SICK InspectorP63 Flex C-mount Series User manual

OPERATING INSTRUCTION S

InspectorP Rack Fine Positioning

2D vision

2Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

Product described

InspectorP Rack Fine Positioning

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch, Germany

Germany

Trademarks

IBM is a trademark of the International Business Machine Corporation.

MS-DOS is a trademark of the Microsoft Corporation.

Windows is a trademark of the Microsoft Corporation.

Other product names in this document may also be

trademarks and are only used here for identification purposes.

Legal information

This work is protected by copyright. The associated rights are reserved by SICK AG. Re-

production of this document or parts of this document is only permissible within the

limits of the legal provisions of copyright law. Any modification, abridgment, or transla-

tion of this document is prohibited without the express written permission of SICK AG.

The trademarks mentioned in this document are the property of their respective own-

ers.

© SICK AG. All rights reserved.

Original document

This document is an original document from SICK AG.

ABOUT THIS DOCUMENT 1

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 3

Contents

1About this document ............................................................................ 5

1.1 About these operating instructions ..............................................................5

1.2 Explanation of symbols ................................................................................. 5

1.3 Further information .......................................................................................6

2Safety information ................................................................................ 7

2.1 Intended use .................................................................................................7

2.2 Inappropriate use..........................................................................................7

2.3 Internet protocol (IP) technology ..................................................................7

2.4 Limitation of liability ......................................................................................7

2.5 Modifications and conversions .................................................................... 8

2.6 Requirements for skilled persons and operating personnel ...................... 8

2.7 Operational safety and specific hazards...................................................... 9

3Product description .............................................................................10

3.1 Scope of delivery .........................................................................................10

3.2 Function and use ........................................................................................10

3.3 Principle of operation..................................................................................11

3.4 Single deep applications.............................................................................12

3.5 Single and double deep applications.........................................................12

3.6 Positioning mark .........................................................................................12

4Installation............................................................................................14

4.1 Software installation ...................................................................................14

4.1.1 SICK AppManager............................................................................14

4.1.2 SOPASair (web server) .....................................................................14

4.1.3 Saving parameter set ......................................................................15

4.1.4 Installing firmware updates.............................................................16

4.2 Mounting......................................................................................................16

4.2.1 Mounting procedure ........................................................................16

4.2.2 Mounting device...............................................................................16

4.3 Electrical installation...................................................................................17

4.3.1 Notes on electrical installation .......................................................17

4.3.2 Interfaces .........................................................................................17

5Commissioning and operation ..........................................................19

5.1 Establishing a connection: Ethernet ..........................................................19

5.2 Establishing a connection: PROFINET........................................................19

5.3 Parameterizing device with SOPASair........................................................20

5.3.1 SOPASair user interface ..................................................................20

5.3.2Setting up user interface .................................................................20

5.3.3 Fine adjustment of the device.........................................................21

5.3.4 Calibration of the device..................................................................22

1ABOUT THIS DOCUMENT

4Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

5.3.5 Fine adjustment and calibration in single and double deep

applications ................................................................................ 22

5.3.6 Adjusting target region ....................................................................23

5.3.7 Optimizing image brightness ..........................................................23

5.3.8 Setting up Ethernet interface..........................................................24

5.3.9 Additional parameters.....................................................................24

5.3.10 Completing configuration ..........................................................25

5.4 Specification of the interface and interaction with the control................25

5.4.1 Communication process ................................................................. 25

5.4.2 Interfaces .........................................................................................25

5.4.3 Commands from the control to the device.....................................26

5.4.4 Answer from the device to the control ...........................................29

5.4.5 Control via digital inputs and digital outputs .................................30

6Annex ....................................................................................................32

6.1 Parameter....................................................................................................32

6.2 Licenses ...................................................................................................... 35

ABOUT THIS DOCUMENT 1

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 5

1About this document

1.1 About these operating instructions

These operating instructions provide important information on how to use devices

from SICK AG.

Prerequisites for safe work are:

•Compliance with all safety notes and handling instructions supplied.

•Compliance with local work safety regulations and general safety regulations for de-

vice applications.

The operating instructions are intended to be used by qualified personnel and electri-

cal specialists.

NOTE

Read these operating instructions carefully to familiarize yourself with the device

and its functions before commencing any work.

The instructions constitute an integral part of the product and are to be stored in the

immediate vicinity of the device so they remain accessible to staff at all times. Should

the device be passed on to a third party, these operating instructions should be

handed over with it.

These operating instructions do not provide information on operating the machine or

system in which the device is integrated. For information about this, refer to the oper-

ating instructions of the specific machine.

Related publications

The following related publications must be read:

Part number (language)

Publication

8019946 (English),

8019945 (German),

8019947 (French)

InspectorP63x Flex C-mount and S-mount Operating Instructions

8018486 (German and

English)

Technical Information for Ring Illumination Unit VI55I

1.2 Explanation of symbols

Warnings and important information in this document are labeled with symbols. The

warnings are introduced by signal words that indicate the extent of the danger. These

warnings must be observed at all times and care must be taken to avoid accidents,

personal injury, and material damage.

DANGER

… indicates a situation of imminent danger, which will lead to a fatality or serious

injuries if not prevented.

WARNING

… indicates a potentially dangerous situation, which may lead to a fatality or seri-

ous injuries if not prevented.

1ABOUT THIS DOCUMENT

6Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

CAUTION

… indicates a potentially dangerous situation, which may lead to minor/slight in-

juries if not prevented.

NOTICE

… indicates a potentially harmful situation, which may lead to material damage if

not prevented.

NOTE

… highlights useful tips and recommendations as well as information for efficient

and trouble-free operation.

1.3 Further information

NOTE

Other documentation for the device can be found on the online product page at:

•www.sick.com/InspectorP_Rack_Fine_Positioning

There, additional information has been provided depending on the product, such

as:

•Model-specific online data sheets for device variants, containing technical

data, dimensional drawing, and specification diagrams

•These device operating instructions, available in English and German, and

in other languages if applicable

•Other publications related to the devices described here

•

Publications dealing with accessories

SAFETY INFORMATION 2

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 7

2Safety information

2.1 Intended use

InspectorP Rack Fine Positioning is suited for storage and conveyor applications in

which precise positioning of automated storage and retrieval systems is required when

putting goods into and taking them out of storage.

The management, commissioning and operation of the device is done on a PC by using

the SICK AppManager and SOPASair software. The device sends results to a higher-

level control (e.g. PLC) in order to coordinate further processing via the host interface.

SICK AG assumes no liability for losses or damage arising from the use of the product,

either directly or indirectly. This applies in particular to use of the product that does

not conform to its intended purpose and is not described in this documentation.

2.2 Inappropriate use

Any use outside of the stated areas, in particular use outside of the technical specifi-

cations and the requirements for intended use, will be deemed to be incorrect use.

•The device does not constitute a safety component in accordance with the respec-

tive applicable safety standards for machines.

•The device must not be used in explosion-hazardous or corrosive areas or under ex-

treme ambient conditions.

•Any use of accessories not specifically approved by SICK AG is at your own risk.

WARNING

Danger due to improper use!

Any improper use can result in dangerous situations.

Therefore, observe the following information:

•Device should be used only in accordance with its intended use.

•

All information in these operating instructions must be strictly observed.

2.3 Internet protocol (IP) technology

NOTE

SICK uses standard IP technology in its products. The focus is on availability of

products and services.

SICK always assumes the following prerequisites:

•The customer ensures the integrity and confidentiality of the data and rights

affected by its own use of the aforementioned products.

•In all cases, the customer implements the appropriate security measures,

such as network separation, firewalls, virus protection, and patch manage-

ment.

2.4 Limitation of liability

Relevant standards and regulations, the latest technological developments, and our

many years of knowledge and experience have all been taken into account when com-

piling the data and information contained in these operating instructions. The manu-

facturer accepts no liability for damage caused by:

2SAFETY INFORMATION

8Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

•Non-compliance with product documentation (e.g. operating instructions)

•Improper use

•Use of untrained staff

•Unauthorized conversions

•Technical modifications

•Use of unauthorized spare parts, consumables, and accessories

The actual scope of delivery may differ from the features and illustrations shown here

where special variants are involved, if optional extras have been ordered, or as a result

of the latest technical changes.

2.5 Modifications and conversions

NOTICE

Modifications and conversions to the device may result in unforeseeable dan-

gers.

Interrupting or modifying the device or SICK software will invalidate any warranty

claims against SICK AG. This applies in particular to opening the housing, even as part

of mounting and electrical installation.

2.6 Requirements for skilled persons and operating personnel

WARNING

Risk of injury due to insufficient training!

Improper handling of the device may result in considerable personal injury and

material damage.

•

All work must only ever be carried out by the stipulated persons.

This product documentation refers to the following qualification requirements for the

various activities associated with the device:

•Instructed personnel have been briefed by the operating entity about the tasks as-

signed to them and about potential dangers arising from improper action.

•Skilled personnel have the specialist training, skills, and experience, as well as

knowledge of the relevant regulations, to be able to perform tasks assigned to them

and to detect and avoid any potential dangers independently.

•Electricians have the specialist training, skills, and experience, as well as

knowledge of the relevant standards and provisions, to be able to carry out work on

electrical systems and to detect and avoid any potential dangers independently. In

Germany, electricians must meet the specifications of the BGV A3 Work Safety Reg-

ulations (e.g., Master Electrician). Other relevant regulations applicable in other

countries must be observed.

The following qualifications are required for various activities:

Activities

Qualifications

Mounting, maintenance

•

Basic practical technical training

SAFETY INFORMATION 2

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 9

Activities

Qualifications

•

Knowledge of the current safety regulations in the

workplace

Electrical installation, device re-

placement •Practical electrical training

•Knowledge of current electrical safety regulations

•Knowledge of the operation and control of the de-

vices in their particular application

Commissioning, configuration

•Basic knowledge of the WindowsTM operating sys-

tem in use

•Basic knowledge of the design and setup of the

described connections and interfaces

•Basic knowledge of data transmission

•Knowledge of the programming of image-pro-

cessing systems and network components

Operation of the device for the spe-

cific application •Knowledge of the operation and control of the de-

vices in their particular application

•Knowledge of the software and hardware environ-

ment for the particular application concerned

2.7 Operational safety and specific hazards

You can find more detailed safety information in the product documentation of the In-

spectorP63x Flex C-mount and S-mount. The product documentation is available in the

Internet as a download at www.sick.com/8019946.

3PRODUCT DESCRIPTION

10 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

3Product description

3.1 Scope of delivery

The scope of delivery includes the following components:

No.

of

units

Component

Note

1

Device in the version ordered

V2D63xP-xMxSCxx (single deep applica-

tions)

or

V2D63xP-xMxSExx (single and double

deep applications)

2

Sliding nut with 5.5 mm-deep M5

threaded mounting hole

Positioned in the slot on the right side of

the device on delivery.

Alternative mounting option for the device

instead of tapped blind hole. Use in pairs!

1

Hexagon key WAF 2

For manual actuation of the focus screw.

Labels (round, self-adhesive)

Protects the focus setting when using an

S-mount lens. Adjustment is performed

with the focus adjustment screw. The la-

bel can be stuck over the access opening

for the screw on the top of the device af-

ter adjustment.

1

Printed safety notes, multilingual

(8022655)

Brief information and safety notes for de-

vices of series ICR6xx and V2D6xx.

3.2 Function and use

Temperature-, load- and steel construction-dependent influencing variables generate

varying geometric conditions at transfer points in the storage and conveyor technology.

These conditions make safe automated positioning of automated storage and retrieval

systems more difficult when putting in and removing load carriers from storage.

InspectorP Rack Fine Positioning supports precise positioning when putting in and re-

moving load carriers from storage. In doing so, positioning processes can be controlled

both for single deep applications as well as combined applications with single and

Figure 1: Negative influencing variables during automated positioning processes

PRODUCT DESCRIPTION 3

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 11

double deep racks. The device is mounted to the automated storage and retrieval sys-

tem. The device takes pictures when putting goods into and taking them out of storage

and detects a hole or a round reflector as a positioning mark in the rack. Using this po-

sitioning mark, the device sends a deviation of the current position of the automated

storage and retrieval system from the target position to a higher-level control (e.g.

PLC), which initiates rack fine positioning of the automated storage and retrieval sys-

tem. This prevents load carriers from colliding with the racks.

3.3 Principle of operation

Rack fine positioning takes place with a positioning mark on the rack. Positioning is

possible over holes (recommended hole diameter: 13 mm) and round reflectors as po-

sitioning marks. A distinction is also made between single and double deep racks. In

single deep racks, the shelf has space for a storage unit. In double deep racks, two

storage units are operated one behind another, whereby the shelf is twice as deep.

The device is able to handle both applications. Depending on the application (type of

positioning mark, rack depth), there are differences in system design such as the se-

lection of the lens focal length and the use of lighting filters.

The positioning mark (hole or reflector) is typically placed in the center of the camera

image and defined as the target region during alignment and rack fine positioning of

the device. The target region typically corresponds to the area around the center point

of the image. If necessary, the target region can be moved into another area of the im-

age using the operating software. The device detects the current position of the posi-

tioning mark during operation and forwards the deviation from the target region to the

control. Using the information provided by the device, the control initiates rack fine po-

sitioning of the automated storage and retrieval system. If the positioning mark is lo-

cated in the target region, goods may be put onto or taken off the rack. If the position-

ing mark is outside the target region, the relative position in relation to the target re-

gion is displayed using ambient sectors.

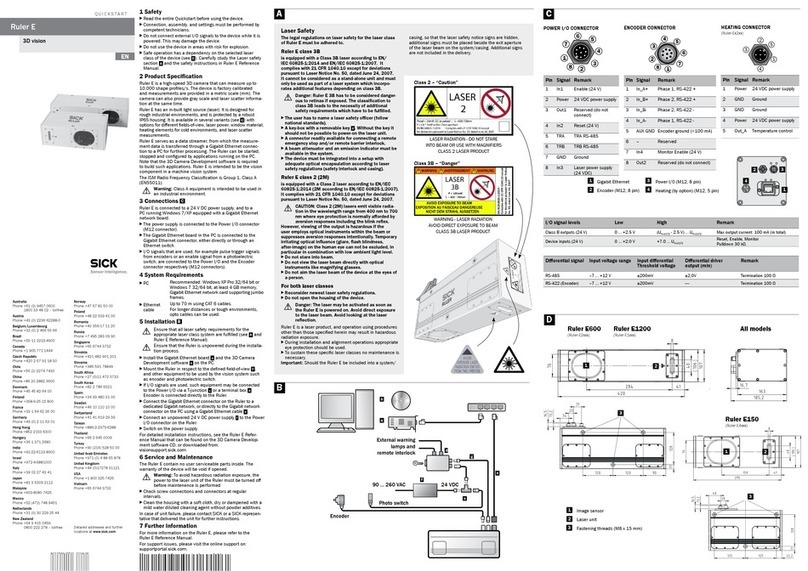

Figure 2: Detection and output related to the target region (example)

(1) Ambient sector (blue)

(2) Positioning mark (red)

(3) Target region (green)

3PRODUCT DESCRIPTION

12 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

3.4 Single deep applications

Single deep applications can be used in the following case:

•Single deep applications with working distances up to a maximum of 300 mm be-

tween the front screen of the device and the rack.

This application has a large field of view at close range.

3.5 Single and double deep applications

Combined applications with single and double deep racks can be used in the following

cases:

•Combination of single and double deep racks.

•Single deep applications with working distances from 300 mm between the front

screen of the device and the rack.

3.6 Positioning mark

Only relevant for single deep applications: The type of positioning mark (hole or reflec-

tor) can be set in SOPASair in the Setup window using the Preconfiguration applica-

tion parameter.

Applications with holes

Holes as positioning marks can be used both for single deep applications as well as

combined applications with single and double deep racks.

Applications with reflectors

Round reflectors as positioning marks can only be used for single deep applications.

NOTE

Using the following reflectors is recommended:

•PL22-1 (part number: 1003546)

•PL22-2 (part number: 1003621)

•PL22-3 (part number: 1004488)

•PL22-4 (part number: 5327829)

You can find the reflectors as accessories in the Internet at www.sick.com by en-

tering the respective part number into the search field.

During rack fine positioning with round reflectors, lights structures are searched for on

darker surfaces. Use a polarizing filter to prevent total reflection of the illumination.

The polarizing filter hides the total reflecting light from the surface. Do not use the po-

larizing filter for applications with holes.

NOTE

You can find the polarizing filter (part number: 2088229) as an accessory in the

Internet at www.sick.com by entering the part number into the search field.

PRODUCT DESCRIPTION 3

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 13

The following graphic shows step-by-step mounting of the polarizing filter:

(1) Scope of delivery of polarizing filter kit (part number: 2088229): Polarizing filter disk.

(2) Turn optics cover counterclockwise.

(3) Remove optics cover.

(4) Turn spacer ring counterclockwise.

(5) Remove spacer ring.

(6) Clip on polarizing filter disk, making sure the alignment is correct: Centering ring downwards,

recesses over retaining clips.

(7) Put on optics cover.

(8) Turn optics cover clockwise.

Figure

3: Polarizing filter mounting

4INSTALLATION

14 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

4Installation

4.1 Software installation

4.1.1 SICK AppManager

Installation of the SICK AppManager is required to execute the following actions:

•Reading out and changing the IP address.

•Saving currently valid parameter set on the PC (back-up) or a microSD memory card

in the device (cloning).

•Installing firmware updates.

Installing SICK AppManager

To install SICK AppManager, open the installation file (*.exe) and follow the instruc-

tions on the screen.

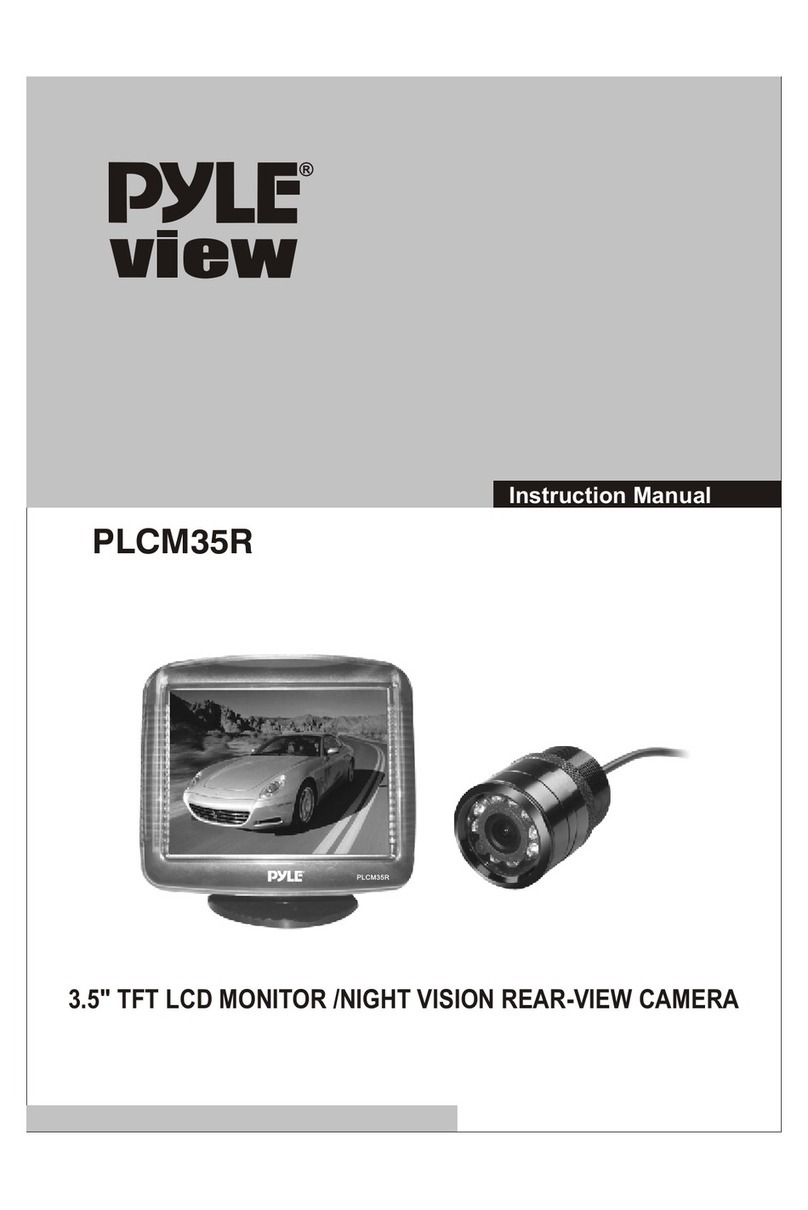

SICK AppManager user interface

(1) Device window (window name changes depending on the connected device)

(2) Device Search window

(3) Firmware window

4.1.2 SOPASair (web server)

The device is set up and parameterized using the SOPASair operating software. You

can call up the operating software with a web browser (recommendation: Google

NOTE

The current version of SICK AppManager can be downloaded in the Internet at:

www.sick.com/SICK_AppManager

Figure 4: SICK AppManager user interface

INSTALLATION 4

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 15

Chrome). It is not necessary to install software. The device must be supplied with volt-

age and connected to the PC via the Ethernet interface in order to use the SOPASair

web server.

Starting SOPASair

1. Start web browser (recommendation: Google Chrome).

2. Enter the device IP address into the address line.

The SOPASair user interface appears.

4.1.3 Saving parameter set

The currently valid parameter set can be backed up using SICK AppManager. The com-

plete environment of the device is then available if support is necessary.

Saving on the PC (back-up)

1. In the SICK AppManager, in the Device window, click on the Backup button.

The Backup Apps and Data window opens.

2. Fill out the Name, Version and Filename fields.

3. Select the path for data back-up.

4. Select all available options.

5. To run the back-up, click on the Backup button in the Backup Apps and Data win-

dow.

Saving on a microSD memory card (cloning)

NOTICE

Risk of damage to the memory card!

▸To avoid damaging the memory card, make sure the device is de-ener-

gized when you insert or remove the card. For this purpose, disconnect

the device from the supply voltage accordingly.

The card slot for the microSD memory card is located at the top of the device at the

rear under the hinged cover.

1. Switch off the supply voltage to the device.

Figure

5: “Backup Apps and data” window

4INSTALLATION

16 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

2. Undo the screws on the hinged cover and open the cover.

3. Insert the microSD memory card.

4. Close the hinged cover. Make sure that the cover is completely flush with the

housing.

5. Tighten the screws on the hinged cover again.

6. Switch on the supply voltage for the device.

7. In the SICK AppManager, in the Device window, click on the Clone button.

From now on, the device will back up the current parameter set on the mi-

croSD memory card.

4.1.4 Installing firmware updates

Firmware updates are installed via SICK AppManager:

1. Pull the file with the firmware update into the Firmware window with drag &

drop.

2. Select the file you want to install.

3. Click on the Install button in the lower right section of the window to install the up-

date.

4.2 Mounting

4.2.1 Mounting procedure

The device is delivered with pre-mounted illumination, pre-focused optics, pre-installed

software and pre-configured defaults. This enables quick and easy commissioning.

The optics are already pre-focused at a distance which is suitable for most applica-

tions. It might be a good idea to optimize the focus position in rare cases, see Figure 8:

Manual focus screw, page 22.

The procedure for mounting the device is divided into the following steps:

•Mount device with a view to the positioning mark.

•Connect device to interfaces and supply voltage.

•Align device with aiming laser.

4.2.2 Mounting device

Install the device to the mechanics with the bracket so that the device points vertically

to the positioning mark on the rack.

NOTE

It should be mounted so that it is exposed to as little shock and vibration as pos-

sible. Ensure that the position of the device is not moved by vibrations during op-

eration.

After switching on the supply voltage, the device starts and automatically activates the

aiming laser. The aiming laser helps align the device. The device projects two red laser

points on the rack, signaling the viewing direction of the camera. The center of the im-

age is between the two points. Align the device so that the positioning mark on the

rack is between the two laser points and is therefore in the center of the image. Press

the arrow button to switch the aiming laser on and off.

INSTALLATION 4

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 17

In a combined application with single and double deep racks, first align the device on

the single deep rack. Then adjust the position of the device for the double deep rack, if

applicable.

4.3 Electrical installation

4.3.1 Notes on electrical installation

NOTE

For detailed information on device connection, see the operating instructions of

the InspectorP63x Flex C-mount and S-mount at www.sick.com/8019946.

4.3.2 Interfaces

The device offers both an Ethernet interface and digital inputs and digital outputs for

communicating with the control. Parallel use of the two interfaces for communicating

with the control is not recommended.

Ethernet interface

The device is parameterized with the SOPASair operating software via the Ethernet

interface. Furthermore, the device transfers the deviation between the actual and the

target position of the automated storage and retrieval system to the control via the

Ethernet interface.

In doing so, the device precisely forwards the deviation between the actual position

and the target position to the control using X- and Y-values. Based on these values, the

control initiates position correction of the automated storage and retrieval system. The

necessary communication protocol (PROFINET, TCP/IP or UDP) is set using the

SOPASair operating software, see 5.3.8 Setting up Ethernet interface, page 24.

Digital inputs and digital outputs

The device is triggered via the digital input. The device outputs the position results us-

ing 4 digital outputs.

The device only delivers information on the direction (up, down, left, right) via the digi-

tal outputs. The automated storage and retrieval system can approach the target posi-

tion step-by-step based on this direction information. A quantitative statement about

Figure

6: Mounting example

4INSTALLATION

18 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

the deviation between the actual and the target position of the automated storage and

retrieval system is not transmitted.

Use the following pins to use the digital inputs and digital outputs:

•Pin 10: Sensor 1, digital input, IN 1 (switch continuous measurement on and off)

•Pin 15: Sensor 2, digital input, IN 2 (activate and deactivate double deep mode)

•Pin 13: IN/OUT 3 (direction specification: up)

•Pin 14: IN/OUT 4 (direction specification: down)

•Pin 16: IN/OUT 5 (direction specification: right)

•Pin 17: IN/OUT 6 (direction specification: left)

For further information on digital inputs and digital outputs, see 5.4.5 Control via digi-

tal inputs and digital outputs, page 30.

COMMISSIONING AND OPERATION 5

8024534 / / 2019-08-19 Operating Instructions | InspectorP Rack Fine Positioning 19

5Commissioning and operation

5.1 Establishing a connection: Ethernet

Opening user interface

The device must be supplied with voltage and connected to the PC via the Ethernet in-

terface in order to use the SOPASair web server.

1. Start web browser (recommendation: Google Chrome).

2. Enter the device IP address into the address line. For the TCP/IP or UDP communi-

cation protocol, the following IP address is pre-configured by default: 192.168.0.1

The SOPASair user interface appears.

Changing the IP address

1. Start SICK AppManager.

The connection status of the device and software is displayed below in the

list.

2. In the Device Search window, click on the Scan button.

The network is scanned.

The Device Search window lists all devices found in the network.

3. Select the desired device.

The Device window shows the application currently loaded on the device.

4. Click on the Edit IP Adress button.

The Edit IP Adress window opens.

5. Select the Use manual IP settings option.

6. Enter an IP address.

7. Confirm changes with OK.

5.2 Establishing a connection: PROFINET

In order to use the PROFINET communication protocol, the local device setting must be

in the Profinet Ethernet mode:

1. Change the IP address in SICK AppManager.

2. Open SOPASair.

3. In SOPASair, switch to the Operator user level. To do so, click on the button with

the currently set user level at the top right in the user interface.

4. Open the Interfaces window.

5. In the Ethernet mode area, set the Profinet mode.

The device restarts.

The PROFINET interface is active.

The PROFINET device name is used for identification. The IP address is usually as-

signed by the PROFINET IO controller (PLC) and then cannot be changed using SICK

AppManager.

To make other settings on the PROFINET interface on the side of the PROFINET IO con-

trollers (PLC), see 5.4.2 Interfaces, page 25.

5COMMISSIONING AND OPERATION

20 Operating Instructions | InspectorP Rack Fine Positioning 8024534 / / 2019-08-19

5.3 Parameterizing device with SOPASair

5.3.1 SOPASair user interface

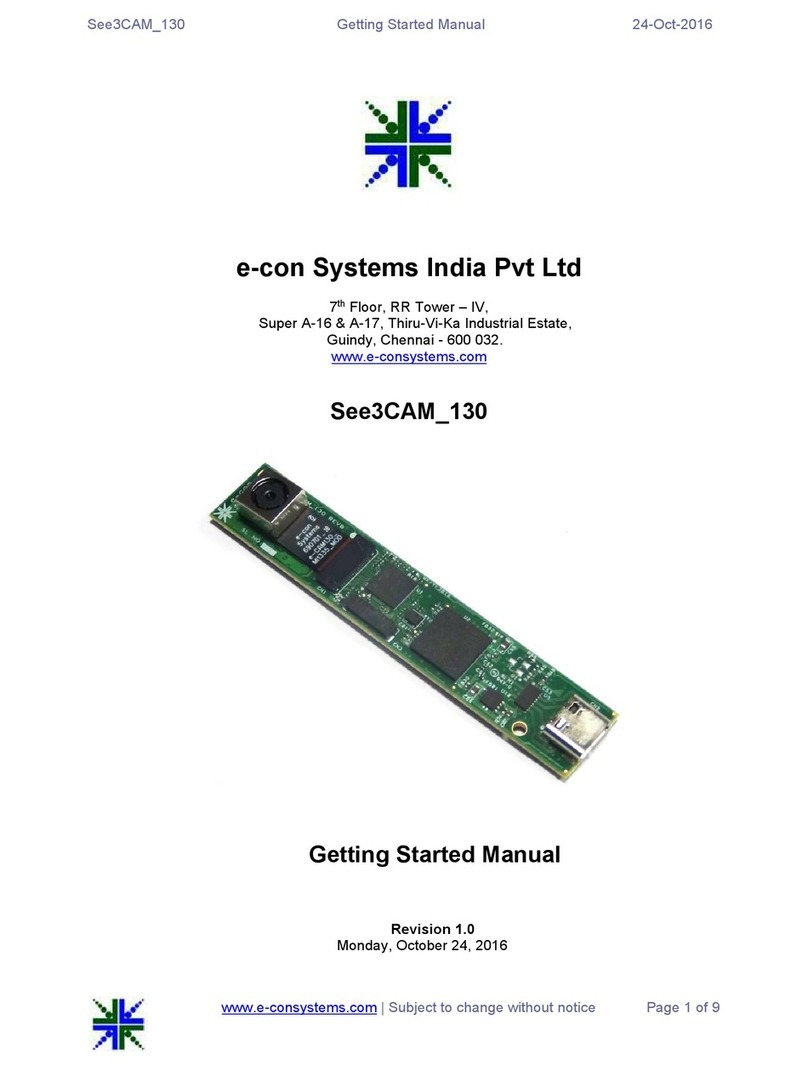

(1) Menu bar with available windows

(2) Window settings

(3) User level currently set

(4) Parameter bar (areas with available parameters)

(5) Digital output area (shows the current position of the positioning mark

(6) Target region (green)

(7) Positioning mark (red)

5.3.2 Setting up user interface

Setting user level

Several user levels are available in SOPASair. To change the user level, click on the

button with the currently set user level at the top right in the user interface.

The following user levels are available:

User levels

Password

Application

Run

No password

required.

•Observe the system during operation.

•Switch continuous measurement on and off.

•Activate and deactivate double deep applications.

•

Switch image output on and off.

Operator

No password

required. •Additional settings needed for initial commissioning of

the device.

•Minor adjustments during operation (e.g. measurement

tolerances).

•Since the device is preset when delivered, the parame-

ters available here are usually sufficient for operation.

Maintenance

Password:

main •

User: Maintainer.

•

Maximum number of available parameters.

Figure

7: SOPASair user interface

Other manuals for InspectorP63 Flex C-mount Series

2

Table of contents

Other SICK Machine Vision System manuals

Popular Machine Vision System manuals by other brands

Vision & Control

Vision & Control pictor N Series user manual

Omron

Omron SYSMAC FH Series user manual

National Instruments

National Instruments NI CVS-1458 Getting started guide

Omron

Omron fh series user manual

Cognex

Cognex In-Sight EZ-700 Series manual

Panasonic

Panasonic Micro-Imagechecker PV310 Use manual