Siensor AF107 User manual

PASSPORT

Siensor AF107

Liquid Level Sensor

www.siensor.com

ПАСПОРТ

说明书

2

1. Overview

2. Technical Specications

3. Pacakage Contents

4. Mounting Dimensions

5. Mounting Guidelines

5.1. The Sensor Connector Pin Assignments

for Connection to an External Device

5.2. Connecting the Liquid Level Sensor

to an External Device

5.3. Sealing

5.3.1. Installing a Protective Seal

on the Liquid Level Sensor

5.3.2. Installing a Protective Sealing

on the Connector

6. Opeartion Guidelines

7. Storage and Service Requirements

8. Utilization

3

4

6

9

12

14

15

17

17

17

18

19

19

TABLE OF CONTENTS

3

1. OVERVIEW

The Siensor AF107 liquid level sensor (hereinafter

referred to as LLS) is an intelligent device designed for

accurate measurement of fuel level and temperature

in vehicle tanks and stationary reservoirs, which are

not subject to the explosion protection requirements

for equipment. The Siensor AF107 digital capacitive

sensor converts measured values into an analog

or frequency signal and transmits it to an external

device.

The sensor allows for the measuring probe to be cut

to 20% of its original length.

Changing the length of the LLS measuring probe

might aect the extent of measurement error!

4

2. TECHNICAL SPECIFICATIONS

Table 2.1 Technical specications

* the sensor can take measurements, but with lower accuracy

** the temperature at which the device retains its performance

characteristics

Power supply:

Power supply voltage, V 7 to 45

Power consumption, W:

• typical

• maximum

• at short circuit on an analog output

0.6

0.9

max 1.6

Level measurement:

Measurement interval, sec 1

Relative reduced measurement error, % max ±1.0

Additional relative reduced

measurement error caused by

temperature change over the entire

operating temperature range, %

max 1.2

Analog output:

Output voltage range, V 0…20

DA conversion width, bit 12

Analog output load resistance, Ohm min 2000

Output ripple, % max 0.15

5

Continuation of Table 2.1 Technical specications

Frequency output

Output modulation, % frequency-

pulse

Output frequency range, Hz 30…2000

Maximum frequency output load current

in the "open collector" mode, mA 300

Internal pull-up resistance to positive

power supply voltage, Ohm 1500

General information:

Galvanic isolation strength is no less

than, V 250

Operating temperature, °С –40 to +80

Extended operating temperature range*,

°С –55 to +80

Minimum permissible temperature**, °С –60

Maximum permissible temperature**, °С +85

Dust and water protection IP69К

Mean time between the sensor failures,

h, minimum 100000

Average lifetime, years, minimum 8

Dimensions, mm 125×74×730

6

No Name Quantity

1Siensor AF107 liquid level sensor 1 pce

2LLS cable for connection to an

external device, 7 m 1 pce

3Installation kit 1 pce

4Warranty card 1 pce

5Passport 1 pce

6Box 1 pce

3. PACKAGE CONTENTS

Table 3.1 Package contents

7

No Name Quantity

1Nozzle to the LLS measuring

probe to x it in a vertical position 1 pce

2Nozzle spring 1 pce

3Socket cone-point set screw for

fastening a nozzle with a spring 2 pcs

4Hexagon-head bolt for plugging

an air vent 1 pce

5Fuse holder with a cable 1 pce

62A fuse 1 pce

7Ferrule wire connector (for xing

cable layups) 6 pcs

8Rubber gasket for mounting the

LLS to a gasoline tank 1 pce

9Sealing rubber ring 1 pce

10 Plastic mounting plate 1 pce

Table 3.2 Installation kit

8

11 Metal mounting plate optional

12

Self-tapping countersunk screw

for fastening a mounting plate to

the tank

5 pcs

13

Self-tapping round head screw for

fastening of a mounting plate to

the tank

4 pcs

14

Countersunk head cap screw for

fastening of a mounting plate to

the tank (Phillips slot)

5 pcs

15

Hexagon socket head cap screw

for fastening a mounting plate to

the tank

4 pcs

16 Threaded rivet nuts (zinc-galvanized

steel, М5 6.9х20) 5 pcs

17 Seal 2 pcs

18 Sealing screw (stainless steel, round

head, inner hexagon, M4 thread) 1 pce

Continuation of Table 2.1 Installation kit

9

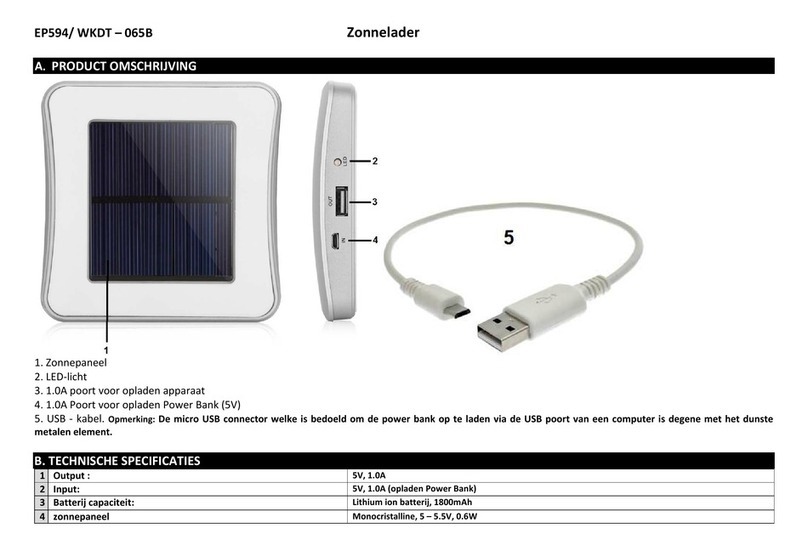

4. MOUNTING DIMENSIONS

Fig. 4.1

Mounting

dimensions.

The LLS overview

10

Fig. 4.2 Mounting dimensions.

Installation of a mounting plate

11

Fig. 4.3 Mounting dimensions.

The LLS top view

12

5. MOUNTING GUIDELINES

Mounting procedure:

1. Select a place to install the LLS.

2. Prepare the fuel tank for installation.

3. Cut the LLS adjusting it to the depth of the fuel

tank.

4. Congure the LLS using the Siensor Monitor

application.

5. Mount the LLS.

6. Prepare and run a cable to connect the LLS to an

external device.

7. Connect the LLS.

8. Install the fuse.

9. Calibrate the fuel tank.

10. Sealing:

10.1. Installing a protective seal on the liquid level

sensor;

10.2. Installing a protective seal on the connector.

To provide optimum mounting of the LLS and better

tightness with the tank, it is recommended to mount

the LLS using ve holes in the plate center (see Fig. 5.1).

13

Fig. 5.1 Recommended method

of the LLS mounting to a tank

When installing the LLS, observe safety regulations

for automotive vehicle repairs as well as the safety

requirements set by an enterprise.

The detailed installation guidelines are given in the

"User Guide. Siensor AF107 Liquid Level Sensor".

14

5.1 THE SENSOR CONNECTOR PIN ASSIGNMENTS

FOR CONNECTION TO AN EXTERNAL DEVICE

Pin Color Signal

1red PWR

5blue GND

2white A_F

6brown A_GND

3 green RS-485 A

7yellow RS-485 B

4* pink closed to pin 8 inside the connector

8* grey closed to pin 4 inside the connector

Table 5.1 The LLS connector pin assignments

* The contact is used to detect disconnection of the LLS from the

cable for an external device.

Fig. 5.2

The LLS cable for

connection to an external

device

1

5

2

6

3

7

4

8

15

5.2 CONNECTING THE LIQUID LEVEL SENSOR

TO AN EXTERNAL DEVICE

The LLS is connected to an external device in

accordance with the connection diagram (see Fig. 5.3,

Fig. 5.4, Fig. 5.5, Fig. 5.6).

Fig. 5.3 The sample diagram of Siensor AF107 connection to

an external device via a frequency output

Fig. 5.4 The sample diagram of connection Siensor AF107

to an external device via the analog output with a single

common terminal of analog sensors (GND A)

*The Rп resistor can be enabled or

disabled depending on the sensor

settings.

External

device

External

device

On-board power

system or battery

On-board power

system or battery

Circuit

Circuit Circuit

DA converter

Circuit

Siensor AF107

LLS

Siensor AF107

LLS

16

Figure 5.6 illustrates the sample diagram of

connection the LLS to an external device using pins 4

and 8 to control connection integrity with the sensor,

where R is an external or internal pull-up.

Fig. 5.5 The sample diagram of connection Siensor AF107

to an external device via the analog output without a single

common terminal of analog sensors (GND A)

Fig. 5.6 The sample diagram of connection the LLS to an

external device using pins 4 and 8

External

device

On-board power

system or battery

Circuit

Circuit Con

Contact 4 4

Contact 8 8

GND 5

PWR 1

Siensor AF107

LLS

External

device

On-board power

system or battery

Circuit

Circuit

DA converter

Siensor AF107

LLS

17

Fig. 5.7 Installing a protective seal on the liquid level sensor

3. Connect the wire ends and fasten them by the seal.

5.3.2 Installing a Protective Sealing on the

Connector

1. Pass the sealing wire through the holes in the

retainer screw as shown in the gure (see Fig. 5.8).

Fig. 5.8 Installing a protective sealing on the connector

5.3 SEALING

5.3.1 Installing a Protective Seal on the Liquid

Level Sensor

1. Fasten the retainer screw (see 1 in Fig. 5.7).

2. Pass the sealing wire through the holes in the

retainer screw and the sensor housing as shown in

the gure (see Fig. 5.7).

the gure (see Fig. 5.7).

1

18

6. OPERATION GUIDELINES

The ambient temperature must not fall outside the

operating temperature range.

Do not expose the LLS to mechanical damage.

Prevent the installation cable from insulation

damage.

Use the LLS only with liquid oils maintaining their

state of matter in the operating temperature range.

Use of poor fuel might cause the LLS incorrect

operation.

Dielectric permittivity of the measured uid must

be constant. Failure to comply with this requirement

might increase the measuring error.

The detailed service instructions are given in the "User

Guide. Siensor AF107 Liquid Level Sensor".

Fig. 5.8 Installing a protective seal on the connector

2. Connect the wire ends, strain the wire and fasten

the seal.

When sealing, do not allow the wire to slack

between the holes on the connector!

19

7. STORAGE AND SERVICE

REQUIREMENTS

Keep the LLS in a dry, enclosed area. It is

recommended to keep the LLS at temperature of -40

to +80 °С and relative humidity of 30 to 80 % at 25 °С

without condensation.

The LLS can be transported in any enclosed vehicle

and at any distance. The LLS can be transported in a

shipping container at the ambient temperature of 60

to +85 °С in compliance with measures of protection

against impacts and vibrations.

Keep and transport the LLS away from the substances

that cause metal corrosion and/or containing

aggressive additives.

8. UTILIZATION

Internal components (a printed circuit board) and the

LLS cover must be disposed as municipal solid waste.

The sensor housing with the measuring probe and the

cable must be disposed as nonferrous scrap.

20

1. Общие сведения

2. Технические характеристики

3. Комплектность

4. Установочные размеры

5. Указания по монтажу

5.1. Назначение выводов разъема

датчика для подключения к внешнему

устройству

5.2. Подключение ДУТ к внешнему

устройству

5.3. Опломбирование

5.3.1. Установка защитной пломбы

на ДУТ

5.3.2. Установка защитной пломбы

на разъем

6. Указания по эксплуатации

7. Условия хранения и транспортирования

8. Утилизация

21

22

24

24

30

32

33

35

35

35

36

37

37

Table of contents

Languages:

Other Siensor Accessories manuals

Popular Accessories manuals by other brands

Sensortech Systems

Sensortech Systems ST-3300 Series installation instructions

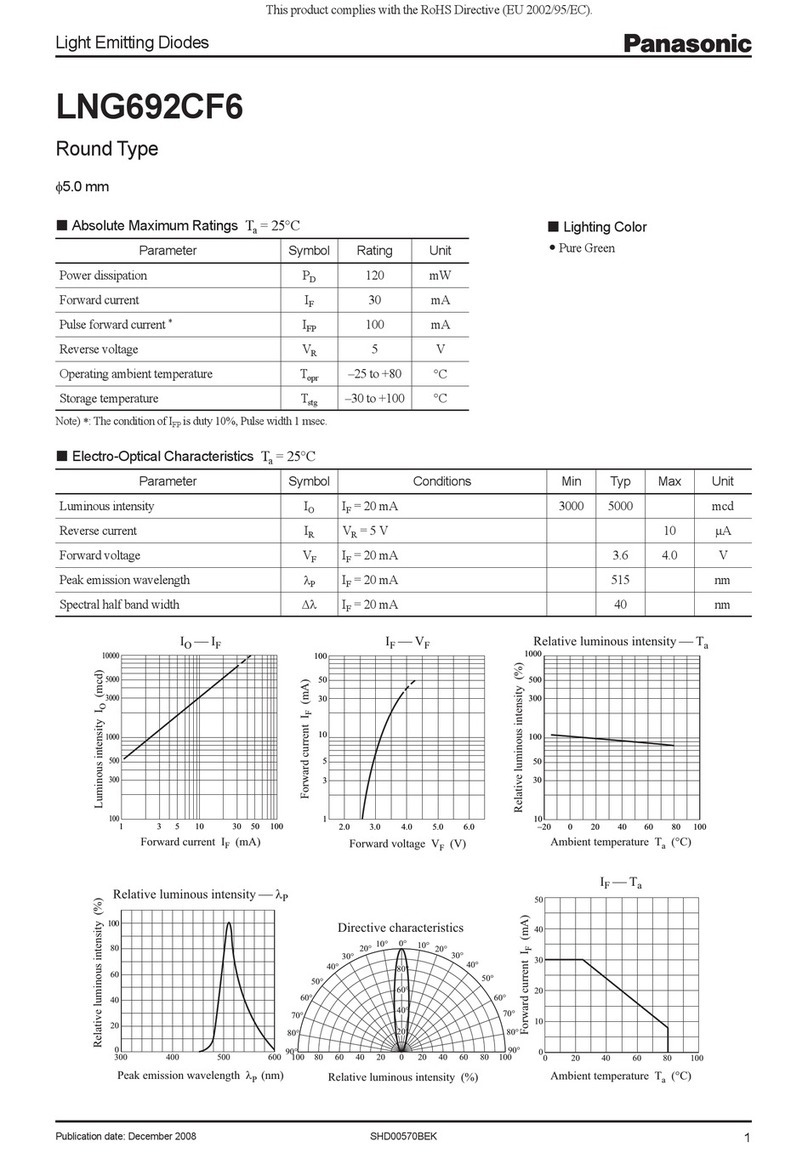

Panasonic

Panasonic Light Emitting Diodes LNG692CF6 Specifications

COMPASS HEALTH

COMPASS HEALTH Roscoe Medical Ultra-5 user guide

PASCO

PASCO UI-5101 reference guide

BeeWi

BeeWi BBP200 EU user guide

Panasonic

Panasonic CF-VNP Series operating instructions