Document No. 129-129

Installation Instructions

Rev. 3, August, 2000

Information in this publication is based on current specifications. The company reserves the right to make changes in specifications and

models as design improvements are introduced. © 2000 Siemens Building Technologies, Inc.

Siemens Building Technologies, Inc.

Landis & Staefa Division

1000 Deerfield Parkway

Buffalo Grove, IL 60089-4513

U.S.A.

Your feedback is important to us. If you have

comments about this document, please send

them to technical.editor@sbt.siemens.com

Document No. 129-129

Printed in the U.S.A.

Page 3 of 3

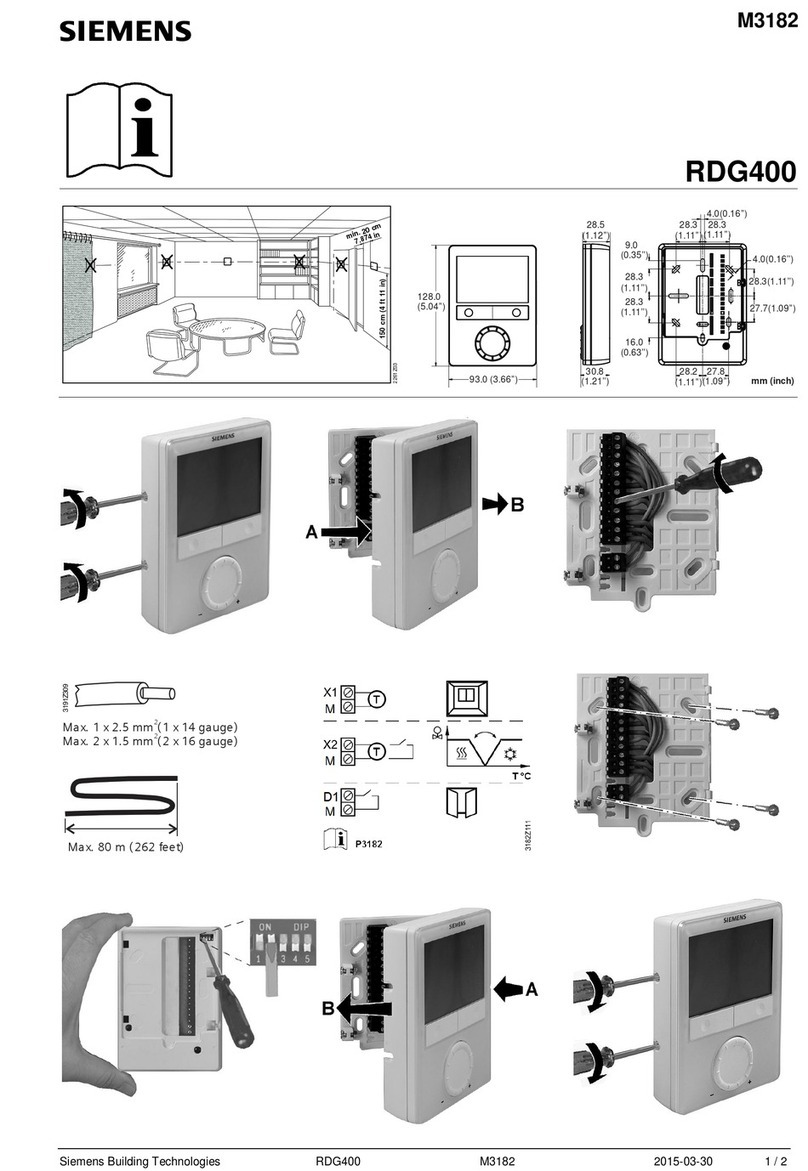

Installation, Continued

Figure 5. Heating/Cooling Changeover.

4. Rotate adjustment post to give an output within

1/2 psi (3.4 kPa) of calibration pressure.

5. Adjust PRV for 18 psi (124 kPa) air supply;

observe the control pressure. If not within

1/2 psi (3.4 kPa) of calibration pressure, adjust

the reverse acting adjustment until it is. Apply

ambroid to the screw setting.

6. Remove test port gauge; close bleed screw.

7. Replace cover and knob.

8. Lock knob in place with pointer at bulb

temperature.

9. Set knob at desired temperature setting.

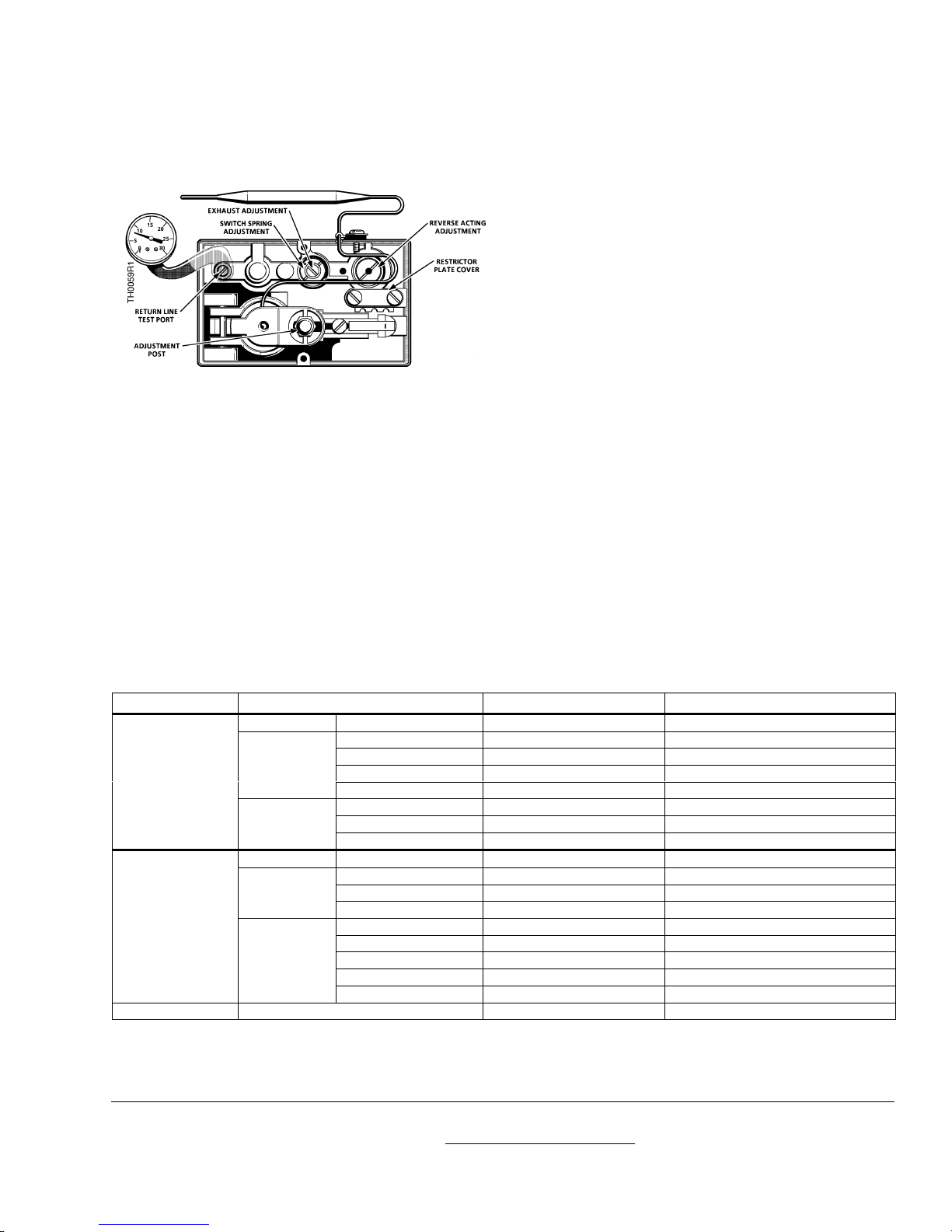

Heat–cool thermostat changeover

See

Table 1

for air pressure and changeover

pressure.

The changeover is a factory adjustment; it is sealed

with ambroid and does not require field adjustment.

If, for some reason, this adjustment is disturbed, re-

adjust as follows (See

Figure 5

):

1. Supply the thermostat with an air supply

pressure equal to the appropriate changeover

pressure (

Table 1

).

2. With the exhaust adjustment (center screw)

backed out several turns, turn the switch spring

adjustment (outer screw) down snug, and then

back off until air can be heard bleeding out.

3. Turn the exhaust adjustment down snug and

back off approximately 1/8 turn.

4. Seal both screws with ambroid to prevent

further movement.

The installation is now complete.

Reference

Technical Instructions

TH 188-2

155-064P25

Table 2. Troubleshooting.

Complaint Check Possible Cause Corrective Action

Supply Air No Air As Required

Calibration Out of calibration Recalibrate

Restrictor Clogged or dirty Clean or replace

Sensing element Loss of charge Replace sensing element

*Heating

25 psi

(172 kPa) Direct acting stage Internal binding or leaking Replace thermostat

Calibration Out of calibration Recalibrate

Throttling pin Dirt built up around pin Clean or replace nozzle assembly

Return line

pressure

0 psi

(0 kPa) *Cooling

18 psi

(124 kPa) Reverse acting stage Internal binding or leaking Replace thermostat

Supply Air Pressure Too High As Required

Calibration Out of calibration Recalibrate

Throttling Pin Dirt built up around pin Clean or replace nozzle assembly

*Heating

25 psi

(172 kPa) Direct acting stage Internal binding Replace thermostat

Calibration Out of calibration Recalibrate

Restrictor Clogged or dirty Clean or replace

Sensing element Loss of charge Replace sensing element

Reverse acting stage Improperly adjusted Re-adjust

Return line

pressure

18 psi

(124 kPa) or

greater *Cooling

18 psi

(124 kPa) Reverse acting stage Internal leaks or binding Replace thermostat

Excessive cycling Lever assembly Sticking or binding of levers As required

* See

Table 1

for Honeywell and Johnson Controls pressures.