Sigma Controls QUADCAL Assembly instructions

1

QUADCAL LOOP CALIBRATOR

OPERATOR INSTRUCTION MANUAL

VISIT OUR WEBSITE SIGMACONTROLS.COM

QUADCAL MANUAL 021319

2

The Sigma C ntr ls Quadcal calibrat r is designed t generate (simulate) 4 is lated channels f

4/20MA signals sink/s urce and read 4 Channels (sink) f 4/20MA inputs that share a c mm n

return but are is lated fr m the 4 utputs. The inputs are pr tected fr m accidental ver

currents by means f resettable fuses and p larity pr tecti n and clamp di des.

The display res luti n is f r 2 digits after the decimal p int f r b th the inputs and utputs.

DC p wer c nnecti n.

The unit is p wered by a 5 VDC 1A “plug in” p wer supply r USB c nnecti n. The barrel jack

supply c nnecti n is n the t p f the unit.

N te: The center pin n the c nnect r must be the p sitive (+) f the DC supply.

USB Data c nnecti n. F r future use.

Test Lead c nnecti ns

3

Test Lead c nnecti ns Example 1: Simulating the signal t a n n- p wered 4-20mA input using

Channel 1. Channel must be in the SOURCE m de. While reading the p wered 4-20mA anal g

utput fr m a device n Channel 1 READ display

Test Lead c nnecti ns Example 2: Simulating the signal t a p wered sens r input n Channel

1. Channel must be in the SINK m de.

4

SETUP MODE:

When p wer is first applied, a “splash screen” is displayed which sh ws its m del name,

c pyright inf rmati n, the current l aded s ftware versi ns, and the date and time acc rding t

its internal cl ck.

F ll wing the intr duct ry screen c mes the “Setup Screen” which all ws f r perating

parameter selecti n. It all ws y u t set if an utput channel is in s urce (p wer supplied

internally f r the l p) r sink m de (emulating a 4/20MA l p p wered device). It

als all ws y u t select the display m de f r the ( utput) channel (MA r %), and

the display m de f r the c rresp nding input channel (MA r %). This is

acc mplished by turning the c rresp nding kn b f r that channel pair until the

c rrect selecti n is sh wn. The p ssible ch ices f r each channel are: SRCE MA

– SHOW MA, SRCE % - SHOW MA SRCE MA – SHOW %, SINK MA – SHOW

MA, SINK % - SHOW MA, SINK MA – SHOW % and SINK % - SHOW %. These

ch ices are independent f r each f the channel pairs.

Setup m de can als be entered by pressing the 1 and 2 keys at the same time.

When the selecti ns are c rrect f r y ur applicati n, press the ‘3’ and ‘4’ kn bs at

the same time t save the settings. The unit will remember y ur setting when y u

apply p wer t the unit the next time.

OPERATING MODE:

Set Channel 1 t supply

the l p v ltage and vary

its milliamps. Display

value in mA

Set Channel 4 t vary

the milliamps f a

p wered l p. Display

value in %

Set Channel 1 t

measure a p wered 4-

20mA signal. Display

value in mA.

5

The “Operating M de” f ll ws the “Setup” screen.

The display sh ws the status f the f ur sets f utputs (simulate) and inputs

(read).

In fr nt f each f the simulate utput readings will be either an up arr w r a

d wn arr w. The up arr w indicates the Quadcal is s urcing the current f r that

l p, and the d wn arr w indicates the Quadcal is just sinking current f r that

l p. Next is the reading that l p is set t and then the display m de (MA r

%). If the l p is n t c nnected r is set up as “sinking” when it sh uld be

‘s urcing”, the reading will be “Open”, instead f the setting f r that l p.

The right side f the display f r that l p pair will sh w either the current

sensed in that input l p, r the percent f the 4/20 reading (%) ass ciated

with that current l p. If the reading is n n-existent due t the l p being pen,

r much bel w 3.5MA, the display will sh w “OPEN” instead f a current/percentage reading.

If y u need t change the perating m de f r the unit, pressing the ‘1’ & ‘2’ kn bs at the same

time will return the Quadcal t the “SETUP MODE”.

CHANGING AN OUTPUT CURRENT OR PERCENTAGE:

There are several ways f changing the current utput f a channel:

Turning the kn b f the channel ne ‘click’ will change the current setting by either 0.25MA r

.25%, depending n the utput m de selected f r that channel.

Pressing the kn b d wn and turning it while pressed d wn will change the current setting by

either 0.01MA r 0.01%, depending n the utput m de f r that channel.

Pressing and releasing the kn b with ut turning it will cause the channels utput t step

between the current reading and ne f three presets (see PRESETS ADJUST) f r the channel.

The initial presets are 4MA, 12MA and 20MA r 0%, 50% and 100%, depending n the

perating m de selected f r that channel.

PRESETS ADJUST:

This m de is entered fr m the OPERATING MODE by pressing b th the ‘1’ & ‘3’ kn bs at the

same time.

6

In this m de, kn b ‘1’ is used t select the channel (1-4) t select f r changing presets, kn b ‘2’

is used t select which preset (1-3), kn b ‘3’ is used t change the preset, and kn b ‘4’ is used

t st re the change. If y u d n t press and release kn b ‘4’, the value f r that channel/preset

will NOT be changed. N te that there are 6 presets st red f r each utput channel: 3 f r MA

m de, and 3 f r percent (%) m de perati n, and the presets f r each channel are selected

based n the perating m de f r that channel.

As in OPERATING MODE, pressing kn b ‘3’ while turning will all w changing f the preset in

0.01MA r 0.01% steps, instead f 0.25MA r 0.25% steps.

T exit back t OPERATING MODE, press b th kn bs ‘3’ and ‘4’ at the same time.

These settings are als remembered by the unit.

DISPLAY ADJUST:

This m de lets y u adjust the display c ntrast and back light brightness.

T enter the m de fr m the OPERATING MODE, press b th the ‘2’ and ‘4’ kn bs at the same

time.

Turn kn b ‘1’ t adjust the c ntrast f the display and kn b ‘2’ t adjust the back light brightness.

Press kn bs ‘3’ and ‘4’ at the same time t return t OPERATING MODE.

These settings are als remembered by the unit.

DATE/TIME ADJUST:

This m de is primarily f r future expansi n when s ftware upgrades will all w the Quadcal t d

data l gging and/ r run ‘canned’ test sequences al ng with the data l gging.

The date/time are st red in a battery backed cl ck chip in the Quadcal.

T enter the m de, press the ‘1’ and ‘4’ kn bs at the same time.

Use kn b ‘1’ t select the date/time settings t change – they are indicated by the underlining f

the digits that are t be changed.

Use kn b ‘2’ t change the value f the displayed date/time inf rmati n.

Press kn bs ‘3’ and ‘4’ at the same time t return t OPERATING MODE.

7

All Sigma Controls, Inc. products are warranted to be free from defective materials

and workmanship for one (1) ear from date of shipment. Sigma reserves the right

to repair or replace at its option an product found to be defective. In no event shall

Sigma Controls, Inc. be liable for an consequential, incidental, or special damages

and the limit of its liabilit shall not exceed the purchase price of the supplied

equipment.

RETURN FOR REPAIR POLICY (WARRANTY/NON

RETURN FOR REPAIR POLICY (WARRANTY/NONRETURN FOR REPAIR POLICY (WARRANTY/NON

RETURN FOR REPAIR POLICY (WARRANTY/NON

-

--

-

WARRANTY REPAIR)

WARRANTY REPAIR)WARRANTY REPAIR)

WARRANTY REPAIR)

Return status can be determined upon factor inspection of returned

equipment.

A completed Return Authorization form must accompan all items returned

for repair.

Repairs will be evaluated as quickl as possible. Cost for non-warrant

repairs will be provided before repairs are initiated and repairs will be

completed onl after approval b customer.

***

**IMPORTANT*****

SENSORS AND CABLE THAT HAVE BEEN USED IN WASTE

WATER OR HAZARDOUS LIQUIDS MUST BE THOROUGHLY

CLEANED BEFORE RETURNING. UNITS RETURNED

UNCLEANED WILL BE CONSIDERED UNREPAIRABLE AND

RETURNED TO SENDER OR DISCARDED. NOTE: DO NOT

SUBMERGE UNITS FOR CLEANING WITH CABLE CUT OR

REMOVED. THIS WILL ALLOW CLEANING FLUID TO ENTER

HOUSING, DAMAGING ELECTRONICS AND VOIDING THE

WARRANTY.

WARRANTY

217 S. Fifth Street, Perkasie, PA 18944 PH: 215-257-3412 FAX: 215-257-3416

Table of contents

Popular Test Equipment manuals by other brands

Hygiena

Hygiena PCD4000 quick start guide

National Instruments

National Instruments USB Digitizers NI USB-5132 Getting started guide

Sonotron NDT

Sonotron NDT ISONIC utPod operating manual

cctv camera pros

cctv camera pros MON-LCD35P user manual

Rigol

Rigol DS2000E Series quick guide

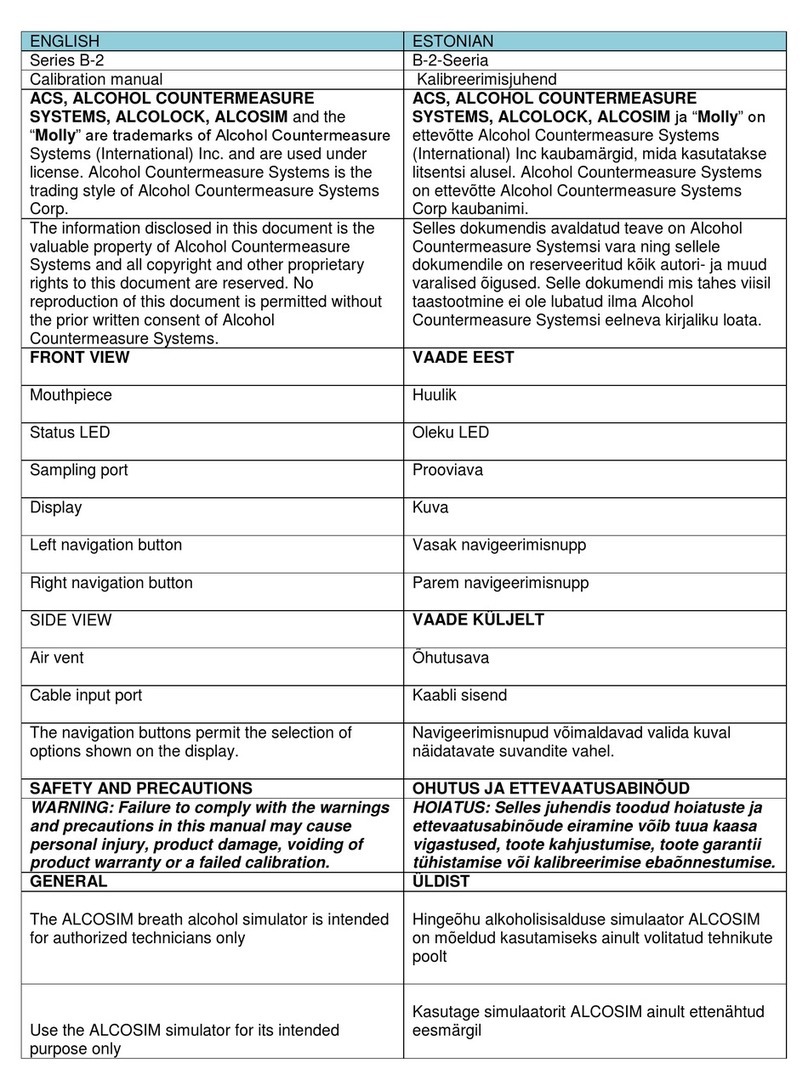

ACS

ACS ALCOLOCK B-2 Series Calibration manual