EVOCA Orchestra Touch Owner's manual

INSTALLATION, OPERATION, MAINTENANCE

Translation of original instructions

EN English

Doc. No. H5505EN00

Edition 1 01 - 2019

Orchestra Touch

DICHIARAZIONE DI CONFORMITA’ - DECLARATION OF CONFORMITY

- DÉCLARATION DE CONFORMITÉ - KONFORMITÄTSERKLÄRUNG -

DECLARACIÓN DE CONFORMIDAD - DECLARAÇÃO DE CONFORMIDADE -

VERKLARING VAN OVEREENSTEMMING - OVERENSSTEMMELSESERKLÆRING

- FÖRSÄKRAN OM ÖVERENSSTÄMMELSE - VAATIMUSTENMUKAISUUSVAKUUTUS

- ERKLÆRING OM OVERENSSTEMMELSE - PROHLÁŠENÍ O SHODĚ -

DEKLARACJA ZGODNOŚCI - ДЕКЛАРАЦИЯ СООТВЕТСТВИЯ -

IT La presente dichiarazione di conformità è rilasciata sotto l’esclusiva

responsabilità del fabbricante. Si dichiara che l’apparecchiatura, descritta

nella targhetta di identicazione, è conforme alle disposizioni legislative delle

Direttive Europee e successive modiche ed integrazioni.

Vengono riportate le norme armonizzate o le speciche tecniche (designa-

zioni) che sono state applicate in accordo con le regole della buona arte in

materia di sicurezza in vigore nella UE.

EN This declaration of conformity is issued under the manufacturer’s sole

responsibility. It is declared that the equipment described by the identication

plate is in compliance with the legal provisions of the European Directives as

well as its subsequent amendments and supplements.

The harmonised standards or the technical specications (designations) ap-

plied in compliance with the safety rules of good practice in force in the EU are

stated herein.

FR La présente déclaration de conformité est délivrée sous la responsabilité

exclusive du fabricant. On déclare que l’appareillage décrit sur la plaquette

d’identication est conforme aux dispositions législatives des Directives

européennes et leurs modications et intégrations ultérieures. Sont indiquées

les normes harmonisées ou les spécications techniques (désignations) qui

ont été appliquées conformément aux bonnes règles de l’art en matière de

sécurité en vigueur dans l’UE.

ES La presente declaración de conformidad se entrega bajo la exclusiva respon-

sabilidad del fabricante.Se declara que el aparato, descripto en la etiqueta de

identicación, es conforme con las disposiciones legislativas de las Directivas

Europeas y con sus sucesivas modicaciones e integraciones.

Se indican las normas armonizadas o las especicaciones técnicas (designacio-

nes) que han sido aplicadas de acuerdo con las reglas del buen arte en materia

de seguridad en vigencia en la UE.

DE Diese Konformitätserklärung wurde unter ausschließlicher Verantwor-

tung des Herstellers verfasst. Es wird erklärt, dass das auf dem Typenschild

beschriebene Gerät den gesetzlichen Bestimmungen der Europäischen

Richtlinien und anschließenden Änderungen und Ergänzungen entspricht. Es

werden die harmonisierten technischen Spezikationen (Bestimmungen) auf-

geführt, die gemäß den Regeln der Kunst hinsichtlich den in der EU geltenden

Sicherheitsnormen angewendet wurden.

PT A presente declaração de conformidade é emitida sob exclusiva respon-

sabilidade do fabricante. Declara-se que o equipamento, descrito na placa

de identicação, está em conformidade com as disposições legislativas das

Diretivas Europeias e sucessivas modicações e integrações. São indicadas

as normas harmonizadas ou as especicações técnicas (designações) que

foram aplicadas de acordo com as regras de boa engenharia em matéria de

segurança, em vigor na UE.

Direttive europee

European directives

Sostituita da

Repealed by

Norme armonizzate / Speciche tecniche

Harmonised standards / Technical specications

2006/95/CE 2014/35/EU (LVD) EN 60335-1:2012 + A11:2014

EN 60335-2-75:2004 + A1:2005 + A11:2006 +

A2:2008 + A12:2010

EN 62233:2008

2006/42/EC (MD) EN60335-1:2012+A11:2014

97/23/EC 2014/68/UE (PED) EN60335-1:2012+A11:2014

2004/108/EC 2014/30/EU (EMC) EN 55014-1:2006+A1:2009+A2:2011

EN 55014-2:2015

EN 61000-3-2:2014

EN 61000-3-3:2013

EN 61000-3-11:2001

2002/72/CE+2008/39/CE

EC 1935/2004 EN16889:2016 EDQM Practical Guide CM/RES (2013)9

EC10/2011 EC10/2011+UE2016/1416

EC 2023/2006 (GMP)

2002/95/EC 2011/65/UE (RoHS) EN 50581:2012

2002/96/CE 2012/19/UE (WEEE)

2014/53/EU * (RED) EN62311:2008

EN60335-1:2012+A11:2014

EN60335-2-75:2004+A1:2005+A11:2006

+A2:2008+A12:2010

ETSI EN 301 489-1 V1.9.2:2011

ETSI EN 301 489-17 V2.2.1:2012

ETSI EN 301 328 V2.1.1:2016

ANDREA ZOCCHI

C.E.O

Il fascicolo tecnico è costituito e disponibile presso:

The technical le is compiled and available at: Evoca S.p.A.

NL Deze verklaring van overeenstemming wordt uitsluitend onder de

verantwoordelijkheid van de fabrikant verstrekt. Men verklaart dat het ap-

paraat, beschreven op het identicatieplaatje, overeenstemt met de wettelijke

bepalingen van de Europese Richtlijnen en daaropvolgende wijzigingen en

aanvullingen.Hierna worden de geharmoniseerde normen of de technische

specicaties (aanwijzingen) aangegeven die toegepast werden in overeen-

stemming met de regels van de goede techniek op gebied van veiligheid, die

in de EU van kracht zijn.

DA Denne overensstemmelseserklæring udstedes ene og alene på fabrikan-

tens ansvar. Det erklæres hermed, at apparaturet, der er beskrevet på udsty-

rets typeskilt, opfylder de lovgivningsmæssige i krav i de europæiske direktiver

samt senere ændringer og tilføjelser. De anvendte harmoniserede standarder

eller tekniske specikationer (betegnelser), som er anvendt i overensstemmel-

se med reglerne i de tekniske sikkerhedsforskrifter gældende i EU.

SV Denna försäkran om överensstämmelse utfärdas av tillverkaren på dennes

egna ansvar.Vi försäkrar att utrustningen, som beskrivs på märkskylten,

överensstämmer med lagar och författningar i EU-direktiven och i ändrad och

kompletterad lydelse. Harmoniserade standarder eller tekniska specikationer

(beteckningar) återges som har tillämpats enligt sunda tekniska principer i frå-

ga om säkerheten som gäller inom EU och som anges i listan på samma sida.

FI Tämä vaatimustenmukaisuusvakuutus annetaan valmistajan yksinomaisen

vastuun alla.Vakuutamme, että arvokilvessä kuvattu laite vastaa neuvoston

direktiivejä sekä niihin liittyviä muutoksia ja täydennyksiä. Lisäksi annetaan

yhdenmukaistetut standardit tai tekniset erittelyt (käyttötarkoitukset), joita on

sovellettu EU-maissa, voimassa olevien turvallisuutta koskevien valmistukseen

liittyvien määräysten ohella.

NO Denne samsvarserklæringen er utferdiget under eneansvar av produ-

senten. Det erklæres at apparatet, beskrevet på typeskiltet, er i samsvar med

gjeldende europeiske direktiver og senere endringer og tillegg. Harmoniserte

standarder eller tekniske spesikasjoner (betegnelser) anvendt i samsvar med

EUs gjeldende sikkerhetsregler er angitt.

RU Настоящая декларация соответствия выдается только под экс-

клюзивной ответственностью изготовителя. Свидетельствуется, что

оборудование, описанное в идентификационной табличке, соответствует

законодательным положениям Европейских Директив, а также после-

дующим изменениям и дополнениям. Приводятся гармонизированные

нормы или технические спецификации (указания), которые были при-

менены в соответствии с правилами качественного выполнения работ в

отношении безопасности, действующими в ЕС.

*Solo con moduli radio di Evoca S.p.A. / Only with radio modules of Evoca S.p.A.

Ed. 11 17

EVOCA S.p.A.

ad unico socio

Sede amministrativa e operativa: Via Roma 24

24030 Valbrembo (BG) Italia

Tel +39 035 606111

Fax +39 035 606463

www.evocagroup.com

Sede legale: Via Tommaso Grossi 2

20121 Milano (MI) Italia

Cap. Soc. € 41.138.297,00 i.v.

Reg. Impr. MI, Cod. Fisc. e P.IVA: 05035600963

Reg. Produttori A.E.E.: IT08020000001054

Cod. identicativo: IT 05035600963

Declaration of conformity

The declaration of conformity is

issued under the manufacturer’s

sole responsibility.

The declaration of conformity with

the European Directives and Standards

provided for by the laws in force is supplied

by the rst page of this manual, which is an

integral part of the machine.

-The legal provisions of the European

Directives in force (with the subsequent

amendments and integrations thereof)

-The harmonised standards in force

-The technical specifications (designa-

tions) applied in compliance with the

safety rules of good practice enforced in

the EU and listed on the same page.

integration of radio modules

In compliance with Article 17 of Direc-

tive 2014/53/EU (RED), the manufacturer

checks whether the radio equipment is in

compliance with the essential requirements

of article 3 of the Directive.

The procedure used to check compliance

is at the manufacturer’s discretion.

If a radio module is built in a “non-radio”

equipment, the subject integrating the

module will become the manufacturer of

the end product and it must therefore check

the compliance of the end product with the

essential requirements of the 2014/53/EU

(RED) Directive.

As a matter of fact, the integration of radio

modules in other products can inuence

the compliance of the end product with the

essential requirements of the Directive.

definitions according to the law

The manufacturer is a natural person who

or a public body which manufactures radio

equipment and/or electric material or has it

engineered, manufactured or marketed by

putting its own trademark or name on it.

An importer or distributor who places

radio equipment or electric material on the

market by putting its own name or trade-

mark becomes the manufacturer.

An importer or distributor who makes any

change to radio equipment or electric mate-

rial already placed on the market to such an

extent that the said change may condition

the compliance with the listed directives

is held to be the manufacturer and it must

therefore assume the relative obligations

according to the said directives.

Symbology

The following symbols may be present

inside the machines, according to models

(signs of danger)

Attention: dangerous voltage

Power o before removing the

cover

Attention

Danger of crushing your han-

ds

Attention

Hot surface

The signs of danger must be readable

and visible; they shall be neither hidden

nor removed. Damaged or unreadable

labels must be replaced.

Warnings

This document intended for the technical

personnel is made available in the electron-

ic format at the manufacturer's (reserved

area web site).

for installation

The installation and any subsequent

maintenance operation shall be carried

out by the personnel skilled and trained

on the utilisation of the machine ac-

cording to the rules in force

The use of kits and/or accessories not

type-approved by the manufacturer can not

guarantee the observance of safety stand-

ards, in particular for live parts.

The installer will be the sole person respon-

sible for any damage improper installation

may cause to the machine or to things and

people.

The manufacturer declines all responsibility

for the use of non type-approved compo-

nents.

Assembly and any testing operation

must be carried out by qualied per-

sonnel who have a specic knowledge

of the machine operation from the point

of view of electric safety and health

rules.

The intactness of the machine and its

compliance with the standards of rel-

evant installations must be checked by

skilled personnel at least once a year.

Package materials must be disposed of in

observance of the environment.

For the vending machines of hot drinkts

only

The machine is equipped with an automatic

washing system for the mixers with the rela-

tive water circuit and the brewing unit.

If the machine is not used for some time

(weekends, etc.) even for pauses longer

than two days, it is recommended to enable

the automatic washing functions (e.g. be-

fore starting to use the VM.

for use

The machine can be used by children over

8 years and by people having reduced

physical, sensorial or mental skills under

the supervision of people responsible for

their safety or specically trained on the

use of the machine.

Children shall not be allowed to play with

the machine by the people in charge of

their supervision

Children shall not be allowed to clean or

service the machine.

for the environment

Some tricks will help you to protect the

environment:

-use biodegradable products to clean the

machine;

-properly dispose of all the packages of the

products used to fill and clean the ma-

chine;

-power off the machine during inactivity for

energy saving.

for dismantling and disposal

When dismantling the machine, it is rec-

ommended to destroy the machine rating

plate. The symbol shows that the ma-

chine can not be disposed of as

common waste, but it must be

disposed of as it is established by

the 2012/19/EU (Waste Electrical

and Electronic Equipment - WEEE)

European Directive and by the national

laws arising out of it in order to prevent any

negative consequence for environment and

human health.

The dierentiated collection of the machine

at the end of its life is organised and man-

aged by the manufacturer.

For the correct disposal of the machine

contact the sales point where you have

purchased the machine or our after-sales

service.

The unlawful disposal of the machine im-

plies the application of the administrative

sanctions provided for by the rules in force.

Attention!

If the machine is equipped with a cooling

system, the cooling unit contains HFC-

R134a uoridised greenhouse eect gas

ruled by the Kyoto protocol, the total heat-

ing potential of which is equal to 1300.

INTRODUCTION 1

transport and storagE 1

in casE of failurE 2

idEntification of thE machinE and its fEaturEs 2

using thE vEnding machinEs of hErmEtically sEalEd prod-

ucts 3

positioning thE vEnding machinE 3

tEcHNical fEaturEs 4

variablE combination lock 6

LOADING AND CLEANING 7

food hygiEnE, clEaning and safEty 7

main switch 7

coNtrols aND compoNENts 8

visioshop trays 9

softvEnd 11

proDuct loaDiNg 12

powEr on 15

opEration tEmpEraturE 15

clEaNiNg at rEgular iNtErvals 15

clEaning thE vEntilation grids of thE cooling systEm16

INSTALLATION 17

main switch 17

unpacking thE vEnding machinE 18

intErnal componEnts 18

paymEnt systEm assEmbly 19

ElEctric connEction 20

cooling unit 21

first powEr-on 21

opEratioN 22

trays 22

dispEnsing compartmEnt lock 22

softvEnd 22

dispEnsing compartmEnt automatically opEnablE 23

display on trays 23

NOTES 25

powEr on 25

Normal opEratioN moDE 26

programming and navigation modE 29

fillEr mENu 30

statistics 30

print 30

display 30

dElEtE 30

iNDiviDual pricE 31

maNagEmENt of cHaNgE tubEs 31

spEcial sElEctioNs 31

virtual sElEctions 31

virtual pricE rEturn 31

two-motor sElEctions 32

photocEll paramEtErs 32

tEst 32

tEst sElEction 32

motor tEst 32

autotEst 32

tEmpEraturE tEst 33

EvaDts 33

connEction 33

tEcHNiciaN mENu 34

paymENt systEms 34

validator 34

ExEcutivE 34

bdv 35

mdb 36

pricEs 40

individual pricE 40

global pricE 40

promotional timE band 40

4 pricE bands 40

EnablE sElEctions 41

multi-salE discount 41

vm coNfiguratioN 41

datE and timE sEt 41

cooling paramEtErs 41

db managEmEnt 43

display 43

mEnu managEmEnt 46

spirals/sElEctions 46

softvEnd paramEtErs 48

photocEll paramEtErs 50

dispEnsing compartmEnt lock paramEtErs 50

EnErgy saving 51

machinE lighting out of sErvicE 51

vm sErial numbEr 51

programming thE opErator codE 51

installation datE 51

mastEr / slavE 52

tEst 53

tEst sElEction 53

motor tEst 53

autotEst 53

tEmpEraturE tEst 54

English

statistics 54

ElEctronic countEr 54

Eva dts 55

rEsEt 56

display statistics 56

dElEtE statistics 56

display rElativE statistics 56

dElEtE rElativE statistics 57

print statistics 57

commuNicatioN 59

up-kEy 59

failurEs 59

rEading failurEs 59

failurE rEsEt 60

motor Errors 60

motor statE 61

motor Error rEsEt 61

failurE history filE 61

failurE history filE rEsEt 61

grapHical scrEEN 61

nutritional information 61

list of sElEctions (baskEt function) 61

numbEr of products in thE baskEt 61

usb mENu 62

up-kEy 62

sEtup managEmEnt 62

upkEy statistics managEmEnt 62

playlist grapHic sEtup 62

sEtup 62

mmi 62

playlist 62

product databasE 62

complEtE backup 62

statistics 62

toucH mENu 63

Display 63

contrast rEgulation 63

touchscrEEn calibration 63

touch scrEEn clEaning 63

product shEEt changE 63

languagE changE function 63

tEchnical support contacts 63

scrEEn savEr 63

configuration of promotions 63

configuration of product catEgoriEs 63

sElEction labEl changE (planogram) 63

NEtwork coNfiguratioN 64

EthErnEt EnablE 64

ip addrEss 64

subnEt mask 65

gatEway 65

dns 65

mac addrEss 65

softwarE rElEasE 65

MAINTENANCE 66

main switch 66

coNfiguratioN of visiosHop trays 67

product spacEr 70

walls of compartmEnts 71

brackEt for bottlE bridgE with springs 71

spiral guidE 71

product dividEr 72

product raisEd support 72

hEat sEparators 73

product EjEctor 74

rEmoving trays 74

rEplacing spirals 75

changing thE numbEr of trays 77

rEclining trays 77

configuration of bottlE / can trays 78

rEinforcEmEnts and maximum loads visioshop tray 79

assEmbling and rE-positioning pricE labEls 79

rEfrigEratED box coNfiguratioN 80

boarD fuNctioNs 81

cpu board 81

glassfront lighting board 82

compartmEnt lighting board 82

touch scrEEn 82

softwarE updatE 83

ElEctric panEl 83

accEss to thE cooling unit 84

APPENDIX 85

01-2019 5505 00 1

Introduction

The technical documentation supplied

is an integral part of the equipment and

it must therefore accompany the equip-

ment whenever it is either moved or

transferred to enable the various opera-

tors to consult it.

Before starting to install and use the ma-

chine, it is necessary to carefully read and

understand the content of the documenta-

tion since it can supply important informa-

tion on installation safety, utilisation rules

and maintenance operations.

Some illustrations of this manual might

show details or parts which deviate from

those of the machine without changing the

basic information whatsoever.

The manual is divided into tree chap-

ters.

The rst chapter is intended to describe the

ordinary lling and cleaning operations that

shall be carried out in areas of the machine

that can be accessed with the simple use of

the door key, without using any other tool.

The second chapter contains the instruc-

tions for correct installation as well as the

information necessary for optimal utilisation

of the machine performance.

The third chapter is intended to describe

the maintenance operations involving the

use of tools for access to potentially dan-

gerous areas.

The operations described in the second

and third chapter must be carried out

only by the personnel who have a spe-

-

tion from the point of view of electric

safety and health rules.

TRANSPORT AND STORAGE

traNsport

To avoid any damage to the equipment and

any injury to the people, the equipment

must be handled with great care.

While handling, there is the danger of

crushing one's hands and/or feet: never

shoes.

Handle the equipment by using lifting

means suitable for the size and the

weight of the equipment (e.g. lifting

Lifting means may only be used by per-

Please avoid:

-overturning and/or tilting the equipment;

-dragging or lifting the equipment by means

of ropes or alike;

-lifting the equipment by its sides;

-shaking or impacting the equipment and

its package.

storagE

The storage area must be dry and its tem-

perature lie between 0 and 40°C

If the equipment should freeze, condition it

at a temperature between 0° and 40°C.

Wait for the temperature of the equipment

to adjust to the room temperature before

powering it on.

Before powering on the equipment, please

wait for the humidity condensate (if any) to

dry completely.

201-2019 5505 00

IN CASE OF FAILURE

In most cases, any technical problem can

be solved by carrying out minor operations.

As a consequence, we suggest carefully

reading this manual before contacting the

manufacturer.

In case of failures or malfunctions that can

not be solved, please apply to:

Evoca S. p. A.

Via Roma 24

24030 Valbrembo

Italy - Tel. +39 035606111

IDENTIFICATION OF THE

MACHINE AND ITS FEATURES

Every single machine is identied by a spe-

cic serial number that can be found on the

rating plate arranged inside.

The plate is the only one recognised by the

manufacturer and it contains all the data

that enable the manufacturer to supply

technical information of any kind in a quick

and safe manner and to facilitate the man-

agement of spare parts.

TYPECODE MODEL SERIAL NR

BOILER SOLUBLE

PRESSURE Mpa

CAPACITY dm3

MAINS WATER PRESSURE

VOLTAGE FREQUENCY

POWER CURRENT

WPOWER

CAFE VAPOUR

Mpa Min - Max

REFRIGERATOR SYSTEM

1

2

3

4

5

6

7

8

9

Fig. 1

1. product code

2. type

3. model

4. operating voltage

5. absorbed power

6. serial number

7. frequency

8. current

9. type and quantity of refrigerating gas

01-2019 5505 00 3

USING THE VENDING MACHINES

OF HERMETICALLY SEALED

PRODUCTS

The control electronics of the machine ena-

bles you to separately assign every single

selection a dierent sales price.

In its maximum conguration, the machine

can be used at the same time to:

-Dispense products requiring no refrigera-

tion (snacks)

-Dispense products requiring refrigeration

for preservation (food).

The preservation of these products is

guaranteed by the “food” area of the ma-

chine; the food area can be recognised by

the presence of labels on dividing trays.

-Dispense food drinks originally sealed.

-

-

pliance with hygiene and food safety

needs.

Strictly comply with the producer’s

instructions on the temperature of

preservation and the pull date for each

product.

Any other use shall be considered as

improper and thus potentially danger-

ous.

POSITIONING THE VENDING

MACHINE

The machine is not suitable for installation

outdoors. It must be installed in a dry room

at a temperature ranging from 5°C to 32°C.

It can not be installed in a room where

water jets are used for cleaning (e.g. large

kitchens, etc.).

The machine shall be placed near a wall.

The ventilation system enables you to place

the back of the machine against the wall,

thus saving space, since air is aspirated

from the bottom and discharged through a

grid in the front.

If not correct, ventilation can com-

promise the good operation of the cool-

ing unit.

The machine must be arranged in such a

way that the maximum inclination will not

exceed 2°.

If necessary, level it by using the adjustable

feet.

401-2019 5505 00

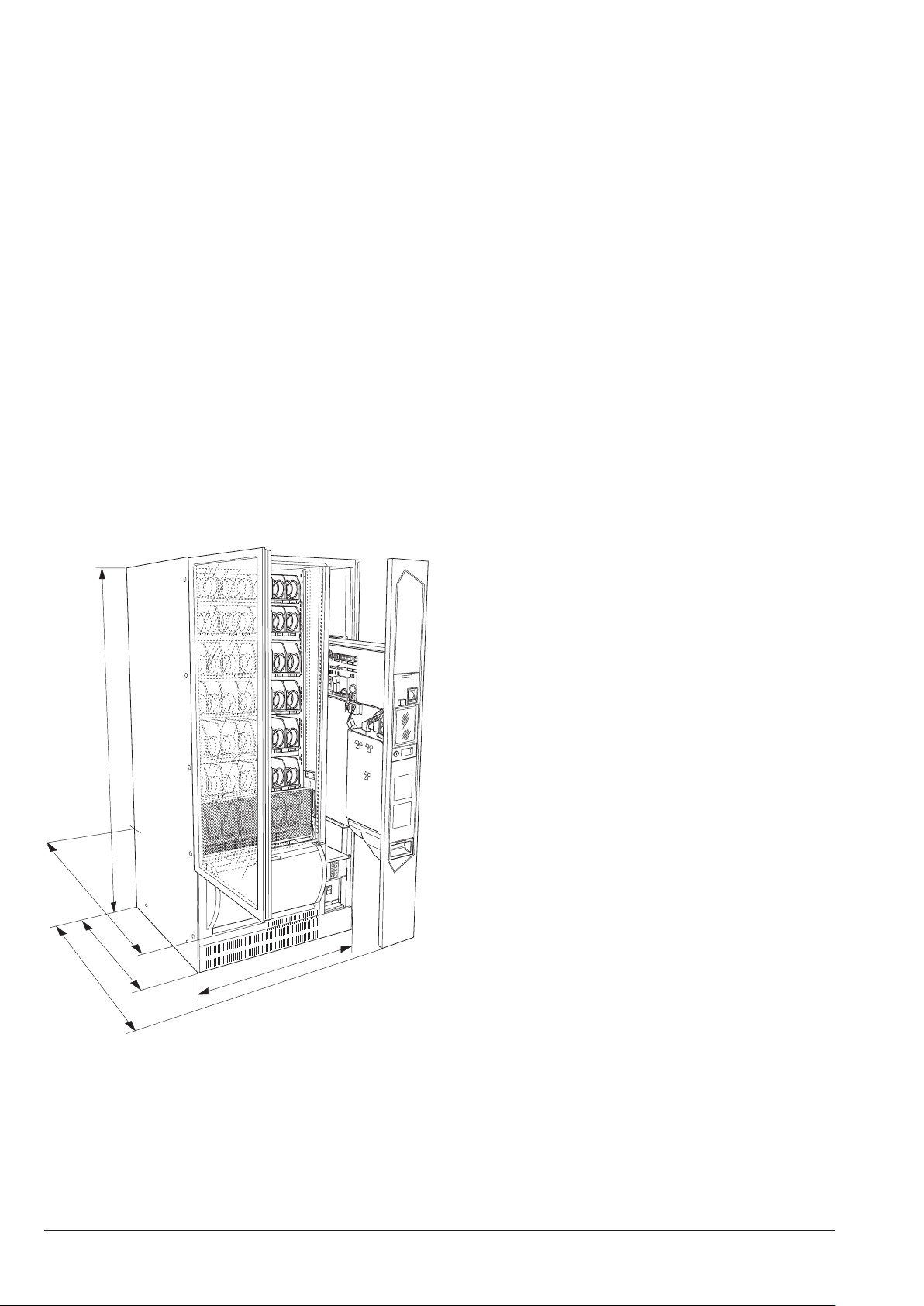

TECHNICAL FEATURES

-Height mm 1830

-Width mm 890

-Depth mm 793

-Overall dim. with open door mm 1495

-Overall dim. with open slide-in interface

mm 1205

-Loadless weight Kg 280

-Power supply voltage V∿ 230/240

-Power supply frequency Hz 50/60

-Maximum power W 360

maximum opEratiNg coNDitioNs:

-Room temperature °C 32

-Relative humidity % 65

cooliNg systEm:

-Ventilated evaporator

-Programmable defrost cycle

1830

1495

1205

890

793

Fig. 2

NoisE lEvEl

The continuous, equivalent, weighted

sound pressure level is below 70 dB.

paymENt systEm

The machine can be electrically arranged

for the systems with an Executive, BDV and

MDB protocol and for the assembly of 24

Vdc validators.

The space is not only arranged to accom-

modate the coin mechanism, but also to

assemble the most widespread payment

systems (optionals).

ligHtiNg

By means of LEDs; the light produced by

LED's is generally screened by the glass-

front (no risk or risk-free).

If lighting is active without shielding for any

reason whatsoever (moderate risk), never

salEs pricEs

For every single selection you can set a dif-

ferent sales price on 4 programmable time

bands for each day of the week.

According to factory settings, the sales

price is the same for all selections and no

time band is used.

coiN box

You can also mount a cover and a lock.

coNtrols aND safEty DEvicEs

-manual main switch

-maximum sales motor supply time

-compressor heat protection

-fuses on the primary and secondary trans-

former

-motor protection PTC

-safety temperature control for preserving

food products

-slide-in user interface opening control

-glassfront opening control.

01-2019 5505 00 5

accEssoriEs

Accessories can be mounted on the ma-

chine to vary performances.

The accessories and kits that can be ap-

plied on the equipment are made available

at the manufacturer’s.

The accessories and kits are supplied with

mounting and testing instructions that shall

be strictly followed to preserve the machine

safety.

The installer is the sole person responsi-

ble for any damage improper installation

may cause to the machine or to things and

people.

Important !!!

The use of accessories and kits not type-

approved by the manufacturer can not

guarantee the observance of safety stand-

ards, in particular for live parts.

The manufacturer declines all responsibility

for the use of non type-approved compo-

nents.

Assembly and any subsequent test-

ing operation must be carried out by

from the point of view of electric safety

and health rules.

ElEctric ENErgy coNsumptioN

The electric energy consumption of the ma-

chine will depend on many factors, such as

temperature, room ventilation, equipment

location, product loading temperature and

refrigerated box temperature.

On the following conditions:

-The room temperature is 25°C

-The temperature inside the refrigerated

box is 3°C (food version) and 8°C (snack

version)

-The temperature of loaded products is 5°C

The following daily average consumption

values were measured:

-Food version 7 KW

-Snack version 5 KW

The energy consumption calculated on

the values above shall be understood as

merely indicative.

601-2019 5505 00

VARIABLE COMBINATION LOCK

Some models are supplied with a variable

combination lock.

The lock is complete with a silver key, with

the standard combination, for opening and

closing.

It is possible to customise the locks by us-

ing a kit made available as an accessory

and intended to change the lock combina-

tion.

The kit is composed by a change key

(black) of the current combination as well

as by change (gold) and use (silver) keys of

the new combination.

Sets of change and use keys with other

combinations can be supplied upon re-

quest.

Moreover, further sets of use keys (silver)

may be requested by specifying the combi-

nation stamped on the keys.

usual opening operations since this

To change the combination:

1. Open the door of the equipment to avoid

having to force the rotation;

2. Slightly lubricate by using a spray inside

the lock;

3. Insert the current change key (black) and

turn it until you reach the change posi-

tion;

4. Remove the current change key and

insert the change key (gold) with the new

combination;

5. Turn the change key slightly several

times without completing the rotation

6. Turn it until you reach the close position

and remove the change key.

The lock has now assumed the new combi-

nation.

no longer used.

time, it is recommended to lubricate the

Other types of lubricants may trap dirt

0°

90°

Fig. 3

01-2019 5505 00 7

Chapter 1

LOADING AND CLEANING

The machine is not suitable for installation

outdoors. It must be installed in a dry room

at a temperature ranging from 5°C to 32°C.

It can not be installed in a room where

water jets are used for cleaning (e.g. large

kitchens, etc.).

FOOD HYGIENE, CLEANING AND

SAFETY

The operator of an automatic vending

machine is responsible for its hygiene

and cleaning on the basis of the health

and safety rules in force.

The machine is arranged to sell and dis-

pense products that do need refrigeration

to be preserved (food).

The vending machine can be used to sell

and dispense packaged products that

do not need refrigeration to be preserved

(snacks).

-

ance with food safety requirements.

For all products strictly comply with

the producer’s instructions on the stor-

age method and pull date for each

product.

Any other use shall be considered as

improper and thus potentially danger-

ous.

Some parts of the machine can be dam-

aged by corrosive detergents.

The manufacturer disclaims all respon-

sibility for any damage caused to peo-

ple by the non-observance of the rules

in force.

MAIN SWITCH

To access the main switch, extract the

slide-in interface.

The manual main switch will power o the

electric installation of the equipment to ser-

vice and clean on fully safe conditions.

Only the parts protected by covers and

signalled by the following symbol re-

main live inside the machine.

Before removing these covers, detach

the power supply cable from the mains.

801-2019 5505 00

CONTROLS AND COMPONENTS

The controls and information for the user

are arranged on the slide-in interface.

The credit and the operation messages are

displayed.

To dispense a product, dial the selection

number corresponding to the product you

wish.

The machine can have the following stand-

ard or optional components:

-visioshop modular trays equipped with

variable-width compartments are pre-con-

figured for dispensing various products

-Trays configured for dispensing sandwich-

es

- softvEnd pocket for placing the dispensed

products in the dispensing compartment

-Product passage photocells

-Dispensing compartment automatically

openable

-Display on tray

12

3

4

5

6

7

8

9

10

11

12

13

14

15

Fig. 4

1. glassfront

2. glassfront opening grip

3. trays

4. advertising space

5. slide-in interface

6. coin insert

7. coin return button

8. touch screen

9. lock and handle intended to open the slide-in

compartment

10. space for instructions

11. coin return flap

12. softvend (optional)

13. main switch

14. dispensing compartment

15. feet cover grid

01-2019 5505 00 9

VISIOSHOP TRAYS

Trays are pre-congured for dispensing

most products.

The compartments may be of dierent

sizes (single, double or of greater width)

according to the dimensions of the prod-

ucts you wish to dispense.

The compartments of trays can be cong-

ured for:

sNacks aND rEfrigEratED proDucts

No special accessory is necessary to dis-

pense snack products.

The products requiring refrigeration

for preservation must be placed in the

4

1 2 3

Fig. 5

1. single compartment

2. double compartment

3. walls

4. wide compartment

Narrow proDucts

The products having “narrow” packages

(e.g. cereals bars, etc.) can be dispensed

only by using the special spacer.

1

Fig. 6

1. spacer

sticks of caNDiEs aND/or alikE

A divider is used to dispense sticks of can-

dies and/or similar products; the spirals of

these compartments rotate by 180° only, in-

stead by 360°, thus doubling the autonomy

of the compartment.

1

Fig. 7

1. divider

10 01-2019 5505 00

caNs aND juicE iN tEtrapacks

Cans up to 69 mm in diameter and juice in

0.2 lt tetrapacks can be dispensed by every

single compartment having the product

raised support;

1

2

3

Fig. 8

1. selection label / tray display support

2. product raised support

3. spiral guide

bottlEs

Plastic bottles whose cap is turned up-

wards can be dispensed by using the re-

tainer bridge (with springs) and the product

raised support

The compartments complete with the re-

tainer bridge can dispense:

-0.33/0.5/0.6 litre plastic bottles

-0.375 / 0.5 litre cans

-0.25/0.33 litre "slim" cans

vertically, thus improving the readability of

the product label.

Fig. 9

Table of contents

Other EVOCA Vending Machine manuals

Popular Vending Machine manuals by other brands

MEI

MEI Cashflow 690 series Quick reference card

Coca-Cola

Coca-Cola Freestyle 9100 user guide

WAYFARER

WAYFARER TGX150 Service manual

American Games

American Games MAXIM 4200 Operator's manual

Seaga

Seaga Space Saver Series Operator's manual

Evoca Group

Evoca Group Snakky SL Installation, use and maintenance manual