Showa Denki Workresa WRM-04H Series User manual

YFWA11A-Y000E

Instruction Manual

Dust Collector with Worktable

Workrésa (WRM)

Introduction

Thank you for purchasing our Showa Denki “Dust Collector with Worktable (WRM).”

We at Showa Denki Co., Ltd., as a special manufacturer of blowers and dust collectors, have

strived to produce products by making the best use of “Flow technology” and “Rotating machine

technology.” WRM is a dust collector with worktable that utilizes these technologies. In order to

demonstrate sufficient performance of this machine and use this machine for a long time without

malfunctions, read this instruction manual well.

Keep this manual in a place easily accessible by workers in charge of maintenance and

inspection. The latest issue of the instruction manual can be downloaded from the homepage of

Showa Denki Co., Ltd. (http://www.showadenki.co.jp/pam phlet_download.html)

This manual describes the details from installation to use method of the duct collector with

worktable.

WRM-04H-□□□(-A) Standard specifications (-A type includes optional air coupler)

WRM-04B-□□□(-A) Simple explosion-proof specifications (-A type includes optional air coupler)

WRM-04S-□□□(-A) Spark countermeasure specifications (-A type includes optional air coupler)

This instruction manual is for standard models. When purchasing a custom-made product,

please comply with the instructions in this manual and observe the terms and conditions of use

included separately.

Workers in charge of handling and maintenance and inspection of this Machine must receive

education and training for this Machine.

Caution marks in this manual

The marks in this manual indicate the following:

This mark indicates that mishandling may cause death and

serious accidents.

This mark indicates that mishandling may cause personal

injuries and property damages.

This mark indicates prohibited items.

This mark indicates items to which attention should be paid.

This mark indicates items that must be done without fail.

WARNING

CAUTION

Table of contents

Page

Chapter 1 Safety precautions -1-

Chapter 2 Equipment Overview -3-

Equipment overview -3-

Structure of this machine -3-

Parts diagram - 3-

Chapter 3 Installation -4-

Installation -5-

Electric wiring -5-

Test run -5-

Chapter 4 Operation -7-

Daily operation -7-

Precautions -7-

Hood -8-

Shakingr -9-

Coupler -9-

Chapter 5 Maintenance and inspection -10-

Inspection item and frequency -10-

Filter cloth replacement -11-

Shaking rope tension adjustment -11-

Size of replacement filter cloth -12-

Troubleshooting -12-

Specifications -13-

Outer dimensions -13-

Chapter 6 Disposal -15-

Chapter 7 Warranty statement -16-

- 1 -

◼

Chapter 1 Safety precautions

Never intake the following:

Lit cigarettes, cigarette butts or ash, fire sources like matches, and other high-

temperature powder dusts.

Sparks generated by sanders, grinders, etc.

The filter cloth is flammable. It may ignite due to sparks, etc., resulting in a fire.

If a fire should occur in this machine, immediately turn off the switch and insert,

through the suction inlet, an extinguishant suitable for the collected materials, then

close both the suction inlet and discharge outlet.

Gasoline, paint thinner, or kerosene cutting oils or cleaning liquids with a

flashpoint lower than 125℃.

Flammable gas, explosive gas, gasoline or other combustible vaporized gas.

There is risk of ignition or explosion by heat generated by sparks or the electric motor

due to internal electric components, static electricity, contact with metal, etc.

Powder dust such as aluminum, carbon or starch posing dust explosion risk

Explosion due to dusts may occur depending on the particle size, concentration, etc.

●Substances that generate heat and change into dangerous substances if mixed.

If different materials are collected in the same machine, a potentially dangerous

chemical reaction may occur. Please responsibly determine if mixed intake is safe for

your materials. If it is dangerous, please use the machine after clearly displaying it

as a dedicated dust collector for each material.

Never operate this machine with the main body front door open. The door may close

due to negative pressure, and cause fingers, etc. to be caught. In addition, the motor

may be overloaded.

Never ride on this machine. Doing so may deform the machine or cause an accident

due to a fall.

When handling dust that may cause an explosion, be sure to use a dust-explosion-proof

product (Simple explosion-proof specifications). When handling high-temperature dust

and sparks generated during grinding, be sure to use a spark-countermeasure model.

Do not use when unable to make sound judgements.

The design life of this product is 8 years, excluding consumable parts. If using for longer, the risk

of failure or malfunction may increase due to aging and deterioration of materials.

WARNING

- 2 -

Never Intake the following, as they may cause malfunction.

High-temperature gas and heat-generating substances

Gas at 40°C or higher that is suctioned in or generated within the machine by heat-

generating materials may cause insulation failure of internal electric components.

Adhesive dusts

The filter cloth may clog if dust adheres to it and cannot be shaken.

Solid materials such as workpieces and tools

These objects may damage the duct, filter cloth, etc.

Fine powder dust such as carbon (5 μm or less)

Powder dust may leak if a standard filter cloth is used. Use a high-performance filter

cloth.

Light powder dust such as feather, cotton, paper and styrene foam dusts

These objects may get entangled internally and suspend without falling.

Highly abrasive powder dust such as glass powder and abrasives

The filter cloth may be perforated due to wear and powder dust may leak.

Furthermore, the duct and main body of the machine may be punctured.

Corrosive gas and mists

The machine main body and parts may corrode.

Do not apply high pressure to this machine with other pressure machines.

Never increase operation speed using an inverter, etc.

Doing so may cause damage to the blower.

Except when reusing the material collected by this machine, dispose of it appropriately

in accordance with the relevant laws and regulations set by national and local

governments. Dispose of old filter cloths and other wastes similarly.

This machine collects 5μm or larger-sized particles with a standard filter cloth and 1μm or larger

particles with an optional high-performance filter cloth. Powder dust amount must be 1g or less per

1 m3/min of air. If the intake powder dust is beyond this performance range, it is possible that dust

will leak through the filter cloth, pressure loss of filter cloth increases, or clogging, etc. will occur.

CAUTION

- 3 -

◼

Chapter 2 Equipment Overview

This machine separates and collects dusts and mists scattered in the worktable hood when

workpiece cutting powder/oil are air-blown or generated when grinding with electric tools. It cannot

process large amounts of powder or mist in a short time, intake liquids not in a mist state, nor

perform shaking during operation. If clogging decreases air volume, stop operating and perform

shaking. Continuous shaking cannot be done.

Structure of this machine

Air containing the collected materials is separated in the main body and filtered by the filter cloth.

Cleaned air passes through the blower to the machine back and exhausted. Filtered dust is shaken

by operating the shaking handle to beat the filter surface with the shaking mechanism. Shaken

dust accumulates on the dustpan and is removed via the front door easily.

Dust explosion countermeasure (simple explosion-proof specifications) models are equipped

with: an antistatic filter medium to prevent static electricity sparks; an explosion outlet which

releases internal pressure in the event of an explosion; a check valve to prevent backflow into the

duct; and an electric motor with specifications equivalent to Japanese increased-safety explosion-

proof specifications.

*Dust explosion countermeasure (Simple explosion-proof specifications) models cannot

completely prevent explosions.

Spark countermeasure specifications machines equip parts making it difficult for high-

temperature dust and sparks from grinding a workpiece with a power tool to reach the dustpan.

Parts diagram

Hood

Switch

Handle

Shaking handle

Power cord

Exhaust port

(rear)

Front door

Caster

Worktable

Protective cover with

acrylic window (openable)

Dustpan

Filter cloth clip

Front door

- 4 -

◼

Chapter 3 Installation

When you receive the product, confirm the product is as ordered by checking the model, voltage,

frequency, etc. on the nameplate. In addition, check accessories. We take all possible precautions

when packing, but if damages from transportation or missing parts are observed, contact your

dealer or our nearest branch or sales office immediately.

Nails are used in the wooden pallets and frames used for packing. Pull them out immediately

after unpacking; there is risk of injury due to protruding nails. Dispose properly of unnecessary

packing materials in accordance with relevant local and national laws and regulations.

Install this machine where the following conditions are met:

Indoors without exposure to rainwater

The Workrésa is a machine for indoor use.

Avoid installation locations easily wet with water, as the water can cause electric shock

or malfunction.

Condensation-free at room temperature

Ambient temperature: 5°C-40°C

Humidity: 80% or less

Horizontally flat without vibration

Installing on a not-flat floor may cause abnormal vibration and cause a fall.

Free of dangerous chemicals nearby

Installing this machine near flammable chemicals, such as gasoline and paint thinner,

or an explosive atmosphere may cause an explosion or fire. Operation near chemicals

generating corrosive gas such as hydrochloric acid and sulfuric acid may cause main

body and parts to be corroded.

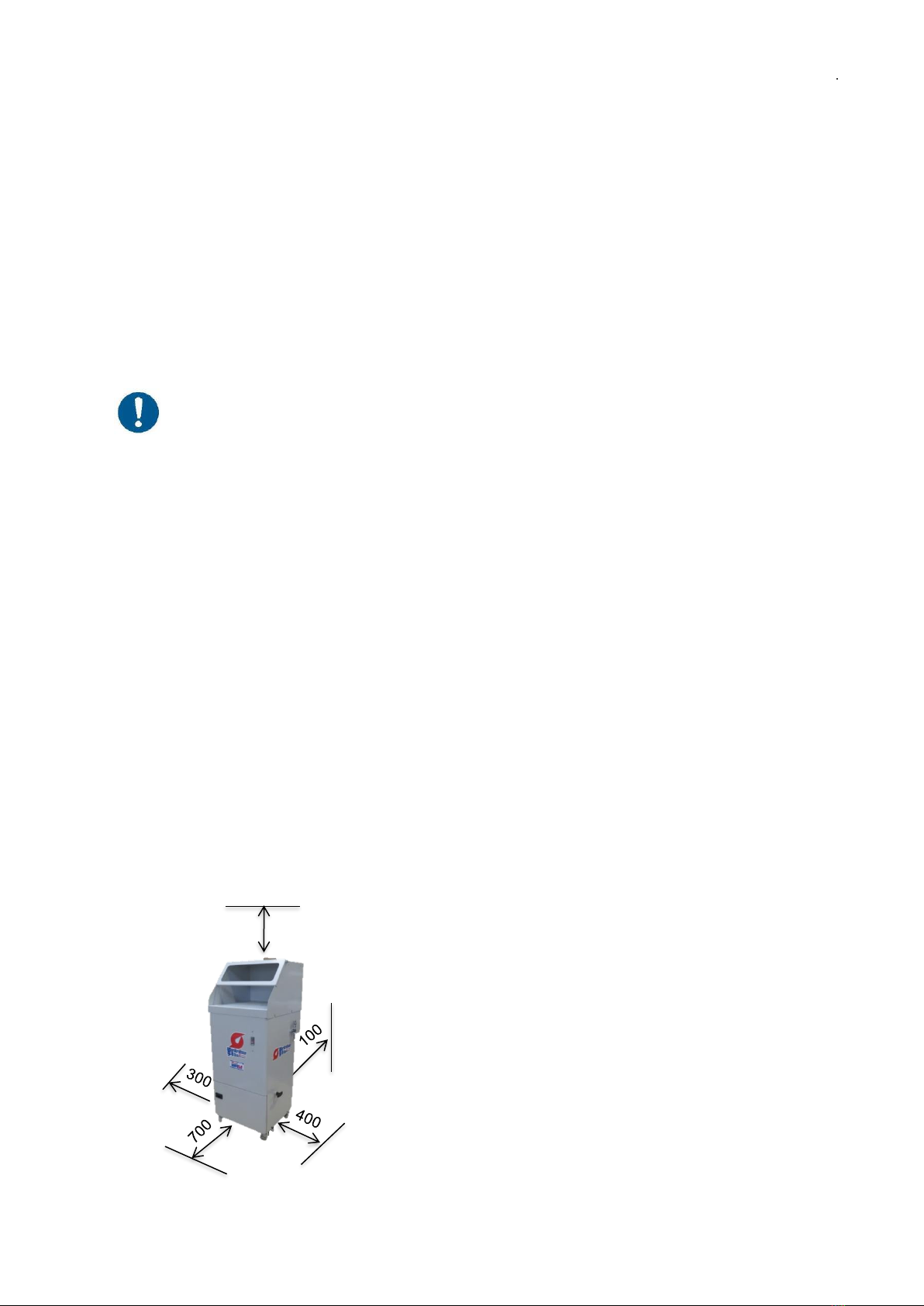

Easily accessible for maintenance

Maintain space as shown at left for elimination of collected

materials, filter cloth replacement, and air exhaust.

Unit: mm

High temperature and dew/condensation may cause

electrical component failure or electric shock.

400

- 5 -

Installation

This machine can be easily moved with the equipped casters. However, use the

stoppers on the front wheels to lock the machine during operation. In addition, avoid

operation on a slope. When moving this machine, move it slowly on a flat floor and

be careful not to tip it over.

When lifting the machine, use the two handles provided on either side of the machine.

Do this work with two or more people.

If the exhaust port is blocked, normal suction power cannot be exerted. Maintain a

sufficient space around the exhaust port.

Leave nearby a fire extinguisher suitable for the collected materials.

For the dust explosion countermeasures (simple explosion-proof specifications)

models, be sure to install the explosion emission port in a safe direction away from

workers.

Electric wiring

●Use the power supply designated on the nameplate. Operation using power supply

other than specified may cause malfunction and is extremely dangerous.

Before connecting the power supply, be sure to connect the ground cable.

Use a power supply fuse (circuit breaker) suitable for the startup current.

Use a voltage within ±5% of the rated voltage.

(Temporary fluctuation in voltage: ±10% or less)

Use a current within the rated current.

Never increase operation speed run using an inverter. Doing so may damage the

blower.

Rated Current for Standard Products

100V single-phase

220V single-phase

50Hz

60Hz

50Hz

6.0A

7.8A

2.8A

For three-phase power supply, voltage specifications other than the above in single- or three-

phase, or other custom specifications, please contact us.

Test run

Re-check the following items before a trial or test run:

The power cord and ground cable connection, insulation and voltage within the

specified value:

- 6 -

The main body front door is closed completely:

No tools, bolts, nuts, etc. left on the worktable:

For dust explosion countermeasure (Simple explosion-proof specification) models,

the explosion outlet port lid is not displaced.

- 7 -

◼

Chapter 4 Operation

Daily operation

Operation steps (1) Check that the front door is closed.

(2) For dust explosion countermeasure (Simple explosion-proof

specification) models, ensure the explosion outlet port lid is not

displaced.

(3) Turn on the switch to start operation.

Shutdown (1) Turn off the switch.

(2) Perform shaking after about two minutes and remove the collected

materials accumulated on the dust pan.

Precautions

The switch is equipped with an overload protection device:

If the dust is very fine, at the start of operation, a small amount of dust may leak

temporarily. If dust adheres properly to the filter cloth, there will be no leak. If leaking

does not cease, replace filter with the optional high-performance filter cloth:

Continual operation of the machine will clog the filter and decrease suction power.

Stop operation, shake the filter, and discharge the collected materials:

Shaking and collected materials removal during operation is not possible:

Since the dust pan is fixed with a spring, it catches when pulling it in and out. When

inserting, insert the pan until it clicks back into place.

Be careful not to allow too much collected materials in the dust box. Also, if too

much liquid is stored in the dustpan and spills out, it may leak from the front door.

When removing the collected material, use suitable protective equipment, such as

protective goggles, a dust mask, and gloves.

If using the machine with collected materials accumulated in the machine between

the workbench and the dustpan, the collected materials n may be ignited by sparks.

Perform a trial run and inspect according to instructions if using a machine that has

been in stored or that was shutdown and has not been operated for a long time.

Although the life of filter cloth varies depending on use time, characteristics of powder

dust and dust amount, the usual lifespan is 1 to 2 years. If the suction power is not

restored even after shaking, or shaking becomes heavy, replace the filter cloth.

Filter cloth damage should not occur with normal use, but if it is damaged, stop

operation and replace the filter cloth with a new one. Continuous use with a broken

the filter cloth may cause not only powder dust to leak and be released to the

atmosphere but also the blower to be damaged.

- 8 -

Hood

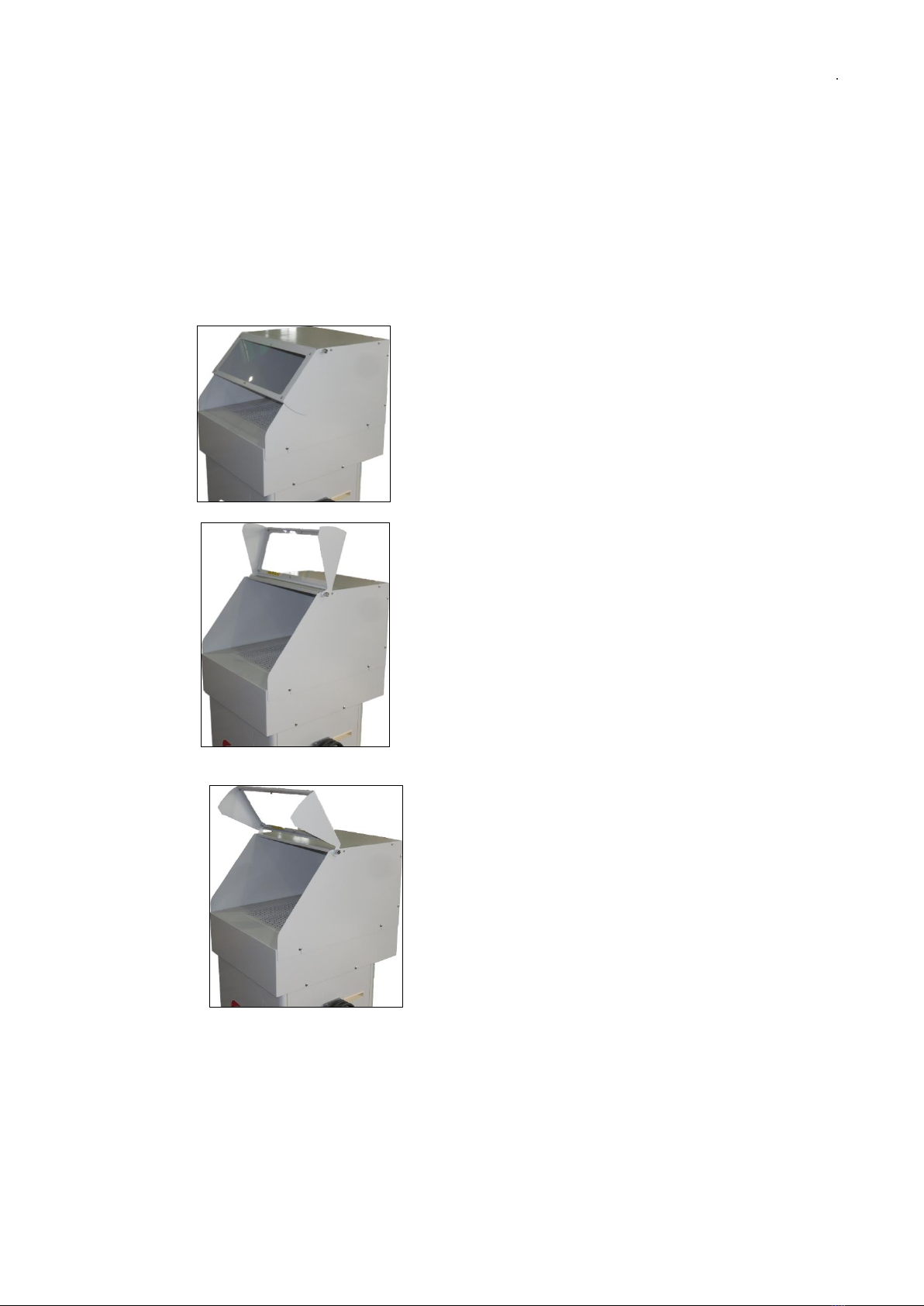

The door on the hood front side with protective acrylic window can be slid open upwardly. Operate

this machine with the door closed. The blowing speed decreases if the door is slid upward. Also,

do not operate with the protective cover opened just partway. The protective cover with acrylic

window may close suddenly, causing injury,

Protective cover with acrylic window closed

(Recommended state during operation)

Protective cover with acryclic window open

(Wind speed slows down)

Protective cover with acrylic window opened

halfway

(May cause injury)

- 9 -

Shaking

Pull the shaking handle approx. 3 times while supporting the main body with hand to prevent it

from moving. Return the handle so that the handle does not slack.

Coupler (When optionally included)

•The machine is equipped with a coupler for attaching the compressor and air tool hose

couplers.

Coupler Specifications: Nitto Kohki Super Coupler (socket・plug)

•This optional feature can also be installed post-purchase at a later date.

- 10 -

◼

Chapter 5 Maintenance and inspection

Perform maintenance and inspections to prevent malfunctions and accidents and

ensure long life of this machine Be sure to turn off the power supply before inspecting

internally. While performing maintenance and inspection work or replacing the filter cloth,

wear protective glasses, a dust mask, and gloves.

If this machine falls under the Industrial Safety and Health Act (Organic Solvent

Ordinance, Lead Ordinance, Specified Chemicals Ordinance, Dust Ordinance), inspect

this machine according to the periodic self-inspection guidelines specified by law.

Inspection item and frequency

Inspection item

Frequency

Inspection details

Front door

Before

operation

Is the door closed completely?

Dust pan

Have collected materials been discharged?

Motor load current

Once/day

Inspect by ammeter on control panel, etc.

Exhaust condition

Is there any dust leak through the filter?

Vibration of blower

Is there no abnormal vibration or abnormal sound?

Shaking device

Is there no abnormal sound or malfunction?

Filter cloth

attachment

Once/month

Is there no detachment, looseness, breakage, etc.?

Each electric wiring

Is insulation proper? Is there no looseness in the

terminal?

Inside of main body

r

Clean stuck materials or powder.

(Increase inspection frequency depending on use)

Main body

Once/year

Is there no corrosion or apertures/gaps/cracks?

●When cleaning the outer or inner surface of the main body, wipe it with a waste cloth soaked

in water or a neutral detergent. Wiping with a solvent such as paint thinner may cause peeling

or discoloration of the coated surface.

- 11 -

Filter cloth replacement

(1)

Pull out the dust pan, then pull up the

filter cloth clip toward you.

(2)

Pull out the filter cloth and lower the

front side of the filter cloth. Remove

filter cloth.

(3)

Insert a new filter cloth in the direction

shown in the following photo. Check

that it is inserted into the groove at the

back before pushing it in fully.

(4)

Lift up the front side of the filter cloth

and secure it with filter cloth clip. Insert

the dustpan fully.

Shaking rope tension adjustment

If the shaking handle becomes loose or the filter cloth is replaced, adjust the shaking rope tension.

(1)

Loosen the two wing nuts for the rope

holder and let the shaking handle come

in contact with the main body.

(Remove the filter cloth.)

(2)

While pulling the rope end, rotate the

rope holder in the curved arrow

direction by 2 to 3cm.

(3)

Tighten the wing screws of the rope

holder while pulling the rope.

Detail of rope holder

If the rope breaks or is worn severely, replace it with a new one.

Pay attention to

the direction.

Rope

Rope holder

Note: Even after rope tension adjustment, some air

leakage may occur where the rope passes through, but

that will not affect the performance of this machine.

- 12 -

Replacement

rope

Starter rope

(Nylon solid braided rope)

Φ4 mm 50-60 cm

Ropes are also available at home improvement stores, etc.

Size of replacement filter cloth

Size of filter cloth

Number of

cloths used

420 mm x 420 mm x 75 mm

1

Use our genuine filter cloth for replacement.

Wear protective glasses, a dust-proof mask, and gloves during replacement work.

Troubleshooting

Malfunction

Cause

Solutions and Countermeasures

Blower motor

does not start.

•Power supply is not

turned on

•The thermal protection

has activated.

•Motor failure

•Turn on the power supply

•Investigate root cause, resolve issue, and

restart the machine.

•Inspection or replacement (Consult us.)

Abnormal sound

from the blower

Abnormal

vibration

•Damaged motor bearings

•Contamination by foreign

matter

•Impeller imbalance

•Replacement of bearing(or motor

replacement)

•Removal of foreign matter

•Cleaning of impellers

•Imbalance correction (Consult us,)

Dust leakage

•Damaged or detached

filter cloth

•Deterioration of packing

•Too fine powder dust

•Replacement or reattachment of filter cloth

•Packing replacement

•Replace current filter with high-performance

filter.

Weak suction

power.

•Suction duct etc. is

clogged or blocked.

•Clogged filter cloth

•Remove blockage

•Refer to the next item

Clogged filter

cloth

•Aging filter cloth

•Unsuitable dust

characteristics

•Replacement of filter cloth

•Other measures required (Consult us.).

- 13 -

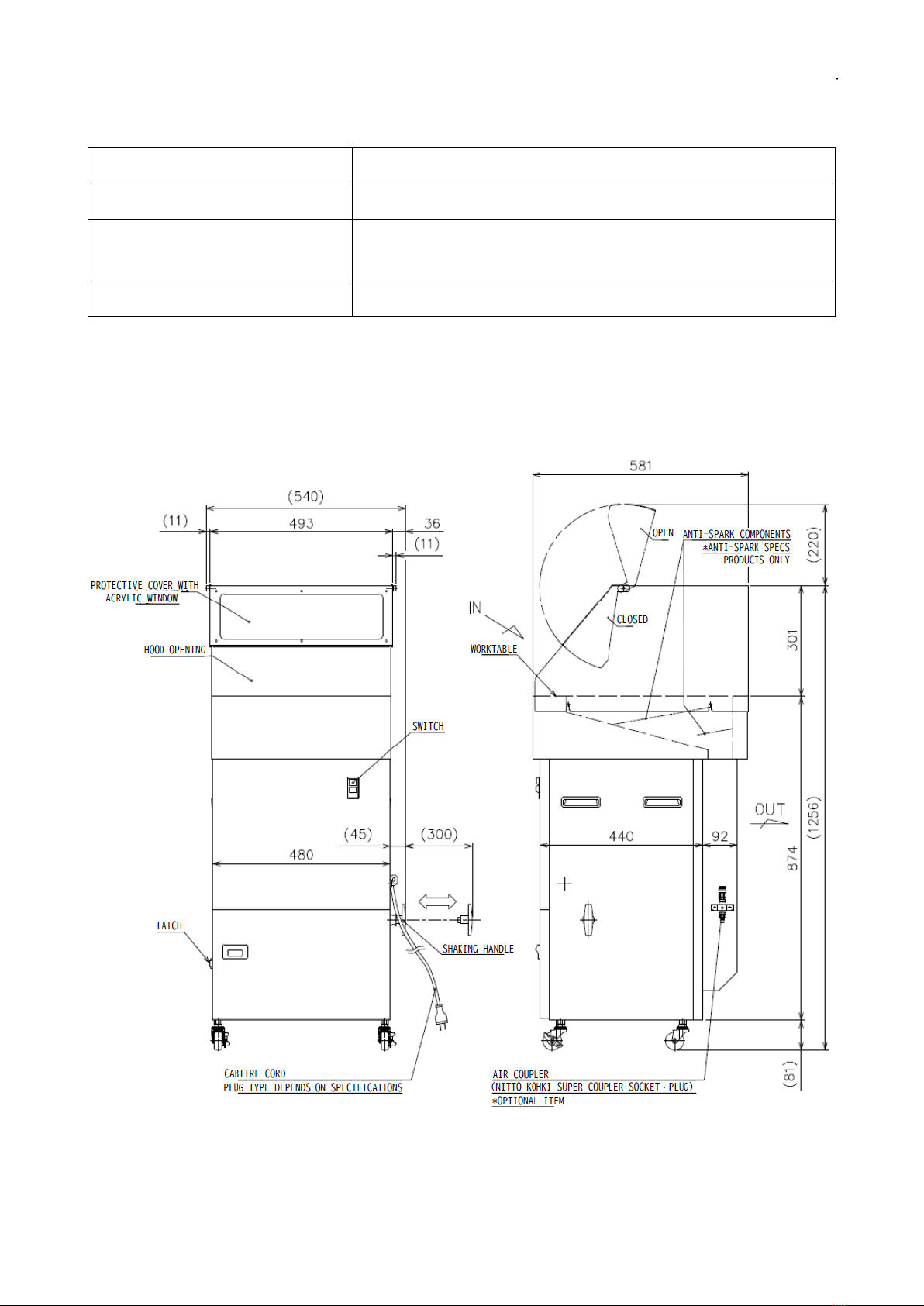

Specifications (Standard specifications, Spark countermeasure specifications)

Frequency

50Hz or 60Hz

Hood face velocity

1.2m/sec

Body dimensions

545mm 537mm H1281mm

(H1476mm when protective cover with acrylic window is fully

open)

Body mass

70/68kg (Spark countermeasure type: 72/70kg)

Outer dimensions (mm)

- 14 -

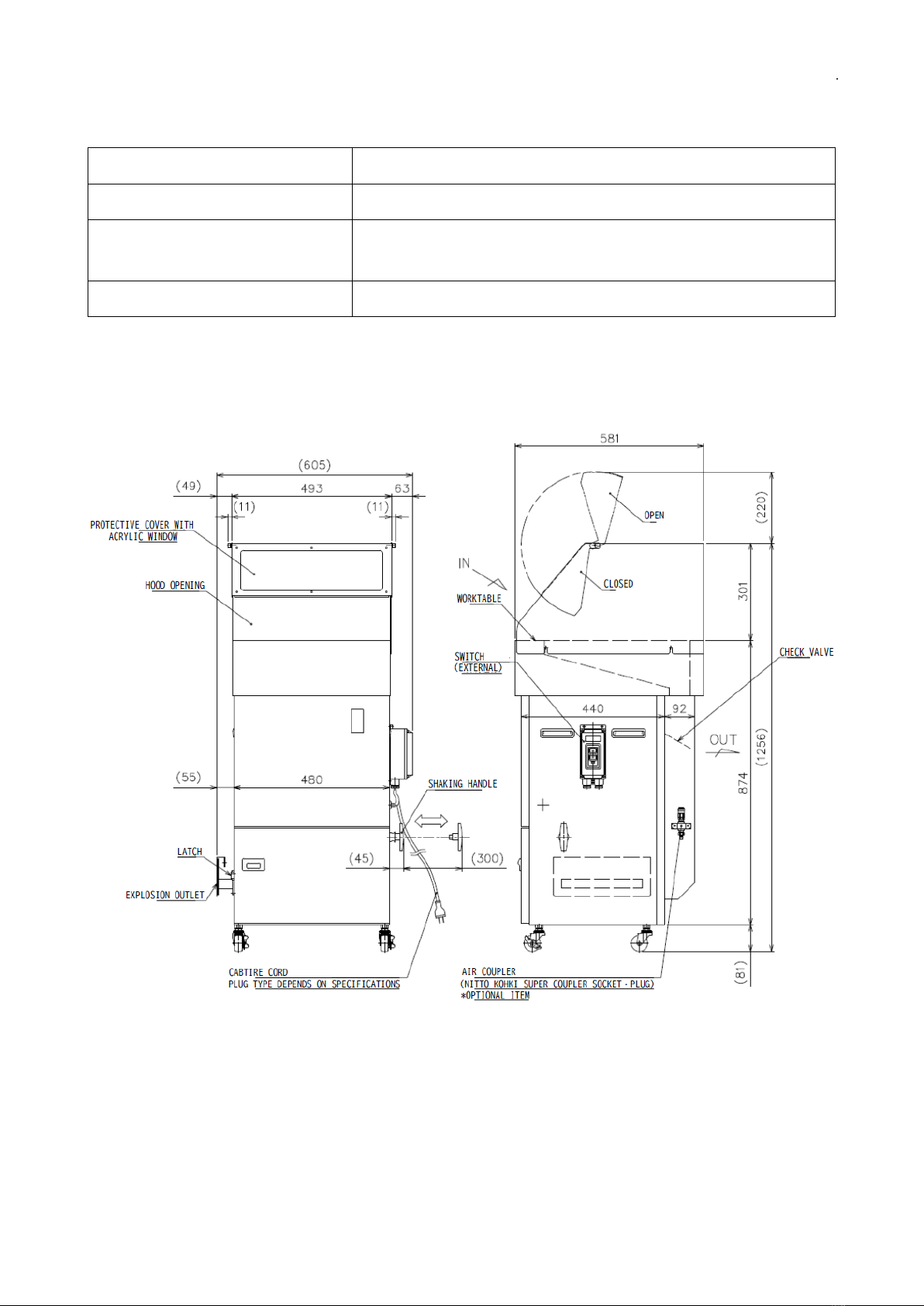

Specifications (Simple explosion-proof specifications)

Frequency

50Hz or 60Hz

Hood face velocity

1.2m/sec

Body dimensions

545mm 537mm H1281mm

(H1476mm when protective cover with acrylic window is fully

open)

Body mass

74/72kg

Outer dimensions (mm)

- 15 -

◼

Chapter 6 Disposal

Collected materials

Properly dispose in accordance with relevant national and local laws and regulations.

Used filters

Properly dispose in accordance with relevant national and local laws and regulations.

Waste cloth for cleaning containing collected materials

Properly dispose in accordance with relevant national and local laws and regulations.

Materials no longer needed post-replacement

Properly dispose in accordance with relevant national and local laws and regulations.

Disposing of this machine

Remove the collected material adhering to the machine and recycle the machine as

metal waste. Properly dispose of filters and waste clothes for cleaning in accordance

with relevant national and local laws and regulations.

- 16 -

◼

Chapter 7 Warranty statement

If a malfunction of the machine occurs within the warranty period despite normal usage conditions

in accordance with cautions in the instruction manual and labels on the main body, we will repair

the product free of charge according to the contents of this warranty statement.

Warranty period

The warranty period shall be 12 months after the date of delivery.

Warranty coverage

If a malfunction occurs under normal use conditions within the warranty period due to a

manufacturing defect, we will repair or replace the parts in question free of charge.

However, secondary loss resulting from the malfunction such as opportunity or operation loss

are not covered by this warranty.

Repair or replacement costs will be charged in the following cases, even within the warranty period.

Malfunctions and damages due to improper use and repair or modification not in accordance

with the cautions in the instruction manual, attached labels, etc.

Malfunctions and damage due to transportation, drop by mishandling, etc. after purchasing

Malfunctions and damages due to environmental factors such as fire, earthquake, storm and

flood damage, lightning strike or other natural disasters, salt damage, pollution, abnormal

voltage, or use of power supply (voltage, frequency) other than the specified, etc.

Malfunctions and damages due to repair and modification by parties other than our company

(including drilling holes into the product)

Malfunctions and damages due to use of parts other than specified by our company

Malfunctions and damages due to powder dust intake other than as was discussed and

consulted with our company

Malfunctions and damages due to damage done to the filter cloth and packing by intake of

sharp materials

Problems such as discoloration, wear, or marks due to aging or use.

Malfunctions or damages induced by failure to perform maintenance and inspections as

specified in the instruction manual

Replacement of consumable parts such as filter cloth and packing.

* Note

(1) The content of this instruction manual is subject to change without notice.

(2)Every effort has been made to ensure the contents of the manual are correct. However, if

there is an unclear point, error or omission, contact our nearest branch or sales office.

(3) If the frequency of power supply is changed due to a change in place of use, the fan must be

replaced. Contact our nearest branch or sales office.

(4) When making an inquiry, please inform us of the model and manufacturing serial number

listed on the product nameplate.

Notes :We are not responsible for any accident or malfunction caused by usage not in accordance with

this manual, or improper repair or remodeling.

Business Promotion Dpt.

1-25 Shinden Kita-machi, Daito-city, Osaka, Japan 574-0052

Tel: +81-72-870-5708 Fax: +81-72-870-7243

Email: sales@showadenki.co.jp

http://www.showadenki.co.jp

This manual suits for next models

5

Table of contents

Other Showa Denki Dust Collector manuals

Popular Dust Collector manuals by other brands

Scheppach

Scheppach HD12 instruction manual

V.Brøndum

V.Brøndum RONDA CF-502 Series user manual

Black & Decker

Black & Decker BDH7200M instruction manual

NSGV

NSGV CYCLONE Series manual

Oneida Air Systems

Oneida Air Systems 5HP High Pressure Dust Collector owner's manual

Dustcontrol

Dustcontrol S 21000 EX manual