SIASUN GCR Series User manual

GCR Series Collaborative Robot

User Manual

(Software)

Robot Model GCR20-1100 & GCR14-1400

Robot Version 1.2.15

User interface Version 2.2.14

SIASUN Co., Ltd

Copyright © SIASUN Co., Ltd. 2019. All rights reserved.

This document and parts must not be reproduced or copied by any third party without the written

permission of SIASUN Co., Ltd.

Trademark Statement

The words or images like “SIASUN” 、“新 松 ”、“SIASUN 新 松 ” and etc are protected by

trademark registration. The registered trademark information can be found in the open trademark

registration information.

All other trademarks or registered trademarks mentioned in this manual are the property of their

respective owners.

Attention

Your purchase of products, services or features, etc., shall be subject to the commercial contract

and terms and conditions of SIASUN Co., Ltd. All or part of the products, services or features

described in this manual may not be within the scope of your purchase or use. Unless otherwise

agreed in the contract, SIASUN Co., Ltd. makes no representations or warranties, either express or

implied, with respect to the contents of this manual.

Due to product version upgrade or other reasons, the contents of this manual will be updated from

time to time. Unless otherwise agreed, this manual is used only as a guide, and all statements,

information and recommendations in this manual do not constitute any guarantee either express or

implied.

SIASUN Co., Ltd.

Address:NO.257 Jinzang Rd. Pudong New District, ShangHai Zip:201206

Website:http://www.siasun-in.com

Contents

1 Preface....................................................................................................................................................1

1.1 Intended Audience............................................................................................................................1

1.2 Representation of warnings and notes.............................................................................................2

1.3 Special statement............................................................................................................................. 3

2 Safety...................................................................................................................................................... 4

2.1 Abstract............................................................................................................................................4

2.2 Limitation of Liability...................................................................................................................... 4

2.3 Risk Assessment............................................................................................................................... 5

2.4 Safety Operations.............................................................................................................................6

2.4.1 Emergency Stop........................................................................................................................6

2.4.2 Movement without Drive Power.............................................................................................. 7

3 Introduction........................................................................................................................................... 8

4 Power On & Power off..........................................................................................................................9

5 User Interface Introduction............................................................................................................... 12

5.1 Jog Page........................................................................................................................................ 12

5.2 Program Page................................................................................................................................18

5.3 Run Page........................................................................................................................................21

5.4 Status Page.................................................................................................................................... 23

5.5 Setting Page................................................................................................................................... 25

5.6 About Page.....................................................................................................................................36

5.7 Disconnect Page............................................................................................................................ 36

6 Robot Programming........................................................................................................................... 37

6.1 Create program..............................................................................................................................37

6.2 Move tab........................................................................................................................................ 41

6.3 Function tab...................................................................................................................................42

6.4 Socket tab: internet communication functions...............................................................................46

6.5 Variable Tab Establishment........................................................................................................... 46

6.6 Example......................................................................................................................................... 47

7 Robot External Communication Protocol........................................................................................ 50

8 Script Language Guide.......................................................................................................................59

8.1 Introduction....................................................................................................................................59

8.2 Data Types and Variables.............................................................................................................. 59

8.2.1 1.6.2.1 Built-in Data Types.....................................................................................................59

8.2.2 1.6.2.2 System Constants........................................................................................................59

8.2.3 Variables................................................................................................................................. 60

8.3 Expression......................................................................................................................................61

8.3.1 Arithmetic Operation Expression........................................................................................... 61

8.3.2 Relational Operation Expression............................................................................................ 61

8.3.3 Logical Operation Expression................................................................................................ 61

8.3.4 Assignment Expression...........................................................................................................62

8.3.5 Function Call Expression........................................................................................................62

8.4 Statement........................................................................................................................................62

8.4.1 While Loop Statement............................................................................................................ 62

8.4.2 Break Statement......................................................................................................................62

8.4.3 Function Definition.................................................................................................................62

8.4.4 Return Statement.................................................................................................................... 63

8.4.5 Conditional Control Statement............................................................................................... 63

8.5 System Function Description.........................................................................................................64

8.5.1 Movement Control..................................................................................................................64

8.5.2 TCP/IP Socket client...............................................................................................................68

8.5.3 System Functions and Peripherals..........................................................................................72

8.5.4 Debug Function...................................................................................................................... 79

8.5.5 Modbus................................................................................................................................... 80

1

1 Preface

1.1 Intended Audience

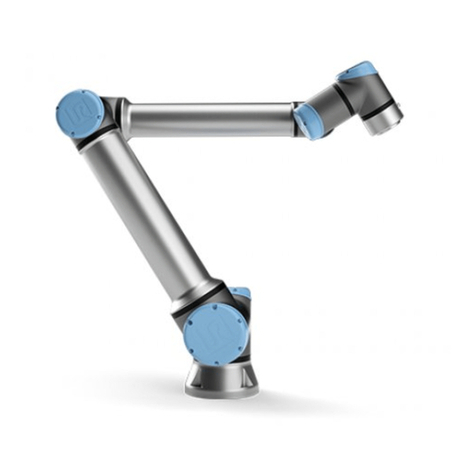

This document provides operating instructions for the SIASUN GCR

Series Collaborative Robot, so that users can learn more about the robot

basic information and use the robot more safely and conveniently. Be

sure to operate this robot on the basis of careful reading and full

understanding of this document.

This document applies for the following users:

On site robotic engineer

Robotic software engineer

Hardware installation engineer

On site Maintenance engineer

System maintenance engineer

Operators must receive basic training before robot’s operation.

2

1.2 Representation of warnings and notes

The table below defines general hazards related symbols, please read through the

description carefully.

Symbol

Description

Used to warn of emergency situations that, if not avoided, could

result in death or serious personal injury.

Used to warn of potentially dangerous situations that, if not

avoided, could result in death or serious personal injury.

Used to warn of potentially dangerous situations that, if not

avoided, may result in moderate or minor personal injury.

Used to convey device or environmental security warnings that, if

not avoided, may result in damage to the device, loss of data,

degradation of device performance, or other unpredictable results.

Caution does NOT involve personal injury.

Used to highlight important / critical information, best practices

and tips.

"Tips" is not a safety warning message, does not involve

personal, equipment and environmental damage information.

3

1.3 Special statement

This manual is only used as a guide. Its content (such as equipment

appearance, software interface) is based on laboratory equipment

information. The content provided in this manual is of general guidance

and does not guarantee that all usage scenarios cover all models. Due to

the software upgrade and equipment model inconsistency, the content

provided in the manual may NOT be consistent with the robot used by

the user. Please take the information of user equipment as the standard,

this manual will no longer address the differences caused by the above

situations.

The maximum value provided in this manual is the maximum that a

device achieves in a lab-specific scenario that meets the appropriate

standards (For example, constant temperature, humidity, interference free

environment, typical operating conditions and etc.). In reality working

situation, the maximum value of equipment testing may NOT be

consistent with the data provided in the manual, due to different working

conditions, specific working conditions and inconsistent testing methods.

4

2 Safety

2.1 Abstract

This section describes important safety and risk assessments that you

need to be aware when installing, applying, and maintaining on robot and

its components. The user must read and fully understand this information

before the robot is powered on for the first time.

Before performing any operations, be sure to read all operating

instructions provided with the equipment, in particular, instructions that

may endanger personal safety and equipment safety, such as hazards,

warnings, and cautions, to minimize the chance of an accident. When this

document differs from the documentation shipped with the device, the

documentation shipped with the device shall prevail.

The technicians responsible for installing and maintaining the equipment

must be a trained person who has proper methods of operation and all

safety precautions. Only trained and qualified technicians are able to

perform equipment installation and maintenance.

2.2 Limitation of Liability

This information neither includes how to design, install and operate a

complete robot system, nor any peripherals that affect the overall system.

In order to protect personal safety, an outstanding system must be

designed and installed in accordance with the safety requirements

stipulated in the standards and regulations of the country where the robot

is installed.

The robot integrator is responsible for ensuring that the robot system

complies with the applicable safety laws and regulations of the country or

region where the robot is located and that the necessary safety equipment

for the protection of the robot system operator is properly designed and

correctly installed. Limitation of Liability

Specifically including but not limited to the following:

5

Ensure that the robot system meets all basic requirements;

Perform a risk assessment of the complete system;

Ensure the design and installation of the entire system is

accurate;

Make appropriate security settings in the software and

ensure that it will not be modified by the user;

Develop detailed operating instructions;

Issue a declaration of conformity;

Collect all information in technical documents;

Label the integrator's logo and contact information on the

installed robotic system.

SIASUN Co., Ltd. is committed to providing reliable safety information,

but does not assume responsibilities. It is important to declare that even if

all operations are carried out in a safe manner, there is no guarantee that

the robot system will not cause personal and property damage to the user.

2.3 Risk Assessment

Risk assessment is one of the most important tasks that integrators must

accomplish. The robot itself is a partially completed machine, and the

safety of the robot installation depends on how the robot is integrated (e.g.

tools, obstacles and other machineries).

It is recommended that integrators perform risk assessment in accordance

with ISO12100 and ISO10218-2. Alternatively, technical specification

ISO / TS 15066 may be selected as additional guidance. Integrators

performing a risk assessment should consider all procedures during the

entire lifespan of the robot, including but not limited to:

Teach robots when developing robots;

Fault diagnosis and maintenance;

General operation of robot installation.

Risk assessment must be performed before the robot arm is powered on

for the first time. Part of the risk assessment performed by the integrator

is the necessity to identify the correct security configuration settings and

additional protections for emergency stop buttons and / or for specific

robot applications.

6

The following list identifies the significant risks that integrators must

consider. Please note that there may be other significant hazards from

certain robotic devices.

Finger is clamped between joint 4 and joint 5;

Sharp edges and sharp spots on the tool or the tool

connector may cause damage to human skin;

The obstacles sharp edges and sharp spots, which is closed

by the robot trajectory, may be dangerous to human skin;

Sprains or fractures due to impact between the robot

payload and a solid surface;

Consequences due to loosening of bolts used to secure

robotic arms or tools;

Items fall off the tool. For example, due to insufficient

clamping or accidentally power down;

Operating error due to different emergency stop button

allocation and types.

2.4 Safety Operations

2.4.1 Emergency Stop

Emergency stop takes precedence over all the other robot control

operations. Pressing emergency stop will cause all controlled hazards to

stop, removing the motor power from the robot drive. It will remain in

effect until reset manually.

Activate emergency stop button to immediately stop the robot from any

motion. The user must perform a restoration procedure, resetting the

emergency stop button and pressing the "Power On" button on

demonstrator, to resume normal operation. Emergency stop shall not be

used as a risk reduction measure, but as a secondary protective device.

Emergency stop must not be used for normal program stop; constantly

pressing may result in additional unnecessary wear on the robot.

7

2.4.2 Movement without Drive Power

In rare cases, it may be necessary to move one or multiple robot joints in

the event of a robot power failure or an emergency situation that does not

require power, which can force the robot joints to move with the

following method:

Manual brake release: Remove the M3 screws that secure the joint cover

and remove the joint cover. Press the plunger in the small electromagnet

to release the brake.

Manually moving the robot arm is limited to

emergency situation and may damage joints.

If manual release the break, gravity may cause

the robot arm to fall. Always hold the robot arm,

tools and work-pieces when releasing the break.

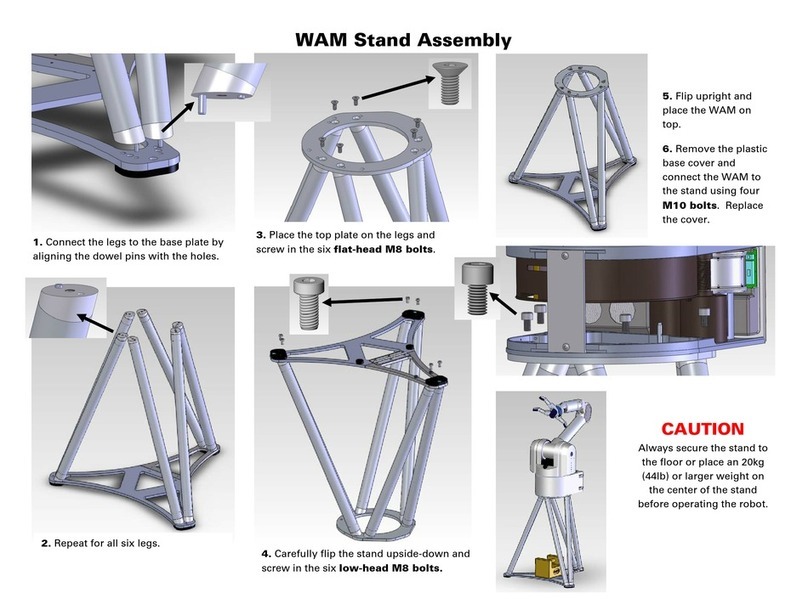

Image 2.4.2 Manual break release schemata

8

3 Introduction

The following chapter will introduce how to operate the GCR20-1100 &

GCR14-1400 collaborative robot. The user interface version is 2.2.14

and robot version is 1.2.15.

9

4 Power On & Power off

The power button is on the side of the control box. Plug in the 220VAC power cable and

press down the power on button to enable the operation system.

After pressing the power button, the indicator light will turns on. The system initialize

till the welcome page appears on the demonstrator.

Click the “Start” button in the middle of demonstrator to start operating robot.

10

System will show the robot installation orientation and flange loading information. For

example, “Robot install: Longitudinal TCP load 0 kg”. If any information does NOT

match with actual, for safety concern, please modify them from system setting before

any other operations. These parameter settings will affect the zero-gravity manual

jogging function and the collision detection function. Click “Modify” button for further

editing.

Click “OK” button, while the above information has been verified. The white flange

light demonstrates the robot has been power on. The first time power on process may

take a while for initializing. After each axis has been initialized, the stand-by indicators

turn from red to blue on demonstrator. Click “Enable All” button to enable the control of

the robot and release all axial breaks. After the flange light turns blue, which indicates

all axial breaks have been released, the robot is ready to be operated via demonstrator.

11

To disconnect the robot, click the “Disconnect” button from demonstrator home page

top right corner. To shut off the system, click the switch off icon to completely shut off

the system.

12

5 User Interface Introduction

There are 7 tabs on the top of home page. It is called navigation bar. Each tab has an

unique function, such as “Jog(manual move)”,” Program”,” Run”, “Status”, “Setting”,

“About” and “Disconnect”. The default home page is “Jog” after power on the system.

5.1 Jog Page

Click the “Jog” button on the navigation bar will open “Jog” page.

There are 6 navigation buttons on the “Jog” page to help you switch through different

functions: Coordinate button, 3D View button, Joint Move button, Line Move button,

Teach (zero-gravity move) button and Speed button.

1. Current joints position & flange origin position

Selecting the 3D View button, the page will show the current joint positions and the

flange origin position.

Click the joints/ flange origin data will open then “Enter joint Values” window. In

this window you can enter the target position value and move the robot to the target

position. After entering the joint value, hold Press Move button to move the robot,

releasing the button will stop the current movement. Click Cancel to close the

“Enter joint Values” page.

13

2. Coordinate

Click Coordinate button will show the coordinate selection page. The robot will

use base coordinate by default. Base coordinate is established at the bottom of the

robot which is also indicated on the 3D robot view. If you have other attachment

tool installed on the flange, you can also click Tool Coordinate or User

Coordinate. Tool coordinate set tool end as origin. User coordinate origin needs to

be set up by user.

While swapping different coordinates, the robot parameters displayed, jogging

orientation and programming coordinate will be changed respectively.

It is not functional for setting up coordinate when

running program. When programming, it requires to

reset coordinate with functions.

Click Tool Coordinate or User Coordinate to set up coordinate while need, refer

to coordinate setting page.

14

3. 3D View

Click 3D View button to show the robot 3D simulation. The simulation is based on

real robot. The simulation interface will show whether the robot is located at home

position.

15

4. Joint Move

Joint Move is set by default move joint. The blue progress bar shows the current

joint position and the limitation for each joint. Hold left/right button to move

forward and backward. Release the arrow button will stop at current move. The

buttons 1-6 on the demonstrator correspond to the joints 1-6 here.

5. Line Move

Click Line Move button will change to move flange origin window. Holding the

corresponding arrow button will let the robot flange origin to move along the axis.

Releasing the button will stop current move. The X, Y, Z illustrates moves

orientation is along X, Y, Z axis and RX, RY, RZ illustrates flange end rotational

orientation.

Before manually jogging the flange end, Please verify

the coordinate is correct comparing with the real

condition.

6. Traction Teach

While the robot is stopped with no task left, hold the Teach button and wait until the

flange light turns to flashing green, the robot is in “traction teach” mode. In traction

16

teach mode, it is able to jog the robot arm by human and move the arm quickly to

the target point. Release the button to exit traction teach mode.

While the robot is in traction teach mode, it is able to modify the drugging smooth

by click the +or -button. In addition, if individual axis jogging smooth requires

modifying, it is able to adjust it by clicking the Joint Force control setting button.

In traction teach mode, while the axis reach maximum or

minimum limitation, there is opposite notification force

acted. By enough force continue jogging to the maximum

or minimum limitation, it is able to reach close enough to

the limitation. The robot is about to send an alert only if the

axial limitation has been reached.

This manual suits for next models

2

Table of contents

Other SIASUN Robotics manuals