Siemens Building Technologies, Inc.

Landis Division

120

Powers™Controls

Te

TeTe

Tec

cc

ch

hh

hn

nn

ni

iiic

cc

ca

aa

al I

l Il I

l In

nn

ns

ss

st

tttr

rr

ru

uu

uc

cc

ct

ttti

iiion

onon

on

Document No. 155-065P25

TH 192-1

Rev. 1, July, 1999

TH 192 S Single Temperature Room

Thermostat

80

70

TH0355R1

POWERS

6050 70 80

D

DD

Des

eses

esc

cc

cr

rr

ri

ii

ip

pp

pt

tt

ti

ii

io

oo

on

nn

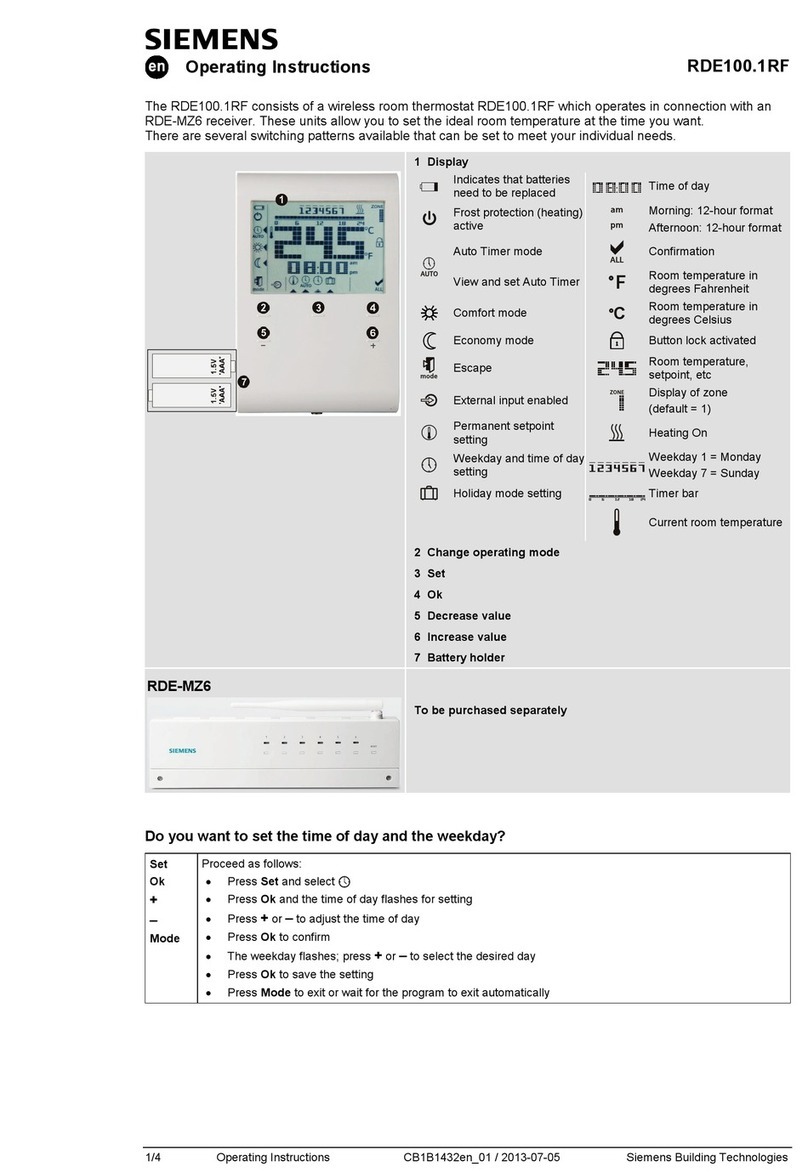

nThe TH 192 S thermostats are proportional single output, single set point, 1-pipe (low

air capacity) or 2-pipe (high air capacity) sensor controllers. Each thermostat includes a

wall mounting plate for installation in a variety of rough-in terminal boxes. A sensitive

bimetal responds to temperature change to modulate control air through a flapper

nozzle. One set point dial is provided. Air connections are made with 5/32” (4 mm) OD

plastic tubing, directly to the thermostat chassis for retrofit applications or with plug-in

adapters (provided with the TH 192 rough-in terminal box or optional accessories)

which slide into the wall mounting plate.

F

FF

Fe

ee

ea

aa

at

tt

tur

urur

ures

eses

es •Direct and reverse acting models for one and two-pipe

•Fahrenheit or Celsius set point dials

•Highly sensitive bimetal thermostatic element

•Field adjustable sensitivity with graduated scale

•Integral field adjustable limit stops

•Control pressure test port accessible without removing cover

•Easily replaceable thermometer, set point dial, filters, and restrictor plate

•Covers available for concealed or exposed thermometers and for either concealed,

key, or exposed knob adjustment and set point indication

•Standard plastic thermostat covers provide desert beige or white finish

O

OO

Op

pp

pt

tt

ti

ii

io

oo

on

nn

na

aa

al

ll

l D

DD

De

ee

es

ss

si

ii

ign

gngn

gn

F

FF

Fe

ee

ea

aa

at

tt

tur

urur

ures

eses

es •Fixed temperature limit stops meet government specifications

•Competitor adapter mounting kits available

•Metal covers available in standard configurations with a variety of finishes

•All thermostat chassis available with optional 1/2” large set point adjustment knobs