Sicce BLAGDON HYDRATECH MULTI 800 User manual

Established over 40 years ago, Blagdon are

committed to producing a comprehensive

range of high quality, easy to use, pond

equipment. An ongoing programme of

research and development ensures

excellent performance and value for all

their customers. This product excellence is

demonstrated by Blagdon’s award winning

range of water gardening equipment. As

a result Blagdon’s reputation for quality is

unrivalled amongst experienced pond

gardeners and retailers alike.

Blagdon -The Pond Masters

The name you can rely on

Interpet

Dorking, Surrey, RH4 3YX

Leaflet Code: POS 0008

IMPORTANT

Please attach proof of purchase to this

manual and file in a safe place.

THE POND MASTERS

GUIDE TO

HYDRATECH

MULTI

800/1500/2500/3250/

4000/6000

Multi Instructions 3250 AW 23/3/06 10:23 am Page 1

Congratulations on buying a Blagdon Hydratech Multi Pump.

Hydratech Multi pumps are high quality pumps manufactured

with advanced technology, to run pond fountains, waterfalls,

filters and water features. The powerful motors are easy to

maintain having a single moving part impeller system

featuring highly wear-resistant ceramic shaft design.

THE POND MASTERS GUIDE TO

HYDRATECH MULTI

1

Getting to know your Hydratech Multi pump .............................................. 1

Opening and closing cage / inserting and removing pump .............................. 1

Parts descriptions / spares codes - with exploded diagrams ......................... 2-5

Pump performance / flow chart ....................................................................... 6

Technical specifications ....................................................................................6

Installation ..................................................................................................... 7

Electrical installation ........................................................................................ 7

Installing pump in pond ............................................................................... 8-9

Maintenance and cleaning ............................................................................ 9

Cleaning ...........................................................................................................9

Step by step guides .................................................................................... 9-11

Routine maintenance ....................................................................................... 9

Monthly maintenance .................................................................................... 10

Annual maintenance ...................................................................................... 11

Winter storage ............................................................................................... 11

Troubleshooting ........................................................................................... 12

Troubleshooting and maximising performance .............................................. 12

Faults - problem procedure ......................................................................... 13

Consumer advice contact details ................................................................... 13

Returning faulty pumps ................................................................................. 13

Guarantee ..................................................................................................... 13

CONTENTS

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

OPENING AND CLOSING CAGE

INSERTING AND REMOVING PUMP

Ensure telescopic pipe is screwed into pump outlet.

Lay the pump on half the open cage and match up the telescopic

riser pipe with the pump outlet hole, ensuring the pump rests

on the supporting brackets.

Insert cable into the cable outlet hole.

Close the cage halves together and secure with the locking clip.

To open and remove: Reverse steps 1-4 above

3

4

2

2

1

1

2

3

4

4

Multi Instructions 3250 AW 23/3/06 10:23 am Page 3

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

2 3

HYDRATECH MULTI 800/1500/2500/

3250/4000/6000 PRE-FILTER CAGE

No. Pre-filter Cage Part Description Spare Code

1. Pre-filter cage N/A

2. Cable outlet hole N/A

3. Light port (not on 800 model) 1040723

4. Locking clip 1040730

5. Carry handle N/A

6. Pump outlet hole N/A

7. Pump support brackets N/A

8. Filter cage hinges N/A

1

2

4

5

6

7

8

3

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

HYDRATECH MULTI 800

Hydratech Multi 800

No. Part Description Spare Code

1. Pump motor unit N/A

2. Impeller complete 1040815

3. Pump outlet N/A

4. Impeller cover N/A

5. Water bell 1040747

6. Double Daisy 1040747

7. 23cm telescopic riser pipe 1040761

5

7

6

2

13

4

Parts 5 and 6 are supplied as one package.

Multi Instructions 3250 AW 23/3/06 10:23 am Page 5

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

HYDRATECH MULTI 1500/2500/3250/4000

4 5

Hydratech Multi 1500/2500/3250/

No. 4000 Part Description Spare Code

1. Pump motor unit N/A

2. ‘O‘ ring seal 1040785

3. Pump outlet N/A

4. Impeller housing N/A

5. Impeller complete (1500 model) 1040822

(2500 model) 1040839

(3250/4000 model) 1040846

5A. Impeller shaft locator 1040792

6. Impeller cover (1500 model) 1040860

(2500 model) 1040877

(3250 model) 1040884

(4000 model) 1040891

7. 24cm telescopic riser pipe 1040778

8. 17cm extension pipe with coupling 1021005

9. Dual control ‘T’ piece 1040808

10. Water bell large 1014144

11. Daisy 3 stage 1040754

1

24

5A 55A 6

3

7

9

10

11

8

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

HYDRATECH MULTI 6000

No. Hydratech Multi 6000 Part Description Spare Code

1. Pump motor unit N/A

2. Pump outlet N/A

3. Impeller housing N/A

4. Shaft locator 1017671

5. Ceramic shaft and locator 1017664

6. Impeller only 1017626

7. Impeller cover ‘O’ ring 1017640

8. Impeller cover 1017633

9. Impeller cover screw 1017657

10. 24cm telescopic riser pipe 1040778

11. 17cm extension pipe with coupling 1021005

12. Dual control ‘T’ piece 1040808

13. Water bell large 1014144

14. Daisy 3 stage 1040754

15. Iris jet head only N/A

16. 6000 ‘T’ adapter N/A

12

4

56

37

9

13

12

10

14

15 16

11

8

4

Multi Instructions 3250 AW 23/3/06 10:23 am Page 7

Electrical installation

The power supply must meet the specifications on the product.

The pump is intended to be used with either a weatherproof

cable connector or permanently connected to the fixed wiring

in the main system other than by means of a plug and socket.

The cores in the supply cable are coloured in accordance with the following

code: Brown = Live, Blue = Neutral, Green/Yellow = Earth.

The electric cable is permanently connected and sealed in the motor body.

If the supply cable is damaged the pump must not be used.

Do not use the supply cable to lift the pump as this may cause damage.

WARNING - THIS PUMP MUST BE EARTHED

A Residual Current Device (RCD), also know as the Residual

Current Circuit Breaker (RCCB), with a tripping current not

exceeding 30mA must be installed in the supply circuit.

A means of disconnection from the supply having a contact separation

of at least 3mm in all poles must be incorporated in the fixed wiring.

INSTALLATION

For permanent installations to the mains supply, it is necessary to conform to

the regulations of the local electricity authority and this would include the use

of a metal or plastic conduit to protect the cable.

Attention has been drawn to the fact that special rules may exist concerning

the installation of your pond pump (i.e. local building regulations).

These pumps must not be used in swimming pools, or areas where people are

in contact with the water.

Always disconnect the mains electricity supply whilst the equipment is being

installed, repaired, maintained or handled. Consult a qualified electrician if in

any doubt about wiring this product to the main supply.

Warning - The Hydratech Multi pump is provided with a

thermal cut out that temporarily switches off the pump in case

of overheating and the pump may automatically restart.

6 7

Pump performance / flow chart

Technical Specification and Performance

GETTING TO KNOW YOUR HYDRATECH MULTI PUMP

CC

_

CC

_

CC

_

CC

_

CC

_

CC

_

HYDRATECH MULTI 800 1500 2500 3250 4000 6000

Cable Fitted 10m 10m 10m 10m 10m 10m

Voltage 230V 230V 230V 230V 230V 230V

Hertz 50Hz 50Hz 50Hz 50Hz 50Hz 50Hz

Watts 13 36 40 42 46 89

Safety Rating IP68 IP68 IP68 IP68 IP68 IP68

Maximum Flow 790 ltr/hr 1550 ltr/hr 2750 ltr/hr 3350 ltr/hr 3800 ltr/hr 5850 ltr/hr

174 gal/hr 341 gal/hr 606 gal/hr 737 gal/hr 837 gal/hr 1287 gal/hr

Maximum Lift 1.25m 2.3m 3m 2.75m 3m 3.7m

4’1” 7’5” 9’8” 9’2” 9’8” 12’1”

Multi Instructions 3250 AW 23/3/06 10:23 am Page 9

Warning - Failure to carry out routine maintenance leaving the

pump under reduced or no flow conditions for long periods

(i.e. blocked pre-filter cage) will result in a shorter pump life

and will invalidate the guarantee.

Blagdon Hydratech Multi pumps are centrifugal pumps with a magnetic

impeller movement driven by a watertight synchronous motor. They require

minimum cleaning, only periodic cleaning of the pre-filter cage and impeller is

necessary.

Cleaner

The use of Blagdon Pond Pump Cleaner will give improved performance and

pump life by removing built-up lime scale and waste. Use before dismantling

for easier and cleaner handling.

Routine Maintenance

Carry out routine maintenance when pump flow is visibly reduced.

1. Switch off electricity.

2. Remove pump from pond (do not use the cable to lift the pump).

3. Open pre-filter cage and remove pump (see page 2). Wash thoroughly in

fresh water. A blocked pre-filter cage will reduce the pump flow rate.

MAINTENANCE & CLEANING

8 9

Locating your Hydratech Multi

The Hydratech Multi pump should be located on a firm and level base in the

pond/water feature in a depth of at least 10cm, but no more than 2m.

It is advisable to keep the pump off the bottom of the pond to avoid silt

entering the pump causing excessive wear and increasing pre-filter cleaning.

Fountain

Make sure there is ample cable from mains supply. Place pump in desired

location. Adjust telescopic riser pipe so fountain head is above surface of

the pond. Fountain height can now be adjusted, see “Adjusting dual control

‘T’ piece” diagram below (not 800 model). See “Getting to know your

Hydratech Multi” for parts and descriptions.

Tip: Ensure that any fountain, waterfall, filter or feature fitted does not empty

water out of pond/water feature.

INSTALLATION INSTALLATION

BELL FOUNTAIN

Adjust bell by

moving head

higher for small

bell and lower for

a wider bell shape.

ADJUSTING DUAL CONTROL ‘T’ PIECE

AND TELESCOPIC RISER PIPE

Adjust height by pushing or

pulling 24cm telescopic riser pipe.

17cm extension pipe can be added

if required (see “Getting to know

your Hydratech Multi” for parts

descriptions).

1” OUTLET FLOW

CONTROL VALVE

Supply water features,

waterfalls and filters by

adding 1” hose. Adjust flow

by turning flow control valve.

FOUNTAIN FLOW

CONTROL VALVE

Adjust fountain jet flow by

turning flow control valve.

∆

_

Water Feature / Filter / Waterfall

Install as for Fountain. Depending on water feature to be supplied, your Hydratech

Multi can be used with the dual control ‘T’ piece 1" hose fitting (see “Adjusting

dual control ‘T’ piece” diagram). Hose clips should be used to secure hose.

Tip: The larger 1" hose will give maximum performance when fitted to the

Hydratech Multi 1500, 2500, 3250, 4000 or 6000.

3

2

1

1

2

3

Multi Instructions 3250 AW 23/3/06 10:23 am Page 11

Annual Maintenance

Following as for routine and monthly maintenance, once a year you should

service your pump by using Blagdon Pond Pump Cleaner, (this may need to

be done more frequently in hard water areas).

Dismantle pump and examine all parts for wear or damage, replacing any

parts that show obvious wear and/or damage. (See “Getting to know your

pump” for parts/description and replacement parts codes.) Particular care

should be taken to examine the cable entry point and the cable; if there is any

sign of damage the pump should be discarded. On models 1500, 2500, 3250

and 4000 also check ‘O’ ring seal (see diagram below)

Winter Storage

The pump can be run in the pond during the winter but care should be taken

to ensure that it is fully immersed and cannot freeze solid. If the pump is not

used during the winter, follow annual maintenance procedure and store frost-

free in the house or garage until spring.

MAINTENANCE & CLEANING

10 11

MAINTENANCE & CLEANING

Remove impeller cover by pulling gently upwards from the base.

Remove impeller from pump motor. Wash parts with fresh water carefully.

Monthly Maintenance

Following as for Routine Maintenance (steps 1 to 3).

800 MODEL: MONTHLY MAINTENANCE

To check the ‘O’ ring

seal, turn impellor

housing anti-clockwise

and pull away pump

motor. Remove and

check seal.

Replace carefully.

1500/2500/3250/4000 MODELS: ANNUAL MAINTENANCE

HT Multi 6000 model only, remove screw.

Remove impeller cover by turning anti-clockwise to

release lock. Then pull firmly away from pump motor.

Carefully remove impeller shaft locator and washer. Place in a safe place.

Remove impeller from pump motor. Wash parts with fresh water carefully.

1500/2500/3250/4000/6000 MODELS: MONTHLY MAINTENANCE

2

1

2

1

1

1A

2

3

2

2

&3

1

1A

Multi Instructions 3250 AW 23/3/06 10:23 am Page 13

12

FAULTS - PROBLEMS PROCEDURE

Before returning your Hydratech Multi pump to your dealer or contacting

our Consumer Advice Department, please carry out the following steps.

This will solve most problems quickly and easily.

1. Ensure electrical procedure has been followed fully. Check fuse and any

cable connectors/switch boxes.

NOTE: If the pump has overheated the thermal overload will temporarily

switch off the pump.

2. (a) Follow routine maintenance and check pump. (b) Follow monthly

maintenance and check pump. (c) Follow troubleshooting guide.

(d) Follow annual maintenance guide.

3. Return pump to point of purchase for inspection and advice (you may

need proof of purchase).

Consumer Advice contact details

Interpet (Blagdon) Consumer Advice Department

Vincent Lane, Dorking, Surrey RH4 3YX

Telephone: 0845 226 7437 (local call charge only)

(Monday to Friday 10am to 4pm except Bank Holidays - Times may vary)

Fax: 01306 876712 E-mail: [email protected]

This product is guaranteed against defects in material and workmanship for 3 years from

the date of purchase, under normal usage. The guarantee DOES NOT APPLY in case of

improper use, negligence, lack of maintenance or accidental damage either to the pump or

to the impeller or impeller shaft. If the pump fails due to a manufacturing fault within this

period it will be either repaired or replaced free of charge. Liability is limited to replacement

of the faulty product only, no other costs will be reimbursed.

This guarantee is not transferable and does not affect your statutory rights. This guarantee

does not confer any rights other than those expressly set out above. Excludes impeller,

which may require replacing annually. If any parts need replacing, spares are available from

your retailer.

GUARANTEE

IMPORTANT

Problem

Low flow from pump

1. Follow routine cleaning procedure.

2. Follow monthly cleaning procedure.

3. Ensure pipe work is not blocked, leaking or is laid so that it gets crushed

or kinked.

4. Keep the height that water is to be pumped from the water surface (called

Head) to a minimum. The higher the head the lower the flow rate and the

more wear on the pump.

5. Use the largest diameter, smoothest bore pond hose over the shortest

distance and keep hose fittings to a minimum. This removes frictional loss

of flow and so increases pump flow rates.

Poor fountain performance

• Reduced height.

• Jets blocked.

Clean flow adjuster and fountain

head. Wash under a tap or hose.

Blagdon Pond Pump Cleaner

should be used to remove lime

scale build-up/waste (see diagram)

for improved results.

No flow from pump

1. Check power supply is on.

2. Check fuse and wiring (SEE ELECTRICAL INSTALLATION).

3. Follow low flow procedure as above.

If none of the above works contact Interpet (Blagdon) Consumer Advice

Department (See Faults problem procedure Page 13).

TROUBLESHOOTING

13

DAISY

To clean, remove

head and rinse.

Or in hard water

areas, use Blagdon

Pond Pump Cleaner.

Multi Instructions 3250 AW 23/3/06 10:23 am Page 15

This manual suits for next models

5

Table of contents

Popular Swimming Pool Pump manuals by other brands

Hayward Pool

Hayward Pool SP2600X5 Installation and operating instructions

WilTec

WilTec 50253 manual

Xtreme Power

Xtreme Power 75131 Owner's manual and safety instructions

CARVIN

CARVIN SHARKJET 15SHJ-5-25-S1 owner's manual

HeatPumps4Pools

HeatPumps4Pools LCSPC-40 Installation and Maintenance

Blue Wave

Blue Wave NB19798 owner's manual

Kripsol

Kripsol KS EVO BLACK EDITION user guide

Davey

Davey Silensor SLS100 Installation and operating instructions

Pentair Pool Products

Pentair Pool Products DYNAMO Installation, operation & service manual

AQUALUX

AQUALUX VESUVIO VES06R Installation and user manual

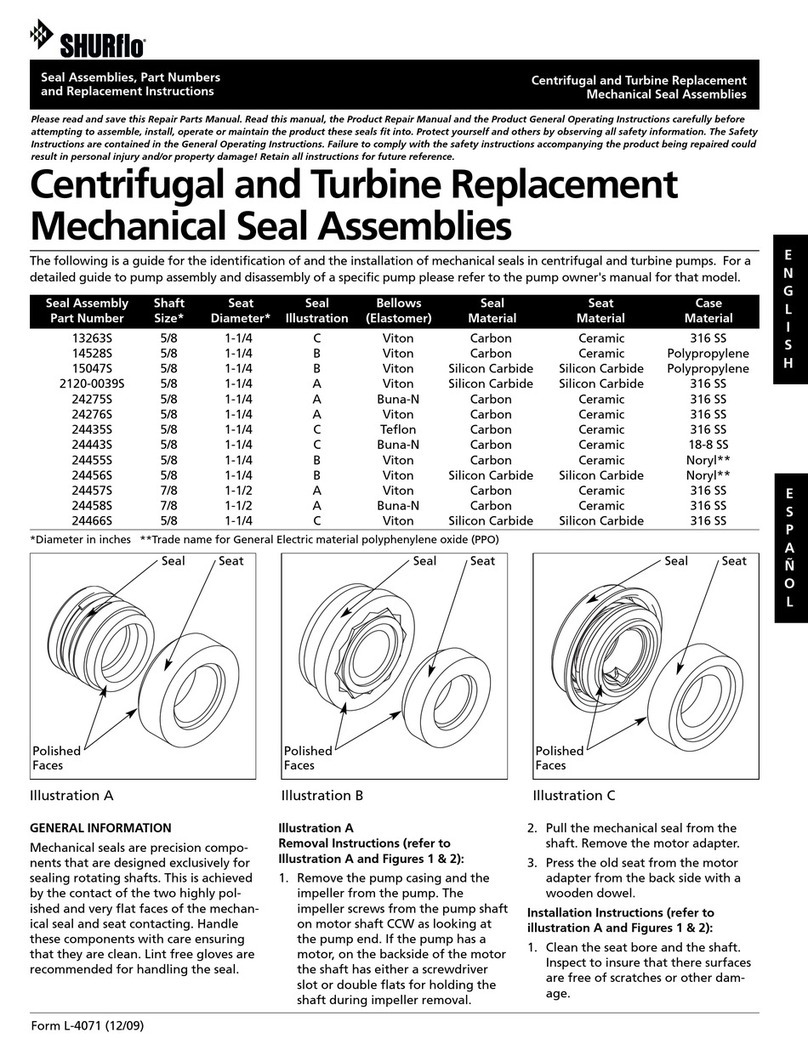

Pentair

Pentair SHURflo Repair parts manual

Madimack

Madimack invermac inverFLOW Series installation manual