Table of Contents

1. Precautions before use .................................................................................................................4

1.1 Electrification and Electric Shock....................................................................................4

1.2 Ground .............................................................................................................................4

1.3 Power ...............................................................................................................................4

1.4 Connect the testing cable to the high voltage output terminal.........................................4

1.5 Warm up ...........................................................................................................................4

1.6 External control host ........................................................................................................4

1.7 Machine malfunction .......................................................................................................4

1.8 Test End............................................................................................................................4

1.9 Placement and Storage .....................................................................................................4

1.10 Emergency Measures .......................................................................................................4

2. General description ......................................................................................................................5

2.1 Package and Accessories..................................................................................................5

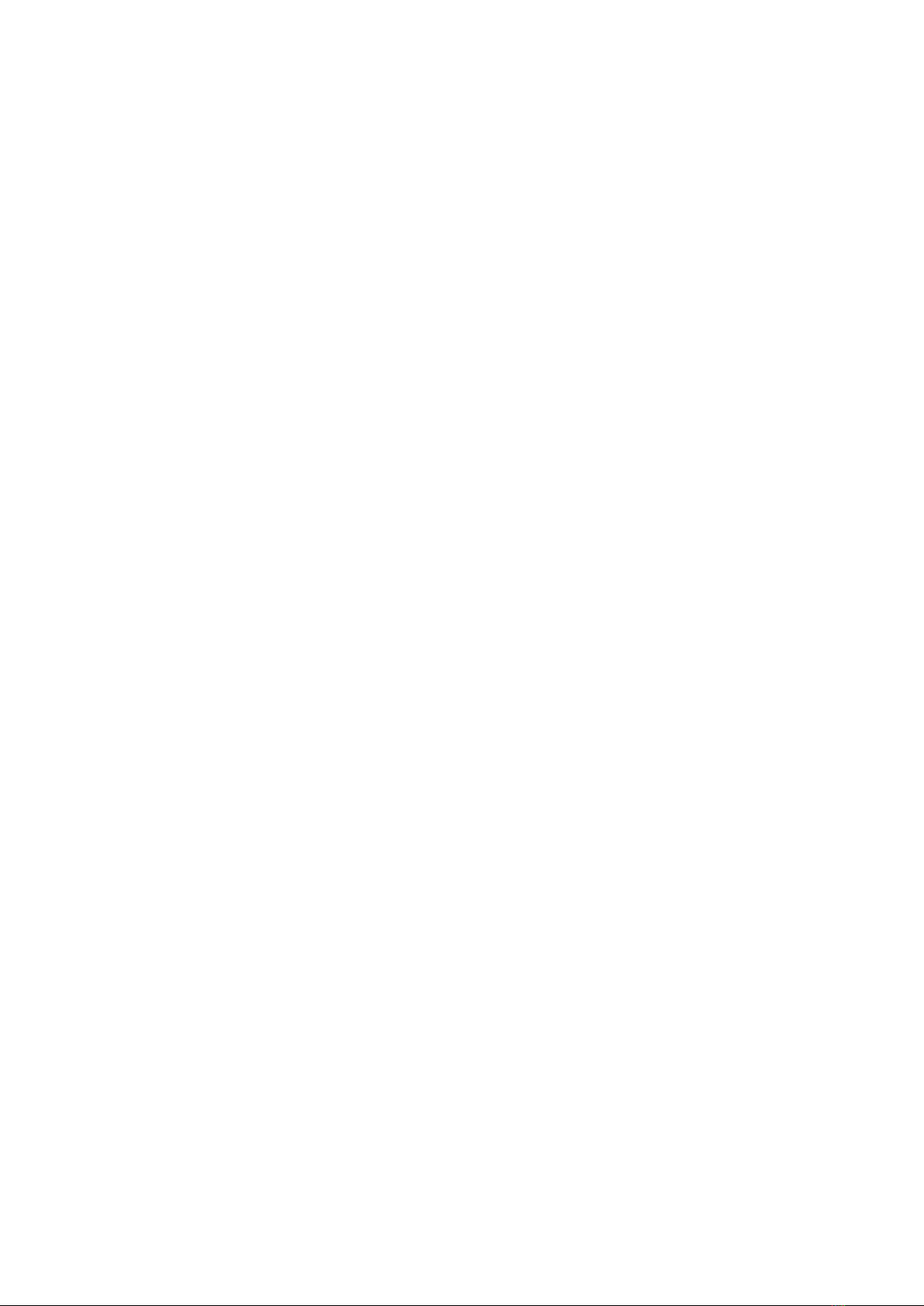

2.2 Front Panel .......................................................................................................................6

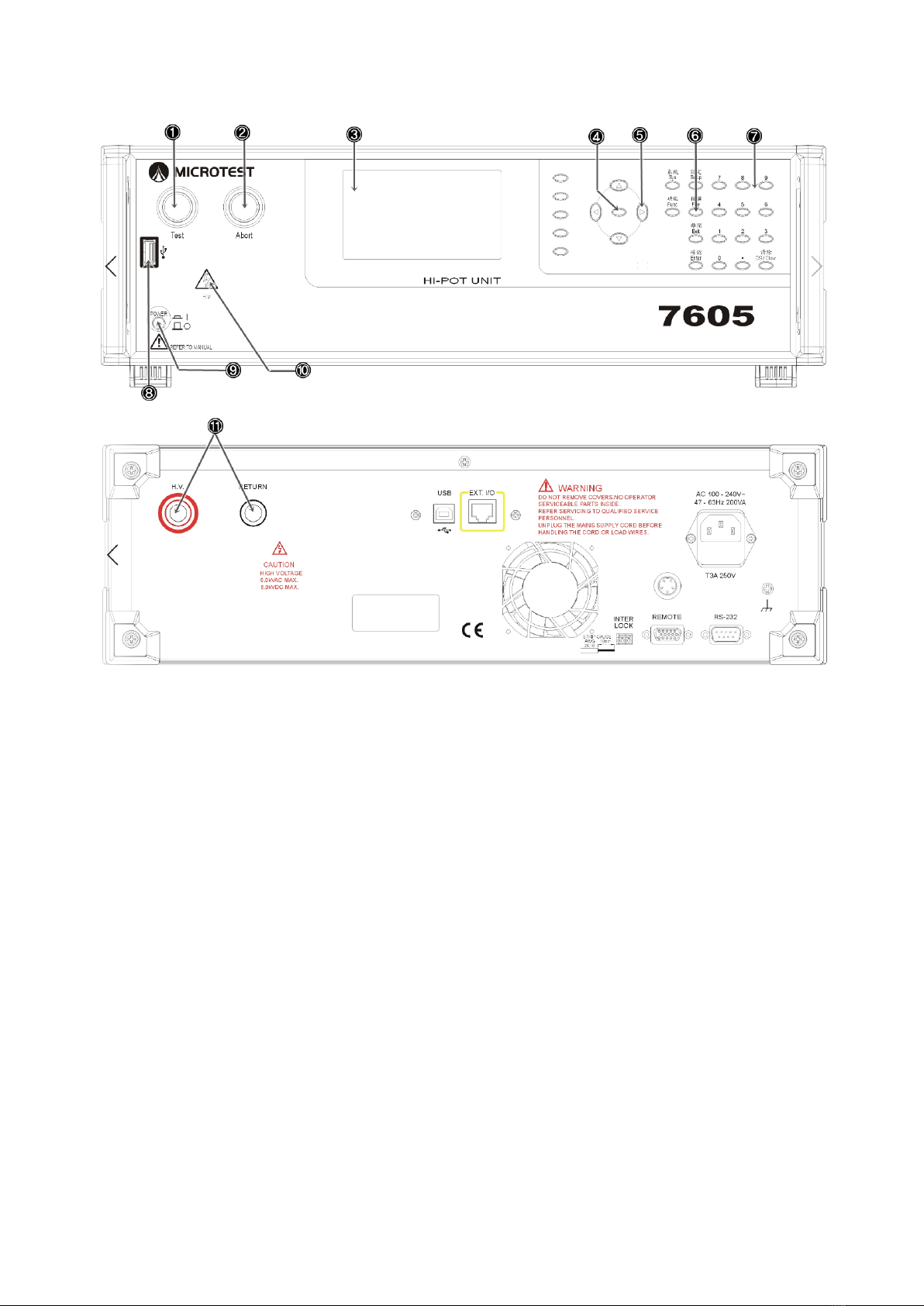

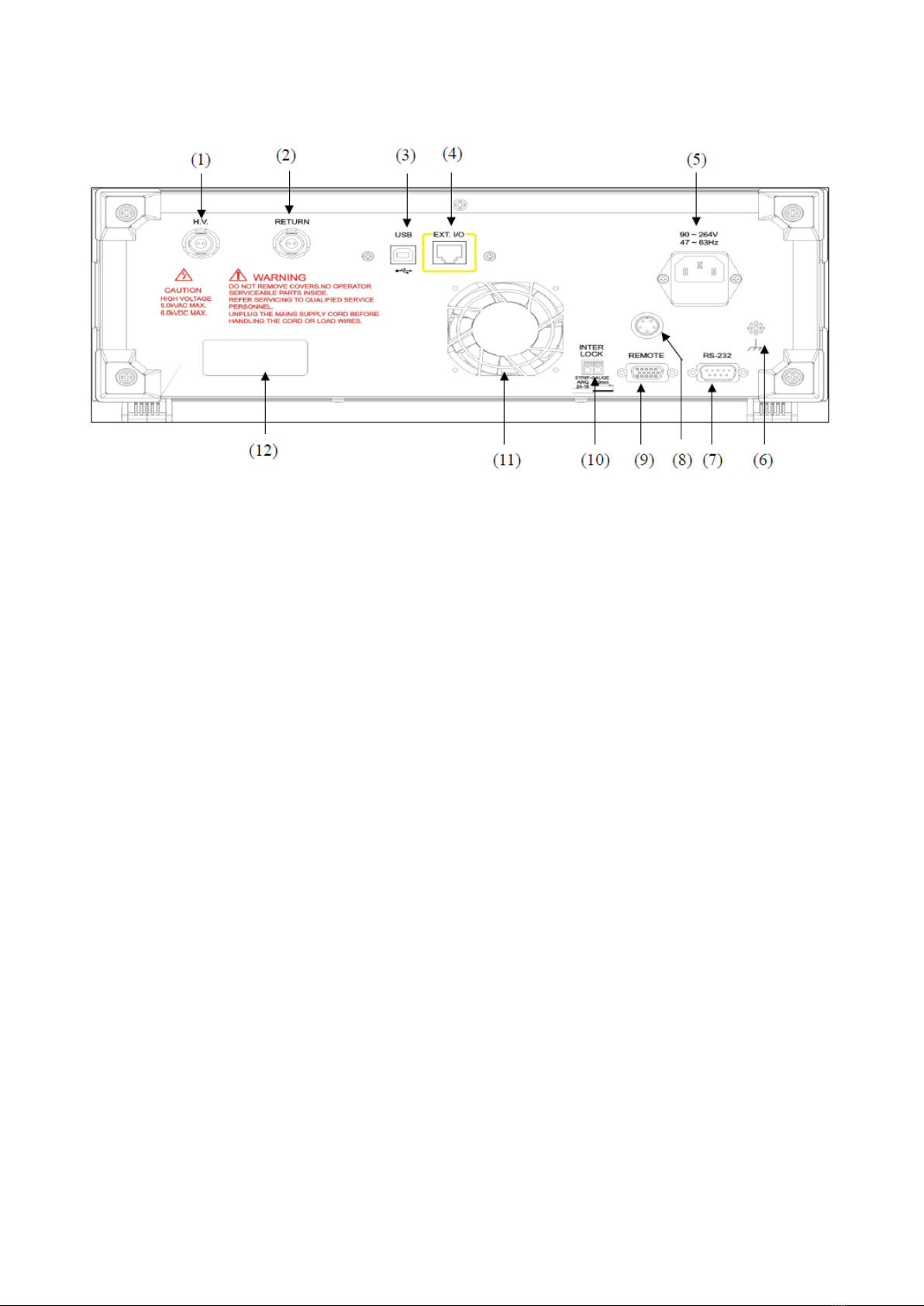

2.3 Rear Panel ........................................................................................................................8

3. Basic Operations ........................................................................................................................10

3.1 Function Block Diagram................................................................................................10

3.2 Standby Screen............................................................................................................... 11

3.3 System Settings (SYSTEM)...........................................................................................12

3.4 Function Setting (FUNC)...............................................................................................13

3.5 Specification Settings Description 1 (SETUP) ..............................................................14

3.6 Specific Setting Description 2 (SETUP)........................................................................15

3.7 File Management (FILE) ...............................................................................................17

4. Start test......................................................................................................................................20

4.1 Before testing .................................................................................................................20

4.2 Testing............................................................................................................................21

4.3 End Test..........................................................................................................................22

4.4 Releasing Determined Result.........................................................................................23

5. Remote Control I/O Description (REMOTE)............................................................................24

6. RS-232/USB DEVICE Instructions ...........................................................................................26

6.1 RS-232 interface specifications .....................................................................................26

6.2 Command Format ..........................................................................................................26

6.3 Connectors .....................................................................................................................26

6.4 Cables and Connecting Methods....................................................................................27

6.5 USB DEVICE Interface Specifications .........................................................................27