Siemens SC9000 User manual

Other Siemens Monitor manuals

Siemens

Siemens SIMATIC HMI IRD400 User manual

Siemens

Siemens 175V User manual

Siemens

Siemens SIREMOBIL Compact L User manual

Siemens

Siemens SCD 1898-I User manual

Siemens

Siemens MCM 1902 User manual

Siemens

Siemens CMTC1720 User manual

Siemens

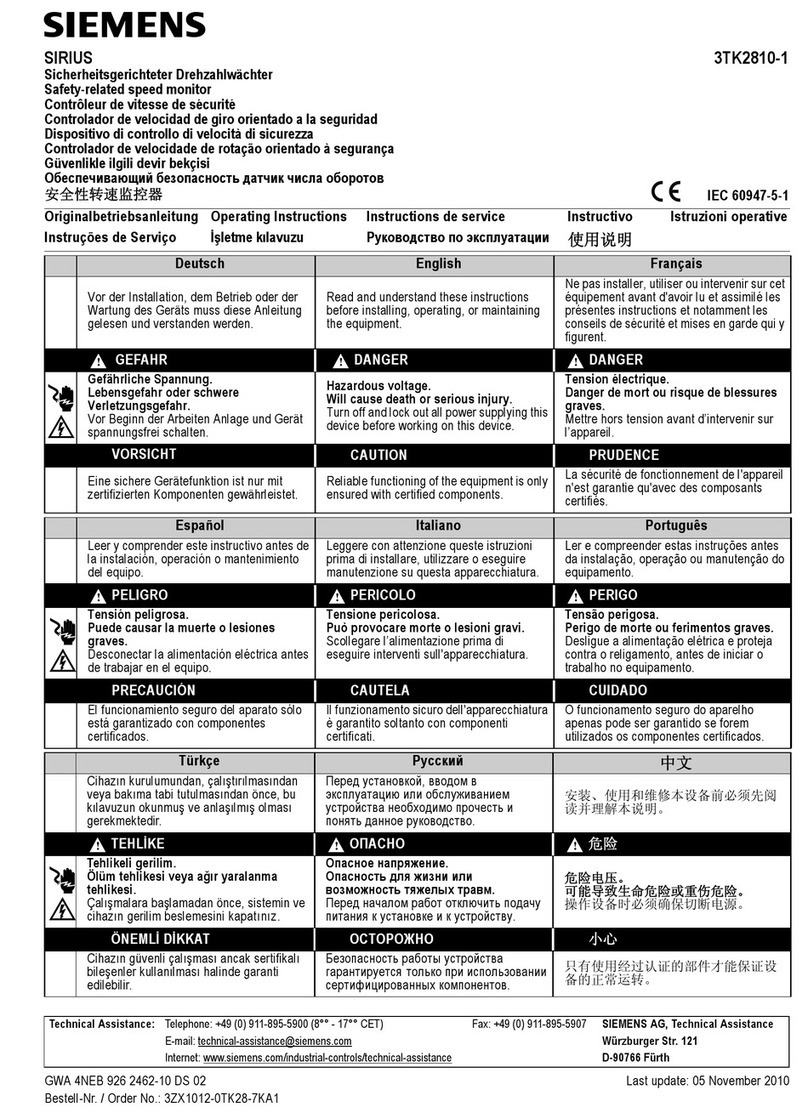

Siemens 3TK2810-1 User manual

Siemens

Siemens SITRANS RD200 User manual

Siemens

Siemens SIMATIC Industrial Flat Panel IFP2200 User manual

Siemens

Siemens FUJITSU S383FA-V151 User manual

Siemens

Siemens FT2014 User manual

Siemens

Siemens CMTC1913 User manual

Siemens

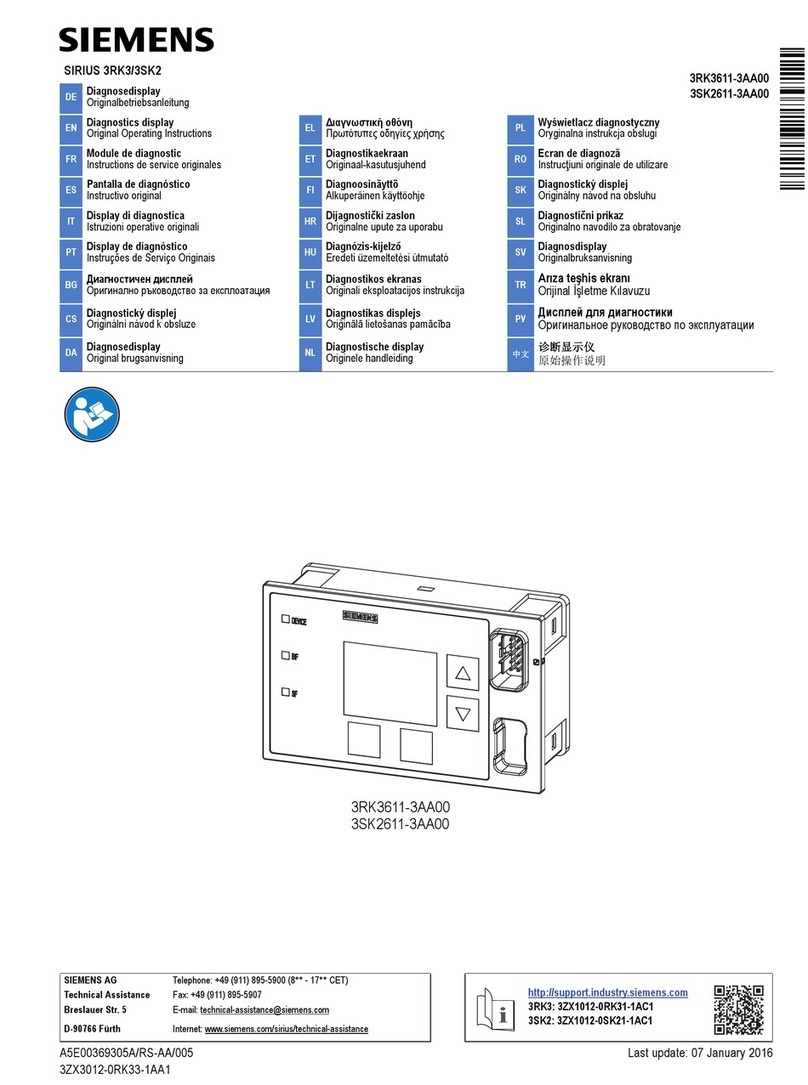

Siemens SIRIUS 3RK3 User manual

Siemens

Siemens SCD 1997-E User manual

Siemens

Siemens SINAMICS G180 User manual

Siemens

Siemens SITRANS RD100 User manual

Siemens

Siemens 125-2134 User manual

Siemens

Siemens SIREMOBIL User manual

Siemens

Siemens AEP User manual

Siemens

Siemens SSD User manual