AutomationDirect ProSense DPM1-P Series User manual

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

2

UL

CUS

R

In this Chapter...

General Information......................................................................................................3

Package Contents.........................................................................................................3

Recycling Instructions...................................................................................................3

General Safety Considerations ......................................................................................3

Symbols Identification ..................................................................................................3

Maintenance ................................................................................................................4

Technical Support ........................................................................................................4

Agency Certifications....................................................................................................4

Device Description.........................................................................................................5

Dimensions and Mounting............................................................................................6

Installation....................................................................................................................6

Wiring Terminals............................................................................................................7

Input Wiring Diagrams..................................................................................................8

Programming Keys ........................................................................................................9

Configuration.................................................................................................................9

Programming numerical values ..................................................................................10

Input Configuration.....................................................................................................11

Operation Mode Configuration ..................................................................................12

Additional Functions....................................................................................................14

Configuration Lock Out...............................................................................................15

Lock-out menu diagram .............................................................................................16

Output Options............................................................................................................18

Relay Configuration....................................................................................................18

Description of Operation............................................................................................18

Direct access to the relay setpoints value programming.............................................20

Analog output............................................................................................................20

Analog output menu diagram ....................................................................................21

Technical Specifications...............................................................................................22

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

3

General Information

Package Contents

• DPM1-P Series digital panel meter

• Quick start guide

• Mounting panel accessories (a sealing gasket and fixing clip)

• Wiring accessories (plug-in terminal block connectors and 2 key tools for wire insertion)

• Adhesive engineering unit label sheet

Recycling Instructions

This electronic instrument is covered by the 2012/19/UE European Directive so, it is properly

marked with the crossed-out wheeled bin symbol that makes reference to the selective collection

for electrical and electronic equipment which indicates that at the end of its lifetime, the final

user cannot dispose of it as unsorted municipal waste.

In order to protect the environment and in agreement with the European legislation regarding

waste of electrical and electronic equipment from products put on the market after August 13,

2005, the user can give it back, without any cost, to the place where it was acquired to proceed

to its controlled treatment and recycling.

General Safety Considerations

All instructions and guidelines for the installation and manipulation that are present in this

manual must be considered to ensure personal safety and to prevent damage to either the

instrument or any equipment connected to it.

Safety of any equipment incorporated to this instrument is the responsibility of the system

installer.

If this electronic indicator is used in a manner not specified by the manufacturer in this manual,

the protection provided by the instrument may be impaired.

Symbols Identification

Warning: Potential risk of danger.

Read complete instructions when this symbol appears in order to know the potential risk and

know how to avoid it.

Warning: Risk of electric shock.

Instrument protected by double isolation or reinforced isolation.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

4

Maintenance

To ensure instrument accuracy, it is recommended to check its performance according to the

technical specifications listed in this manual.

For front cover cleaning, just wipe with a damp cloth and neutral soap product. DO NOT USE

SOLVENTS!

Technical Support

We strive to make our manuals the best in the industry. We rely on your feedback to let us

know if we are reaching our goal. If you cannot find the solution to your particular application,

or, if for any reason you need technical assistance, please call us at:

1-800-633-0405

Our technical support group will work with you to answer your questions. They are available

Monday through Friday from 9:00 A.M. to 6:00 P.M. Eastern Time. We also encourage you

to visit our web site where you can find technical and non-technical information about our

products and our company.

www.AutomationDirect.com

Agency Certifications

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

5

Device Description

These models in the ProSense DPM1-P series offer a simple, low cost digital display for

frequency, tachometer, and rate applications. The DPM1-P has a 4-digit 10mm character

height red LED display, accepts input from AC voltage, magnetic sensors, NPN/PNP sensors,

NAMUR sensors, TTL/24V encoders, or switched contacts, and provides selectable sensor

excitation voltages. The meter is powered from an external AC or DC power supply. The

1/32 DIN housing takes up minimal panel space and the meter face has an IP65 rating.

Configuration parameters can be locked out to prevent unauthorized or accidental changes to

the meter’s operation. ProSense digital panel meters are backed by a 3 year warranty.

• 48 x 24mm 1/32 DIN

• 4 digit (0 to 9999) red LED display

• Frequency/Tachometer/Rate Modes

- AC voltage

- Magnetic sensor

- NAMUR sensor

- NPN/PNP sensor

- TTL/24V encoder

- Switched contact

• Selectable decimal point

• AC or DC powered

• Sensor excitation voltage

• Direct or reverse scaling in Rate mode

• Total configuration lock out

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

6

Dimensions and Mounting

Fixing clip

Sealing gasket

DPM1 Meter

Panel mounting surface

Dimensions mm [in]

Installation

To install the meter, prepare a 45mm x 22mm panel cut-out and slide the unit inwards making

sure to place the sealing gasket between the front side

panel and the front bezel.

While holding the unit in place, put the fixing clip

around the case and slide it until it reaches the panel

at the rear side.

Press slightly to fasten the clips to the latching slots

on the case and get the unit fully assembled and close

fitted to achieve a good seal.

To remove the meter from the panel, pull the rear fixing clips latching tabs outwards until they

are disengaged, then slide the fixing clips back over the case.

Installation

Dimensions 48 x 24 x 125.1mm (1/32 DIN)

Panel Cutout 45 x 22mm

(Max. panel thickness 7mm)

Case Material Polycarbonate UL 94 V-0

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

7

Wiring Terminals

CN3

Analog

Output

1 -0/4-20mA

2 +0/4-20mA

CN2 and CN3 Terminals CN1, CN4 and CN5 Terminals

CN1

AC

Supply DC

Supply

1 Line 1 -VDC

2 Neutral 2 +VDC

CN4

Relay 1

1N.O. Contact

2

CN5

Relay 2

1N.O. Contact

2

CN3

CN1

CN5

CN4

CN2

1

2

11

12

2 2

125 34

Terminals

Connector CN1 CN2 CN3 CN4 CN5

Wire cross section 0.08 to 2.5mm²

(28 to 12 AWG)

0.08 to 0.5mm²

(28 to 20 AWG)

0.08 to 0.5mm²

(28 to 20 AWG)

0.08 to 2.5mm²

(28 to 12 AWG)

0.08 to 2.5mm²

(28 to 12 AWG)

Strip length 8 to 9mm 5 to 6mm 5 to 6mm 8 to 9mm 8 to 9mm

Manufacturer Wago 231-

202/026-000 Wago 733-105 Wago 733-102 Wago 231-

102/026-000

Wago 231-

302/026-000

Cage clamp

connection

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

Insertion tool or

screwdriver with

0.3 mm x 1.8 mm

blade

Insertion tool or

screwdriver with

0.3 mm x 1.8 mm

blade

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

Insertion tool or

screwdriver with

0.5 mm x 3.0 mm

blade

Insertion Tool (included with meter)

Insert wires into the proper terminal

while using the insertion tool to open

the clip inside the connector. Release

the insertion tool to fix wire to the

terminal.

Insertion Tool (included with meter)

Insert wires into the proper terminal

while using the insertion tool to open

the clip inside the connector. Release

the insertion tool to fix wire to the

terminal.

CN2

Signal Input

110 - 600 VAC

2Not used

3+ Input pulses

4Common

5+ Excitation (5, 8, 12V) @

60mA

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

8

Refer to the instructions in this manual to preserve safety protections.

WARNING: If this instrument is not installed and used in accordance with these

instructions, the protection provided against hazards may be impaired.

To meet the requirements of EN 61010-1 standard, where the unit is permanently connected to

main supply, it is obligatory to install a circuit breaking device easily reachable by the operator

and clearly marked as the disconnecting device.

To guarantee electromagnetic compatibility, the following guidelines should be kept in mind:

• Power supply wires should be separately routed from signal wires and never run in the same conduit.

• Use shielded cable for signal wiring.

• Cables section should be ≥0.25 mm².

Before connecting signal wires, signal type and input range should be verified to be within the

right limits. Do not connect simultaneously more than one input signal to the meter.

Input Wiring Diagrams

10-600V AC Input

5 4 3 2 1

CN2

Switched contac

t

5 4 3 2 1

CN2

5 4 3 2 1

CN2

TTL/24V DC Encoder input

+ Exc.

+ Pulses (Out)

Common

NPN / PNP / PWM sensors

NAMUR sensor

5 4 3 2 1

CN2

+ Exc.

+ Pulses (Out)

Common

5 4 3 2 1

CN2

+ Exc.

+ Pulses (Out)

5 4 3 2 1

CN2

Magnetic sensor

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

9

Programming Keys

ENTER: Enters configuration and

validates data and parameters.

UP: Increases value of blinking digit in configuration

mode.

SHIFT: Selects mode or shifts blinking digit in

configuration.

(Bottom View)

Configuration

When the power is applied to the meter, a display test begins automatically to check the function

of the LED’s and digits. Once this test is finished the display shows the internal software version

and then the unit goes to RUN mode.

Configuration follows a structure composed of a number of menus and submenus. By pressing

the ENTER key for <3 seconds, the main menu level is entered and the display will show “Pro”.

Pressing the SHIFT key provides access to the programming menu level which includes menus

for input configuration (InP), display configuration (dSP), relay configuration if present (SEt),

analog output configuration if present (A.out). Press ENTER to access the submenus under

each programming menu.

If configuration has been totally locked-out, when pressing ENTER to access the main menu

level, the display shows dAtA instead of Pro. This indicates that it is only possible to see

programmed information and that it is not allowed to modify any parameter from the entire

configuration. In this visualization mode, the meter automatically switches back to RUN mode

after 15 seconds from the last key press.

Run Mode

(¹) If parameter lock out has been enabled, dAtA will

be displayed instead of Pro

<3sec >3sec <3sec

Enters configuration

menu (non-locked

out parameters).¹

Enters lock

out menu.

Displays detected maximum and

minimum values. Value RESET can

be done by pressing at least 3 sec.

(then new maximum or minimum

value is displayed).²

(²) Additional information provided later in this User Manual

The progress through the programming routines is done by pressing ENTER key. In general,

push SHIFT key a certain number of times to select an option and push ENTER key to validate

the change and move forward to the next step of the program.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

10

Programming numerical values

When the parameter is a numerical value, the display will show the first of the digit to be

programmed blinking.

Digit selecting: Press repeatedly the SHIFT key to shift from left to right over all the display

digits.

Changing the digit value: Press repeatedly the UP key to increase the value of blinking digit

until it has the desired value.

The minus sign is programmed depending on the variable type. A variable that represents the

value of an input will be able to take a value in the range 0 to 9999, without taking into account

the decimal point. When a digit is selected it shows values from (0) to (9), and then (-1), (-), and

comes back to show values from 0 to 9. A variable that represents a display value will be able to

take a value in the range 0 to 9999, without taking into account the decimal point.

Completion of each submenu routine returns the meter to Pro mode. To save data entered or

changed during configuration press the ENTER key while in Pro mode. Stor will be displayed

for a few seconds while all of the configuration data is stored in memory. The meter will then

return to RUN mode.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

11

Input Configuration

The figure below shows the input configuration menu.

INPUT TYPES

1 10-600 V

2 Magnetic sensor

3 NAMUR

4 PNP / PWM

5 NPN / PWM

6 TTL/24 V DC / Encoder

7 Switched contact

5 6 7

E

12 U 8 U 5 U

Pro

InP ModE SEt

1 2 3 4

Operation

mode config.

Setpoints

configuration

Stor

Pro

A.out

Analog output

configuration

(0/4-20mA)

1

Select Excitation Voltage 12V, 8V or 5V

Select

Input

Type

ENTER: Enters configuration and

validates data and parameters.

UP: Increases value of blinking digit in configuration

mode.

SHIFT: Selects mode or shifts blinking digit in

configuration.

(Bottom View)

Programming Keys

(Bottom View)

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

12

Operation Mode Configuration

ModE

invdir

PPr

8888

1

rAtEtAC

dCP

FrEC

0.1

dCP

dSP1

inP1

8888

88.8.8

8.8.8.8

8888

88

8.8

T.Lim

t.Avr

Pro

0.01

1 0.1

Selección posición

punto decimal

Pulsos por

revolución

Frecuencia de

entrada

Punto decimal de la

frecuencia de

entrada

Indicación deseada

para esta frecuencia

de entrada

Posición punto

decimal

Selección

nivel de brillo

de 1 a 4

Tiempo de promediado

de las lecturas

Desde 0.0 a 9.9

segundos

Tiempo límite de espera

llegada pulsos

Desde 1 a 99 segundos

El t.Avr (tiempo de promediado) debe

ser inferior al t.LIM (tiempo límite)

>3s

No

Selección

posición punto

decimal de las

r.p.m.

br 1 br 2 br 3 br 4

Lin

dSP1

inP1

8888

88.8.8

8888

dSP2

inP2

8888

8888

duty

dSP1

inP1

888.8

8888

dSP2

inP2

888.8

8888

Frecuencia de

entrada

Indicación deseada

para esta frecuencia

de entrada

Ciclo de trabajo de

entrada

Indicación deseada

para este ciclo de

trabajo de entrada

Ciclo de trabajo de

entrada

Indicación deseada

para este ciclo de

trabajo de entrada

8.8.8.8 8.8.8.8

8.8

t.Avr

Pro

Selección

nivel de brillo

de 1 a 4

Tiempo de promediado

de las lecturas

Desde 0.0 a 9.9

segundos

>3s

No

br 1 br 2 br 3 br 4

88

T.Lim Tiempo límite de espera

llegada pulsos

Desde 1 a 99 segundos

Operation mode selection

(PWM Function)

Selection of decimal

point position Pulses per

revolution

Selection of

r.p.m. decimal

point position

Input

Frequency 1

Decimal point

of input

frequency 1

Desired display for

input frequency 1

Decimal point

position

Input

frequency 2

Desired display for

input frequency 2

Brightness

selection

from 1 to 4

T.Avr (average measurement time)

must be less than T.Lim (time limit)

Average

measurement

time of readings

From 0.0 to 9.9s

Time limit waiting for

input pulses.

From 1 to 99s

Brightness

selection

from 1 to 4

Time limit waiting for

input pulses.

From 1 to 99s

Average

measurement

time of readings

From 0.0 to 9.9s

Desired display for

input 2duty cycle

Input 2 duty cycle %

Desired display for

input 1duty cycle

Input 1 duty cycle %

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

13

To use the meter to display frequency select the “FrEC” operation mode.

In tachometer mode “tAC” speed is always displayed in rpm based on the specified number of

pulses per revolution from the sensor.

In rate mode “rAtE”display scaling is possible from an input value given in pulses per second

(input frequency) to configure a display-frequency ratio reading in engineering units. If

increasing frequency must result in an increasing display then “dir” (direct proportional

variation) must be selected. Select “inV” (reverse proportional variation) if increasing

frequency must result in a decreasing display.

In the “duty” configuration, the meter is able

to present a display proportional to the cyclic

relationship of the input signal (t on / t off ).

The programming sequence is similar to that of

any analog input, introducing a pair of values for

the input (InP1 and InP2) to which correspond

a pair of display values (dSP1 and dSP2).

InP1 = Ton / toff value in point 1

(programmable from 0 to 100.0%) dSP1 =

Display value for point 1 (programmable from 0

to 9999 plus decimal point position)

InP2 = Value of ton / toff in point 2

(programmable from 0 to 100.0%) dSP2 =

Display value for point 2 (programmable from 0

to 9999)

Modulation of the cyclical relationship (duty cycle)

0% Duty Cycle

100% Duty Cycle

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

14

Additional Functions

MAX/MIN function

With the meter in RUN mode: Activated after pressing the SHIFT key for less than 3 seconds.

From RUN mode, a press shows the maximum value read by the meter since the last time it has

been switched on, unless a RESET MAX/MIN is done, the display will alternate between “Hi”

and the maximum stored value. With a second press the display will alternate between “Lo” and

the minimum stored value. A third press brings the meter back to RUN mode.

Reset MAX/MIN

While the meter shows the peak value (MAX), pressing the SHIFT key for 3 seconds will

produce a reset of the value. Pressing SHIFT key for 3 seconds while the meter shows the valley

value (MIN) will produce a reset of the value.

Configuration Lockout

In mode RUN if the ENTER key is pressed for 3 seconds, the meter will show the indication

CodE, and following 0000, allowing the user to introduce the security code. If the code that

has been introduced is wrong, the meter will go back to RUN mode, if it is correct, it will

allow the access to the security menu. See section detailing Configuration Lockout.

Return to Factory Configuration

From RUN mode press the ENTER key for less than 3 seconds to access Pro programming

mode. Now press the UP key for more than 3 seconds to allow entering the numeric code to

reset the meter to factory configuration parameters. This code is 74. When entering this code

the meter shows the LoAdIng dEFAuLt ConFIGurAtIon, and then StorE, which means

that they have been stored in the non volatile memory of the meter.

>3sec

Run Mode

<3sec Programming Mode

If parameter lock out has been enabled, dAtA

will be displayed instread of Pro

Enter code 74

Save value

Run Mode

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

15

Direct Access to Relay Setpoints

The meter allows direct access to the programming of the relay setpoint values. After accessing

programming mode, Pro, pressing the UP key provides access to each relay setpoint value.

.

.

Relay 1 setpoint

Enter setpoint of 20.0 for

this example

Relay 2 setpoint

Enter setpoint of 80.0 for

this example

Save values

Run Mode

<3 sec.

Programming Mode

Run Mode

Configuration Lock Out

The meter is delivered with the programming not locked out, giving access to all the

programming levels. Once completed the meter programming the following security measures

are recommended:

1. Lock out the programming access to prevent from programmed parameters modifications.

2. Lock out Key Pad functions to prevent from accidental modifications.

3. There are two lockout modes: selective and total. If the parameters are going to be readjusted

frequently, make a selective lockout. If no adjustment is going to be made, make a total

lockout. Key Pad functions lockout is always possible.

4. The access to the lockout routine is allowed by entering a personalized code. If the code set at

factory is changed, be sure to write down your personalized code and keep it in a safe place.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

16

TOTAL LOCKOUT

The access to the programming routines to read data is allowed even if all parameters are locked

out ALL=Yes, but it will not be possible to enter or modify data. In this case, when entering

in the programming mode, the display shows the indication “-dAtA-”.

PARTIAL LOCKOUT

When only some parameters are locked out, all configuration data can be read but only non

protected parameters can be modified. In such case, when entering in the programming

mode, the display shows the indication -Pro- “.

Menus or submenus that can be locked out are:

• Relay 1 Configuration (C.SP.1).

• Relay 2 Configuration (C.SP.2).

• Relay 1 Setpoint Value (V.SP.1).

• Relay 2 Setpoint Value (V.SP.2).

• Input configuration (InP).

• Display (dSP).

• Analog output configuration (A.Out). If present in meter.

• Programming of the key TARE (tArE).

Lock-out menu diagram

The following figure shows the lock-out menu. The access to this menu is accomplished from

the run mode by pressing the ENTER key for 3 seconds, until the “CodE” indication appears.

The meter is shipped from factory with the following default code: “0000”. Once this code is

entered, the “CHAn” menu is available to change to a personal code. Write down and keep this

code in a safe place (Do not count on your memory). This personal code makes the default

code useless.

If an incorrect code is entered, the meter will return automatically to the run mode. Total

lockout programming is achieved by changing ALL to Yes. Changing ALL to No will lead to

the selective lockout of the programming variables. Programming each one of the parameters

to 1 will active the lockout, if they are set to 0 programming will be accessible. Though the

programming is locked out, it remains possible to visualize the current programming.

The “Stor” indication informs that the modifications effectuated have been stored correctly.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

17

inP

..

..

..

..

.

Enter secret code to access this routine (default code is 0000).

If secret code is forgotten, proceed to load default configuration

to have access to lock-out configuration again.

Previous settings will be lost.

Allows to change secret code

selecting 'YES'

Total lock-out of parameters

Menu partial lock-out.

0= unlocked

1= locked-out

Mode menu lock-out

SETPOINT1 menu lock-out

SETPOINT2 menu lock-out

SETPOINT1 value menu lock-out

SETPOINT2 value menu lock-out

Serial output menu lock-out

.

Analog output menu lock-out.

(only appears if ANAP is installed. Only

in this case serial output menu does

not appear).

Run Mode

>3s

ENTER

:

Enters configuration and

validates data and parameters.

UP: Increases value of blinking digit in configuration

mode.

SHIFT: Selects mode or shifts blinking digit in

configuration.

(Bottom View)

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

18

Output Options

All output are optoisolated with respect to input signal and power supply.

Relay Configuration

Introduction

All DPM1-P models are equipped with 2 relays that can provide individual alarm and control

capabilities. Each relay can be configured to function based on independent setpoint values

within the full configured display range, time delay (in seconds), hysteresis (in counts of display)

and selectable HI/LO acting.

Description of Operation

The relay outputs activate when the display value reaches the corresponding programmed relay

setpoint value. The following relay operational parameters must also be set:

HI/ LO ACTING MODE.

In HI mode, the output activates when the display value exceeds the setpoint level and in LO

mode, the output activates when the display value falls below the setpoint

PROGRAMMABLE TIME DELAY or HYSTERESIS.

Each output action can be deferred by a programmable time delay or hysteresis level.

The time delay is the time that takes the output to activate after passing through the setpoint in

the up or down direction, while the hysteresis band will be selected asymmetrical i.e. only acts

on the output deactivation edge. The delay is programmable in seconds, from 0 to 99.

The hysteresis can be programmed, in counts, within the full display range. The decimal point

appears in the same position as programmed in the display configuration module.

The figures 1 and 2 show the time delay action (dly) and the hysteresis action (hys) of two

alarms (SET1 and SET2) programmed to activate in HI mode (OUT1) and LO mode (OUT2)

Delay action

Asymmetrical hysteresis

dly

dly dly

dly

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

19

Activating mode selection:

Lo: Low level activation

Hi: High level activation

CnF

dLy HyS

88 8888

Lo Hi

Pro

Setpoint 1 configuration block

Delay / Hysteresis selection

Delay: from 0to 99s

Hysteresis:

From 0000to 9999 points

of display.

Stor

Set

Activating mode selection:

Lo: Low level activation

Hi: High level activation

CnF

dLy HyS

88 8888

Lo Hi

Setpoint 2 configuration block

Delay / Hysteresis selection

Delay: from 0to 99s

Hysteresis:

From 0000to 9999 points

of display.

DPM1-P User Manual, 1st Edition

User Manual - DPM1-P Series Panel Meters

20

Direct access to the relay setpoints value programming

It is possible to directly access the relay setpoint values without the need to go through the

programming menu just by pressing the UP key in Pro mode, as shown in diagram below.

Remember that the decimal point

position is determined by what has

been programmed.

.

.

Relay 1 setpoint

Enter relay 1 setpoint

value

Relay 2 setpoint

Enter relay 2 setpoint

value

Save values

Run Mode

<3 sec.

Programming Mode

Run Mode

Analog output

Introduction

DPM1-P models include an analog output (0/4-20 mA).

The output is opto-isolated with respect to the signal input and the power supply.

The meter provides a two terminal connector [(+ ) and (-)] that drives out a signal variation

from 0-20mA or 4-20mA proportional to a user-defined display range.

The signal can be used to transmit display information to a variety of terminal equipment such

as graphic recorders, controllers, remote displays or other devices that accept input data in

analog form.

The display values producing the full scale output (HI and LO) are introduced via front-panel

buttons in the same programming module. The analog output then follows the display variation

between the HI and LO programmed points.

The output signal can be set up for reverse action by programming the low display for the high

output (HI) and the high display for the low output (LO).

This manual suits for next models

2

Table of contents

Other AutomationDirect Measuring Instrument manuals

AutomationDirect

AutomationDirect OP-406 User manual

AutomationDirect

AutomationDirect ProSense LPM1 Series User manual

AutomationDirect

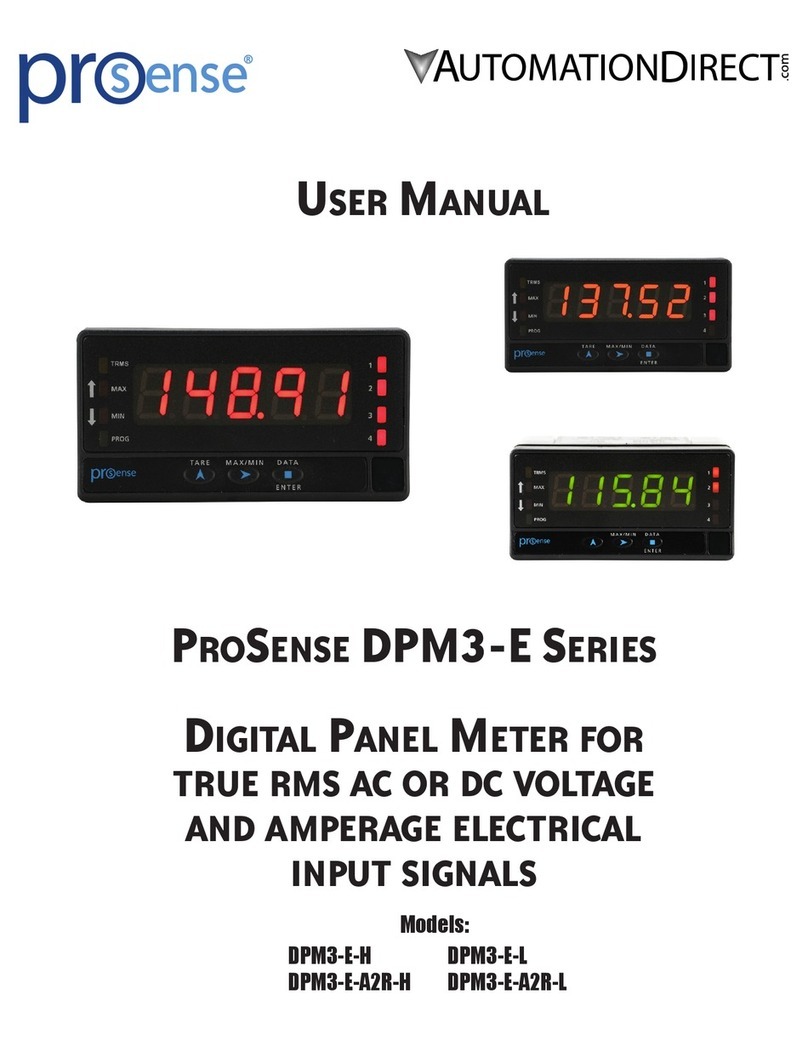

AutomationDirect ProSense DPM3 Series User manual

AutomationDirect

AutomationDirect ProSense DPM2 Series User manual

AutomationDirect

AutomationDirect ProSense FG1 Series User manual

AutomationDirect

AutomationDirect prosense TTD-20-N40160F-H User manual

AutomationDirect

AutomationDirect ProSense DPM1 Series User manual

AutomationDirect

AutomationDirect ProSense VFS50-5-1001 User manual

AutomationDirect

AutomationDirect ProSense DPM2-E Series User manual

AutomationDirect

AutomationDirect ProSense DPM3-E Series User manual