Sievert 299001 User manual

GB

D

S

F

NL

OPERATORS MANUAL ................................ 2-13

BRUKSANVISNING ..................................... 14-25

MODE D´EMPLOI ........................................ 26-37

GEBRUIKSAANWIJZING ............................ 38-49

BEDIENUNGSANLEITUNG ........................ 50-61

HOT-AIR AUTOMATIC WELDING MACHINE

299001 400 V ~ / 299047 220-230 V ~

CAUTION

The voltage rating stated on the hot-air welding

machine should correspond to the mains voltage.

For personal protection, we strongly recommend

the TW 5000 hot-air welding machine be

connected to an RCCB (Residual Current

Circuit Breaker) before using it on any type of

application.

The TW 5000 hot-air welding machine must be

operated under strict supervision.

The heat can ignite ammable materials which

are not in view.

Protect the TW 5000 hot-air welding machine from

any and all standing water, rain and dampness.

WARNING

DANGER! Always unplug any electronic tool

before opening it as live components and

connections are exposed.

Improper use of the TW 5000 hot-air welding

machine could cause re and/or an explosion

hazard.

Never operate electronic equipment near com-

bustible materials and/or explosive gases.

Touching the element housing and/or nozzle

during or after operation could cause burns.

CAUTION! Element housing and/or nozzle have

hot surfaces.

Allow the hot-air welding machine to cool down.

Do not point the hot-air ow at people or animals.

SAFETY

TABLE OF CONTENTS

PLEASE READ OPERATORS MANUAL CAREFULLY BEFORE USE AND

KEEP FOR FURTHER REFERENCE.

- 2 -

SAFETY................................................... 2

PRODUCT DESCRIPTION.................. 3-4

ASSEMBLY............................................. 5

OPERATION........................................ 6-8

MAINTENANCE................................... 8-9

TROUBLESHOOTING GUIDE................ 10

SERVICE AND REPAIR.......................... 10

ACCESSORIES & SPARE PARTS......... 11

TW 5000 OVERVIEW......................... 12-13

WARNING! To reduce the risk of electric shock, do not expose this product to

rain or moisture. Store indoors. Read operators manual before using.

When servicing use only Sievert identical replacement parts.

! !

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

▪

GB

- 3 -

PRODUCT DESCRIPTION

▪

▪

▪

▪

▪

▪

▪

▪

Adjustable handle made of sturdy steel.

Separate free rolling wheels for easy transport.

Adjustable front wheels to avoid sliding when

welding at different angles.

Belt and wheels made of silicon rubber.

Four wheel drive system.

Specially designed nozzle and heat protection

cover in stainless steel.

Independent suspension pressure roller.

Powerful drive system.

Equipped with two lifting handles.

Removable additional weights.

Built-in temperature sensor.

Digital LED display showing temperature,

speed and operating status.

Display lamps indicate operation status of the

machine.

Fully adjustable speed, temperature and fan.

Automatic start/stop sensor when hot-air tool

is engaged/disengaged in the drive position.

All electronics are made in accordance to

highest industrial standard.

All electronics are sealed with high degree

coating for maximum humidity protection.

FEATURES

▪

▪

▪

▪

▪

▪

▪

▪

▪

GB

PRODUCT DESCRIPTION

Sievert TW 5000 is an electrical hot-air automatic

overlap welding machine, specially designed for

handling all types of single-ply roong membranes

such as thermoplastic, rubber and modied bitumen

(CSPE, ECB, EPDM, PVC, TPO, SBS, APP).

The machine is equipped with a standard nozzle

for welding seams up to 50mm width. As an option

a separate nozzle is available for handling wider

welding seams. The high power fan and heating

element ensure high quality welding at maximum

speed.

The Sievert TW 5000 has a unique four-wheel drive

system, which assures wrinkle free welding for thin

roong membranes. In addition to this, the front

wheels are adjustable to allow easy operation at

different angles. The powerful motor and efcient

drive system allow climbing ability up to 30°.

- 4 -

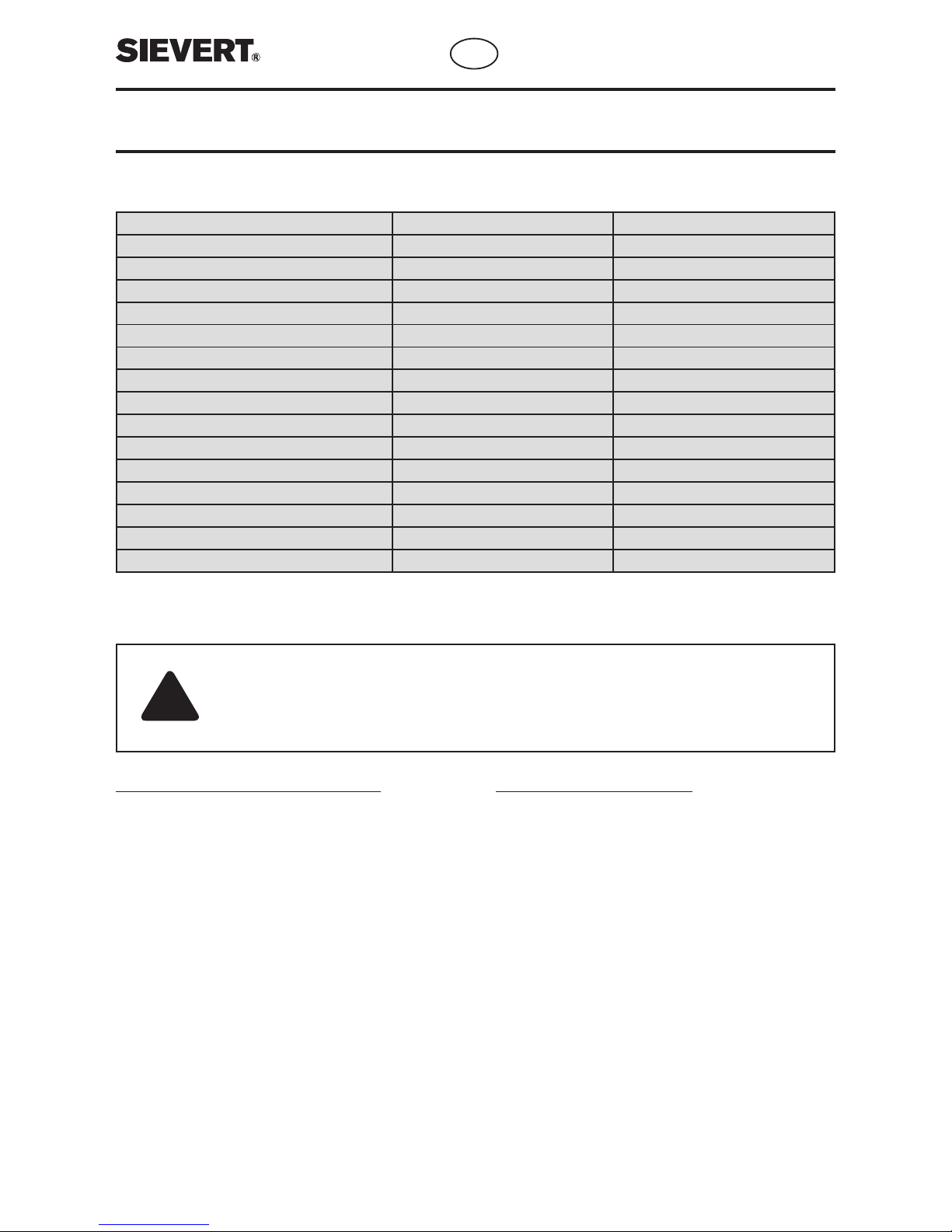

TECHNICAL SPECIFICATIONS

PRODUCT DESCRIPTION

General information for electric supply

The TW 5000 is delivered with power cord: 3 x 2.5 mm²,

earth (ground) is green/yellow; the two other wires are

neutral and phase 1 at single phase connection and

phase 1 and phase 2 at two phase connection.

▪ Use direct supply from main electric distributor or

use a generator.

▪ Use cables with 3 wires. Please note that the earth

(ground) wire is green and yellow.

▪ Recommended diameter of wires minimum 2,5 mm²,

maximum cable length 55 metres. If 1,5 mm² wires

are used, maximum cable length 35 metres.

▪ Use only extension cords with sufcient wire

diameter in accordance with information above.

▪ Your country’s specications of electric tools and

installations should be respected.

POWER SUPPLY AND EXTENSION CORDS

Selecting the right generator

To make sure you choose the right generator,

go through these steps:

▪ Identify the items you want to run.

▪ Calculate the total surge watts required for all items.

▪ Select a generator that exceeds your total surge watts.

The multiplying factor between rated and surged

watts for TW 5000 and TH 1650 is approx. 1.2. For

instance if you run one TW 5000 (220 V) and one TH

1650 (120 V) your total surge watts will be 8040 W

((5000+1700)*1.2). Thus in this case we recommend

selecting minimum a 10,000 W generator with 50-

amp service.

Be sure to verify wattage requirements for starting

and running. Start one item at a time beginning with

the largest and ending with the smallest.

CAUTION! To provide continued protection against risk of electric shock, connect to properly

grounded outlets only.

CAUTION! To reduce the risk of electric shock, keep extension cord connection dry and off

the ground.

!

Type no. 299001 299047

Voltage 400 V ~ ± 10% 220 / 230 V ~ ± 10%

Cable Connection 400 V L1-L2 220 V L1-L2 / 230 V N-L1

Power Consumption 6300 W 5000 W

Frequency 50 Hz 60 Hz / 50 Hz

Temperature, fully adjustable 40°C – 650 °C / 100°F - 1200°F 40°C – 650 °C / 100°F - 1200°F

Drive, fully adjustable 0 – 7 m/min / 0 – 20 ft/min 0 – 7 m/min / 0 – 20 ft/min

Air ow, fully adjustable 0 - 48 l/s / 0 – 12.7 gal/s 0 - 48 l/s / 0 – 12.7 gal/s

Emission level 70 dB 70 dB

Nozzle 40 mm / 1.58” 40 mm / 1.58”

Width of welding seam 40 – 50 cm / 1.5” – 2” 40 – 50 cm / 1.5” - 2”

Dimensions 56x38x25 cm / 22”x15”x10” 56x38x25 cm / 22”x15”x10”

Weight (4 kg / 8.8 lb built-in weight) 30 kg / 68 lb 30 kg / 68 lb

Additional weight (included) 8 kg / 17.6 lb 8 kg / 17.6 lb

Additional weight (not included) 4 kg / 8.8 lb (art no 299301) 4 kg / 8.8 lb (art no 299301)

Power cord length 91 cm / 3 ft. 91 cm / 3 ft.

GB

- 5 -

ASSEMBLY

▪ Attach the handle by sliding it into

place over the two receptacles on the

machine.

▪ Adjust the handle to a suitable height

for the operator.

▪ Lock with the two screws provided.

▪ Unassembled parts.

(1) Handle

(2) Screws

▪ Attach the mains cable to the cable

hook on the handle.

▪ Connect the machine to the mains.

3

2

1

5

4

CAUTION! The voltage rating

stated on the hot-air welding

machine should correspond

to the mains voltage.

!

GB

MACHINE ASSEMBLY

CABLE CONNECTIONS

TW 5000 MAINS

Earth*

L1

L2

1-PH

230 V Europe

Earth*

L1

L2

2-PH

400 V Europe

220 V USA

Earth*

Neutral

L2 Phase

Earth*

Neutral**

L2 Phase

L1 Phase

L3 Phase**

FemaleMale

*Green/Yellow

**Not used

This manual suits for next models

2

Table of contents

Languages:

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual