Rev.1 – 01.2016.EL950.1.9 4

OVERVIEW

Thismanual covers Installation, Setup, Programming and Service instructions. It is extremely important that

this manual be read thoroughly prior to commissioning the vending machine in the field. This will ensure a

satisfactory long-term performance.

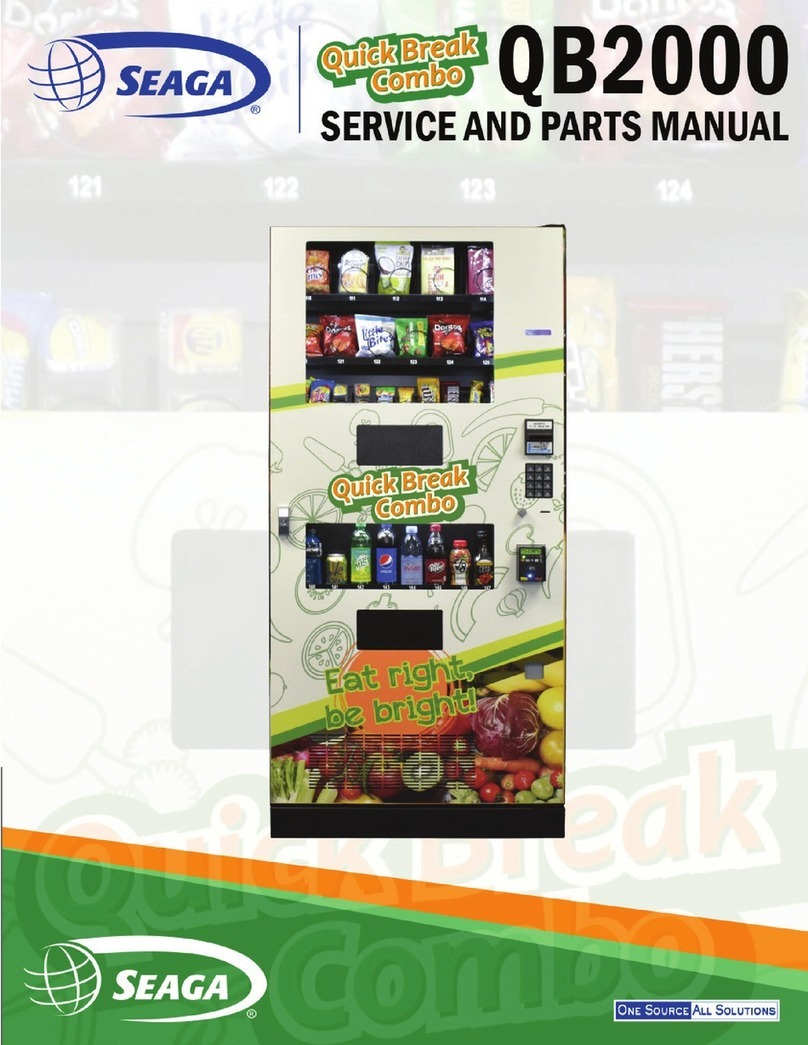

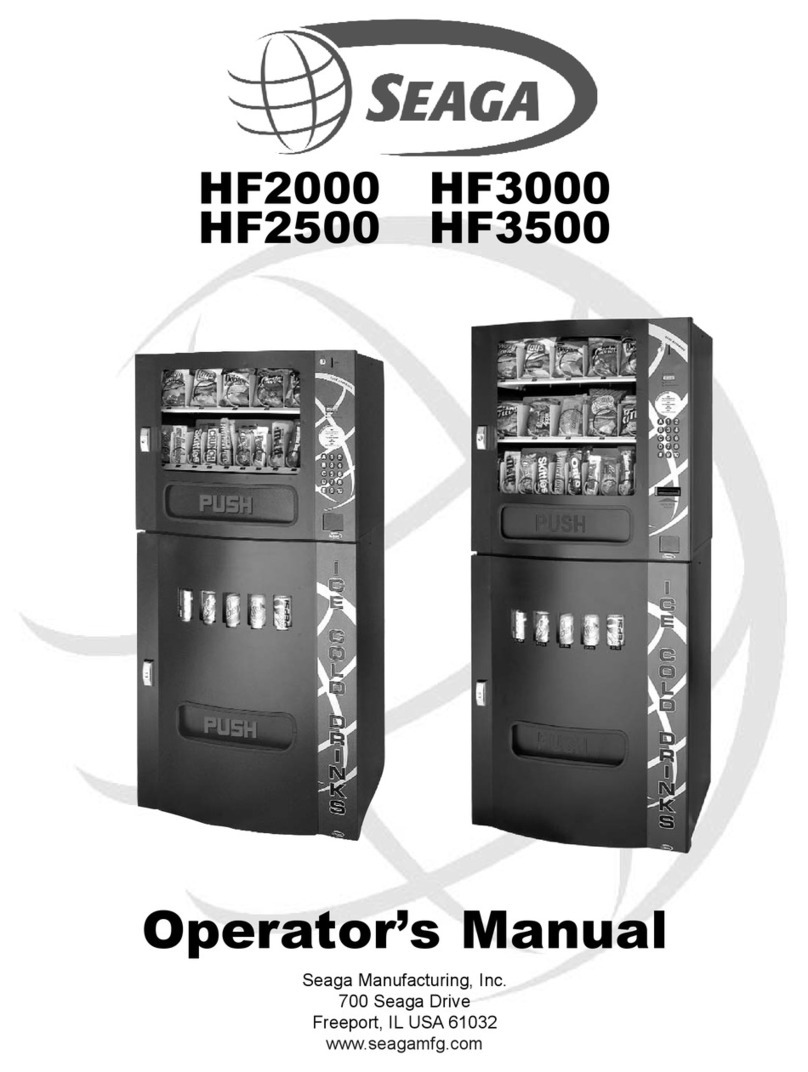

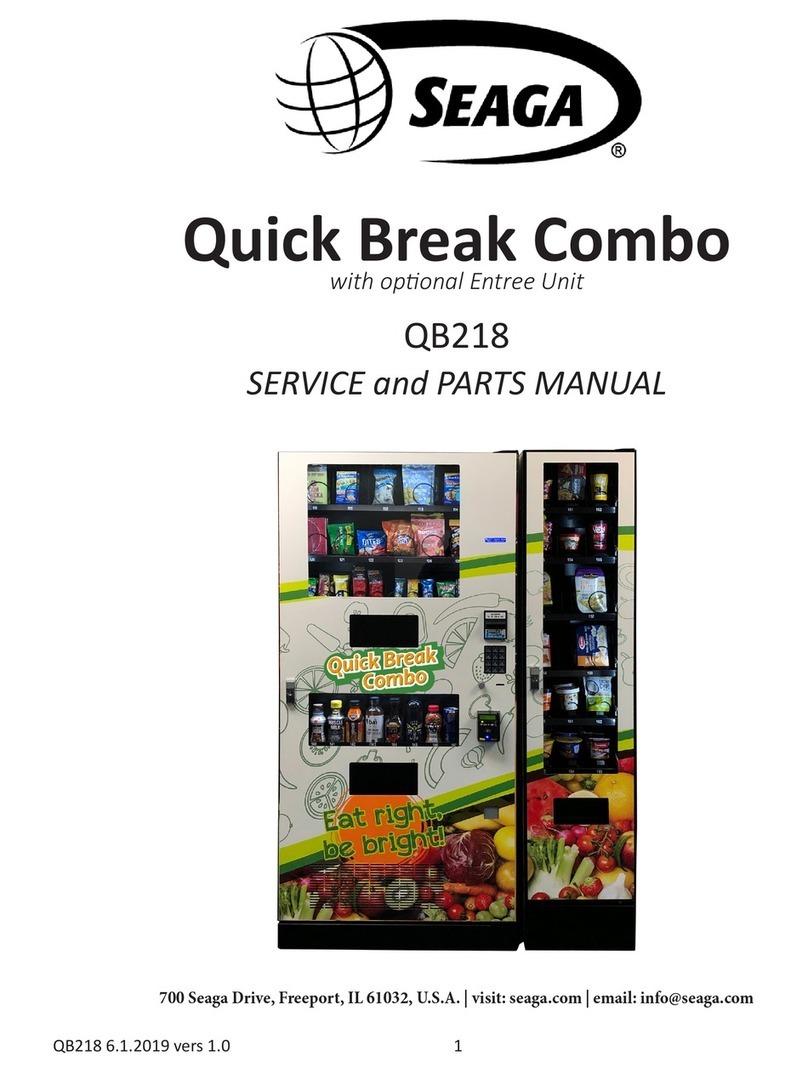

The vending machine consists of two (2) separate cabinets that are installed together via mechanical means

and connected via electrical connections to operate as ONE unit.

The Snack Vendor (SM16S) consists of two (2) trays. The first and second trays have 4 selections each

(Tray 1 – 111, 113, 115, 117, Tray 2 – 121, 123, 125, 127). The third tray has 8 selections (131 through

138). The top two trays are normally used for products that are wider such as chips, pastries etc. and the

third tray is used for Confectionary items such as candy bars. The Snack Vendor (SM16S) also houses all

the paymentmechanisms and electronic VendingMachine Controller (VMC) on the right side of the cabinet,

as shown in Figure 19. The payment mechanisms, electronic components (such as VMC) and transformer

are installed on a vertical shelf that slides out for easy access. The connectors to connect the Beverage

Unit (SM6RD) are also provided in this vertical shelf of the Snack Vendor (SM16S).

The Beverage Vendor (SM6RD) is designed with a vertical dropsystem. The Beverage Vendor also houses

the removable Refrigeration System. The cabinet of the Beverage Vendor has a delivery system that has

6 selections for Cans or Bottles (140 through 146). The loading instructions are given in subsequent

sections. The refrigeration system is installed at the bottom of the Beverage Vendor and there is a foamed

separation between the cabinet interior and the refrigeration system. The installation, setup and functionality

of the refrigeration system is explained in the section titled Refrigeration.

RECEIVING, INSPECTION, UNPACKING AND TESTING

After you have received your vending machine, inspect all three individual vendor components. Note: Any

damages that may have occurred during shipping must be reported to the delivery carrier immediately.

Reporting damages and the seeking of restitution is the responsibility of the equipment owner. The factory

is willing to assist you in this process in any way possible. Feel free to contact Seaga Customer Care with

questions you may have on this process. Once you have your vending machine located, we suggest that

you keep this manual for future reference.

The vending machine is placed on a wooden pallet and stretch-wrapped. Please exercise caution while

cutting into the stretch-wrap with a sharp tool such as a utility knife, as it may cause scratch marks on the

machine.

The Snack and Beverage Units are boxed in two (2) separate cardboard boxes. The Snack Unit box is

placed on top of the Beverage Unit. After removing the stretch wrap, remove the Snack Unit and place it

aside. USE EXTREME CAUTION AS THE TOP OF THE BOX IS NOT ATTACHED TO THE BOTTOM OF

THE BOX. The top of both the snack and beverage units slide up for removal. Remove the Beverage Unit

from its box and place it in the desired vending location. Remove the Snack Unit from its box and place it

on top of the Beverage Unit carefully. Please use proper lifting and safety precautions while placing the

Snack Unit on top of Beverage Unit.

Open all Unit doors and remove the packing materials. Keys can be found in the white envelope placed in

the vend area of the Snack Unit. Remove the tape on the tray levers of the Snack unit. Also remove the

protective paper from under each coil as well as ties securing the ends of the coils during shipping. Remove

all protective plastic from the window lenses.

Remember: at least two people are necessary to move any of the components of the vending machine.

Follow proper safety standard for lifting and working with electronic/refrigerated equipment.