Sielaff SU 1500 EC02 Series User manual

GB

With Technical Manual

Original Operating Instructions

SÜ

FS

Softdrop

SÜ 1500............ EC02

SÜ 2020............ EC02

SÜ 2020............RO02

SÜ 2020............ EO02

SÜ 2020............ SO02

SÜ 2020............ SE02

SÜ 2020.............EL02

SÜ 2020............ LO02

FS 1500............ EC02

FS 2020............ EC02

FS 2020............ EO02

FS 2020............RO02

316 00 540 02 _ 251

GB

04.09.20

OPERATING INSTRUCTIONS

2

SÜ/ FS

316 00 540 02 _ 251

1 General..................................................................................................................4

1.1 Technicaldata/Machineidenticationplate..............................................................6

1.2 Safetyinformation......................................................................................................7

1.3 Explanationofsignsandsymbols..............................................................................9

2 Machine diagram................................................................................................10

2.1 Versions ...................................................................................................................10

2.2 SÜ2020model .........................................................................................................11

2.3 FS2020model.........................................................................................................13

2.4 SÜ2020EL02(Softdrop).........................................................................................14

2.5 MachineswithR290chillerunit ...............................................................................15

3 Transport.............................................................................................................16

4 Installing the machine .......................................................................................17

4.1 Requirementsonsite...............................................................................................17

4.2 Installationandcommissioning................................................................................18

4.3 Electricalconnection................................................................................................19

4.4 Fittingacoinmechanism(optional) .........................................................................20

4.5 Mountingthecoinmechanism .................................................................................20

4.6 Settingtheeccentricdisc.........................................................................................20

4.7 Connectingtheadapterkit.......................................................................................20

4.8 Assigningsoftware...................................................................................................20

4.9 Fillingthecoinmechanism(optional).......................................................................21

4.10 Productspecications..............................................................................................21

4.11 Multiex-pusher........................................................................................................21

5 Daily use .............................................................................................................22

5.1 Notesfortheller.....................................................................................................22

5.2 Openingthemachinedoor.......................................................................................22

5.3 Pullingouttheproductcontainers............................................................................22

5.4 Fillingthespiralproductcontainers .........................................................................22

5.5 Goldenrulesforllingspirals...................................................................................22

5.6 Fillingthechutes(FS-seriesonly)............................................................................23

5.7 Doorcontactswitch(Softdroponly).........................................................................23

5.8 Temperature-controlledversion(fresh-foodversion) ...............................................23

5.9 Foodsafetyproductstorage ....................................................................................23

5.10 Foodlabellingdirective ............................................................................................23

6 Cleaning and maintenance................................................................................24

6.1 Caringfortheexternalsurfaces...............................................................................24

6.2 Cleantheproductcontainers...................................................................................24

6.3 Cleaningthedeliveryunit.........................................................................................24

6.4 Cleaningthedustlter .............................................................................................24

7 Software..............................................................................................................25

7.1 Servicekeypadanddisplay .....................................................................................25

7.2 Structureofmainmenu............................................................................................26

7.3 [CHECK] M0 ............................................................................................................27

7.4 [PROGRAMMINGMODE]M1 .................................................................................27

OPERATING INSTRUCTIONS

3316 00 540 02 _ 251

SÜ/ FS

7.5 [COOLINGPROGR.]M2 .........................................................................................28

7.6 [TEST VEND MODE] M3.........................................................................................29

7.7 [SHOW STATISTICS] M4 ........................................................................................29

7.8 [SHOW FULL STAT] M5 ..........................................................................................29

7.9 [PROG./TIMELOCKS]M6 ......................................................................................30

7.10 [INSTALLING MODE] M7 ........................................................................................31

7.11 [SERVICEMODE]M8 .............................................................................................38

7.12 [TUBEINVENTORY]M9..........................................................................................39

7.12.1 SOFTDROP [M10] ............................................................................................................. 42

8 Maintenance work..............................................................................................44

8.1 Maintenanceschedule.............................................................................................44

8.2 Heightadjustment....................................................................................................46

8.3 Routingtheribboncable..........................................................................................47

8.4 Spirals......................................................................................................................47

8.5 Adjusting:Spiralendposition...................................................................................47

8.6 Changingthespiralconguration ............................................................................48

8.7 FittingaMultiexpusher..........................................................................................48

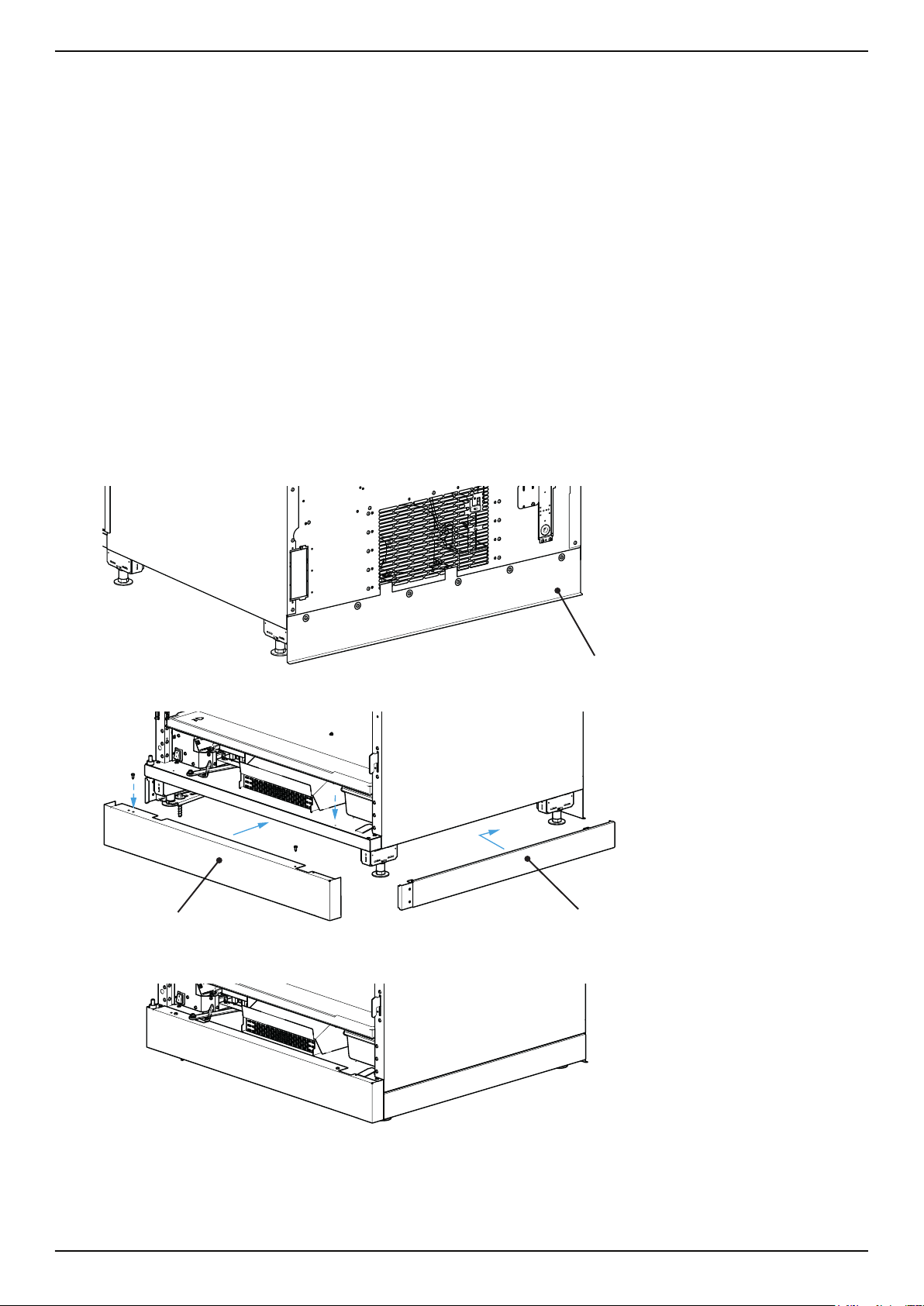

8.8 Removingchutes(FS-seriesonly)...........................................................................49

8.9 Motorlookup/homeposition...................................................................................49

8.10 Back-upbattery........................................................................................................49

8.11 Chillerunit ................................................................................................................50

8.11.1 Removingthechillerunit..................................................................................................... 50

8.11.2 Cleaningthechillerunit....................................................................................................... 51

8.12 ChillerunitSKA705(R290)only .............................................................................52

8.12.1 Checkthegassensor ......................................................................................................... 52

8.12.2 Cleanthegassensor .......................................................................................................... 52

8.12.3 Initiateselftest .................................................................................................................... 52

8.12.4 Checktheanaloguevoltage................................................................................................ 53

8.12.5 Testthesensor.................................................................................................................... 54

8.12.6 Changethegassensor....................................................................................................... 55

8.13 Overviewoftheslots(M32SÜcontrolboard) .........................................................56

8.14 Softwareupdate.......................................................................................................57

8.14.1 Programmingequipment(RedBox).................................................................................... 57

8.14.2 With PC............................................................................................................................... 57

9 Malfunctions.......................................................................................................58

9.1 Errormessages........................................................................................................58

9.2 Displayswhenoperatingandmalfunctions..............................................................59

9.3 Clearingbottlejams(FS-seriesonly).......................................................................59

10 Machineconguration.......................................................................................60

10.1 Containernumbering ...............................................................................................60

10.2 Allocatingmotors .....................................................................................................60

10.3 Tableofmainallocations.........................................................................................61

11 Decommissioning and disposal .......................................................................62

12 Index....................................................................................................................66

13 EU-/EG Declaration of Conformity....................................................................67

OPERATING INSTRUCTIONS

4

General SÜ/ FS

316 00 540 02 _ 251

1 General

Modications

Thetexts,picturesanddatainthismanualreectthetechnicalstatusofthemachineatthetimeofprinting.

Wereservetherighttomakechangesinordertomakefurtherdevelopments.

Complete document

Thisdocumentconsistsof68pages.Ifallthepagesareinconsecutiveorder,yourdocumentiscomplete.

Availability of instructions

Inordertoensuresafeuse,theoperatinginstructionsmustalwaysbeaccessibletotheoperator.These

shouldbereadilyavailableforreferralatalltimes.

ThisoperatingguidecanalsobeaccessedviatheInternetfromoursecuredownloadcentre:(http://www.

siela.de/download-centre/)

Third party documentation

Paymentsystemssuchascoinmechanism,billvalidatororcashlesspaymentsystemscanbettedtothis

machine.

Wewouldliketopointoutthatspecialaccessoriesmayberequiredandspecialsettingsmayneedchanging

inthemachinesoftwareinordertoensureerror-freeoperationofthepaymentsystembeingused.Please

refertotheadditionalthird-partdocumentationfromtherelevantmanufacturer.

Manufacturer

SielaGmbH&Co.KG

Automatenbau

MünchenerStraße20

91567Herrieden

Germany

Hotline

Enquiriesandordersaredealtwithatthefollowingaddress:

Telephone+49982518-0 Switchboard

+49 9825 18-31 51 02 Service-Hotline

Telefax +49982518-315499 Service

+49982518-315299 Sparepartsordering

info@siela.de;www.siela.de

Variants

Pleasenotethattheseoperatinginstructionscoverdierentmachineversions.Forthisreasonsomeofthe

informationmaynotapplytoyourmachine.

This manual covers the following versions:

Model .... Part no.

SÜ 1500 EC02..321 00 000 22

SÜ 2020 EC02..325 00 000 72

SÜ2020RO02 .325 00 000 76

SÜ 2020 EC02..325 00 000 77

SÜ 2020 SO02 .325 00 000 78

SÜ 2020 SE02..325 00 000 79

SÜ 2020 EL02 ..3250000096(Outdoormachine,Soft-

drop)

SÜ 2020 LO02..3250000097(Outdoormachine,Soft-

drop)

FS 1500 EC02..321 00 000 32

FS 2020 EC02..325 00 000 82

FS 2020 EO02..3250000087(Outdoorma-

chine)

FS2020RO02..3250000088(Outdoorma-

chine)

General OPERATING INSTRUCTIONS

5316 00 540 02 _ 251

SÜ/ FS

Identication

1

2

34

1. Manufacturer

2. Machinetype

3. Electricalsupplyratings

4. IfchillerunitusesR290:Symbolfor

“Warningammablesubstances”

Copyright

©SIELAFFGmbH&Co.KGAutomatenbau

Thisdocumentationisprotectedbycopyright.Nopartsofthismanualmaybeusedorreproducedoramend-

edinanymannerwhatsoeverwithoutwrittenpermissionfromtheCopyrightHolder.Thecompanyreserves

allrights,especiallyfortranslation,re-print,usingchartsandpictures,broadcasting,photo-mechanicorother

reproductionandstorageindata-processingsystems.Thisalsoappliestoextracts.

SIELAFFprovidesnoexplanationsorguaranteeswithrespecttothecontentsofthisoperatingguideand

specicallyrejectsanyresponsibilityforacceptinganyimplieddefectclaims.Furthermore,Sielareservesthe

righttoupdatethispublicationandmakechangestoit,withoutbeingobligedtoinformanypersonofthese

changes.

Features

PackagedandchilledfoodstuscanbedispensedfromtheSÜ1500andSÜ2020vendingmachines..Food

canbechilleddownto4°Cinthefreshfoodversionofthismachine.

Productsthatdonotrequirechillingcanbevended,aslongastheytintothespirals.

ColddrinkscanalsobedispensedfromtheFS1500andFS2020machines.

Atwo-line(LCD)displayprovidesselectionandsysteminformation.

Allmachinefunctionsaremanagedandcheckedviaamicroprocessormodule.Salesanderrordataisstored

onthemachinecontrolboard.

Inservicemodetheselectionkeypadisusedalongwiththeprogrammingkeystoprogrammethemachine

controlboard.

Thevendingmachineispreparedforoperationwithacoinmechanismasstandard.

SIELECTORsoftwareforPC-supportedprogramming,basedonWindows,canbeusedtocongurethema-

chine.Thesoftwaresupportstheduplication,creation,savingandprintingoutofallparameters.

OPERATING INSTRUCTIONS

6

General SÜ/ FS

316 00 540 02 _ 251

1.1 Technical data/ Machineidenticationplate

Theidenticationplateislocatedinsidethecabinet-topright-andisvisiblewhenthedoorisopen.

Type SÜ 1500 SÜ 2020 FS 1500 FS 2020

Selections max.36 max.60 max.24 max.45

Productcontainers max.36 max.60 max.24 max.45

Height[mm] 1830 1830 1830 1830

Width[mm] 700 990 700 990

Depth[mm] 880 880 880 880

Weight[kg] 295 475 360 475

Electricaldata 220-230V

50/60Hz

min.10A

220-230V

50/60Hz

min.10A

220-230V

50/60Hz

min.10A

220-230V

50/60Hz

min.10A

Powerconsumption[W] max.570 max.670 max.570 max.670

Ambienttemperature(standardchillerunit) +16°Cto+32°C

Ambienttemperature(outdoormachineswith

heater)

-20°Cto+32°C

Weightandpowerconsumptionsarestandardvalues.Theweightmaychangeduetodierentcongurations.

A-ratedsound-pressurelevelemissionintheworkplace LpA< 70 dB

Variationfactor KpA= 6 dB

ThevaluesweredeterminedinaccordancewithEN60335-2-75:2004+A1:2005+A11:2006+A2:2008+A12:2010i.V.withENISO11202:2010.

NOTE:Thesumofnoiseemissionandassociatedvariationfactorrepresentsanupperlimitofvalueswhichmightoccurwhenmeasurementsaretaken.

Information regarding regulation (EU) no. 517/2014

Chiller unit Power Cooling agent Filling quantity GWP CO2-equivalent

SKA 280 1200 W R134a 170g 1430 0.243 t

SKA 290 1210 W R134a 170g 1430 0.243 t

SKA 410 1400 W R134a 245g 1430 0.350 t

SKA 700 1500 W R134a 380g 1430 0.543 t

SKA 701T 1640 W R134a 350g 1430 0.500 t

SKA 851 1770 W R134a 350g 1430 0.500 t

SKA 705 E 2650 W R290 150g 30.00045 t

1)containsHFKW-134ainhermeticallysealedequipment.

2)containspropanegas,C3H8inhermeticallysealedequipment.

General OPERATING INSTRUCTIONS

7316 00 540 02 _ 251

SÜ/ FS

1.2 Safety information

General

• Beforecommissioningtheunit,theoperatinginstructionsshouldbereadandunderstood.

• Theoperatinginstructionsshouldbereadilyavailableforreferralatalltimes.

• Whentransporting,settingup,servicingandrepairingthevendingmachine,strictadher-

encetothefollowingrulesandguidelines-intheirlatestversion-isessential:Standards

setbytheappropriateelectricitycompany,UVV-accidentpreventionregulations,trade

associationguidelines,industrialcode,EC-guidelines,VDEregulations,observanceof

thecurrenthygieneregulations,country-specicregulations,IndustrialSafetyRegulation

-BetrSichV,Workplaceregulations-ArbstättV.

Transportation, installation and commissioning

• Duetoitshighcentreofgravity,thereisariskofthemachinetippingover.Thereforecau-

tionmustbeexercised.Donotjerkthemachinewhenlowering.

• Themachinemustbepositionedonahorizontal,stablebase.Ithastobesecuredtothe

walloroor.

• Themachineisonlysuitableforindooruseindryandheatedareas.

• Machineinstallationandrepairsshouldonlybecarriedoutbytrainedserviceengineers.

• Theventingclearancebetweenthebackofthevendingmachineandthewallonsitemust

beobserved.

• DonotlocatemachineswithR290chillerunitdirectlyalongsideanindentationintheoor

(basemententrance,drain,hollow,recessetc.)

Operating

• Thismachinecanbeusedbychildrenfrom8yearsandolderandbypeoplewithlimited

physical,sensoryormentalabilitiesorlackofexperienceand/orknowledge,providedthey

arelookedafterbyanotherpersonresponsiblefortheirsafetyoriftheyhavereceived

instructionshowtousethemachineandareabletocomprehendthedangersresulting

thereof.Cleaningandmaintenanceworkshouldnotbecarriedoutbychildrenwithout

supervision.

• Childrenshouldbesupervisedtoensurethattheydonotplaywiththemachine.The

vendingmachineisnotsuitableforusebychildrenunder3yearsold.

• Themainsplugmustbeeasilyaccessible.Applianceplugsshouldneverbetouchedwith

wethandsorinsertedintosocketswhendamp.

• Pulloutonlyoneshelfatatime,orthecentreofgravitymaybeshifted.

• Inadditiontothestandardcleaningproceduresmaintenanceworkshouldalsobecarried

outonthemachine.

OPERATING INSTRUCTIONS

8

General SÜ/ FS

316 00 540 02 _ 251

Cleaning

• Themachinedispensesfoodproducts.Themachinemustbecleanedatregularintervals

inordertoavoidhealthriskstoconsumers.

• Onlyuseauthorizedfood-safe,cleaningagents.

• Beforecarryingoutanycleaningremovethemainsplugandforapermanentconnection

switchoanysafetydevices.

• Donotcleanthemachinewithawaterhoseorahigh-pressurecleaner.

Repairs

• TheinsideofthemachinemayhavesharpedgesandcornersAlwayswearprotective

gloveswhencarryingoutmaintenancework

• Damagedpowercablesmustonlybereplacedbythemanufacturer,authorisedservice

centreorequallyqualiedpersoninordertopreventseriousaccidents.

• Useonlygenuinereplacementparts.

• OnlyproductsapprovedbySIELAFFmaybeused.

• Themachinemustnotbeconvertedormodiedinanyway.SIELAFFdisclaimsliabilityfor

anydefectsinsuchcases.

Chiller unit with R-290 refrigerant (propane)

• AfterinsertingthemainsplugorswitchingontheF1-circuitbreakertheswitch-odevice

requiresapprox2minutesforthesafetyshutdowntobeoperational.Duringthistimethe

machinedoesnothaveanyotherfunctions.

Shouldthemachinehowevernotstart,theswitch-odevicemayhaveturnedthemachine

oonaccountofafaultychillerunit.

Inthiscaseanyopenamesandburning/glowingobjectswithina5mradiusaroundthe

machinemustberemovedbeforethemachinedoorcanbeopened.

• Thegassensorinstalledinthechilledareamustnotbetamperedwithasthiscanendan-

gerpersonsandthesurroundingarea.

• Oncethesafetyshutdownhasbeenactivatedthemachineshouldonlybeputbackinto

operationbyaqualiedperson.

• Donotdamagetherefrigerantcircuit.

Intended use

• Themachinemustonlybeusedforvendingpre-packagedfoodorsimilaritems.

• BottledorcannedbeveragescanalsobevendedfromtheFS-range.

• Inammableorexplosivegoodsmustnotbevended.

General OPERATING INSTRUCTIONS

9316 00 540 02 _ 251

SÜ/ FS

1.3 Explanation of signs and symbols

Thisvendingmachinewasmanufacturedinaccordancewithstate-of-the-arttechnologystandards.Nevertheless,

eventhemostexpertlydesignedmachine,cannotbewithoutrisks.

Inordertoensurethehighestpossiblelevelofoperatorsafety,additionalsafetyguidelinesarehighlightedbyusing

thefollowingsymbolswithaccompanyingdetaileddenitions.

Adequatesafetyduringoperationisensuredonlywhenthesesafetyprecautionsareobserved.

Texthighlightedasbelowsymbolisesthefollowing:

Danger

Immediatedangerwhichcouldresultindeathorsevereinjury.

WARNING!

Possibledangeroussituationwhichcouldresultindeathorsevereinjury.

CAUTION!

Dangeroussituationwhichcouldresultininjuryordamagetothevendingmachine.

NOTE

Informationtoavoidcausingdamagetothemachine

TIP

Informationtofacilitatehandlinganduseofthevendingmachine.

Thefollowingdangersymbolsmayalsobeusedincertaininstances:

WARNING electrical energy! Risk to life!

Thissymbolwarnsthatelectricallylivecomponentsareinstalledinthisarea.Coversmarkedwith

thesesymbolsshouldonlyberemovedbyauthorisedelectricians.

Observe the handling instructions for contact with electro-statically-sensitive components

and assemblies (ESD)

Behindcoversmarkedwiththissymbolarepartsandcomponentsthataresusceptibletoelectri-

caldischarge.

Itisimperativethatplugconnections,electricalleadsandcomponentpinsarenottouched.

OnlyspecialistpersonnelwithESDknowledgeareauthorisedtoworkonthemachine!

ATTENTION! Risk of injury

Theremaybesharpedgesinsidethemachine.

Wearprotectivegloveswhencleaningthemachine.

Attention! Danger of crushing!

Riskofhandinjuries!

DANGER! Flammable materials!

Thissymbolwarnsaboutammablematerials.Maycauseseriousinjuryordeath.Sourcesof

ignitionsuchasburningcigarettesorlightersmustbedistancedbeforeopeningthemachine

door.

OPERATING INSTRUCTIONS

10

Machinediagram SÜ/ FS

316 00 540 02 _ 251

2 Machine diagram

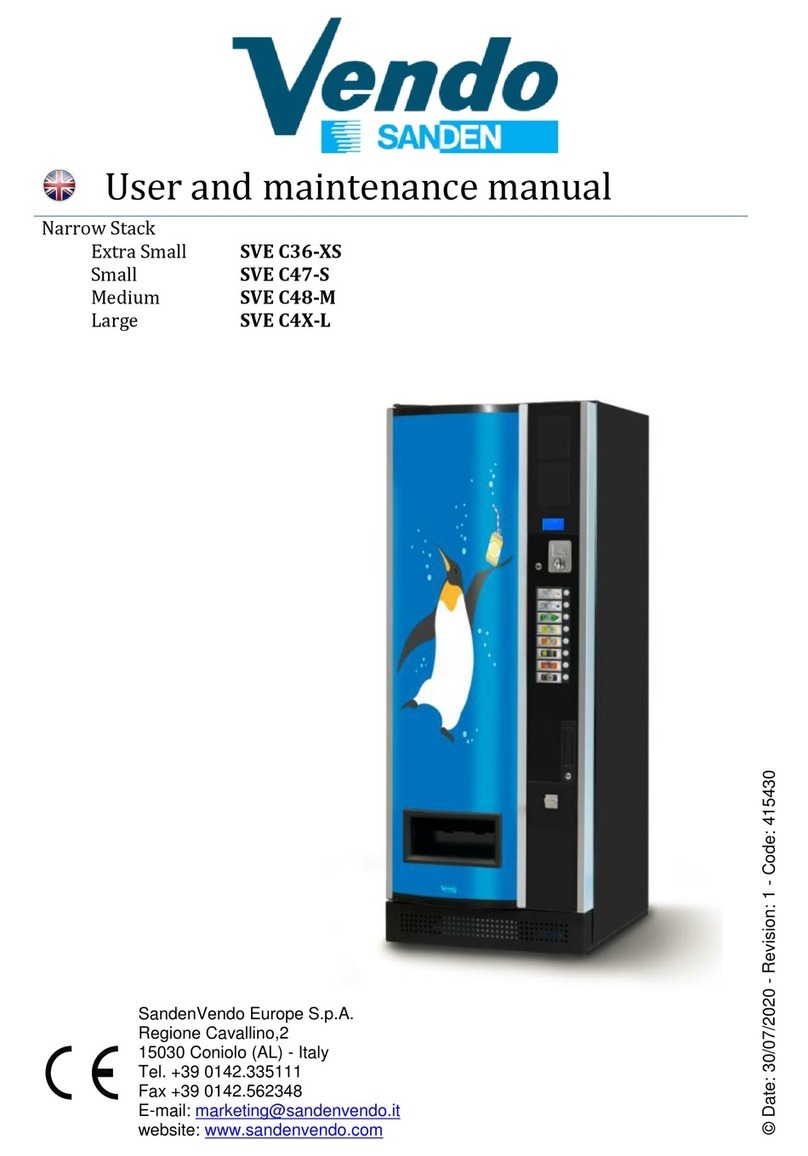

2.1 Versions

FS 1500

SÜ 1500

SÜ 2020 FS 2020

SÜ-Series(confectionery) FS-Series(bottles+confectionery)

Machinediagram OPERATING INSTRUCTIONS

11316 00 540 02 _ 251

SÜ/ FS

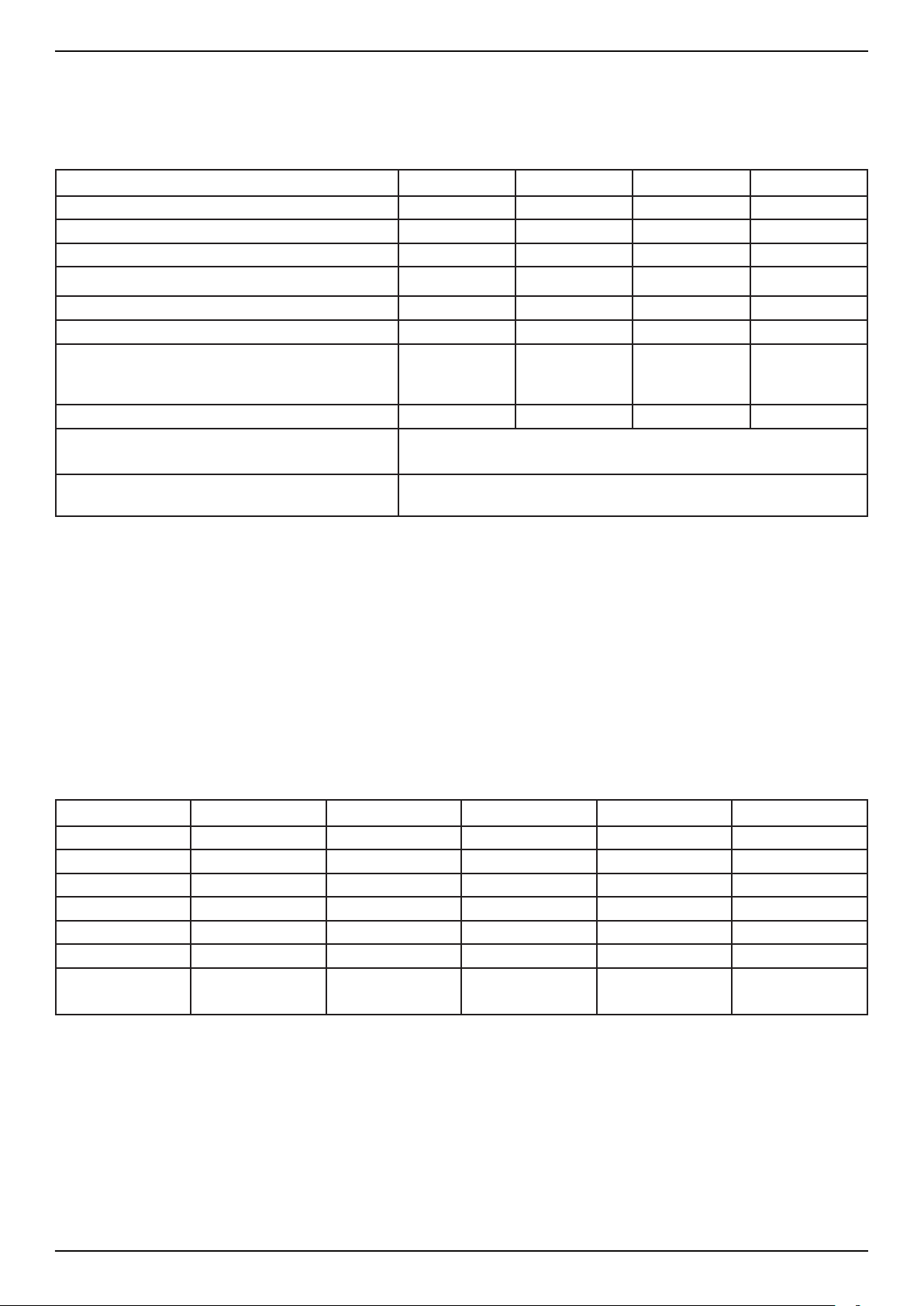

2.2 SÜ2020 model

Mountingbracket

POS

Display

Coininsert

Selectionkeypad

Coinreturnbox

Lockinglever

Kickplate(optional)

Airinletgrid(SÜ20202Tonly)

Internaldoorforcashbox

Servicekeypad

Coinmechanism(optional)

Removablecashbox

refundbutton

OPERATING INSTRUCTIONS

12

Machinediagram SÜ/ FS

316 00 540 02 _ 251

DierencesbetweenSÜ2020andSÜ20202T:Themachine

with2temperaturezoneshasafanonthebackwall

Fan(SÜ20202Tonly)

Spiralcontainer

Evaporator

Productdeliveryunit

Condensedwaterdriptray

Switch(SÜ20202Tonly)

Interiordoor,cover

Mountingbracket

Mainsconnectioncablewithplug

Warmairventilationgrid

Machinediagram OPERATING INSTRUCTIONS

13316 00 540 02 _ 251

SÜ/ FS

2.3 FS 2020 model

Note

Spiralcompartmentsandbottle/canchutescanbe

combinedindividually.

Productcontainer

Spiralcompartment

Chillingmodule

Condensation/evaporationbowl

Kickplate

Displaywindow

Samplebottle

Rearwalldisplaywindow

Illumination

OPERATING INSTRUCTIONS

14

Machinediagram SÜ/ FS

316 00 540 02 _ 251

2.4 SÜ 2020 EL02 (Softdrop)

1 Wallspacingbrackets

2 POS-window

3 Display

4 Coininsert

5 Selectionkeypad

6 Coinreturnbox

7 Lockinglever

8 Kickplate

9 Airinletgrid(SÜ20202Tonly)

10 Deliveryunitap

11 Glasspanel

1 Productdeliveryunit(lightbarrieroptional)

2 Reinforcementforprotectivecover

3 Protectivecover

4 Inspectionwindow

5 Shaftcoupling

Machinediagram OPERATING INSTRUCTIONS

15316 00 540 02 _ 251

SÜ/ FS

Senderboard Receiverboard

Signal

Viewofproductdeliveryunitfromabove(withoptionallightbarrier)

2.5 Machines with R290 chiller unit

ForsafetyreasonsmachineswithchillerscontainingR-290refrigerant(propanegas,C3H8)

arettedwithagassensorinconjunctionwithaswitch-odevice.

Powersupplyboard

Gassensor

9-poleplug(reversepolarityprotected)

Serviceboard

Identicationplatewithsymbol“Warning

ammablesubstances”

Yellow - green - red

Red illuminates for 1 second

Self-testinitiated

Red is on permanently

Self-testfailed

Green is on permanently.

Self-testsuccessful

Yellow is on permanently

Mainsvoltageforthemachinehasbeenenabled.

OPERATING INSTRUCTIONS

16

Transport SÜ/ FS

316 00 540 02 _ 251

3 Transport

Observe the following instructions

▪Movethemachineonlywithapallettruckoraforklift.Placetheforksonthewidesideofthemachine.Removethe

kickplatesrst.

▪Donottransportthemachineintheair.

▪Alwaysmovethemachinewithcare.

▪Preventitfromslidingsideways.

▪Donotmovethemachineoninclinedramps,usestair-walkers.

▪Observethemachine'scentreofgravity.Duetoitsdesignthecentreofgravitycanbehigh.Riskoftippingover.

Storage

▪Thevendingmachineshouldbestoredinacleananddrylocation.Useasuitablecovertoprotectitfromdirt,humidity

anddamage.

▪Removetheproductsandleavethemachinedoorslightlyajartoallowthehumiditytoescape.

Temporary shutdown

Themachinemaybeshutdowntemporarily.

Howtoproceed

▪Removethemainsplug

▪Removetheproducts

▪Cleantheproductcontainers

▪Leavethemachinedoorajar

▪Tore-commissionrefertotherelevantsection

Centreofgravity

Installingthemachine OPERATING INSTRUCTIONS

17316 00 540 02 _ 251

SÜ/ FS

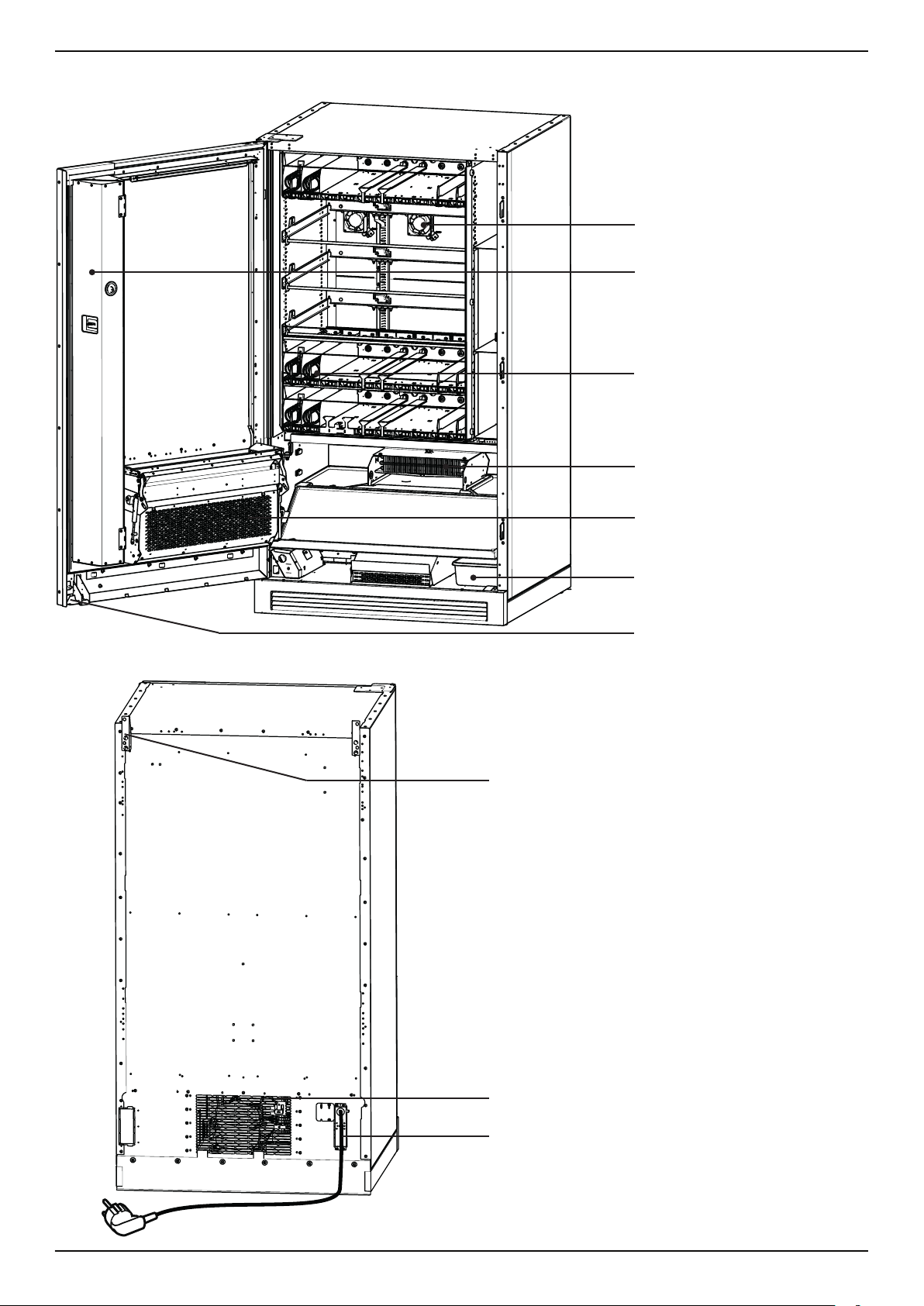

4 Installing the machine

4.1 Requirements on site

▪Themachinesaredesignedforindooruseonly.Theymustnotbeinstalledoutdoors.Exceptforspecial

outdoormod-

els

.

▪Theoormusthaveanadequateloadbearingcapacity.Notetheweight(refertotechnicaldata).

▪Themachinemustnotbeinstalledinaircontainingsaltorchlorine,suchasinanindoorswimmingpool.

▪Checkthattheambienttemperatureisinaccordancewiththeclimateclassofthechillerunit!

▪Donotinstallthemachineinplaceswherewaterhosesorahigh-pressurecleanerisused.

▪Themachine'sglassfrontmustnotbeexposedtodirectsunlight.Thechillerunitisnotdesignedforthis.

▪Inadverseweatherconditions(highhumidity,highoutdoortemperature)thefrontpanelsonthemachinemaymistup.

Thisisatemporaryoccurrenceandnotgroundsforcomplaint.

▪Themachinemustbeinalevelposition.

▪Themachineisdeliveredreadyforconnection,withcableandshock-proofplugforasingle-phaseACsupplyof230

V/50Hz.Ithastobepluggedintoaproperlyinstalledsocketwithearthconnection.Theplugmustbeeasilyaccessible

afterinstallation.Donotuseextensioncablesandmultiplesockets.

▪Apermanentinstallationshouldonlybecarriedoutbyaqualiedelectrician.

2x

50 mm

optional:

Floorxingkit

Part-No.6030263900

Wallspacerbracketskit

Part-No.6050103500

Standardmachine:120°

Outdoormachine:140°

OPERATING INSTRUCTIONS

18

Transport SÜ/ FS

316 00 540 02 _ 251

Kickplate

(optional)

Kickplate

(aerationslotsoptional)

4.2 Installation and commissioning

1. Unpack, position. level and secure the machine

2. Open the machine door; the key can be found at the back of the machine by the power cable

3. Remove transportation locks (if tted)

4. Establish electrical connection

5. Fit suction protection / kickplates (optional)

6. Fit coin mechanism (optional) etc.

7. Switch the machine on at main switch.

→ Themachineisoperationalwhen[READYTOUSE]isshowninthedisplay.

• Inordertoavoidthemachinetakinginthehotair,whichhasalreadybeendischarged,suctionprotectionmustbe

attachedtotherearofthemachine.Itmustbettedsothatitisushwiththeoor.

• Suctionprotectionisnotrequiredifthemachineisttedwitharearadvertisingpanel.

Suctionprotection

Transport OPERATING INSTRUCTIONS

19316 00 540 02 _ 251

SÜ/ FS

4x

4.3 Electrical connection

Standard machine

• Themachineisdeliveredreadyforconnection,withcableandshock-proofplugforasingle-phaseACsupplyof

230V/50Hz.Itmustbepluggedintoaproperlyinstalledsocketwithearthconnection.

• Donotuseextensioncablesandmultiplesockets.

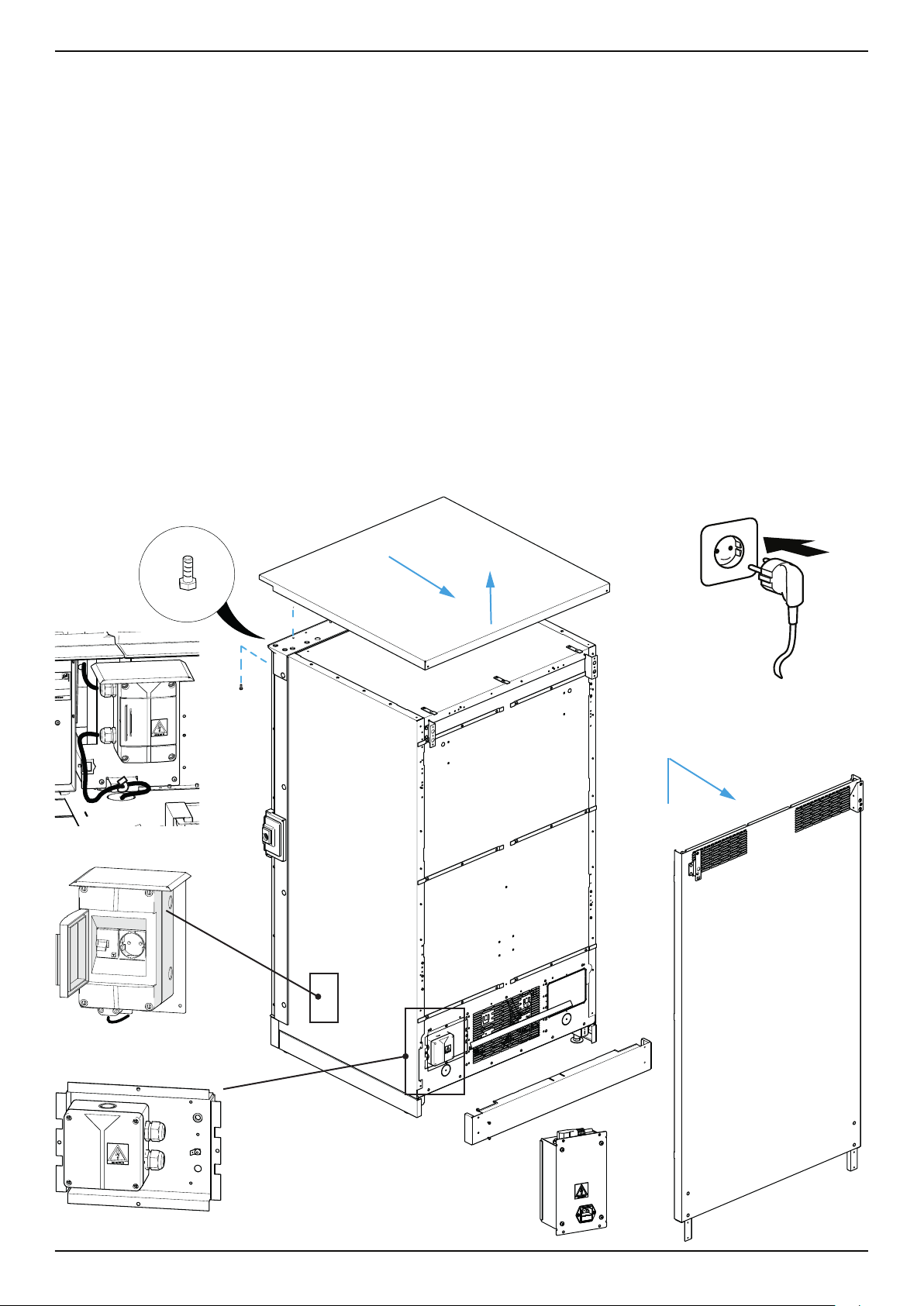

Outdoor machine

• Thexedconnection(hard-wired)shouldonlybeinstalledbyanelectrician

• Removetherainshield;removethe4hexagonalscrews,slidetheroof

backwardsanddetach.Removethebackpanel.

Takecarewhenmakingtheelectricalconnectiontothedistributorbox

Re-attachrainshieldandbackpanelinreverseorder.

• Theconnectioncablehastobeinstalledinawaythatitcannotbedamagedfromtheoutside.

• Includeadisconnectingdevicewithatleast3mmcontactopeningall-pole;fuseprotectionwithmax.16AF1

circuitbreakerwithmax30mAresidualcurrent

• JunctionboxwithF1andshockproofsocket:Themachine'spowercableispluggedintotheshockproofsocket.

Thisgivesthemachineitsownfuseprotection(F1-switch).

optional:

optional:

optional:JunctionboxwithF1

andshockproofsocket

OPERATING INSTRUCTIONS

20

Transport SÜ/ FS

316 00 540 02 _ 251

Coinmechanism

(optional)

Coinrefundmotor

Releaselever

Refundlever

MDB

connection

Motorizedcoinreturn

Holdingplate

4.4 Fitting a coin mechanism (optional)

Machinesaregenerallysetandtestedtoaspecicprotocolfortherelevantcoinmechanism.Fittingthecoinmecha-

nismisusuallycarriedoutbythecustomer.

4.5 Mounting the coin mechanism

Followtheinstructionsprovidedbythecoinmechanismmanufacturer.

Hangthecoinmechanisminthespaceprovided.Usealockingscrewwherepossible.

4.6 Setting the eccentric disc

Adjustthemotorisedcoinreturnsothatthereturnleveronthecoinmechanismisrmlyactivatedwhenpressing“R”

therefundbutton.Positionthecoininsertchutesothatthecoinscaneasilyfallintotheentryfunnelonthecoinmech-

anism.

4.7 Connecting the adapter kit

Thecoinmechanismandthemachinecontrolboard(VMC)mustbeconnectedelectrically.

KitforExecutive:................ 306 02 562 00

KitforBDV:........................ 310 01 530 00

Otheradapterkitsareavailableuponrequest.

Pluginmaleandfemaleconnectorssecurely.

4.8 Assigning software

1. Access the menu [INSTALLING MODE] M7: [ M ] + [ 7 ] + [ E ]

2. Access [CREDIT SYSTEM] by pressing [ M ] x 1. Press [ E ] to enter.

3. Press [1] to set the communications protocol e.g. [Executive].

4. Press [ E ] to enter.

5. Return to the main menu by pressing [ M ] + [ L ].

This manual suits for next models

27

Table of contents

Popular Vending Machine manuals by other brands

Seaga

Seaga SM16S Service and parts manual

SandenVendo

SandenVendo SVE C36-XS User and maintenance manual

Necta Vending Solutions SpA

Necta Vending Solutions SpA Zeta CB Series Installation - use - maintenance

Thames & Kosmos

Thames & Kosmos 550104 Experiment manual

Crane

Crane Linea user manual

Seaga

Seaga Intelligent Inventory Control IQ640 Service and parts manual