Fusesaver | Installation and operation manual 9

4 Installation procedure

Fusesaver installation can be achieved using

live-line or dead-line (under isolation) processes.

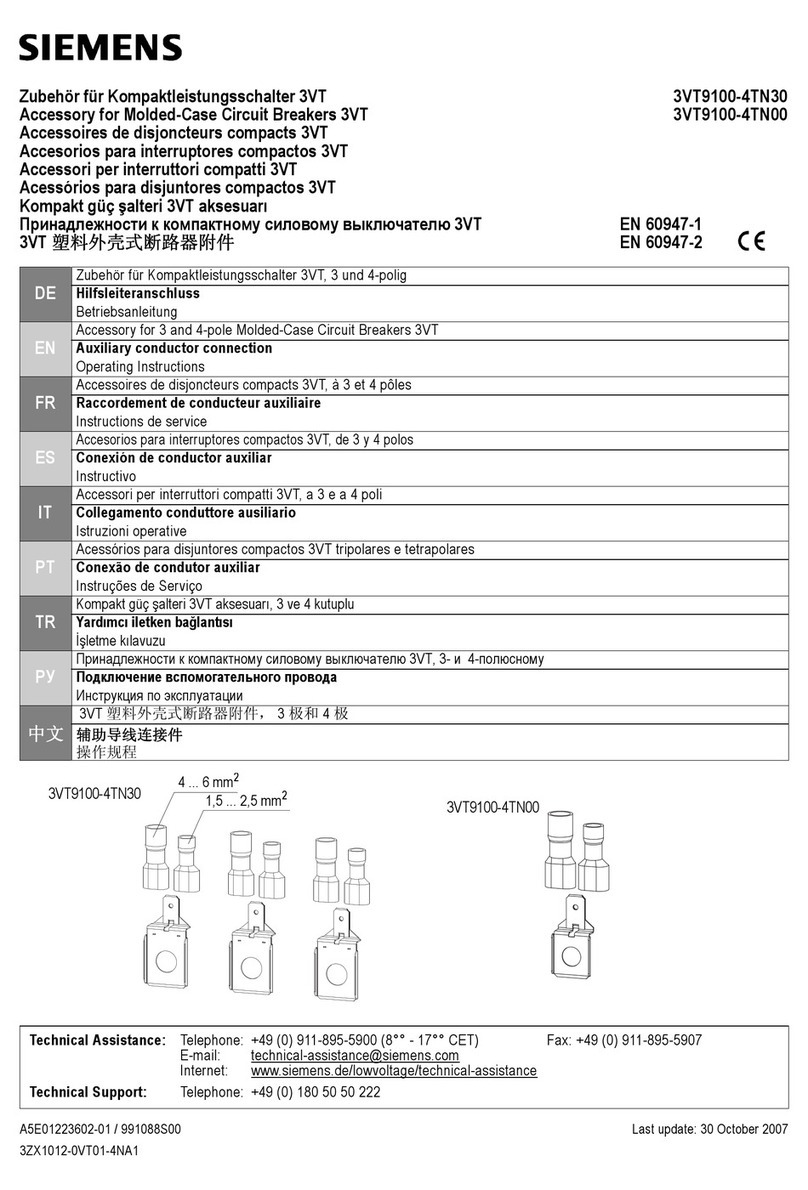

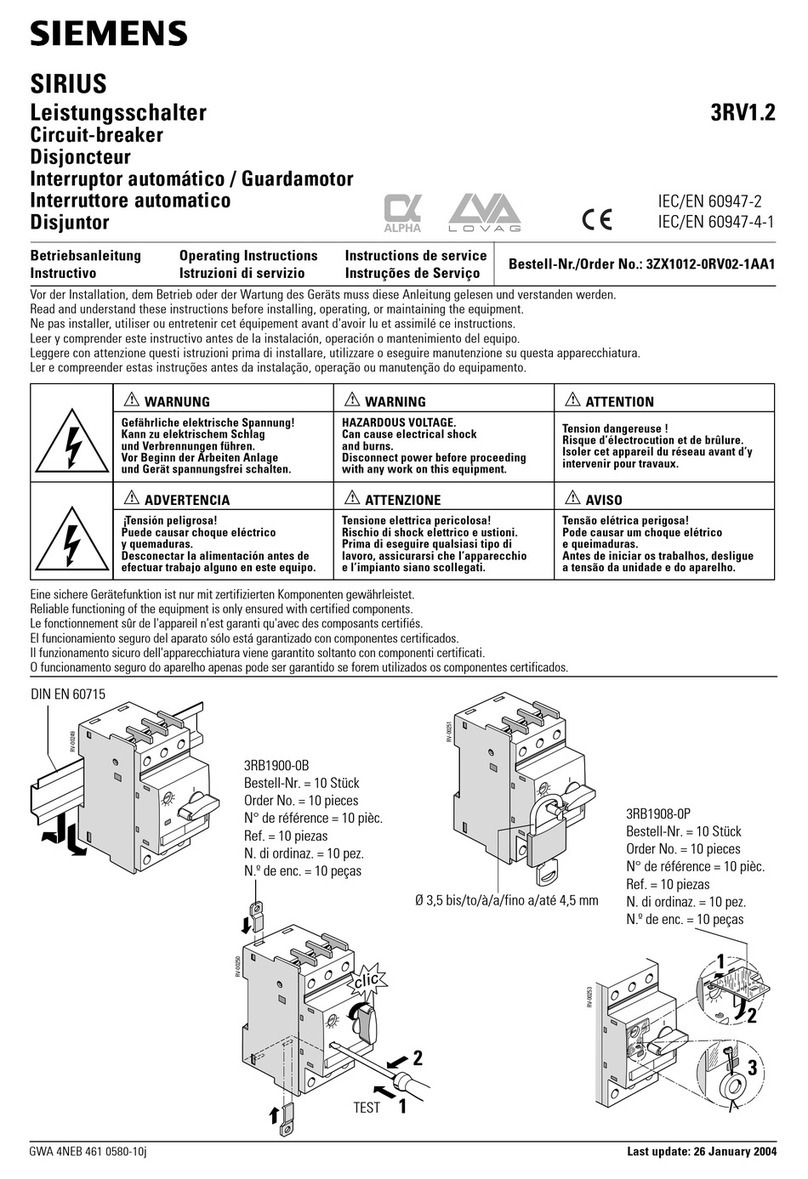

4.1 Connecting cables

The preferred method for connecting to the Fusesaver is with a cable that has a

two-hole NEMA palm crimped to one end. Aluminium cables and palms connected

with galvanized steel bolts are recommended wherever possible. If the connecting

cable is not aluminium, an appropriate bi-metallic lug classified for use with

aluminium terminals is required.

The cable used to connect to the Fusesaver should have the following typical values

by model type to achieve full current rating of the model:

Model Aluminium Copper

Low range > AWG 2 (30 mm²) > AWG 5 (15 mm²)

Standard range > AWG 0 (50 mm²) > AWG 3 (25 mm²)

High range > AWG 0000 (100 mm²) > AWG 000 (70 mm²)

The cable may be bare or insulated. Water blocking is not required. The same cable

used to connect the fuse to the main line is normally adequate for connecting to

the Fusesaver.

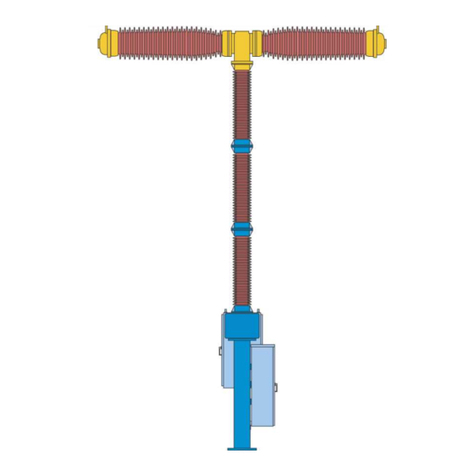

4.2 Fusesaver mounting

The Fusesaver is an electrically floating

device so it requires no grounding and

can be installed using three different

approaches. In all cases, the Fusesaver

should be mounted horizontally.

For mounting options not covered here

contact a Siemens Service Center.

The Siemens Service Center has

available general arrangement

drawings and solid models of various

configurations of the following

installation options, that the end user

can utilize to create their customized

pole top construction drawings.

4.2.1 Line mount installation

The most common method for

mounting of the Fusesaver is to

hang it directly from a suitably sized

conductor. The line clamp assembly

provides a mechanical mounting point

and is not an electrical connection as

it has an insulating sleeve between

the clamp and the line. A cable is still

required to provide an electrical

connection from the Fusesaver terminal

to the line.

Do not hang the Fusesaver device from an

undersized conductor. This may result in

conductor fatigue and failure of the conductor.

It is the user’s responsibility to determine whether

the size and type of conductor or dead-end that the

Fusesaver is being mounted from is mechanically

capable of supporting the weight of the Fusesaver.

As a guide, if the mounting of the Fusesaver causes

a kink in the conductor, then the conductor is not

suitable for line hanging of Fusesaver.