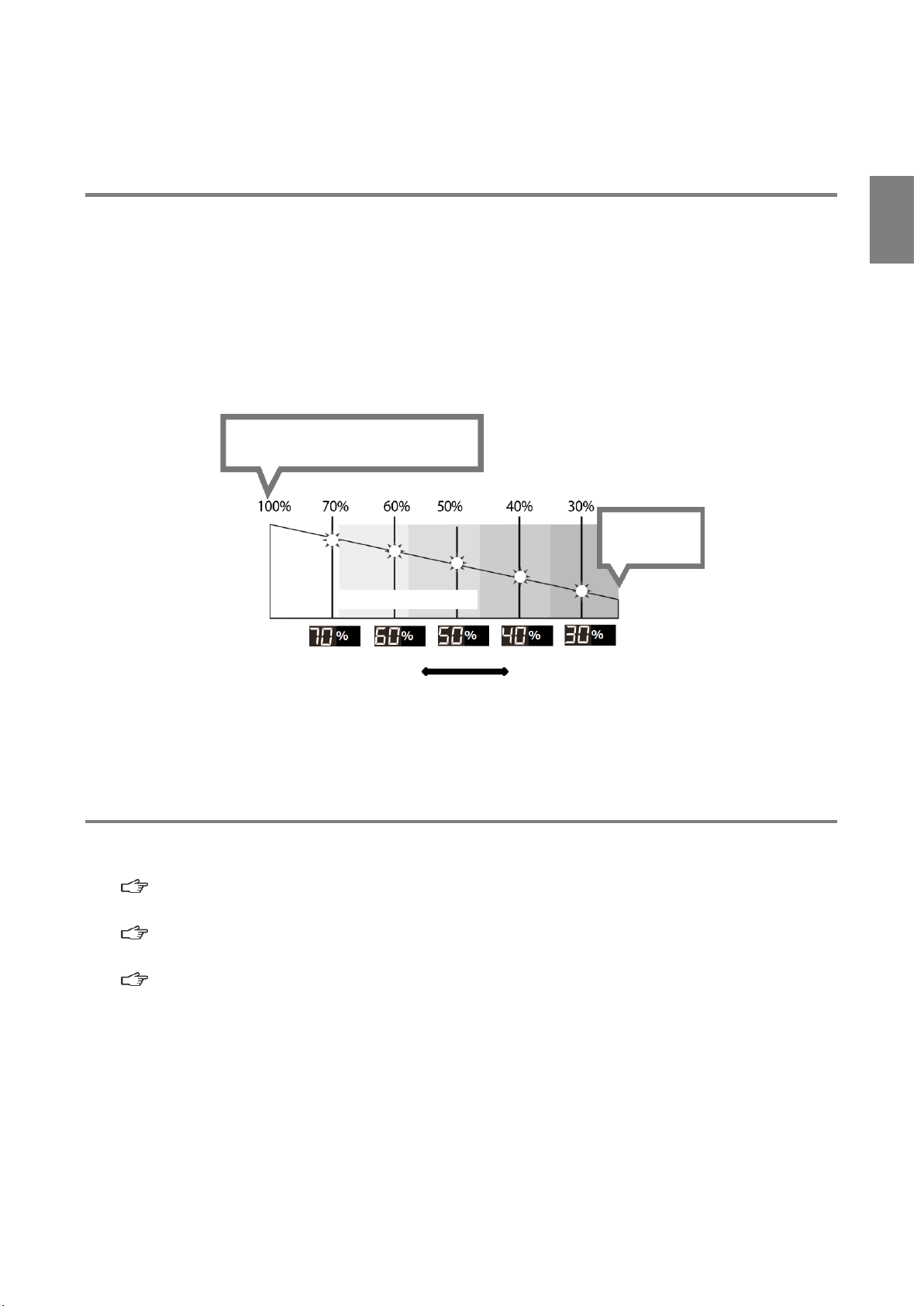

4.3 Air Volume-Down Alert Timing Setting Mode

This mode allows for changing the timing for displaying an air volume-down warning (WARN4) as desired.

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the air volume-down alert timing setting mode

(“Volume Down ST”).

3. Press the ENTER button.

The current setting appears.

The default is 50%, displayed as “3: Down to 50%”.

4. Press the Up/Down arrow buttons to select a timing between 30 to 70%.

A lower setting causes the air volume-down alert to occur later, and vice versa.

5. Press the ENTER button to determine the setting.

6. To exit this mode, press the MODE SELECT button to return to normal mode.

4.4 Other Setting Mode

The parameters listed below can be set.

•Date/time setting

“4.4.1

Clock Calibration Mode” (page 15)

•Accumulated run time resetting

“4.4.2

Accumulated Run Time Reset Mode” (page 16)

•Setpoint resetting

4.4.3

Setpoint Reset Mode” (page 16)

4.4.1 Clock Calibration Mode

This mode sets date and time.

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the other setting mode (“Other Setting”).

3. Press the ENTER button.

The screen displays “TimeAdjust”.

4. Press the ENTER button.

100% of filter performance is available.

The initially registered value is taken as

100%.

Note: The initial pressure applies when the

suction hose and hood are set in

place.

Differential

pressure lower

Differential

pressure higher

(Default)

Less than 30% of

filter performance

is available.

Filter performance

Setpoint

Lighting occurs earlier.

Lighting occurs later.

Lighting timing can be set to five levels.

To advance the lamp-lighting timing To delay the lamp-lighting timing

Chapter 4 Configuring Settings (MODE SELECT Mode)

16

The date setting screen appears.

5. Press the Up/Down arrow buttons to change the value.

6. Press the ENTER button to determine the value.

Set the value in this order: year, month, and day.

7. After the date is set, the time setting screen appears.

8. Press the Up/Down arrow buttons to change the value.

9. Press the ENTER button to determine the value.

Set the value in this order: hours, minutes, and seconds.

10. To exit this mode, press the MODE SELECT button to return to normal mode.

4.4.2 Accumulated Run Time Reset Mode

This mode resets the accumulated run time (“Runtime”).

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the other setting mode (“Other Setting”).

3. Press the ENTER button.

The screen displays “TimeAdjust”.

4. Press the Up/Down arrow buttons to change the display to “[Runtime Reset]”.

5. Press the ENTER button.

The display shows “Reset Runtime Y”, prompting confirmation to reset the accumulated run time.

To reset, press the ENTER button.

6. To exit this mode, press the MODE SELECT button to return to normal mode.

4.4.3 Setpoint Reset Mode

This mode allows for restoring the defaults for communication format, air volume-down alert timing, and

resetting the accumulated run time.

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the other setting mode (“Other Setting”).

3. Press the ENTER button.

The screen displays “TimeAdjust”.

4. Press the Up/Down arrow buttons to change the display to “[Setting Reset]”.

5. Press the ENTER button.

The display shows “1:YES”, prompting confirmation to reset setpoints.

To reset, press the ENTER button.

6. The display shows “1:START” for reconfirmation.

7. Press the ENTER button to reset the setpoints and move the device to normal mode.

4.5 Error History Mode

The error history allows for checking four occurrences of errors.

The error history is cleared by turning off the main power switch.

1. Move to the MODE SELECT mode.

2. Press the Up/Down arrow buttons to move to the error history mode (“Error Data”).

3. Press the ENTER button.

The display indicates the number of the most recent error that has occurred and the accumulated

run time at that occurrence.

4. Press the Down arrow button to display the history of four errors in order from the latest.

5. To exit this mode, press the MODE SELECT button to return to normal mode.

Chapter 5 Maintenance and Checkup

CMN011-006 原本 (Original instructions) 17

English

Chapter 5 Maintenance and Checkup

CAUTION

•Before starting maintenance and checkup, be sure to break the electrical

circuit by turning off the power supply and disconnecting the plug from the

power outlet.

5.1 Replacing Filters

If clogging occurs, a “WARN2” warning appears. Replace the primary filter.

If “WARN2” remains displayed after replacing the primary filter, replace the tertiary filter.

5.1.1 Replacing the Primary filter

IMPORTANT

•The filter`s should be replaced in an area large enough to open the suction-side filter

case.

1. Remove the locks (2 places) on the intake

side filter case and open the filter case.

2. Remove the collision plate and replace

the primary filter.

CAUTION

When installing the filter, attach the

packing downward.

Snap locks

Suction-side filter case

Collision plate

Primary filter

Chapter 5 Maintenance and Checkup

18

5.1.2 Replacing the secondary filter

5.1.1

「

Replacing the

Primary filter

」

(Page

17)

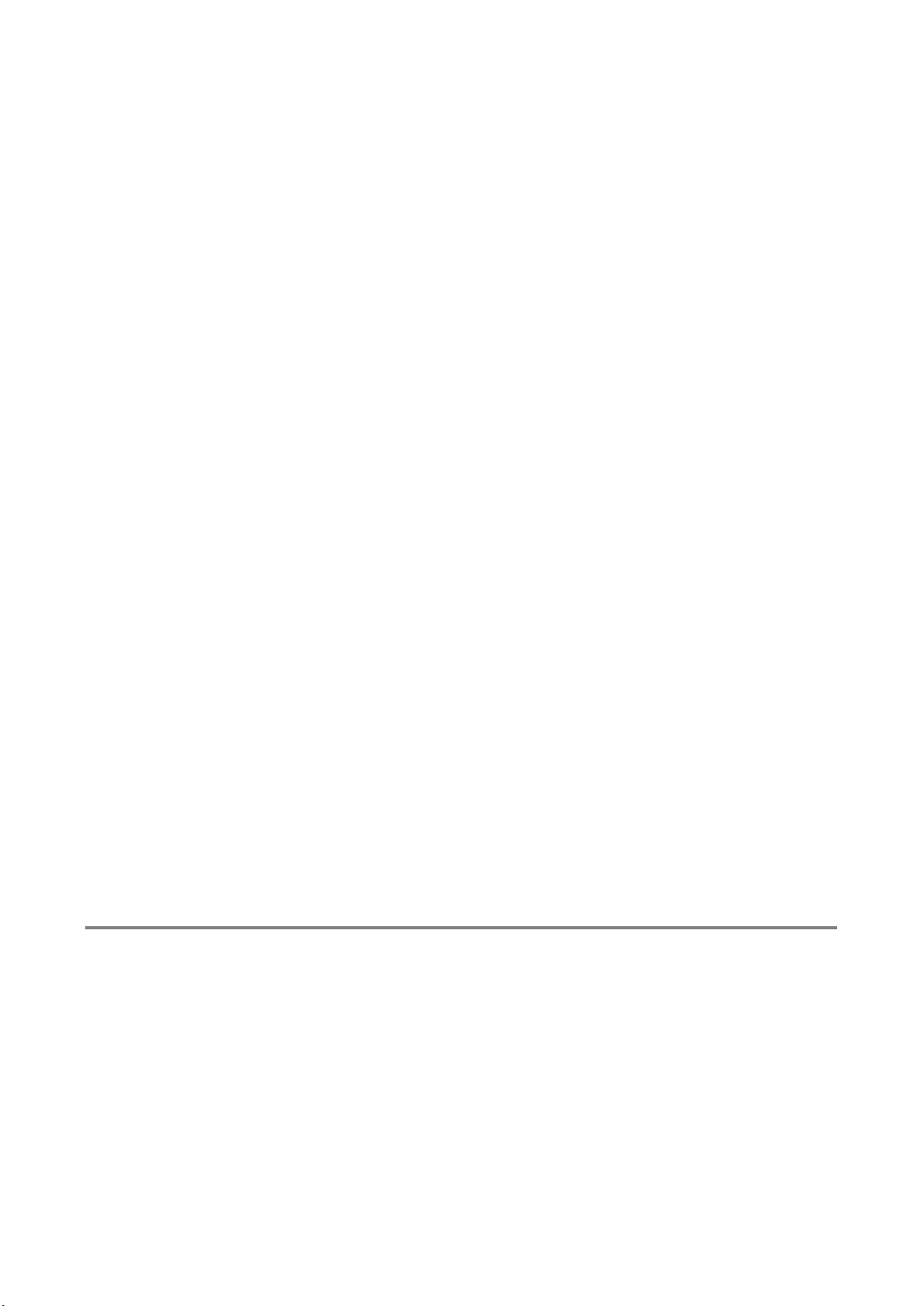

3. Grasp the handle and replace the activated

carbon box.

* The new activated carbon box does not

come with a handle.

Please reuse the handle.

CAUTION

Please use the handle correctly referring to

the photo.

Incorrect use may damage the dust collector.

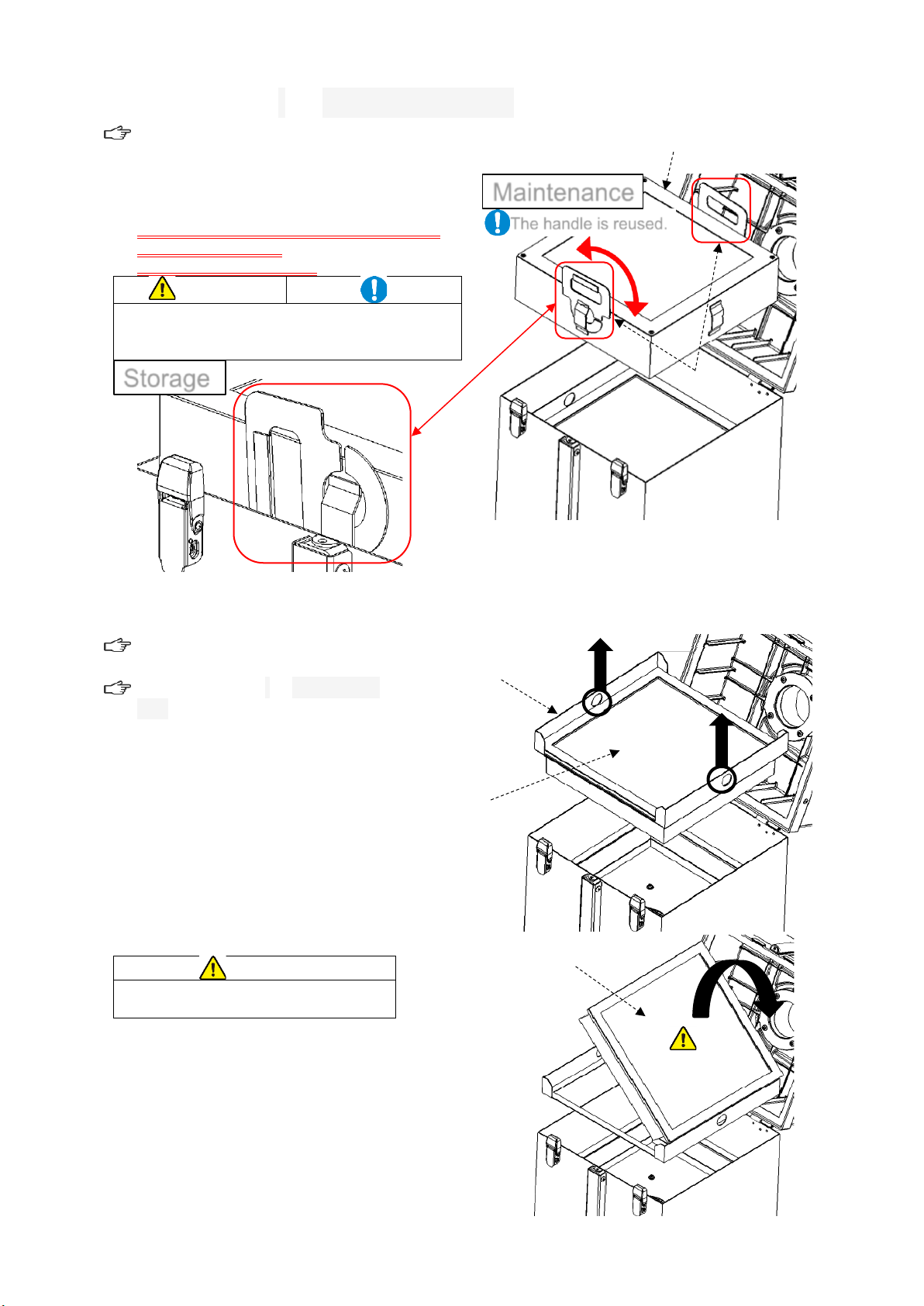

5.1.3 Replacing the tertiary filter

5.1.1

「

Replacing the

Primary

filter

」

(Page

17)

5.1.1

「

Replacing the secondary

filter

」

(Page

18)

4. Remove the third filter frame.

* Hook it and take

5. Replace the third filter.

CAUTION

When installing the filter, attach the

packing upward.

Storage

The handle is reused.

Secondary filter

Maintenance

Handle

Third filter

Third filter frame

Third filter

This manual suits for next models

2

Table of contents

Other Showa Denki Dust Collector manuals