OptiFuse MPO SPLICE-ON Connector Instructions

10

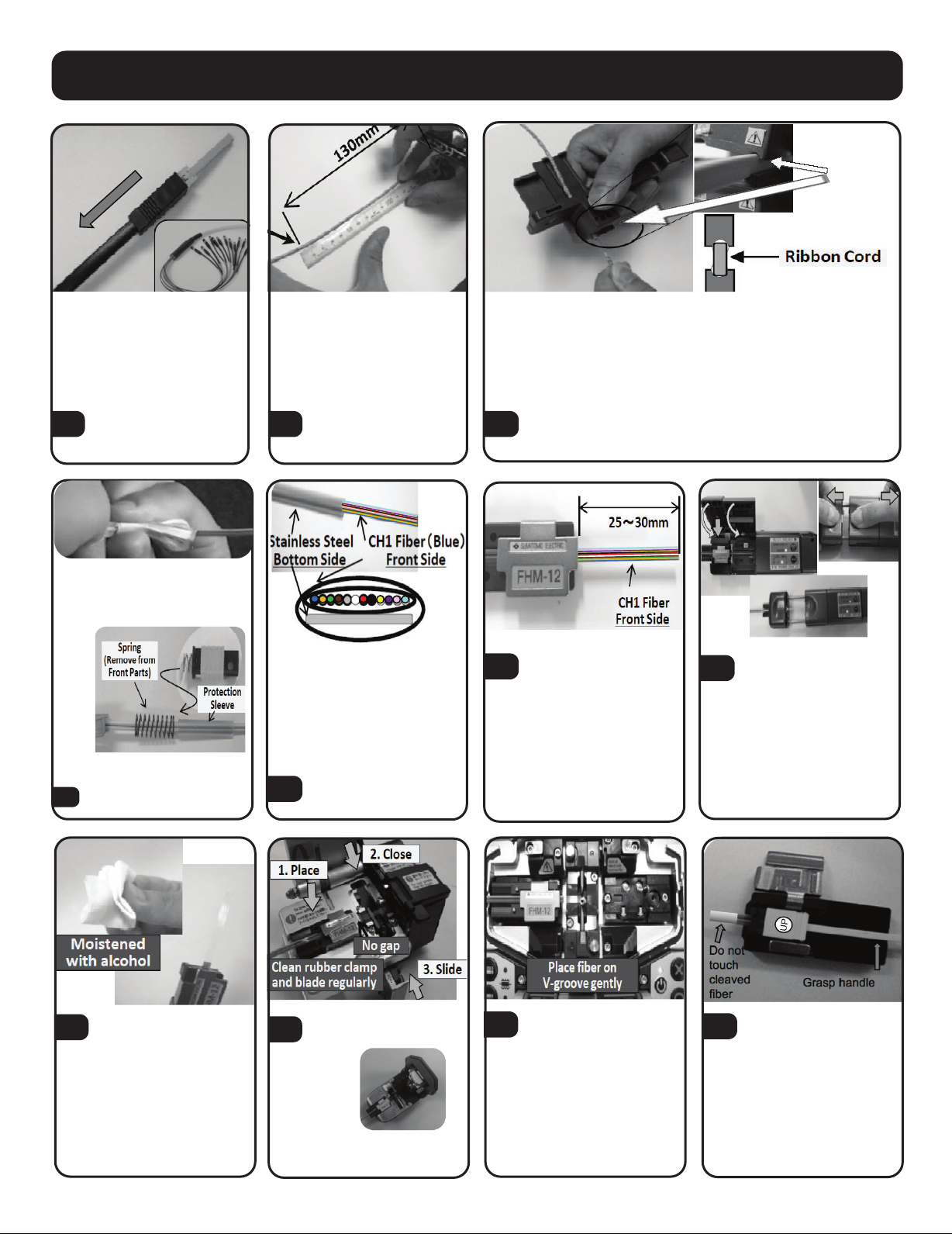

Slide rear parts onto the ribbon

cord.

8

Cut legs to desired length.

Mark off at 130mm from end of

cord.

Slide spring and then heat

shrink protection sleeve onto

the ribbon

11

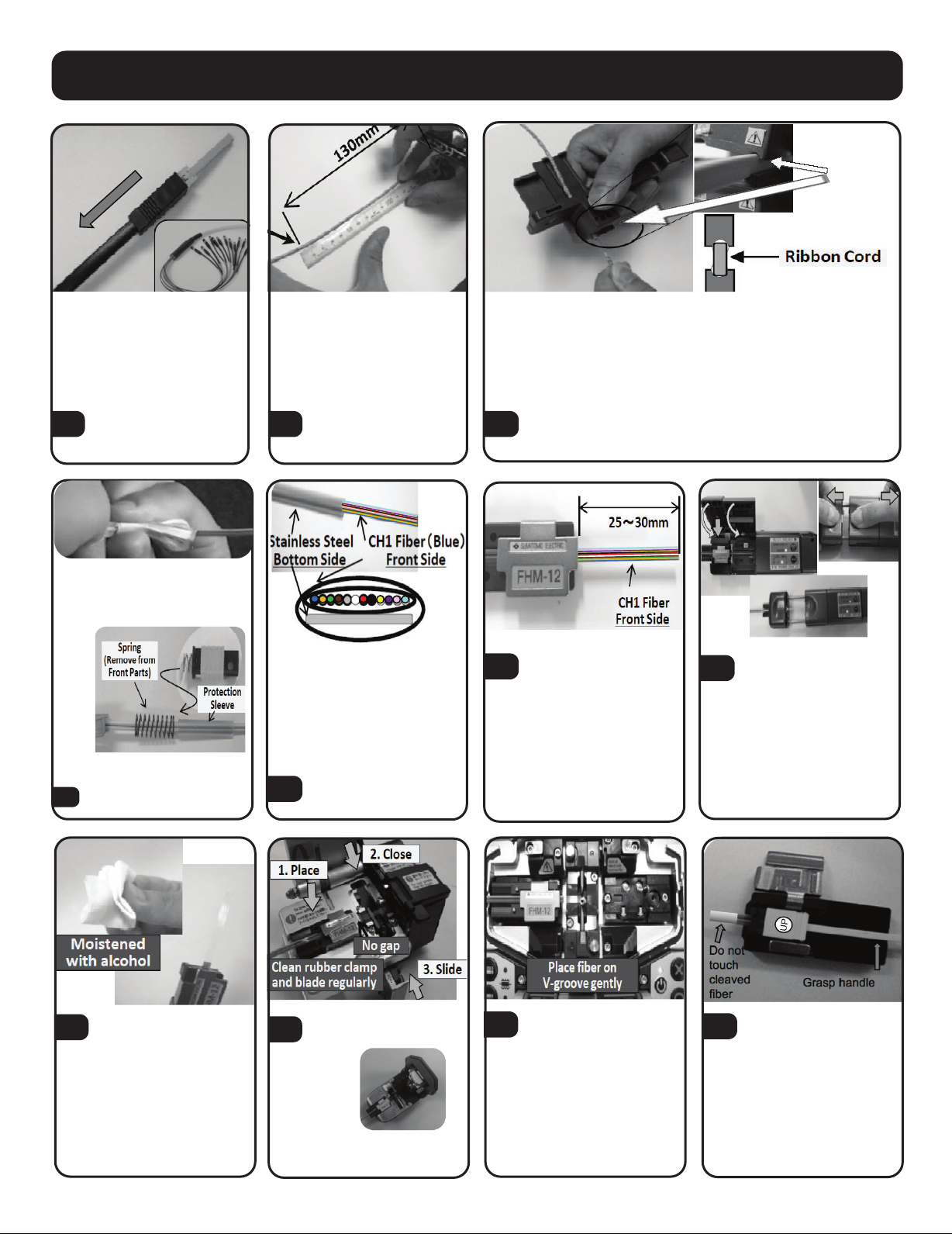

Orient sleeve as shown

above.

12

Remove the ribbon coating

using the JR-6 unit. Ensure

unit is set to high temperature

for best results.

13 Set ribbon fiber in fiber

holder with between 25

and 30mm exposed as shown.

14

Use a fiber optic cleaning

paper moistened with

alcohol to remove any debris.

Gently pull away from jacket.

15

Use LYNX2-CORDTOOL-2&3 to make a slit in cord.

Set the Ribbon cord on “3mm” groove perpendicularly at 130mm

mark as shown and pull tool toward the end of the cord.

Cleave the fiber using the

FC-6M cleaver.

Place the fiber holder with

the cleaved fiber into the

fusion splicer on the left hand side.

Place MT STUB into hold-

er with “UP” text facing

upwards. After stub is set in the

holder, close the holder covers.

17 18

16

Note: The FC-8R cleaver can

also be used with same steps

INS_100.25411.00.qxp_C 1/26/18 3:30 PM Page 2

130mm

mark

Fold back the inner jacket, Kevlar

yarn, and outer jacket to the

marked 130mm line and secure

with tape.