2 / 12

Siemens Semi-flush-mountRoom Thermostatswith LCDCB1N3064en

BuildingTechnologies 24.08.2010

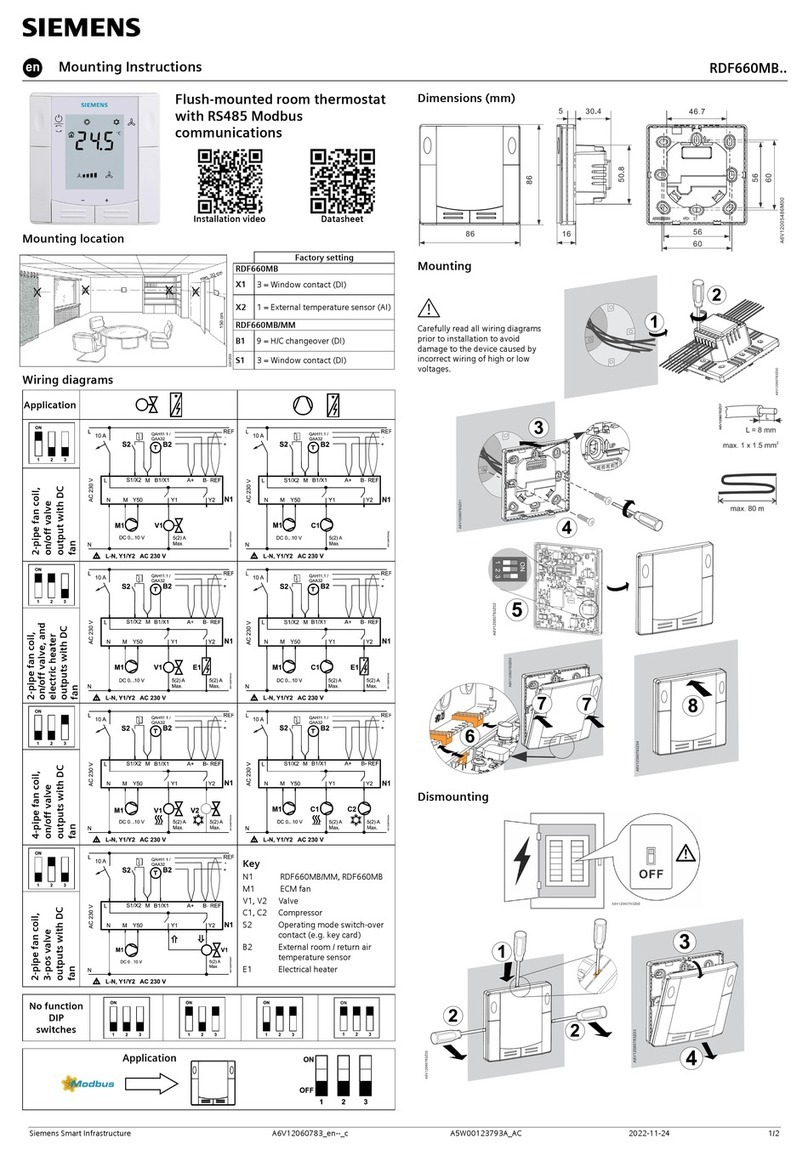

Use

For controllingthe room temperature in individual rooms and zonesthatare:

•heatedorcooled with 2-pipe fan coil units

•cooledwith a single compressorin DX type equipment

The controllercontrols:

•a3-speed fan

•eithera valve actuator in a2-pipe system,or

•a3-wire ball valve actuator in a 2-pipe system, or

•a1-stage compressor in DXtype equipment

Suitable foruse in systems with:

•continuous heating orcooling mode

•manualheating/cooling changeover

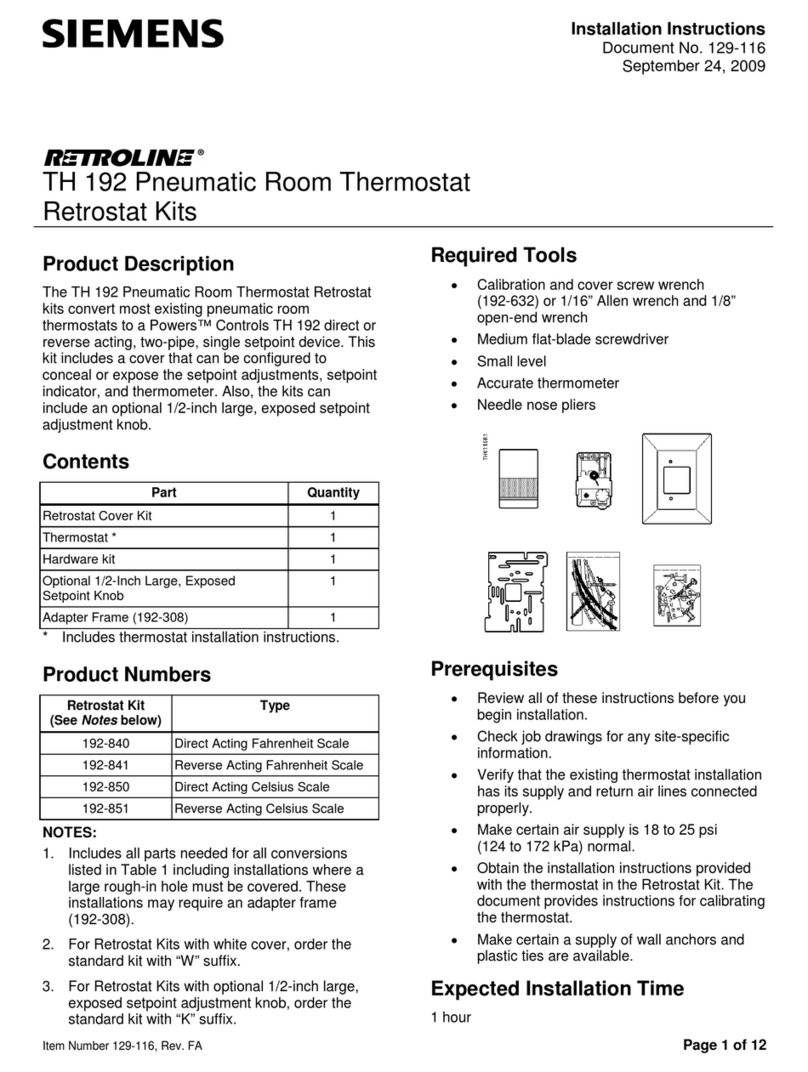

Functions

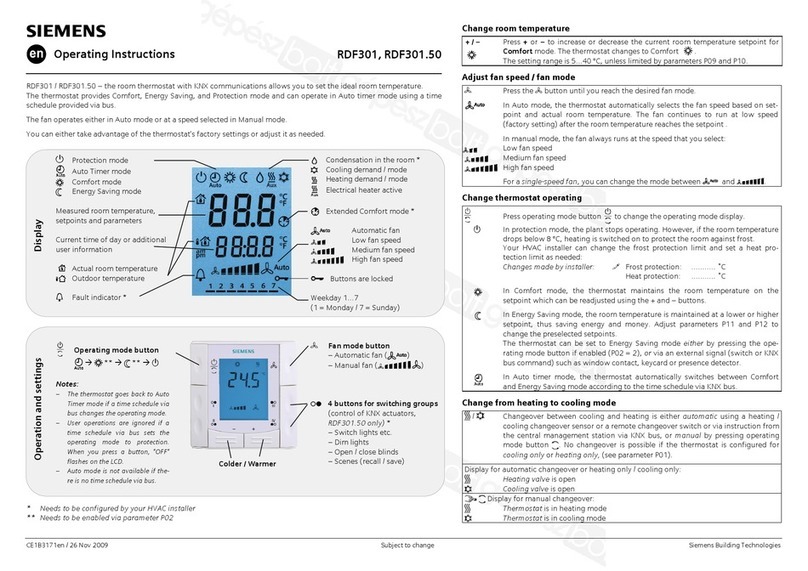

•Changeover between heating andcooling mode is manually

•Maintenance ofroomtemperature withintegrated temperature sensor

•Selection ofoperatingmode with the operatingmode button on the controller

•3-speed fan control (automatic or manual)

•Outputfor 2-position (on/off) valve actuator, 3-wire (on/off) valve actuator or 1-

stage compressor

•Buttonlock (automatic ormanual)

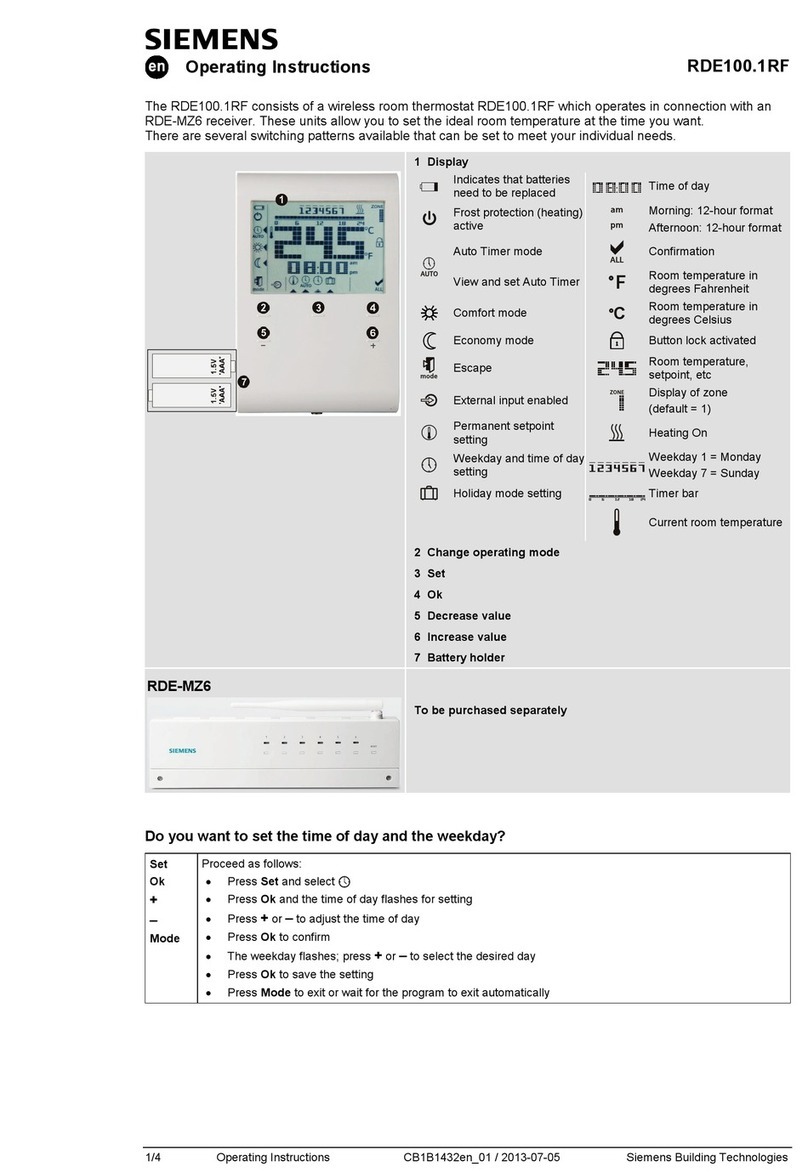

Controller

The controlleracquires the room temperature via its built-in sensor and maintains

the setpoint by delivering 2-position valve control commands orcompressor output

commands.

The switching differential is1 K inheating mode and1 Kin cooling mode (adjust-

ablevia parameters P08 and P09).

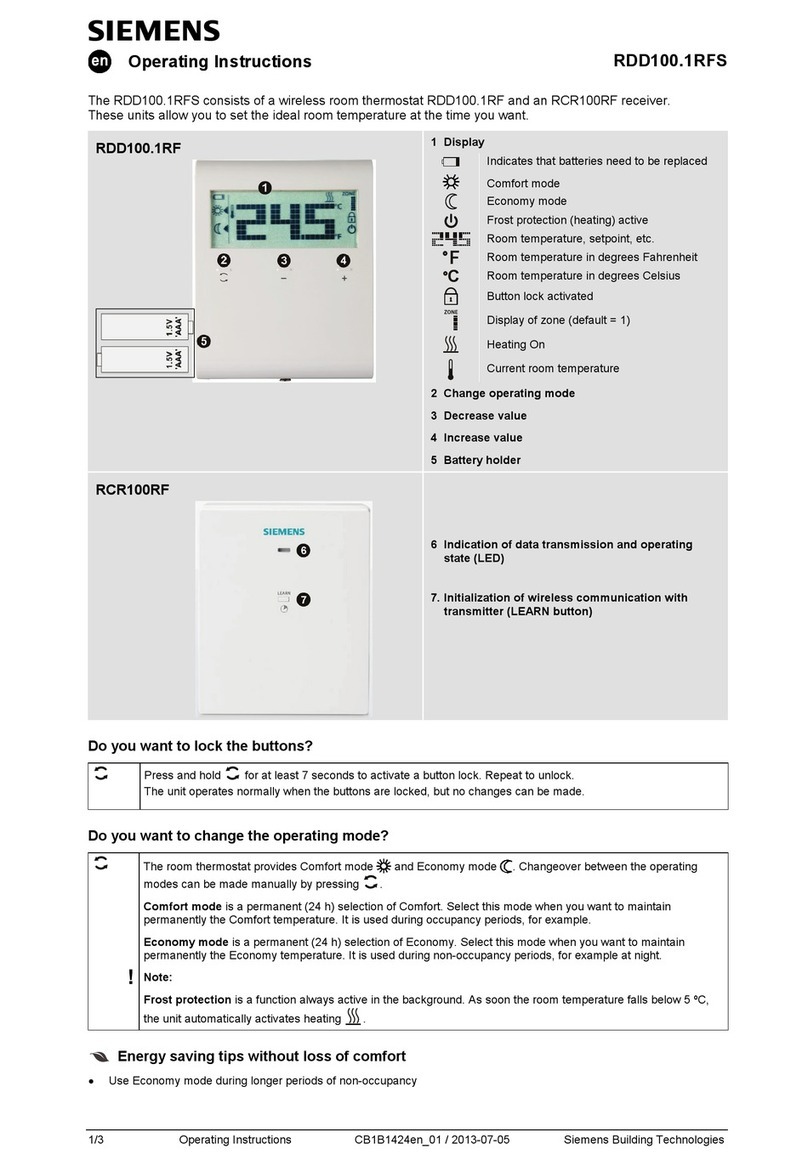

The display can show currentroomtemperature or the setpointadjusted by user.

This can be selected via parameterP18 (factory setting is the currentroom tem-

perature).

The heating and cooling symbols on the display show the status of thefan

coil.This means thatthe symbols are also shown while the controller operates in

the dead zone.

Ifrequired, room temperature and setpoint can also be displayedin Fin place of

C by changing parameter P17.

Operating modes

The following operating modesare available:

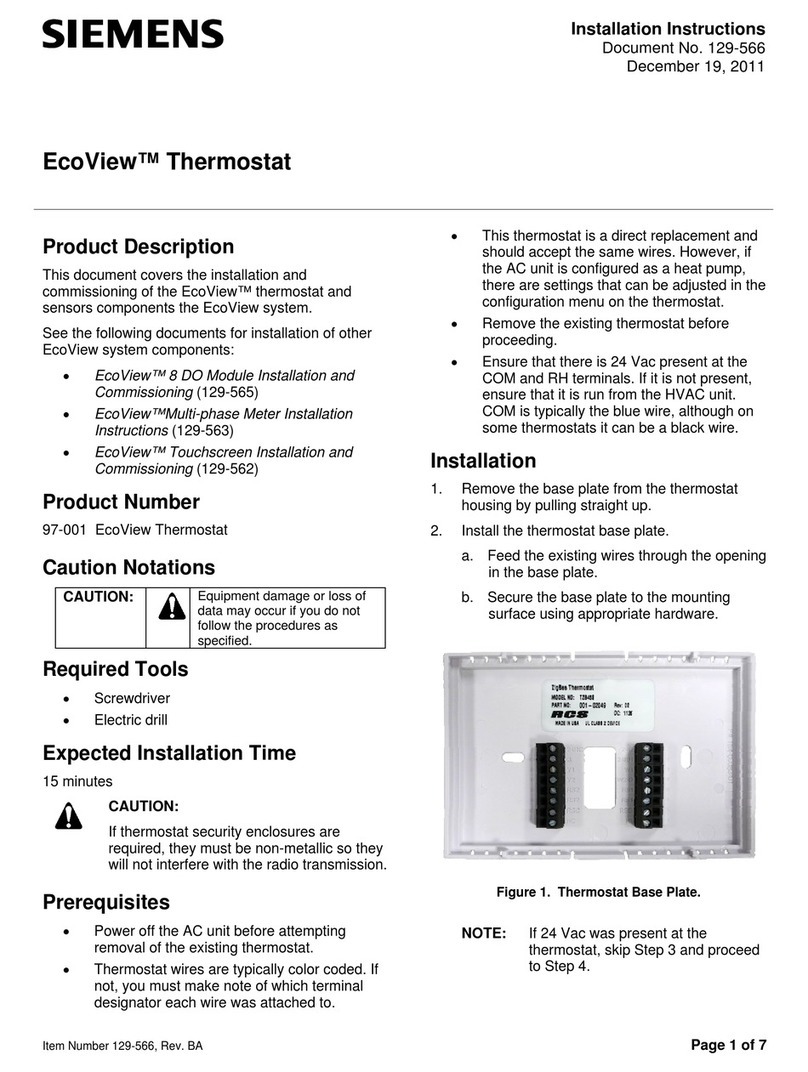

In Comfort mode,the controller maintains the setpoint,which can be adjusted via

the + and –buttons.The fan can be setto automatic ormanual fan speed:Low,

mediumor high.

The setpointsetting range can be limited to a minimum(P05)and maximum (P06).

This helps preventthe waste of energy,thus saving costs.

Whenthe controlleris in Protection mode , the relevant setpoints of heating or

coolingare maintained.These setpoints can be adjusted via control parameters

P03 and P04. Factory setting ofP03 is 8 C; whereas P04 is OFF, which means

thatthe controlleris notactivatedwhen in Protection mode.

To avoid damage due to moisture in very warmandhumid climatic zones resulting

from lack of aircirculation in normal operation (Comfortmode ),the fan can be

Temperaturecontrol

Display

Comfort Mode

Tips

ProtectionMode

Avoiding damage

duetomoisture