TC-2 07/2003

SAFETY SECTION..................................................................................... Pages S-1 - S-16

A COMMITMENT TO SAFETY.................................................................... Page S-2

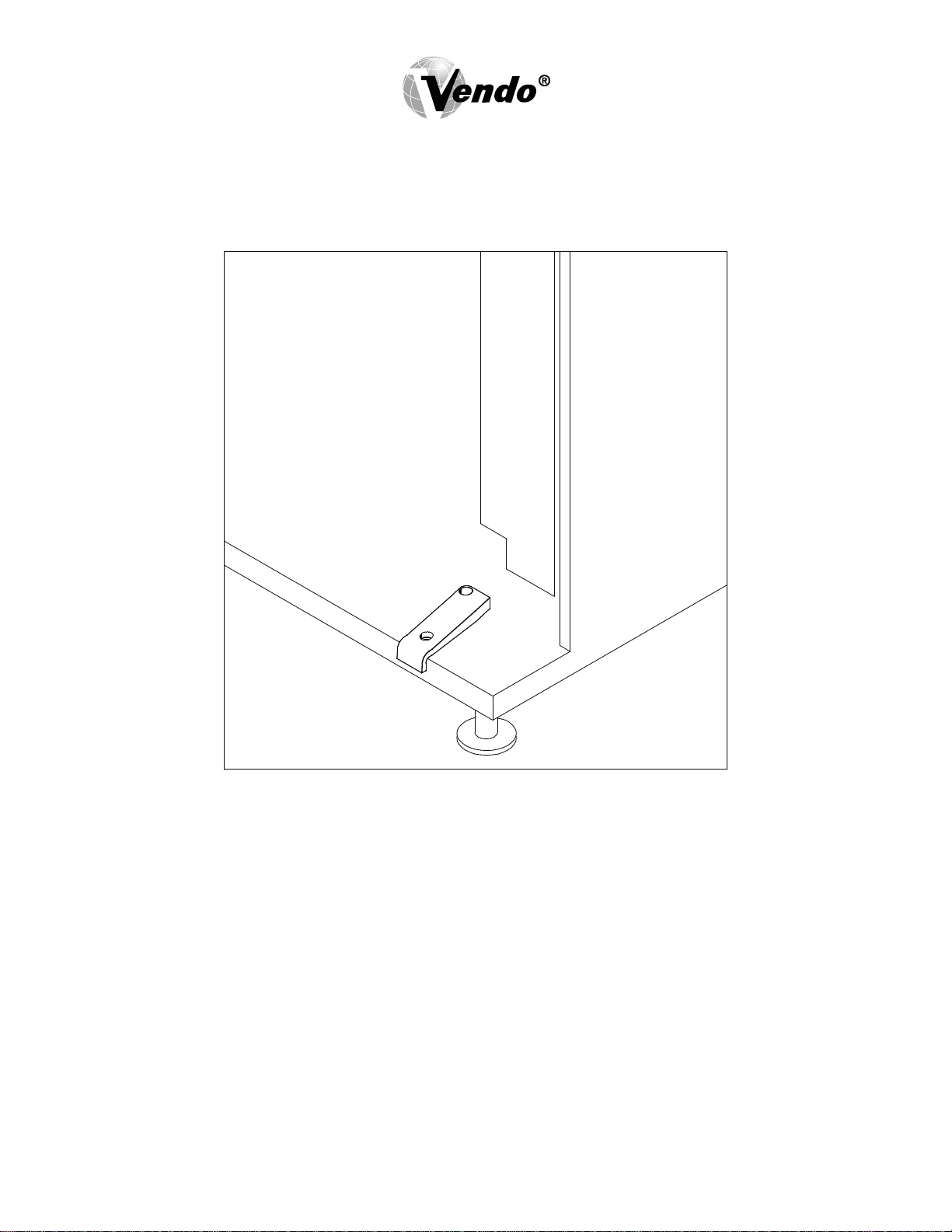

VENDOR INSTALLATION ........................................................................... Pages S-3 - S-6

ELECTRICAL HAZARDS ............................................................................ Pages S-7 - S-8

MECHANICAL HAZARDS........................................................................... Page S-9

REFRIGERATION HAZARDS ..................................................................... Page S-10

SUBSTITUTIONS AND MODIFICATIONS .................................................. Pages S-11 - S-12

CONSUMER SAFETY WARNING .............................................................. Page S-13

PARTS, SALES, AND SERVICE CENTERS OF VENDO/SANDEN CO..... Pages S-14 - S-15

GENERAL INFORMATION......................................................................... Pages G1 - G8

GENERAL INFORMATION.......................................................................... Page G-2

INITIAL SET-UP ......................................................................................... Pages G-3 - G-4

FLAVOR STRIP INSTALLATION................................................................. Page G-5

ALIGNMENT CHECKS................................................................................ Page G-5

LOADING INSTRUCTIONS ........................................................................ Page G-6

VEND MECHANISM PARTS DESCRIPTION ............................................. Pages G-7

CLEANING INFORMATION........................................................................ Pages CL1 - CL4

CARE AND CLEANING............................................................................... Page CL-2 - CL-3

PROGRAMMING SECTION ....................................................................... Pages PG-1 - PG-24

14.1 PROGRAMMING................................................................................. Page PG-2

SET-UP AND CODE DESCRIPTION .......................................................... Pages PG-3 - PG-19

14.1 WIRING DIAGRAMS........................................................................... Pages PG-20 - PG-21

ERROR CODE CHART............................................................................... Page PG-22

SPACE TO SALES ..................................................................................... Page PG-23

CABINET SECTION.................................................................................... Pages C-1 - C-19

READING A PARTS LIST............................................................................ Page C-2

HARDWARE LIST ....................................................................................... Pages C-3 - C-5

CABINET ASSEMBLY ................................................................................. Pages C-6 - C-7

CHUTE ASSEMBLY .................................................................................... Pages C-8 - C-9

POWER BOX ASSEMBLY .......................................................................... Pages C-10 - C-11

LEFT MODULE ASSEMBLY ....................................................................... Pages C-12 - C-13

RIGHT MODULE ASSEMBLY ..................................................................... Pages C-14 - C-15

REFRIGERATION ASSEMBLY ................................................................... Pages C-16 - C-17

HARNESS QUICK REFERENCE GUIDE ................................................... Pages C-18

DOOR SECTION......................................................................................... Pages D-1 - D-16

OUTER DOOR ............................................................................................ Pages D-2 - D-7

SELECTION PANEL.................................................................................... Pages D-8 - D-9

LOCK ASSEMBLY....................................................................................... Pages D-10 - D-11

COINAGE DOOR ASSEMBLY .................................................................... Pages D-12 - D-13

INNER DOOR ASSEMBLY.......................................................................... Pages D-14 - D-15

VARI-PAK TABLE OF CONTENTS