Fehler! Unbekannter Name für Dokument-Eigenschaft.

S100

4© SICK AG • Subject to change without notice 8012238/YY30/2015-02-20

5Mounting.......................................................................................................................... 25

5.1 Definition of the size of the switching field for mobile applications ................ 26

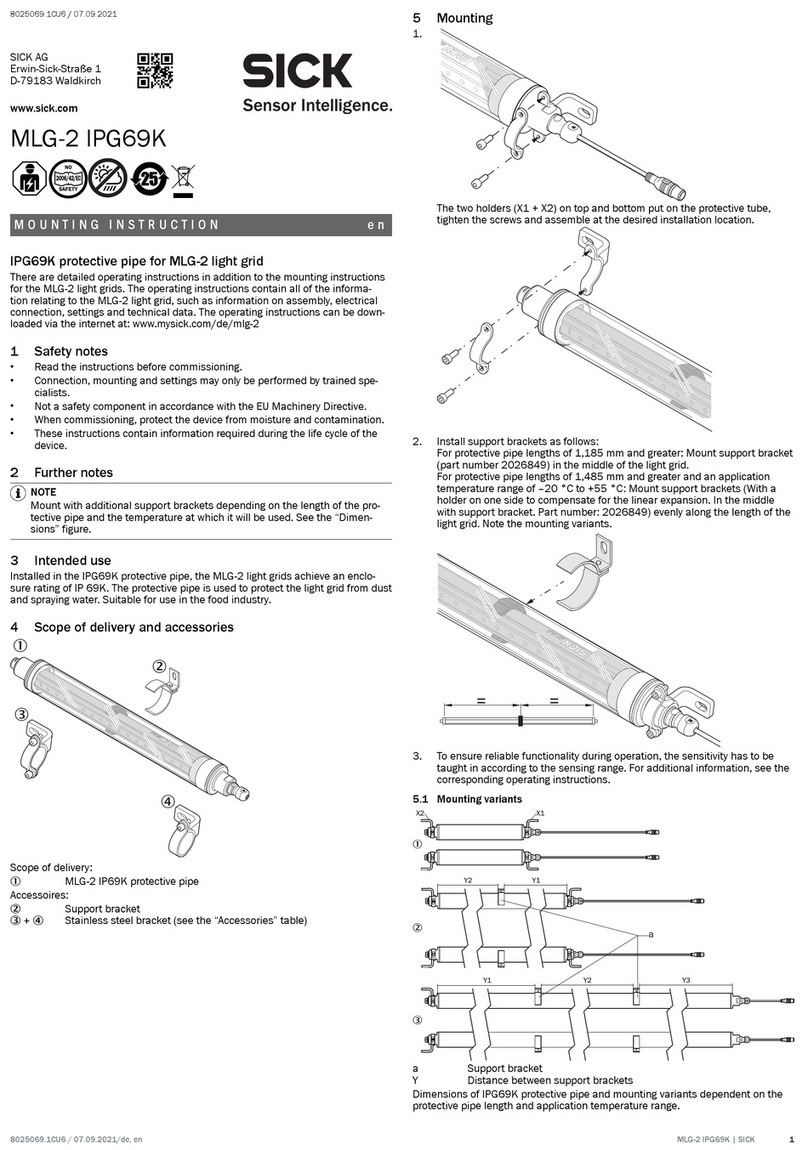

5.2 Mounting steps ................................................................................................... 26

5.2.1 Direct mounting ................................................................................ 27

5.2.2 Mounting with mounting kit 1a or 1b .............................................. 27

5.2.3 Mounting with mounting kit 2 and 3 ............................................... 29

5.2.4 Using multiple S100 laser scanners ............................................... 29

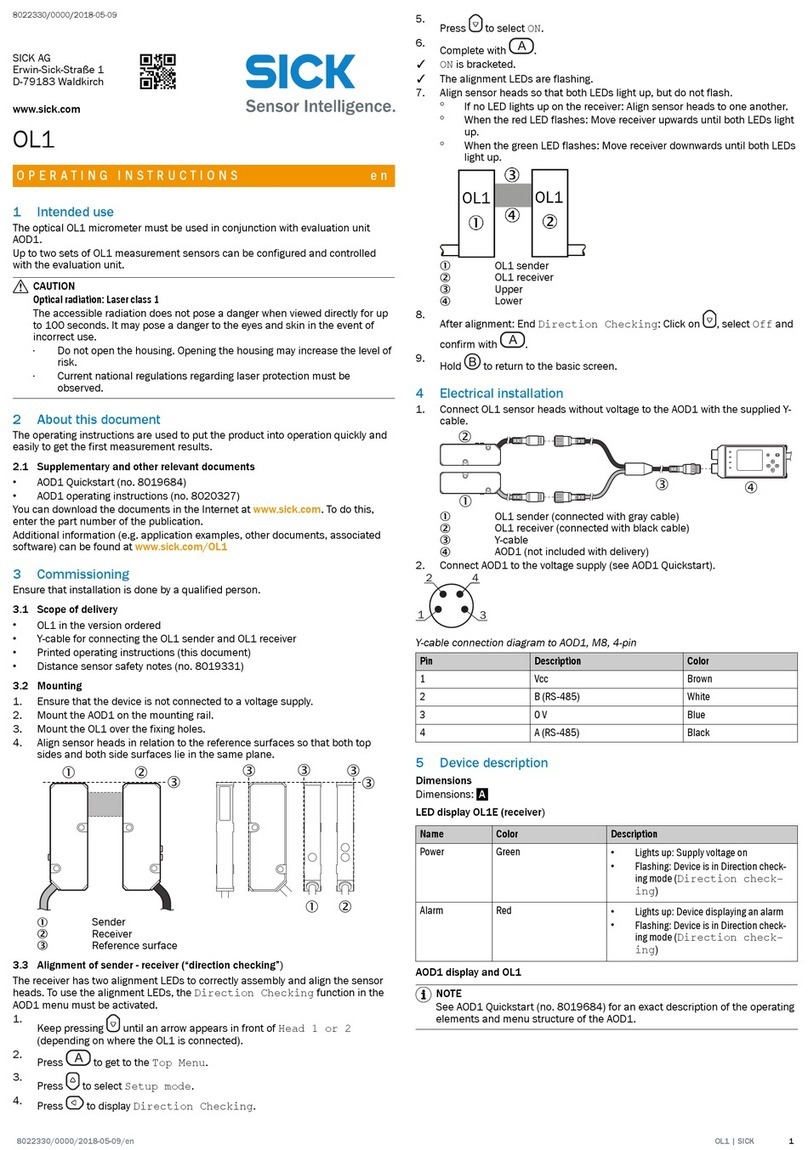

6Electrical installation ..................................................................................................... 32

6.1 System connection ............................................................................................. 32

6.2 System plug assembly........................................................................................ 34

6.2.1 Cable glands ..................................................................................... 34

6.2.2 Wire cross-sections........................................................................... 35

6.3 Pre-assembled system plugs ............................................................................. 35

7Application examples and connection diagrams ........................................................ 36

7.1 Applications with the S100 Standard................................................................ 36

7.2 Applications with the S100 Professional .......................................................... 37

8Configuration................................................................................................................... 38

8.1 Default delivery status........................................................................................ 38

8.2 Preparation of the configuration........................................................................ 38

8.3 Configuration of the CANopen master............................................................... 39

9Commissioning................................................................................................................ 42

9.1 Initial commissioning.......................................................................................... 42

9.2 Re-commissioning .............................................................................................. 43

10 Care and maintenance ................................................................................................... 44

10.1 Cleaning optics cover ......................................................................................... 44

10.2 Replacing optics cover ....................................................................................... 44

11 Diagnostics ...................................................................................................................... 46

11.1 SICK support ....................................................................................................... 46

11.2 Error and status indications on the LEDs.......................................................... 46

11.3 Error and status indications on the 7segment display.................................... 48

11.4 Extended diagnostics ......................................................................................... 51

12 Technical specifications ................................................................................................ 52

12.1 Characteristics .................................................................................................... 52

12.2 Response times .................................................................................................. 53

12.3 Data sheet........................................................................................................... 54

12.4 Dimensional drawings ........................................................................................ 60

12.4.1 S100.................................................................................................. 60

12.4.2 Mounting kits .................................................................................... 60

12.4.3 Scan plane origin .............................................................................. 62

13 Ordering information ...................................................................................................... 63

13.1 Delivery S100 ..................................................................................................... 63

13.2 Available systems ............................................................................................... 63

13.3 Accessories/spare parts .................................................................................... 63

13.3.1 Mounting kits .................................................................................... 63

13.3.2 System plug S100 ............................................................................ 64

13.3.3 Service cable..................................................................................... 64

13.3.4 Self assembly connecting cables .................................................... 64

13.3.5 Documentation ................................................................................. 64

13.3.6 Other.................................................................................................. 65