Sigma Controls 700 PDL Series User manual

1

VISIT OUR WEBSITE SIGMACONTROLS.COM

700 SERIES ‘PDL’

PROCESS DATA LOGGER

INSTRUCTION MANUAL

700 SERIES PDL PROCESS DATA LOGGER 062314

2

TABLE OF CONTENTS

INTRODUCTION………………………………………… 3

Ordering Information

S ecifications

Features

WIRING…………………………………………………… 6

Dwg # 700 PDL Process Data Logger

Showing: In uts (8) 4-20 MA

Digital Out ut (4) Form ‘C’ Relays

PROGRAMMING AND INITIAL SETUP……………... 7

In ut Range Selection

Terminal Block Detail

Initial Setu & Programming

Overview/Key Descri tion

PROGRAMMING RECORD SHEET…………………...

11

TROUBLESHOOTING & MAINTENANCE …………..

1

WARRANTY……………………………………………… 13

*U.L. APPLIES TO OPTIONAL ENCLOSURE

3

INTRODUCTION:

The Sigma 700 Series ‘PDL’ Process Data Logger is a state of the art micro rocessor based, user

configurable instruments for the monitoring and alarming of u to (8) 4/20 MA rocess signals.

The 700 Series PDL erforms the following:

Dis lays information in al ha and numeric format

Allows full user selection of all system variables

Allows user engineering selection

Data logs all variables on user selected interval

Provides USB Port for downloading logs

ORDERING INFORMATION:

Wall Mount Nema 4X Enclosure Sigma 700 Series PDL

SPECIFICATIONS:

ANALOG INPUTS, 4/20MA (8 ea.)

DISPLAY:

LCD, 2 line Al hanumeric, Backlit.

LOOP POWER:

24VDC regulated out ut, 100MA max. (with 110VAC o tion).

3 USER KEYS:

U , Down, Enter

ACCURACY:

0.1% of calibrated s an

LOCKOUT:

User assword, user configurable

INPUT IMPEDANCE:

Voltage 100K, current 100 OHMS

POWER:

24VDC, (110VAC o tional)

ENVIRONMENTAL:

O erating, 0-65° C

Storage, -40° -80° C

R.H., 0-90% non condensing

4

ENCLOSURE:

¼ DIN, ABS lastic 96 X 96 X 110MM or Nema 4X wall mount

FRONT PANEL:

Gasketed Nema 4X Hinged Window

TERMINAL STRIP:

(24) Removable for ease of wiring 28 – 16 AWG

CONNECTIONS:

Removable screw terminal blocks 28 – 16 AWG wire. (27 with 110VAC o tion)

CPU Activity Monitor

PROGRAMMING:

Menu based, all arameters and set oints are user configurable via menu rom ts and user keys.

The reconfigured screens and ‘ ull down’ sub menus with English rom ts assures ra id setu

and commissioning.

1 YEAR WARRANTY

4 M/Byte data logging with USB Port

MODBUS® Master/Slave

Network allows multi le units to be connected together for distributed a lications or remote

monitoring SCADA a lications.

FEATURES:

Micro rocessor Based

LCD Dis lay

3 Function Keys

Isolated 24VDC Sensor Power (with 110VAC o tion)

Fully User Programmable in English

1 Ea. RS485 Port MODBUS® Master/Slave, SCADA

CPU Activity Monitor

5

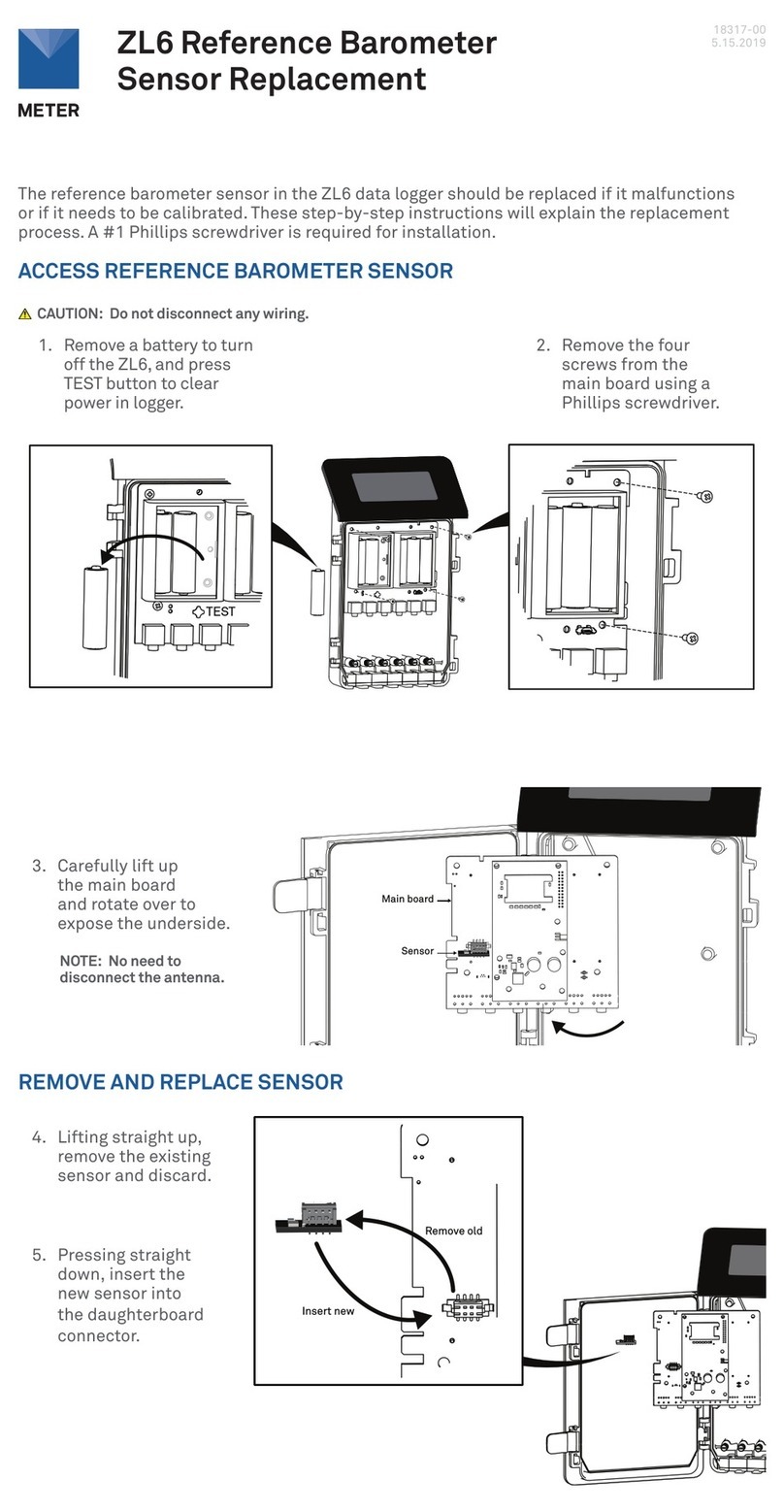

WIRING DETAIL

See Dwg # 13-14

CAUTION

!

All electrical wiring must be in accordance with all local state and national

codes that apply.

Do not exceed

the rated current of the D.C. power supply (100MA) or the form

’C’ relay outputs (5A/ 40VAC resistive).

WARNING

Hazardous voltages are present within the enclosure. Installation or service

should only be carried out by trained personnel.

6

7

Review Screens

The 700 Series PDL utilizes ‘ lain English’ menu driven screens which are sequential and intuitive.

When the unit owers u , the startu screen will a ear as follows:

After the initial screens have a eared, the unit will show the ‘MAIN SCREEN’ which scrolls as

shown below.

NOTE: To pause the screen scroll, press the

buttons.

PROGRAMMING SCREENS

From the Main Menu, Press the button to access the Password Screen:

Software Version #

Identifies the unit

Function and Version #

Shows in uts 1 – 4

with selected

engineering unit and

current value.

Shows in uts 5 - 8

with selected

engineering unit and

current value.

8

se the buttons to enter the re rogrammed assword, then ress to advance to the Menu

Screens.

Use the buttons to advance to the ‘Scaling’ screen.

Press to advance through all in ut screens and when com lete, the controller will save all changed

values and return to the Main Screen.

Use the buttons to enter the dis layed value for channel 1 low. NOTE: Numbers will change faster

with the key held down.

Move to Screen 2

Press to advance to channel 2 settings.

Continue with setting channels 2 – 8 in the same way as described.

And return to the Main Screen.

ADVANCE TO THE ‘SETUP’ MENU’

Setu screen rovides ‘global’ arameters, which affect overall erformance and o eration.

PASSWORD SCREEN

Dis lay shows

that a value of

4MA will

dis lay .00

Shows that a value

of 5.00 will be

dis layed with an

in ut of 20MA.

Show Channel 1

In ut Low Value

Scaling screen allows

user rogramming of all

channels in engineering

units.

9

Setting a assword ‘Locks’ out unauthorized access to rogram items. NOTE: Please make a note of

the password value if changed. Access to the Menus will be unavailable without the correct

password.

Press to advance to the clock/calendar settings.

Use the buttons to change the month. Press to advance.

Use the buttons to change the year. Press to advance.

Use the buttons to change the other settings as reviously described.

Press to advance to the log interval time settings.

NOTE: This screen allows for setting the log interval. As shown the unit will take a reading every 5

seconds.

10

Logging may also be started and sto ed by connecting a dry contact between DI1 and digital

common. It is necessary to remove the screen anel to access this terminal block. Logging

occurs whenever these oints are closed.

Press to advance to the NODE screen. This allows selection of the unit NODE number when used in

MODBUS Network.

Press to advance to the in ut filter screen.

THE DIAGNOSTIC SCREEN

The final menu item is ‘DIAGNOSTICS’. This screen rovides real time information about the current

status of both in uts and out uts.

NOTE: Only digital in ut (1) is used in the 700MM.

This is the Relay

Out ut status.

Shown is Relay

1 and Relay 2

Active. The 8

in uts are shown

the same way.

NOTE:

Use the

in ut filter to

“dam en” noisy or

bouncing values.

NOTE:

No relays in

Data logger.

11

SERIES 700 PROCESS DATA LOGGER

PROGRAMMING RECORD SHEET

Model Number: ________________ Serial Number: _________________

Version: ________________

• Scaling:

Channel 1 Range _________

Channel 2 Range _________

Channel 3 Range _________

Channel 4 Range _________

• Setup

Password ___________

Log Interval ___________

Channel 5 Range ___________

Channel 6 Range ___________

Channel 7 Range ___________

Channel 8 Range ___________

12

• DISPLAY REMAINS AT ZERO OR SHOWS NO CHANGE -- If the dis lay remains at zero or

shows no change but the rocess is changing, check for DC voltage on the loo . With 2 wire (4/20MA)

instruments check with a DC voltmeter at the level instrument, by disconnecting the level instrument

from its 2 wires and measuring across these 2 wires with a DC voltmeter for the resence of 24VDC.

Check the diagnostic screen for analog in ut value.

If DC voltage is resent, reconnect the negative wire of the su ly and insert a milliam meter between

the ositive wires. The loo should rovide a signal between 4 and 20 MA. If no current is resent

or & current exceeds 20MA consult the level instrument su lier.

If DC voltage is not resent check the user su lied ower su ly or if using the 700 DPCF/TPCF su ly

measure across terminals 24VDC and + and -. If no 24VDC is resent consult factory. If 24VDC is

resent check field wiring between the 700 DPC and the field device and recheck ‘SCALE’ functions to

ensure correct setu .

NOTE: This should be done by using the user provided circuit breaker or fuse,

not by removing the power wires at the terminal block. Serious injury or death

can occur if contact is made with the incoming AC power.

MAINTENANCE AND TROUBLE SHOOTING

The Series 700 PDL is a digital solid-state device, which requires no eriodic maintenance.

Occasional checks of the unit should be carried out for hysical and mechanical security of mounting,

terminal blocks, and electrical wiring.

TROUBLE SHOOTING

• UNIT ‘LOCKS UP’ -- Recycle ower to the unit by removing AC ower, waiting 10 seconds and

reconnecting ower.

13

W A R R A N T Y

All Sigma Controls, Inc. roducts are warranted to be free from

defective materials and workmanshi for one (1) year from date of

shi ment. Sigma reserves the right to re air or re lace at its o tion any

roduct found to be defective. In no event shall Sigma Controls, Inc.

be liable for any consequential, incidental, or s ecial damages and the

limit of its liability shall not exceed the urchase rice of the su lied

equi ment.

*****IMPORTANT*****

SENSORS AND CABLE THAT HAVE BEEN USED IN WASTE WATER

OR HAZARDOUS LIQUIDS MUST BE THOROUGHLY CLEANED

BEFORE RETURNING. UNITS RETURNED UNCLEANED WILL BE

CONSIDERED UNREPAIRABLE AND RETURNED TO SENDER OR

DISCARDED. NOTE: DO NOT SUBMERGE UNITS FOR CLEANING

WITH CABLE CUT OR REMOVED. THIS WILL ALLOW CLEANING

FLUID TO ENTER HOUSING, DAMAGING ELECTRONICS AND

VOIDING THE WARRANTY.

RETURN FOR REPAIR POLICY (WARRANTY/NON-WARRANTY

REPAIR)

Return status can be determined upon factory inspection of

returned equipment.

A completed Return Authorization form must accompany all

items returned for repair.

Repairs will be evaluated as quickly as possible. Cost for

non-warranty repairs will be provided before repairs are

initiated and repairs will be completed only after approval by

customer.

217 S. Fifth St., Perkasie, PA 18944 PH: 215

-

257

-

3412 FAX: 215

-

257

-

3416

Table of contents